SIST EN 16755:2017

(Main)Durability of reaction to fire performance - Classes of fire-retardant treated wood products in interior and exterior end use applications

Durability of reaction to fire performance - Classes of fire-retardant treated wood products in interior and exterior end use applications

This European Standard describes the characteristics for fire-retardant treated wood products.

NOTE 1 It is based on maintaining performance undiminished throughout the desired service life in the anticipated conditions of use.

The European Standard prescribes the classification requirements for the durability of the reaction to fire performance of fire-retardant treated wood products to be used in interior and exterior end use conditions.

This European Standard applies to wood which has been treated during a production process with fire retardant products applied either by a penetration process or by a superficial process, such as with a film forming or intumescent fire retardant coating. It covers fire-retardant treated products that are coated with an ordinary paint.

Mechanical properties and biological durability of fire-retardant treated wood products are not covered by this European Standard.

NOTE 2 This standard can be used for other manufactured wood products.

This standard covers wood products. It doesn’t cover wood-based panels.

NOTE 3 Wood based panels for construction are described in EN 13986.

Dauerhaftigkeit des Verhaltens bei Brandeinwirkung - Klassen der mit Feuerschutzmitteln behandelten Holzprodukte für Anwendungen im Innen- und Außenbereich

Die vorliegende Europäische Norm beschreibt die Eigenschaften von mit Feuerschutzmitteln behandelten Holzprodukten.

ANMERKUNG 1 Hierbei wird davon ausgegangen, dass Feuerschutz Eigenschaften über die gewünschte Gebrauchsdauer unter den angenommenen Bedingungen unvermindert vorhalten.

Die Europäische Norm schreibt die Klassifizierungsanforderungen an die Dauerhaftigkeit des Verhal¬tens bei Brandeinwirkung von mit Feuerschutzmitteln behandelten Holzprodukten vor, die in Innen und Außen¬bereichen eingesetzt werden.

Diese Europäische Norm gilt für Holz, das während eines Produktionsprozesses mit einem Feuer-schutzmittel behandelt wurde, auf /eingebracht entweder durch ein eindringendes oder ein oberflächliches Verfahren, z. B. Holz mit einer filmbildenden Beschichtung oder einer Intumeszenz-Beschichtung. Es umfasst mit Feuerschutzmitteln behandelte Produkte, die mit einem üblichen Anstrich beschichtet sind.

Mechanische Eigenschaften und die biologische Dauerhaftigkeit von mit Feuerschutzmitteln behandelten Holzprodukten sind kein Bestandteil der vorliegenden Europäischen Norm.

ANMERKUNG 2 Diese Norm kann für andere be und verarbeitete Holzprodukte genutzt werden.

Diese Norm betrifft Holzprodukte. Sie betrifft keine Holzwerkstoffe.

ANMERKUNG 3 Holzwerkstoffe für den Bau sind in EN 13986 festgelegt.

Durabilité des performances de réaction au feu - Classement des produits à base de bois ignifugés pour utilisation finale en intérieur et en extérieur

La présente Norme européenne décrit les caractéristiques pour les produits en bois ignifugés.

NOTE 1 Le principe est basé sur le maintien et sans diminution de la performance au long de la durée de vie souhaitée dans les conditions d'utilisation prévues.

La présente Norme européenne prescrit les exigences de classification pour la durabilité des performances de réaction au feu des produits en bois ignifugés, destinés à être employés dans des conditions d'utilisation finale en intérieur et en extérieur.

La présente Norme européenne s’applique aux produits en bois ayant fait l'objet d'un traitement ignifugeant durant leur fabrication, appliqué par un processus d'imprégnation à coeur ou en surface, tel qu'un revêtement filmogène ou un revêtement intumescent ignifuge. Il est admis que les produits ignifugés soient revêtus d'une peinture ordinaire (non ignifuge).

Les propriétés mécaniques et la durabilité biologique des produits en bois ignifugés ne sont pas couvertes par la présente Norme européenne.

NOTE 2 Cette norme peut être utilisée pour d'autres produits du bois.

Cette norme couvre les produits en bois. Elle ne couvre pas les panneaux à base de bois.

NOTE 3 Les panneaux à base de bois pour la construction sont décrits dans la norme EN 13986.

Odpornost odziva na ogenj - Razredi lesnih proizvodov, obdelanih z zaščitnimi sredstvi proti ognju, za uporabo v notranjih prostorih in na prostem

Ta evropski standard opisuje karakteristike lesnih proizvodov, obdelanih z zaščitnimi sredstvi proti ognju, pri čemer morajo njihove zaščitne lastnosti proti ognju ostati nedotaknjene skozi celotno življenjsko dobo v pričakovanih pogojih uporabe.

