CEN/TR 15232-2:2016

(Main)Energy performance of buildings - Part 2: Accompanying TR prEN 15232-1:2015 - Modules M10-4,5,6,7,8,9,10

Energy performance of buildings - Part 2: Accompanying TR prEN 15232-1:2015 - Modules M10-4,5,6,7,8,9,10

This Technical Report refers to prEN 15232-1, Energy performance of buildings - Part 1: Impact of Building Automation, Controls and Building Management - Modules M10-4,5,6,7,8,9,10.

It contains information to support the correct understanding, use and national adaption of standard prEN 15232-1:2015.

This technical report does not contain any normative provision.

Performance énergétique des bâtiments - Partie 2 : Rapport technique accompagnant le prEN 15232-1:2015 - Modules M10-4,5,6,7,8,9,10

Energijske lastnosti stavb - 2. del: Razlaga in utemeljitev prEN 15232-1:2015 - Moduli M10-4, 5, 6, 7, 8, 9, 10

To tehnično poročilo se nanaša na standard prEN 15232-1, Energijska učinkovitost stavb – 1. del: Vpliv avtomatizacije stavb, nadzora in upravljanja stavb – moduli M10-4,5,6,7,8,9,10.

Vsebuje informacije za podporo pravilnega razumevanja, uporabe in nacionalne prilagoditve standarda prEN 15232-1:2015.

To tehnično poročilo ne vsebuje nobenih normativnih določb.

General Information

- Status

- Withdrawn

- Publication Date

- 27-Sep-2016

- Withdrawal Date

- 03-Feb-2026

- Technical Committee

- CEN/TC 247 - Controls for mechanical building services

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 09-Mar-2022

- Completion Date

- 04-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Sponsored listings

Frequently Asked Questions

CEN/TR 15232-2:2016 is a technical report published by the European Committee for Standardization (CEN). Its full title is "Energy performance of buildings - Part 2: Accompanying TR prEN 15232-1:2015 - Modules M10-4,5,6,7,8,9,10". This standard covers: This Technical Report refers to prEN 15232-1, Energy performance of buildings - Part 1: Impact of Building Automation, Controls and Building Management - Modules M10-4,5,6,7,8,9,10. It contains information to support the correct understanding, use and national adaption of standard prEN 15232-1:2015. This technical report does not contain any normative provision.

This Technical Report refers to prEN 15232-1, Energy performance of buildings - Part 1: Impact of Building Automation, Controls and Building Management - Modules M10-4,5,6,7,8,9,10. It contains information to support the correct understanding, use and national adaption of standard prEN 15232-1:2015. This technical report does not contain any normative provision.

CEN/TR 15232-2:2016 is classified under the following ICS (International Classification for Standards) categories: 35.240.99 - IT applications in other fields; 91.120.10 - Thermal insulation of buildings; 97.120 - Automatic controls for household use. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TR 15232-2:2016 has the following relationships with other standards: It is inter standard links to CEN ISO/TR 52120-2:2022, EN 16798-17:2017, EN 12098-3:2017, EN 16947-1:2017, EN 15241:2007, EN 16798-5-1:2017, CEN ISO/TR 52003-2:2017, EN 15316-4-3:2017, EN 15378-1:2017, EN 15242:2007, EN ISO 52003-1:2017, CEN/TR 16947-2:2016, EN 15316-1:2007, EN 12098-1:2017, EN ISO 7345:1995. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CEN/TR 15232-2:2016 is associated with the following European legislation: EU Directives/Regulations: 2010/31/EU; Standardization Mandates: M/480. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

CEN/TR 15232-2:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2018

Energijske lastnosti stavb - 2. del: Razlaga in utemeljitev prEN 15232-1:2015 -

Moduli M10-4, 5, 6, 7, 8, 9, 10

Energy performance of buildings - Part 2: Accompanying TR prEN 15232-1:2015 -

Modules M10-4,5,6,7,8,9,10

Performance énergétique des bâtiments - Partie 2 : Rapport technique accompagnant le

prEN 15232-1:2015 - Modules M10-4,5,6,7,8,9,10

Ta slovenski standard je istoveten z: CEN/TR 15232-2:2016

ICS:

91.120.10 Toplotna izolacija stavb Thermal insulation of

buildings

97.120 Avtomatske krmilne naprave Automatic controls for

za dom household use

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TR 15232-2

TECHNICAL REPORT

RAPPORT TECHNIQUE

September 2016

TECHNISCHER BERICHT

ICS 35.240.99; 91.120.10; 97.120

English Version

Energy performance of buildings - Part 2: Accompanying

TR prEN 15232-1:2015 - Modules M10-4,5,6,7,8,9,10

This Technical Report was approved by CEN on 11 April 2016. It has been drawn up by the Technical Committee CEN/TC 247.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2016 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TR 15232-2:2016 E

worldwide for CEN national Members.