Standard predpisuje zahteve za razvrstitev na področju trajnosti odziva na ogenj za lesne proizvode, obdelane z zaščitnimi sredstvi proti ognju, ki so namenjeni za uporabo pod pogoji končne uporabe, tj. v notranjih prostorih in na prostem. Proizvodi morajo prvotno ustrezati zahtevanemu odzivu na vpliv ognja. Pri uporabi v notranjih prostorih in na prostem je treba preveriti higroskopnost. Poleg tega morajo proizvodi za uporabo na prostem izpolnjevati zahteve minimalne trajnosti odziva na ogenj, specifične za končno uporabo.

Zahteve se uporabljajo za les, ki je bil med procesom proizvodnje obdelan z zaščitnim sredstvom proti ognju, in sicer z globinskim impregniranjem ali površinskim nanašanjem, kot je premaz, ki tvori film, ali premaz z intumescentimi zaščitnimi sredstvi proti ognju. Proizvode, obdelane z zaščitnimi sredstvi proti ognju, je mogoče prebarvati z običajno barvo.

Ta evropski standard ne zajema mehanskih lastnosti in biološke trajnosti lesnih izdelkov, obdelanih z zaščitnimi sredstvi proti ognju.

Barve, premazi in laki, ki so namenjeni izboljšanju odziva na ogenj pri gradbenem proizvodu, ki se vgradi na mestu vgradnje, so zajeti v smernicah ETAG 028 [19].

Ta standard se lahko uporablja kot podlaga za sistem odobritve.

General Information

- Status

- Published

- Public Enquiry End Date

- 02-Mar-2016

- Publication Date

- 21-Nov-2017

- Technical Committee

- LLZ - Les, lesni izdelki in zaščita lesa

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 20-Oct-2017

- Due Date

- 25-Dec-2017

- Completion Date

- 22-Nov-2017

Relations

- Effective Date

- 10-Jan-2018

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 01-Oct-2018

- Effective Date

- 19-Jan-2023

Overview

EN 16755:2017 - Durability of reaction to fire performance sets out how to classify the durability of the reaction-to-fire performance of fire‑retardant treated wood products for interior and exterior end uses. The standard covers wood treated by penetration or superficial processes (including film‑forming or intumescent coatings) and products coated with ordinary paint. It is focused on maintaining fire performance over the anticipated service life under expected use conditions. Mechanical properties and biological durability are explicitly not covered. Note: wood‑based panels are excluded (see EN 13986).

Key topics and requirements

- Scope of application

- Applies to treated solid wood and other manufactured wood products (not wood‑based panels).

- Covers both impregnated and surface‑treated (coated) fire‑retardant systems.

- Durability classes (DRF)

- DRF INT1, INT2 and EXT classify treated wood according to expected moisture/ exposure conditions (dry, humid, exterior).

- Initial and maintained reaction‑to‑fire performance

- Initial classification via recognized reaction‑to‑fire standards (preferred: EN 13823 / EN 13501‑1 for construction; IMO FTP for maritime).

- Verification of maintained performance after accelerated or natural weathering.

- Weathering and hygroscopic testing

- Annex A: hygroscopic properties testing (humidity influence).

- Annex B: accelerated weathering procedures for fire testing; natural weathering per EN 927‑3 or artificial per EN 927‑6 are allowed.

- Minimum specimen width for accelerated weathering: 100 mm.

- Fire testing options after weathering

- Preferred: EN 13823 (SBI) for classification.

- Alternative: small‑scale cone calorimeter ISO 5660‑1 (heat flux 50 kW/m2 for ≥1 200 s) - requires at least three replicates and careful specimen preparation.

- Manufacturer declarations and maintenance

- Fire‑retardant retention declared in kg/m3 (or kg/m2 for surface products) conditioned per EN 13238.

- Manufacturers must declare maintenance regime: type, interval, time until first maintenance/recoating, and coating system.

Practical applications and users

- Who uses EN 16755:2017

- Wood product manufacturers and treaters, façade and cladding producers, paint/coating formulators, test laboratories, fire safety engineers, architects, building certifiers and regulators.

- Why it matters

- Provides a framework to demonstrate that treated wood retains fire performance in service conditions - essential for specifying exterior claddings, interior timber elements, and compliance with fire safety regulations.

- Supports product classification, labelling, performance claims, and procurement specifications.

Related standards

- EN 13823, EN 13501‑1 (reaction‑to‑fire classification)

- ISO 5660‑1 (cone calorimeter)

- EN 927‑3 / EN 927‑6 (natural and artificial weathering for coatings)

- EN 13238 (conditioning procedures)

- EN 13986 (wood‑based panels - excluded from EN 16755)

Keywords: EN 16755:2017, fire‑retardant treated wood, durability of reaction to fire, DRF classes, weathering, hygroscopic properties, EN 13823, ISO 5660‑1.

Get Certified

Connect with accredited certification bodies for this standard

ECOCERT

Organic and sustainability certification.

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Sponsored listings

Frequently Asked Questions

SIST EN 16755:2017 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Durability of reaction to fire performance - Classes of fire-retardant treated wood products in interior and exterior end use applications". This standard covers: This European Standard describes the characteristics for fire-retardant treated wood products. NOTE 1 It is based on maintaining performance undiminished throughout the desired service life in the anticipated conditions of use. The European Standard prescribes the classification requirements for the durability of the reaction to fire performance of fire-retardant treated wood products to be used in interior and exterior end use conditions. This European Standard applies to wood which has been treated during a production process with fire retardant products applied either by a penetration process or by a superficial process, such as with a film forming or intumescent fire retardant coating. It covers fire-retardant treated products that are coated with an ordinary paint. Mechanical properties and biological durability of fire-retardant treated wood products are not covered by this European Standard. NOTE 2 This standard can be used for other manufactured wood products. This standard covers wood products. It doesn’t cover wood-based panels. NOTE 3 Wood based panels for construction are described in EN 13986.

This European Standard describes the characteristics for fire-retardant treated wood products. NOTE 1 It is based on maintaining performance undiminished throughout the desired service life in the anticipated conditions of use. The European Standard prescribes the classification requirements for the durability of the reaction to fire performance of fire-retardant treated wood products to be used in interior and exterior end use conditions. This European Standard applies to wood which has been treated during a production process with fire retardant products applied either by a penetration process or by a superficial process, such as with a film forming or intumescent fire retardant coating. It covers fire-retardant treated products that are coated with an ordinary paint. Mechanical properties and biological durability of fire-retardant treated wood products are not covered by this European Standard. NOTE 2 This standard can be used for other manufactured wood products. This standard covers wood products. It doesn’t cover wood-based panels. NOTE 3 Wood based panels for construction are described in EN 13986.

SIST EN 16755:2017 is classified under the following ICS (International Classification for Standards) categories: 13.220.40 - Ignitability and burning behaviour of materials and products; 71.100.50 - Wood-protecting chemicals; 79.040 - Wood, sawlogs and sawn timber. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16755:2017 has the following relationships with other standards: It is inter standard links to SIST CEN/TS 15912:2012, SIST EN 927-3:2019, SIST EN 13823:2020+A1:2022, SIST EN 13501-1:2019, SIST EN 13238:2010, SIST EN 927-6:2019, SIST EN 16755:2017/AC:2018, oSIST prEN 16755:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 16755:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2017

Nadomešča:

SIST CEN/TS 15912:2012

Odpornost odziva na ogenj - Razredi lesnih proizvodov, obdelanih z zaščitnimi

sredstvi proti ognju, za uporabo v notranjih prostorih in na prostem

Durability of reaction to fire performance - Classes of fire-retardant treated wood

products in interior and exterior end use applications

Dauerhaftigkeit des Verhaltens bei Brandeinwirkung - Klassen der mit

Feuerschutzmitteln behandelten Holzprodukte für Anwendungen im Innen- und

Außenbereich

Durabilité des performances de réaction au feu - Classement des produits à base de

bois ignifugés pour utilisation finale en intérieur et en extérieur

Ta slovenski standard je istoveten z: EN 16755:2017

ICS:

13.220.40 Sposobnost vžiga in Ignitability and burning

obnašanje materialov in behaviour of materials and

proizvodov pri gorenju products

71.100.50 Kemikalije za zaščito lesa Wood-protecting chemicals

79.040 Les, hlodovina in žagan les Wood, sawlogs and sawn

timber

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16755

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2017

EUROPÄISCHE NORM

ICS 13.220.40; 13.220.50; 71.100.50

English Version

Durability of reaction to fire performance - Classes of fire-

retardant treated wood products in interior and exterior

end use applications

Durabilité des performances de réaction au feu - Dauerhaftigkeit des Verhaltens bei Brandeinwirkung -

Classement des produits à base de bois ignifugés pour Klassen der mit Feuerschutzmitteln behandelten

utilisation finale en intérieur et en extérieur Holzprodukte für Anwendungen im Innen- und

Außenbereich

This European Standard was approved by CEN on 2 July 2017.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2017 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16755:2017 E

worldwide for CEN national Members.