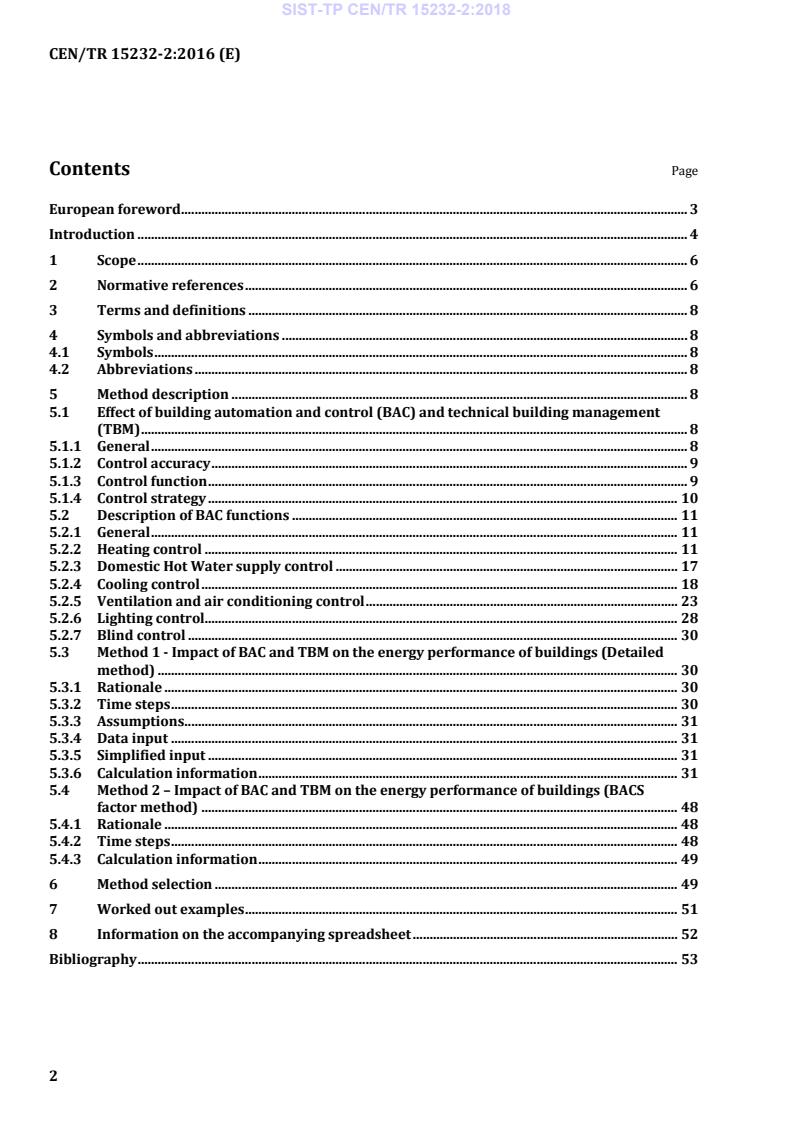

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 8

4 Symbols and abbreviations . 8

4.1 Symbols . 8

4.2 Abbreviations . 8

5 Method description . 8

5.1 Effect of building automation and control (BAC) and technical building management

(TBM) . 8

5.1.1 General . 8

5.1.2 Control accuracy . 9

5.1.3 Control function . 9

5.1.4 Control strategy . 10

5.2 Description of BAC functions . 11

5.2.1 General . 11

5.2.2 Heating control . 11

5.2.3 Domestic Hot Water supply control . 17

5.2.4 Cooling control . 18

5.2.5 Ventilation and air conditioning control . 23

5.2.6 Lighting control. 28

5.2.7 Blind control . 30

5.3 Method 1 - Impact of BAC and TBM on the energy performance of buildings (Detailed

method) . 30

5.3.1 Rationale . 30

5.3.2 Time steps . 30

5.3.3 Assumptions . 31

5.3.4 Data input . 31

5.3.5 Simplified input . 31

5.3.6 Calculation information . 31

5.4 Method 2 – Impact of BAC and TBM on the energy performance of buildings (BACS

factor method) . 48

5.4.1 Rationale . 48

5.4.2 Time steps . 48

5.4.3 Calculation information . 49

6 Method selection . 49

7 Worked out examples . 51

8 Information on the accompanying spreadsheet . 52

Bibliography . 53

European foreword

This document (CEN/TR 15232-2:2016) has been prepared by Technical Committee CEN/TC 247

“Building Automation, Controls and Building Management”, the secretariat of which is held by SNV.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association.

This document is currently divided into the following parts:

— Energy performance of buildings — Part 1: Impact of Building Automation, Controls and Building

Management - Modules M10-4,5,6,7,8,9,10 [currently at Enquiry stage];

— Energy performance of buildings — Part 2: Accompanying prCEN/TR 15232-1:2015 Modules M10-

4,5,6,7,8,9,10 [the present Technical Report; currently at Voting stage].

Introduction

The CENSE project, the discussions between CEN and the Concerted action highlighted the high page

count of the entire package due to a lot of “textbook” information. This resulted in flooding and

confusing the normative text.

A huge amount of informative contents shall indeed be recorded and available for users to properly

understand, apply and nationally adapt the EPB standards

The detailed technical rules in CEN/TS 16629, "Detailed Technical Rules" ask for a clear separation

between normative and informative contents:

— to avoid flooding and confusing the actual normative part with informative content;

— to reduce the page count of the actual standard;

— to facilitate understanding of the package.

Therefore each EPB standard shall be accompanied by an informative technical report, like this one,

where all informative contents is collected.

Table 1 — Position of this standard within the EPB set of standards

Over-arching Building Technical Building System

(as such)

sub1 M1 M2 M3 M4 M5 M6 M7 M8 M9 M10 M11

1 General General General

Common

terms and

Building

2 definitions; Needs

Energy Needs

symbols, units

and subscripts

(Free) Indoor

Maximum

Conditions

3 Application Load and

without

Power

Systems

Ways to Ways to Ways to

Express Express Express

4 x

Energy Energy Energy

Performance Performance Performance

Building

Heat Transfer

Functions and Emission and

5 by x

Building control

Transmission

Boundaries

Building

Heat Transfer

Occupancy Distribution

6 by Infiltration x

and Operating and control

and Ventilation

Conditions

Submodule

Descriptions

Descriptions

Descriptions

Heating

Cooling

Ventilation

Humidification

Dehumidification

Domestic Hot waters

Lighting

Building automation

and control

PV, wind, .

Over-arching Building Technical Building System

(as such)

sub1 M1 M2 M3 M4 M5 M6 M7 M8 M9 M10 M11

Aggregation of

Energy

Internal Heat Storage and

7 Services and x

Gains control

Energy

Carriers

Building Solar Heat Generation

8 x

Partitioning Gains and control

Load

Calculated Building

dispatching

9 Energy Dynamics x

and operating

Performance (thermal mass)

conditions

Measured Measured Measured

10 Energy Energy Energy x

Performance Performance Performance

11 Inspection Inspection Inspection

Ways to

Express

12 BMS

Indoor

Comfort

External

13 Environment

Conditions

Economic

Calculation

Submodule

Descriptions

Descriptions

Descriptions

Heating

Cooling

Ventilation

Humidification

Dehumidification

Domestic Hot waters

Lighting

Building automation

and control

PV, wind, .

1 Scope

This Technical Report refers to prEN 15232-1, Energy performance of buildings — Part 1: Impact of

Building Automation, Controls and Building Management - Modules M10-4,5,6,7,8,9,10.

It contains information to support the correct understanding, use and national adaption of standard

prEN 15232-1:2015.

This technical report does not contain any normative provision.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

prEN 12098-1:2015, Controls for heating systems — Part 1: Control equipment for hot water heating

systems - Modules M3-5,6,7,8

prEN 12098-3:2015, Controls for heating systems — Part 3: Control equipment for electrical heating

systems - Modules M3-5,6,7,8

prEN 12098-5:2015, Controls for heating systems — Part 3: Control equipment for electrical heating

systems — Modules M3-5,6,7,8

EN 13779, Ventilation for non-residential buildings - Performance requirements for ventilation and room-

conditioning systems

EN 15217, Energy performance of buildings - Methods for expressing energy performance and for energy

certification of buildings

prEN 15232-1:2015, Energy performance of buildings — Part 1: Impact of Building Automation, Controls

and Building Management — Modules M10-4,5,6,7,8,9,10

EN 15241:2007, Ventilation for buildings - Calculation methods for energy losses due to ventilation and

infiltration in commercial buildings

EN 15242:2007, Ventilation for buildings - Calculation methods for the determination of air flow rates in

buildings including infiltration

EN 15243:2007, Ventilation for buildings - Calculation of room temperatures and of load and energy for

buildings with room conditioning systems

EN 15316-1:2007, Heating systems in buildings - Method for calculation of system energy requirements

and system efficiencies - Part 1: General

EN 15316-2-1:2007, Heating systems in buildings - Method for calculation of system energy requirements

and system efficiencies - Part 2-1: Space heating emission systems

EN 15316-2-3:2007, Heating systems in buildings - Method for calculation of system energy requirements

and system efficiencies - Part 2-3: Space heating distribution systems

EN 15316-3-2, Heating systems in buildings - Method for calculation of system energy requirements and

system efficiencies - Part 3-2: Domestic hot water systems, distribution

EN 15316-3-3, Heating systems in buildings - Method for calculation of system energy requirements and

system efficiencies - Part 3-3: Domestic hot water systems, generation

EN 15316-4-1:2008, Heating systems in buildings - Method for calculation of system energy requirements

and system efficiencies - Part 4-1: Space heating generation systems, combustion systems (boilers)