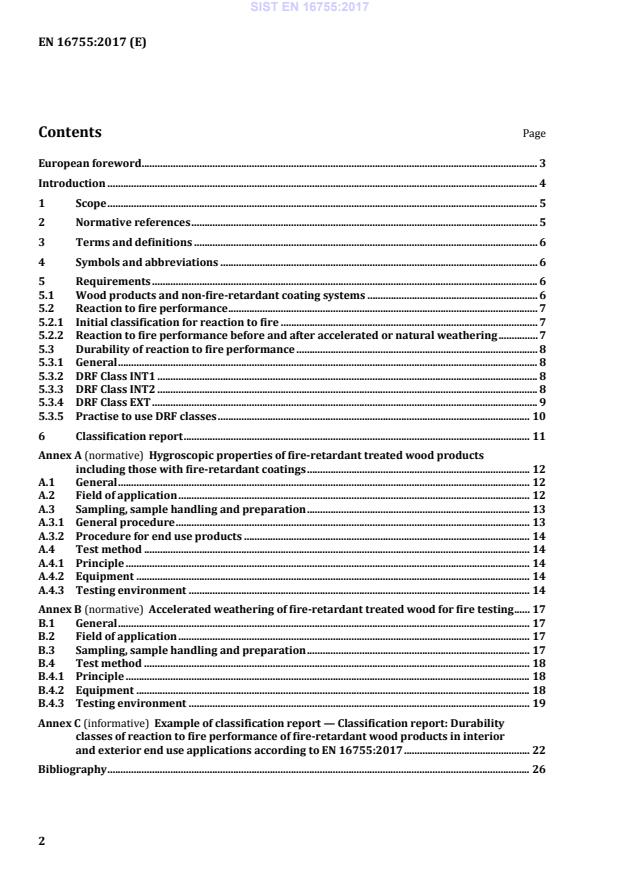

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Symbols and abbreviations . 6

5 Requirements . 6

5.1 Wood products and non-fire-retardant coating systems . 6

5.2 Reaction to fire performance . 7

5.2.1 Initial classification for reaction to fire . 7

5.2.2 Reaction to fire performance before and after accelerated or natural weathering . 7

5.3 Durability of reaction to fire performance . 8

5.3.1 General . 8

5.3.2 DRF Class INT1 . 8

5.3.3 DRF Class INT2 . 8

5.3.4 DRF Class EXT . 9

5.3.5 Practise to use DRF classes . 10

6 Classification report . 11

Annex A (normative) Hygroscopic properties of fire-retardant treated wood products

including those with fire-retardant coatings . 12

A.1 General . 12

A.2 Field of application . 12

A.3 Sampling, sample handling and preparation . 13

A.3.1 General procedure . 13

A.3.2 Procedure for end use products . 14

A.4 Test method . 14

A.4.1 Principle . 14

A.4.2 Equipment . 14

A.4.3 Testing environment . 14

Annex B (normative) Accelerated weathering of fire-retardant treated wood for fire testing . 17

B.1 General . 17

B.2 Field of application . 17

B.3 Sampling, sample handling and preparation . 17

B.4 Test method . 18

B.4.1 Principle . 18

B.4.2 Equipment . 18

B.4.3 Testing environment . 19

Annex C (informative) Example of classification report — Classification report: Durability

classes of reaction to fire performance of fire-retardant wood products in interior

and exterior end use applications according to EN 16755:2017 . 22

Bibliography . 26

European foreword

This document (EN 16755:2017) has been prepared by Technical Committee CEN/TC 175 “Round and

sawn timber”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2018, and conflicting national standards shall be

withdrawn at the latest by April 2018.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

Introduction

Fire-retardant treatments may considerably improve the reaction to fire properties of wood products

and these may result in wood products having the highest fire performance characteristics achievable

with any combustible product. However, the reaction to fire performance may be reduced by exposure

to wet and/or humid conditions [11] and the ability of the treated products to continue to perform even

when exposed to these conditions needs to be demonstrated.

Two aspects of the reaction to fire durability of fire-retardant wood products need to be considered.

One is the risk for high moisture content and migration of the fire-retardant chemicals within the wood

product and salt crystallization on the product surface that may fall off and reduce the improved fire

properties. These hygroscopic properties of the treated wood product can be evaluated by exposure to

high relative humidity.

The other aspect is the risk for decreased fire performance due to loss of the fire-retardant chemicals by

leaching in exterior applications, e.g. facade claddings. Maintained fire performance after weathering

needs to be verified.

This standard is based on the Technical Specification CEN/TS 15912, on a Nordtest standard [20] and

on experience from North America [10, 9].

1 Scope

This European Standard describes the characteristics for fire-retardant treated wood products.

NOTE 1 It is based on maintaining performance undiminished throughout the desired service life in the

anticipated conditions of use.

The European Standard prescribes the classification requirements for the durability of the reaction to

fire performance of fire-retardant treated wood products to be used in interior and exterior end use

conditions.