EN 15316-4-2, Heating systems in buildings - Method for calculation of system energy requirements and

system efficiencies - Part 4-2: Space heating generation systems, heat pump systems

EN 15316-4-4, Heating systems in buildings - Method for calculation of system energy requirements and

system efficiencies - Part 4-4: Heat generation systems, building-integrated cogeneration systems

EN 15316-4-5, Heating systems in buildings - Method for calculation of system energy requirements and

system efficiencies - Part 4-5: Space heating generation systems, the performance and quality of district

heating and large volume systems

EN 15316-4-6, Heating systems in buildings - Method for calculation of system energy requirements and

system efficiencies - Part 4-6: Heat generation systems, photovoltaic systems

EN 15316-4-7, Heating systems in buildings - Method for calculation of system energy requirements and

system efficiencies - Part 4-7: Space heating generation systems, biomass combustion systems

EN 15378, Heating systems in buildings - Inspection of boilers and heating systems

EN 15239, Ventilation for buildings - Energy performance of buildings - Guidelines for inspection of

ventilation systems

EN 15240, Ventilation for buildings - Energy performance of buildings - Guidelines for inspection of air-

conditioning systems

prEN 15500-1:2015, Control for heating, ventilating and air-conditioning applications — Part 1:

Electronic individual zone control equipment — Modules M3-5,M4-5,M5-5

EN 15603:2008, Energy performance of buildings - Overall energy use and definition of energy ratings

prEN 16798–5-1, Energy performance of buildings — Modules M5-6, M5-8, M6-5, M6-8, M7-5, M7-8 —

Ventilation for buildings — Calculation methods for energy requirements of ventilation and air

conditioning systems — Part 5-1: Distribution and generation (revision of EN 15241) — Method 1

prEN 16798–5-2:2015, Energy performance of buildings — Modules M5-6, M5-8 — Ventilation for

buildings — Calculation methods for energy requirements of ventilation systems — Part 5-2: Distribution

and generation (revision of EN 15241) — method 2

prEN 16798-7:2014, Energy performance of buildings — Part 7: Ventilation for buildings — Modules M5-

1, M5-5, M5-6, M5-8 — Calculation methods for the determination of air flow rates in buildings including

infiltration

prEN 16947-1:2015, Building Management System — Module M10-12

FprCEN/TR 16947-2:2015, Accompanying TR for New Work Item — Building Management System

EN ISO 7345:1995, Thermal insulation - Physical quantities and definitions (ISO 7345:1987)

EN ISO 13790:2008, Energy performance of buildings - Calculation of energy use for space heating and

cooling (ISO 13790:2008)

EN ISO 16484-3:2005, Building automation and control systems (BACS) - Part 3: Functions (ISO 16484-

3:2005)

prEN ISO 52000-1:2015, Energy performance of buildings — Overarching EPB assessment — Part 1:

General framework and procedures (ISO/DIS 52000-1:2015)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 7345:1995,

prEN ISO 52000-1:2015 and prEN 15232-1:2015 (the accompanied EPB standard) apply.

4 Symbols and abbreviations

4.1 Symbols

For the purposes of this Technical Report, the symbols given in prEN ISO 52000-1:2015, in

EN 15232-1:2015 (the accompanied EPB standard) apply.

4.2 Abbreviations

For the purposes of this Technical Report, the abbreviations in prEN 15232-1:2015 (the accompanied

EPB standard) apply.

5 Method description

5.1 Effect of building automation and control (BAC) and technical building

management (TBM)

5.1.1 General

The key-role of Building Automation and Control and TBM is to ensure the balance between the desired

human comfort - which shall be maximal, and energy used to obtain this goal - which shall be minimal!

The scope of BAC and TBM covers in accordance with their role from one side all Technical Building

Systems (where the effect of the BAC is used in the calculation procedures) and from another side the

global optimization Energy Performance of a Building.

We could identify several categories of controls:

— Technical Building Systems specific controls; these controllers are dedicated to the physical chain

of transformation of the energy, from Generation, to Storage, Distribution and Emission. We find

them in the matrix starting with the Modules M3-5 to M9-5 and finishing with M3-8 till M9-8. We

could consider that it exist one controller by module, but some time one controller do the control

among several modules. More often, these controllers are communicating between them via a

standardized open bus, such as BACnet, KNX or LON

— BAC used for all or several Technical Building Systems who do multidiscipline (heating, cooling,

ventilation, DHW, lighting…) optimization and complex control functions. For example, one of them

is INTERLOCK, a control function who avoids heating and cooling in same time.

— If all Technical Building System are used in the building, we have (depending of the size of the

building) a Technical Building Management System. Specific global functions are implemented here,

necessary to reach the key-role mentioned above. Usually, in this case, an interrelation with the

Building as such (Module M2) will occur, mainly to take in consideration the building needs; for

example due to outside temperature, taken into account the inertia of the building when the control

will reach the set point in a room.

In a control system dedicated to a building, who is BAC and TBM we can distinguish three main

characteristics as described in 5.1.2, 5.1.3 and 5.1.4.

5.1.2 Control accuracy

Control accuracy is the degree of correspondence between the ultimately controlled variable and the

ideal value in a feedback control system. The controlled variable could be any physical variable such as

a temperature, humidity, pressure, etc. The ideal value is in fact the SET POINT established by the user

(occupant) when he determines his level of comfort. It is clear that the entire control loop is concerned

with all the elements constituent, such as sensors, valves and actuators. The equipment itself is another

important element and usually specific equipment asks for a specific controller. For the energy carrier

hot water, an important issue is the balancing of the hydraulic circuits. For that purposes, balancing

hydraulic valves are need it.

The temperature control accuracy (CA) for a zone temperature is a key number that allows calculating

the additional energy need for heating or cooling caused by the inaccuracy of zone temperature control.

The temperature Control Accuracy (CA) can be calculated from Control Variation (CV) and Control Set

point Deviation (CSD) as described in the main text of prEN 15500:2015. The compliance with CA is also

defined in the standard. This is an important input for EN 15316-2 and for prEN 16798-7, where the

effect of the control for heating, cooling and ventilation is taken into account.

The same standard (prEN 15500-1:2015) describes also the 4 operations modes who deal with the

levels of temperatures: Comfort, Precomfort, Economy and Frost/Building Protection. These 4

predefined operation modes are parameters that could be set by the users (occupant) – the

temperature allocate to each operation mode. These operations modes are important for the control

strategy used for intermittence, which will be described below.

5.1.3 Control function

The control function is the ability of a controller (or set of communicative controllers) to perform a

determined task(s). Usually the functions implemented in the controllers are parametrable or free

programmable. The functions could be performed by a single controller or by a set of communicative

controllers. A controller could perform several functions.

The CONTROL FUNCTIONS present in a BAC or TBM, are present in prEN 15232-1:2015 Table 4. These

functions in Table 4 are organized in the matrix given by Modular Structure of EPB standards. Table 4

starts with Heating Emission, Distribution, Storage and Generation (M3-5, M3-6, M3-7, M3-8) follow by

Domestic Hot Water, Cooling, Ventilation and Lighting (M9-5, M9-6, M9-7, M9-8). Each function is

described in detail, in accordance with the type (level) of the function: from the lower type (NO

AUTOMATIC CONTROL Type = 0) to most advanced types. For each function, an IDENTIFIER who is the

software language for BAC and TBM is also defined, as the destination of the module where the control

function gives his effect. An example of Table 4 is given bellow, as abstract from prEN 15232-1:2015

Table 4.

For practical reasons, four different BAC efficiency classes (A, B, C, D) of functions are defined both for

non-residential and residential buildings. This is the fastest way to specify a BAC or a TBM.

— Class D corresponds to non-energy efficient BAC. Building with such systems shall be retrofitted.

New buildings shall not be built with such systems.

— Class C corresponds to standard BAC.

— Class B corresponds to advanced BAC and some specific TBM functions.

— Class A corresponds to high-energy performance BAC and TBM.

One is in class D: If the minimum functions to be in class C are not implemented.

To be in class C: Minimum functions defined in Table B.1 shall be implemented.

To be in class B: Building automation function plus some specific functions defined in Table 4 shall be

implemented in addition to class C. Room controllers shall be able to communicate with a building

automation system.

To be in class A: Technical building management function plus some specific functions defined in

Table 4 shall be implemented in addition to class B. Room controllers shall be able for demand

controlled HVAC (e.g. adaptive set point based on sensing of occupancy, air quality, etc.) including

additional integrated functions for multi-discipline interrelationships between HVAC and various

building services (e.g. electricity, lighting, solar shading, etc.)

In addition, the hydraulic system should be properly balanced.

The functions assignment to the BACS efficiency classes are listed in prEN 15232-1:2015, Table 5.