This European Standard applies to wood which has been treated during a production process with fire

retardant products applied either by a penetration process or by a superficial process, such as with a

film forming or intumescent fire retardant coating. It covers fire-retardant treated products that are

coated with an ordinary paint.

Mechanical properties and biological durability of fire-retardant treated wood products are not covered

by this European Standard.

NOTE 2 This standard can be used for other manufactured wood products.

This standard covers wood products. It doesn’t cover wood-based panels.

NOTE 3 Wood based panels for construction are described in EN 13986.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 927-3, Paints and varnishes — Coating materials and coating systems for exterior wood — Part 3:

Natural weathering test

EN 927-6, Paints and varnishes — Coating materials and coating systems for exterior wood — Part 6:

Exposure of wood coatings to artificial weathering using fluorescent UV lamps and water

EN 13238, Reaction to fire tests for building products — Conditioning procedures and general rules for

selection of substrates

EN 13501-1, Fire classification of construction products and building elements — Part 1: Classification

using data from reaction to fire tests

EN 13823, Reaction to fire tests for building products — Building products excluding floorings exposed to

the thermal attack by a single burning item

ISO 5660-1, Reaction-to-fire tests — Heat release, smoke production and mass loss rate — Part 1: Heat

release rate (cone calorimeter method) and smoke production rate (dynamic measurement)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

service classes

3.1.1

dry condition

DRF INT1

moisture content in the materials corresponding to a temperature of 20 °C and the relative humidity of

the surrounding air exceeding 65 % only for a few weeks per year

Note 1 to entry: In Eurocode EN 1995–1–1 as Service class 1.

3.1.2

humid condition

DRF INT2

moisture content in the material corresponding to a temperature of 20 °C and a relative humidity of the

surrounding air exceeding 85 % only for a few weeks per year

Note 1 to entry: In EN 1995–1–1 defined as Service class 2.

3.2

ordinary paint

non-fire retardant paint

4 Symbols and abbreviations

The symbols for DRF Classes INT1, INT2 and EXT are the following ones:

Figure 1 — Proposed symbols for classes

5 Requirements

5.1 Wood products and non-fire-retardant coating systems

The treatment manufacturing process and application rate declared by the producer shall be declared

by the manufacturer of the final product. Actual fire-retardant retention shall be expressed in kg/m of

the final wood product, or in kg/m for surface treated products. Values shall be given for products

conditioned at (50 ± 5)% relative humidity at (23 ± 2) °C (as for fire testing) according to EN 13238.

For products in DRF Classes INT and EXT procedures for maintenance shall be provided by the

manufacturers regarding:

— type of maintenance;

— interval of maintenance;

— time until to the first maintenance/recoating (if relevant);

— coating system to be used initially and at maintenance (if relevant).

Verification of DRF Class EXT obtained without a coating system (with an ordinary paint) is valid also

for the same product coated, provided that the coating does not reduce the reaction to fire performance.

The maintained fire performance of a coated product (with an ordinary paint) may be verified by fire

testing according to EN 13823 or ISO 5660-1.

Verification of DRF Class EXT is valid for thicker wood products than verified, but not for thinner.

5.2 Reaction to fire performance

5.2.1 Initial classification for reaction to fire

Classification testing for reaction to fire performance shall be performed. The products shall fulfil a

specified fire performance according to a recognized reaction to fire standard. The recognized

standards are for construction products EN 13501-1 and for maritime application the IMO Code FTP

[12].

5.2.2 Reaction to fire performance before and after accelerated or natural weathering

5.2.2.1 General

Reaction to fire performance before and after weather exposure shall be performed according to 5.2.2.2.

The weather exposure shall be performed according to an accelerated procedure, see Annex B, or

according to EN 927-6 or natural weathering according to EN 927-3. If there is a contestation, the

reference test method is EN 927-3 with fire testing according to EN 13823 before and after weathering.

For the accelerated weathering, it is essential that the exposed samples are large enough to be fire

tested. Thus, minimum width is 100 mm (minimum according to ISO 5660-1).

For the accelerated weathering, it is also essential that the exposed samples are large enough to fulfil

the cutting requirements in 5.2.2.2.3 and Annex B.

For the natural weathering, it is essential that the exposed samples are large enough to be fire tested

either by European standards or by small scale testing, see 5.2.2.2.2 and 5.2.2.2.3.

It is recommended that the natural weathering according to EN 927-3 is extended for at least one year

as specified in EN 927-3, since experience shows that the fire performance may degrade during up to

10 years [21, 20].

For the natural weathering, exposure at 45° slope is recommended.