BAC functions with the purpose to control or monitor a plant or part of a plant which is not installed in

the building do not have to be considered when determining the class even if they are shaded for that

class. For example, to be in class B for a building with no cooling system no Individual room control

with communication is required for emission control of cooling systems.

If a specific function is required to be in a specific BAC efficiency class, it is not required that it is strictly

required everywhere in the building: if the designer can give good reasons that the application of a

function does not bring a benefit in a specific case it can be ignored. For example, if the designer can

show that the heating load of a set of rooms is only dependant on the outdoor temperature and can be

compensated with one central controller, no individual room control by thermostatic valves or

electronic controllers is required to be in class C.

A reference list of BACS functions to reach is defined in prEN 15232-1:2015, Table 6. That table defines

the minimum requirements of BACS functions according to BACS efficiency class C of Table 5.

Unless differently specified this list shall be used for the following:

— to specify the minimum functions to be implemented for a project;

— to define the BACS function to take into account for the calculation of energy consumption of a

building when the BACS functions are not defined in detail.

— to calculate the energy use for the reference case in step 1 of the BACS efficiency factor method.

5.1.4 Control strategy

The control function is the methods employed to achieve a given level of control to reach a goal. Optimal

control strategies deliver a desired level of control at a minimum cost (minimum energy demand). A

CONTROL STRATEGY could consist by a CONTROL FUNCTION or a group of CONTROL FUNCTIONS. An

example of a CONTROL STRATEGY consist by a CONTROL FUNCTION is OPTIMUM START, OPTIMUM

STOP, Night SET BACK described in the standards prEN 12098-1:2015 and prEN 12098-3:2015. The

Timer function is described in prEN 12098-5:2015.

An example of a CONTROL STRATEGY who is realized by a group of CONTROL FUNCTIONS is the

CONTROL STRATEGY used by INTERMITENCE. This function uses several CONTROL FUNCTIONS,

OPERATION MODES, OPTIMUM START-STOP and TIMER in same time. All elements together are called

either Building Profile or User Pattern. Usually, to implement such Building profile, a TBM is a

prerequisite.

The most important CONTROL STRATEGY described and implemented in prEN 15232-1:2015 is

DEMAND ORIENTED CONTROL. Usually these strategies implement the sense of the energy flow (from

GENERATION to EMISSION) with flow of calculation (from building needs to delivered energy). Usually

for this complex CONTROL STRATEGY, a TBM is necessary with a distributed specific control for each

Technical Building System who communicates in system architecture via a communication

standardized bus such as BACnet, KNX or LON.

More clear, this Demand Oriented Control works as follows: When the comfort is reach in the Emission

area, the controller from the Emission sent the message to the controller in charge of Distribution to

stop to distribute energy, who sent the message to the controller in charge of Storage either to store the

energy and if the Storage cannot store more energy sent the message to the controller in charge with

the Generation to stop to generate more energy.

Another important Control Strategy is the control strategy for multi generators either from same type

(e.g. several boilers) or different types (e.g. a boiler and heat pomp) including also the Renewable

Energy Sources. The strategy could be based as follow:

— Priorities only based on running time

— Fixed sequencing based on loads only: e.g. depending on the generators characteristics, e.g. hot

water boiler vs. heat pump

— Priorities based on generator efficiency and characteristics: The generator operational control is

set individually to available generators so that they operate with an overall high degree of

efficiency (e.g. solar, geothermic heat, cogeneration plant, fossil fuels)

— Load prediction based sequencing: The sequence is based on e.g. efficiency and available power of a

device and the predicted required power

The standards enabling to calculate the effect of BACS and TBM functions on energy consumption use

different approaches to calculate this impact. The approaches are described in prEN 15232-1:2015,

6.4.2.

5.2 Description of BAC functions

5.2.1 General

The numbers in italics refer to the numbers in prEN 15232-1:2015, Table 4.

5.2.2 Heating control

1.1 Heating – Emission control

1.1.0 No automatic control

Description: No automatic control of the room temperature.

1.1.1 Central automatic control

Description: Central automatic control of temperature in rooms by means of heating, is acting either on

the distribution or on the generation. Heating control is performed without consideration of local

demand of different rooms, possibly by using one room as reference. This can be achieved for example

by an outside temperature controller conforming to prEN 12098-1:2015 or prEN 12098-3:2015.

Target: To improve EP by minimizing emitted heat by emitters (e.g. radiators) or by air in the building

using central control of temperature and/or flow. This control may be based on outside temperature

and/or a reference sensor inside the building and assumes similar demands in different parts/rooms of

the building.

1.1.2 Individual room control

Description: Individual room control by thermostatic valves or electronic controllers. The individual

room control of heating temperature in rooms is performed either by thermostatic valves or local (non-

communicating) electronic control units. The individual control should/may be combined with

scheduler programs providing different operating modes.

Target: To improve EP by minimizing emitted heat by emitters (e.g. radiators) or by air in the building

using local control of temperature and/or flow in the rooms, thereby adapting to local demand, i.e.

different loads in different rooms.

1.1.3 Individual room control with communication

Description: Individual room control with communication between controllers and to BACS. Individual

control of temperature in rooms by means of heating, with communication between controllers and to

BACS, allows exchange of setpoints, demand and other status information.

Target: To improve EP by minimizing emitted heat by emitters (e.g. radiators) or by air in the building

using local control of temperature and/or flow in the rooms, thereby adapting to local demand, i.e.

different loads in different rooms. Furthermore to obtain energy demand for further use to control

distribution and generators, keeping run time at minimum and setpoints optimal.

1.1.4 Individual room control with communication and presence control

Description: Individual room control with communication between controllers and to BACS, and

presence control performed by occupancy. Individual control of temperature in rooms by means of

heating, with communication between controllers and to BACS, allows exchange of setpoints, demand

and other status information.

Target: To improve EP by minimizing emitted heat by emitters (e.g. radiators) or by air in the building

using local control of temperature and/or flow in the rooms, thereby adapting to local demand, i.e.

different loads in different rooms. Furthermore to obtain energy demand for further use to control

distribution and generators, keeping run time at minimum and setpoints optimal.

1.2 Heating – Emission control for TABS

1.2.0 No automatic control

Description: There’s no automatic control of the room temperature implemented.

Target: Manual controls of a loop apply.

1.2.1 Central automatic control

Description: The central automatic control for a TABS zone (which comprises all rooms which get the

same supply water temperature) typically is a supply water temperature control loop whose setpoint is

dependent on the filtered outside temperature, e.g. the average of the previous 24 h.

Target: The supply water temperature shall be set according to the filtered outside air temperature

(filtered -weather compensated supply water temperature).

1.2.2 Advanced central automatic control

Description: This is an automatic control of the TABS zone that fulfils the following conditions

— If the TABS is used only for heating: The central automatic control is designed and tuned to achieve

an optimal self-regulating of the room temperature within the required comfort range (specified by

the room temperature heating setpoint). “Optimal” means that the room temperatures of all rooms

of the TABS zone remain during operation periods in the comfort range, to meet comfort

requirements, but also is as low as possible to reduce the energy demand for heating.

— If the TABS is used for heating and cooling: The central automatic control is designed and tuned to

achieve an optimal self-regulating of the room temperature within the required comfort range

(specified by room temperature heating and cooling setpoints). “Optimal” means that the room

temperatures of all rooms of the TABS zone remain during operation periods in the comfort range,

to meet comfort requirements, but also uses as far as possible the full range to reduce the energy

demand for heating and cooling.

— If the TABS are used for heating and cooling: the automatic switching between heating and cooling

is not done only dependent on the outside temperature, but also taking at least indirectly the heat

gains (internal and solar) into account.

One solution to achieve these requirements can be found in [2] and [3].

Target: Achieve temperatures within the desired bandwidth for all rooms in the heating/cooling group.

1.2.3 Advanced central automatic control with intermittent operation and/or room temperature

feedback control

Description: Advanced central automatic control with room temperature feedback control:

— Advanced central automatic control with intermittent operation. This is an advanced central

automatic control according to 2) with the following supplement: The pump is switched off

regularly to save electrical energy, either with a fast frequency - typically 6 h on/off cycle time - or

with a slow frequency, corresponding to 24 h on/off cycle time. If the TABS are used for cooling,

intermittent operation with 24 h on/off cycle time can also be used to reject the heat to the outside

air if the outside air is cold. One solution to achieve this requirement can be found in [2] and [4].

— Advanced central automatic control with room temperature feedback control. This is an advanced

central automatic control according to 2) with the following supplement: The supply water

temperature setpoint is corrected by the output of a room temperature feedback controller, to

adapt the setpoint to non-predictable day-to-day variation of the heat gain. Since TABS react slowly,

only day-to-day room temperature correction is applied, an instant correction cannot be achieved

with TABS. The room temperature that is fed back is the temperature of a reference room or

another temperature representative for the zone. One solution to achieve this requirement can be

found in [2].

— Advanced central automatic control with intermittent operation and room temperature feedback

control.

Target: The goal is to compensate room/zone behaviour into the supply water temperature control in

order to optimize emissions taking into account heat gain and radiation.

1.3 Heating – Control of distribution network hot water (supply or return)

1.3.0 No automatic control

Description: The distribution network temperature of the hot water is not controlled.

1.3.1 Outside temperature compensated control

Description: Control of the temperature of the hot water distribution based on outside temperature

compensation.