Natural weathering at relevant conditions for the specific end use is most desirable, but such data are

usually not available. It is recommended that a set of the products going through an accelerated

weathering procedure is also exposed to natural weathering, in order to gain experience on the

relationship between accelerated and natural weathering.

Additional variations of the product, e.g. additional coating systems (with ordinary paints), could

preferably be evaluated at the same time. Examples of weathering studies are given in [21, 20].

5.2.2.2 Testing for reaction to fire performance

5.2.2.2.1 General

The reaction to fire performance after weathering shall be tested according to one of the following two

procedures:

5.2.2.2.2 Fire performance testing according to European standards

The preferred test method is the same as for the initial classification according to 5.2.1, i.e. EN 13823. At

least one replicate may be used for the fire testing after weathering. The same mounting conditions

shall be used for the fire testing before and after weathering.

5.2.2.2.3 Fire performance according to small scale testing

Alternatively, fire testing may be performed in small scale according to the cone calorimeter

ISO 5660-1. This alternative is justified by correlation studies with methods for classification test

methods of many product, e.g. [21, 22, 23]. Some data on limited correlation are also available [19].

At least three replicates at a heat flux 50 kW/m for at least 1 200 s shall be tested. Conditioning for

ISO 5660-1 tests shall be carried out according to EN 13238.

If this alternative is chosen, testing of the product before weathering is also needed for comparison of

the fire performance before and after weathering.

The preparation of small test specimens of fire-retardant treated wood products is very important for

the test results obtained, since the amount of fire-retardant chemicals may vary between small samples.

This is especially important for impregnated solid wood products. Such specimens shall therefore be

cut in order to represent the fire properties of the full wood plank. A suitable procedure as specified in

[13] is recommended:

— Specimens should be cut approximately 0,1 m from the end of the plank;

— Specimens should not have knots in the centre area – sound knots covered by the edge frame in the

ISO 5660 series may be used.

5.3 Durability of reaction to fire performance

5.3.1 General

Three classes for the Durability of Reaction to Fire performance are defined:

— DRF Class INT1 for permanent use in interior dry applications, service class 1 (e.g. wall and ceiling

products);

— DRF Class INT2 for permanent use in interior humid applications, service class 2 (e.g. wall and

ceiling products);

— DRF Class EXT for permanent use in exterior applications, service class 3 (e.g. facade claddings,

exterior conditions).

The following items shall be reported for each DRF class, see Table 1.

5.3.2 DRF Class INT1

— Reaction to fire class, initial, according to 5.2.1.

5.3.3 DRF Class INT2

— Reaction to fire class, initial, according to 5.2.1.

— Hygroscopic properties at (90 ± 5) % RH and (27 ± 2) °C according to Annex A. The test shall be

carried out with samples uncoated (with an ordinary paint). The equilibrium moisture content shall

be < 28 %.

5.3.4 DRF Class EXT

a) Reaction to fire class, initial, according to 5.2.1:

1) initial fire class;

2) maintained fire performance after weathering according to 5.2.2.1 and Table 1.

b) Hygroscopic properties at (90 ± 5) % RH and (27 ± 2) °C according to Annex A. The test shall be

carried out with samples uncoated (with an ordinary paint). The equilibrium moisture content shall

be < 28 %.

Products in DRF Class EXT meet the criteria DRF Class INT1 and INT2, but not vice versa.

NOTE 1 Background information on criteria for reaction to fire performance is available in [21, 22, 23].

Table 1 — Requirements for DRF Classes of fire-retardant wood products in interior and

exterior end use applications

Additional performance requirements at different end

DRF class Existing fire

requirements a

use of fire-retardant wood products

Intended Reaction to fire b Reaction to fire performance

Hygroscopic properties

use class, initial after weather exposure

INT1 Interior dry Relevant fire -

applications class

INT2 Interior Relevant fire - Moisture content < 28 % -

humid class

- No exudation of liquid

applications

- Minimum visible salt with

no increase at surface

f Exterior Relevant fire - Moisture content < 28 % Maintained reaction to fire

EXT

applications class c, d, e

- No exudation of liquid claimed performance

after

- Minimum visible salt with

no increase at surface - Accelerated weathering or

- Natural weathering

Application of specified

maintenance may be included.

a

To be fulfilled using product produced in the same way using the same manufacturing process and having a

similar retention level as for the reaction to fire performance.

b

For INT2 at (90 ± 5) % RH and (27 ± 2) °C according to Annex A. Classes INT2 and EXT are only applicable for

product application rates less than or equal to the highest level tested. Wood products treated to higher application

rates will be assumed to be Class INT1.

c

For EN 13823 according to 5.2.2.2.2, the relevant classification criteria according to EN 13501–1 shall be used.