Target: To improve EP by lowering the mean temperature of the flow, thereby minimizing heat losses.

1.3.2 Demand based control

Description: Control of the temperature of the hot water distribution is based on indoor temperature

measurements.

Prerequisite: Communicating system to room control units.

Target: To improve EP by lowering the mean temperature of the flow as well as decreasing the flow

rate, thereby minimizing heat losses. In addition use energy demand information to keep run time at

minimum and setpoints optimal.

1.4 Heating – Control of distribution pumps in networks

1.4.0 No automatic control

Description: Distribution pumps are not controlled (only protection functions).

1.4.1 On / off control

Description: On / off control. Pumps are switched on and off automatically but once switched the run no

control at maximum speed.

Target: To improve EP by avoiding auxiliary energy consumption of pumps while no energy need to be

circulated.

1.4.2 Multi-Stage control

Description: Speed of pumps is controlled by a multi-step control.

Target: To improve EP by reducing auxiliary energy consumption by adapting (in fixed steps) the speed

of the pump depending on the system conditions.

1.4.3 Variable speed pump control

Description: Speed of pumps is controlled depending on different states of the system. This may be

done with constant or variable Δp and with demand evaluation to reduce the auxiliary energy demand

of the pumps.

Target: To improve EP by reducing auxiliary energy consumption of pumps by optimizing their speed

according to the current system conditions.

1.4.4 Variable speed pump control

Description: Speed of pumps is controlled depending on different states of the system. This may be

done with variable Δp following an external demand signal, e.g. hydraulic requirements, ΔT, energy

optimization, demand evaluation to reduce the auxiliary energy demand of the pumps.

Target: To improve EP by reducing auxiliary energy consumption of pumps by optimizing their speed

for the current system conditions.

1.5 Heating – Intermittent control of emission and/or distribution

1.5.0 No automatic control

Description: No intermittent control (always full energy consumption).

1.5.1 Automatic control with fixed time program

Description: Automatic control is realized to reach intermittent operation of the emission and/or

distribution components.

Target: To improve EP by lowering the temperature setpoints during certain conditions (e.g. night).

This leads to improved EP due to shortened operation time of the generation/distribution, lower losses

of the room(s) due to lower temperature differences to the outside.

1.5.2 Automatic control with Optimum Start/Stop

Description: Automatic control is realized to reach optimized Start/Stop of intermittent operation of the

emission and/or distribution components.

Target: To improve EP through optimized start/stop to maximize time for economy mode by

considering energy capacity of the building in control.

1.5.3 Automatic control with demand evaluation

Description: Automatic control is realized to reach intermittent operation of emission and/or

distribution based on demand (occupancy).

Target: To improve EP through maximizing “pre-comfort” and/or “economy” time periods by detecting

or using information about real demand (e.g. occupancy).

1.6 Heating – Generator control for combustion and district heating

1.6.0 Constant Temperature Control

Description: Generator temperature is controlled to hold a predefined constant temperature within a

defined control deviation.

Target: To improve EP by minimizing the generator operation temperatures and avoiding max boiler

temperature (with highest losses), e.g. compared to thermostatic on/off control.

1.6.1 Variable temperature depending on outdoor temperature

Description: Generator temperature setpoint is variable depending on outdoor temperature.

Target: To improve EP by minimizing the generator operation temperatures using outdoor temperature

information.

1.6.2 Variable temperature depending on the load

Description: Generator temperature setpoint is variable depending on the load of the system.

Target: To improve EP by minimizing the generator operation temperatures using information about

current demand of the system.

1.7 Heating – Generator control for heat pumps

1.7.0 Constant Temperature Control

Description: Heat generation is not optimized to environmental conditions and control is always

towards the maximum allowed temperature.

Inputs: Max allowed temperature setpoint.

1.7.1 Variable temperature depending on outdoor temperature

Description: The control temperature is calculated with the goal to operate the heat pump with

minimized operating temperature setpoints depending on outdoor temperature.

Target: To improve EP by avoiding unnecessary electrical pumping energy by minimizing the generator

operation temperatures using outdoor temperature information.

1.7.2 Variable temperature depending on the load or demand

Description: Heat pump temperature setpoint is variable depending on demand based on the load of the

system.

Target: To improve EP by optimizing efficiency of the heat pump at given environmental conditions

based on current demand of the system.

1.8 Heating – Generator control for outdoor unit

The goal consists generally in maximizing the heat generator efficiency

1.8.0 On/Off-control of heat generator

1.8.1 Multi-stage control of heat generator

Description: Output of heat generator is controlled depending on the load or demand (e.g. on/off of

several compressors)

1.8.2 Variable control of heat generator

Description: Output of he

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...