At least the same classification level as initially shall be reached.

d

Criteria for small scale fire testing according to 5.2.2.2.3 after weather exposure:

- Class B products (according to EN 13501–1): Heat Release Rate, HRR ≤ 150 kW/m during 600 s after

30s ave

ignition and Total Heat Release THR600s increase < 20 % compared to fire testing before the weather exposure.

- Class C products (according to EN 13501–1): HRR 30s ave ≤ 220 kW/m during 600 s after ignition and THR600s

increase < 20 % compared to fire testing before the weather exposure.

e

For DRF Class EXT, the Durability of Reaction to Fire performance classification is only valid for the type of

coating system (with an ordinary paint) to be verified.

f

Verification of DRF Class EXT obtained without a coating system (with an ordinary paint) is valid also for the

same product coated, provided that the coating does not reduce the reaction to fire performance according to 5.2.1.

NOTE 2 Heat Release Rate, HRR is calculated as the sum of the HRR peak value and three values before

30s ave

and after the peak (totally seven values) divided by seven.

5.3.5 Practise to use DRF classes

Practices to use the DRF classification system:

— DRF INT1 and INT2 classifications apply for the lifetime of the wood product provided the product

is only used in the intended service class.

— DRF Class EXT is complex with a number of factors to be considered. The manufacturers should be

consulted regarding service life.

— Manufacturers of fire-retardant wood products with DRF classification shall use a third party

production control system according to Assessment and verification of constancy of performance

System 1.

— Systems in the relevant product standards for CE-marking may preferably be used, since they

include high Assessment and verification of constancy of performance levels for fire-retardant

treated wood products.

— Documentation shall include instructions on maintenance frequency and methods according to 5.1.

— Products approved with a DRF class INT1, INT2 or EXT, should be individually marked with DRF

Class symbols (see below) unless for aesthetic reasons this is not practical. Producer’s name, name

of fire-retardant product or trade name on the package label should also be displayed.

Year of initial testing according to this standard in the symbol, or beside, may be used, see Figure 2.

Figure 2 — Proposed labels to be used for DRF classes INT1, INT2 and EXT with year of initial

testing according to this standard

6 Classification report

Classification report according to this document shall be issued by accredited institutes and approval

bodies. The classification report shall include the following items:

— name and address of the accredited institute or approval body;

— name and address of the organization or person stating the classification;

— name and address of the manufacturer or supplier of the tested product;

— identification of the wood product including type of fire-retardant treatment, retention level and

coating details;

— a general description of the product including density and thickness;

— initial reaction to fire class obtained according to e.g. EN 13501-1 or IMO Code FTP, incl. details on

mounting and fixing;

— identification and number of the test reports referred to;

— accelerated weathering method used for DRF Class EXT;

— information if any maintenance shall be performed during use;

— hygroscopicity and weathering tests, including test method employed;

— performance according to the criteria for the actual DRF class;

— reference to this Standard and the fire classification standard used.

The format for a classification report is given in Annex C.

Annex A

(normative)

Hygroscopic properties of fire-retardant treated wood products including

those with fire-retardant coatings

A.1 General

This test method prescribes the procedure for determining the equilibrium moisture content after

exposure to standard high relative humidity conditions of (90 ± 5) % at (27 ± 2)°C, depending on DRF

class. The method is based on NT Build 504 [16], with changes in A.3 and an additional humid climate

included for testing. It is a modified and extended version of ASTM D3201-94 (with the same title) [10].

The extension aims at more repeatable and reproducible results by requiring conditioning to

equilibrium moisture content (instead of a specified time, one week, without specifying the sample size

or air velocities in the climate chamber in the ASTM version).

In this European Standard, some further modifications are included, mainly testing for two interior

cases, dry and humid.

A.2 Field of application

— The method is applicable for assessing the hygroscopic properties of fire-retardant treated wood

products (with the fire-retardant incorporated during the manufacturing of the wood product). It is

also applicable for wood products with fire-retardant coatings, including film-forming, non-film-

forming and intumescent coatings. The hygroscopic properties of wood and wood products treated

with fire-retardant chemicals may be greater than for untreated products. This is particularly true

at the higher relative humidity conditions. This higher hygroscopicity may cause staining, decay,

poor paint adhesion, migration and exuding of chemicals and moisture at the high humidities.

Corrosion of metal fasteners may also occur. The results obtained with this Standard are important

in determining if the fire-retardant treated wood or wood product has undesirable hygroscopic

properties, i.e. reaches an equilibrium moisture content that exceeds that for untreated wood and

the maximum prescribed level for the applicable DRF Class.

— Two test options are included, one general option and one specific option for end use products.

— The general test option (A.3.1) for impregnation treatments and fire-retardant coatings is carried

out using Scots pine (Pinus sylvestris) sapwood, in an uncoated manner (without

...

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.WHPDauerhaftigkeit des Verhaltens bei Brandeinwirkung - Klassen der mit Feuerschutzmitteln behandelten Holzprodukte für Anwendungen im Innen- und AußenbereichDurabilité des performances de réaction au feu - Classement des produits à base de bois ignifugés pour utilisation finale en intérieur et en extérieurDurability of reaction to fire performance - Classes of fire-retardant treated wood products in interior and exterior end use applications79.040Les, hlodovina in žagan lesWood, sawlogs and sawn timber71.100.50Wood-protecting chemicals13.220.40Sposobnost vžiga in obnašanje materialov in proizvodov pri gorenjuIgnitability and burning behaviour of materials and productsICS:Ta slovenski standard je istoveten z:EN 16755:2017SIST EN 16755:2017en,fr,de01-december-2017SIST EN 16755:2017SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16755

October

t r s y ICS

s uä t t rä v râ

s uä t t rä w râ

y sä s r rä w r English Version

Durability of reaction to fire performance æ Classes of fireæretardant treated wood products in interior and exterior end use applications Durabilitß des performances de rßaction au feu æ Classement des produits à base de bois ignifugßs pour utilisation finale en intßrieur et en extßrieur

Dauerhaftigkeit des Verhaltens bei Brandeinwirkung æ Klassen der mit Feuerschutzmitteln behandelten Holzprodukte für Anwendungen im Innenæ und Außenbereich This European Standard was approved by CEN on

t July

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s y CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s x y w wã t r s y ESIST EN 16755:2017

Hygroscopic properties of fire-retardant treated wood products including those with fire-retardant coatings . 12 A.1 General . 12 A.2 Field of application . 12 A.3 Sampling, sample handling and preparation . 13 A.3.1 General procedure . 13 A.3.2 Procedure for end use products . 14 A.4 Test method . 14 A.4.1 Principle . 14 A.4.2 Equipment . 14 A.4.3 Testing environment . 14 Annex B (normative)

Accelerated weathering of fire-retardant treated wood for fire testing . 17 B.1 General . 17 B.2 Field of application . 17 B.3 Sampling, sample handling and preparation . 17 B.4 Test method . 18 B.4.1 Principle . 18 B.4.2 Equipment . 18 B.4.3 Testing environment . 19 Annex C (informative)

Example of classification report — Classification report: Durability classes of reaction to fire performance of fire-retardant wood products in interior and exterior end use applications according to EN 16755:2017 . 22 Bibliography . 26

3.1.1 dry condition DRF INT1 moisture content in the materials corresponding to a temperature of 20 °C and the relative humidity of the surrounding air exceeding 65 % only for a few weeks per year Note 1 to entry: In Eurocode EN 1995–1–1 as Service class 1. 3.1.2 humid condition DRF INT2 moisture content in the material corresponding to a temperature of 20 °C and a relative humidity of the surrounding air exceeding 85 % only for a few weeks per year Note 1 to entry: In EN 1995–1–1 defined as Service class 2. 3.2 ordinary paint non-fire retardant paint 4 Symbols and abbreviations The symbols for DRF Classes INT1, INT2 and EXT are the following ones:

Figure 1 — Proposed symbols for classes 5 Requirements 5.1 Wood products and non-fire-retardant coating systems The treatment manufacturing process and application rate declared by the producer shall be declared by the manufacturer of the final product. Actual fire-retardant retention shall be expressed in kg/m3 of the final wood product, or in kg/m2 for surface treated products. Values shall be given for products conditioned at (50 ± 5)% relative humidity at (23 ± 2) °C (as for fire testing) according to EN 13238. For products in DRF Classes INT and EXT procedures for maintenance shall be provided by the manufacturers regarding: — type of maintenance; — interval of maintenance; SIST EN 16755:2017

Intended use Reaction to fire class, initial Hygroscopic propertiesb Reaction to fire performance after weather exposure INT1 Interior dry applications Relevant fire class

- INT2 Interior humid applications Relevant fire class - Moisture content < 28 % - No exudation of liquid - Minimum visible salt with no increase at surface - EXTf Exterior applications Relevant fire class - Moisture content < 28 % - No exudation of liquid - Minimum visible salt with no increase at surface Maintained reaction to fire claimed performancec, d, e after - Accelerated weathering or - Natural weathering Application of specified maintenance may be included. a To be fulfilled using product produced in the same way using the same manufacturing process and having a similar retention level as for the reaction to fire performance. b For INT2 at (90 ± 5) % RH and (27 ± 2) °C according to Annex A. Classes INT2 and EXT are only applicable for product application rates less than or equal to the highest level tested. Wood products treated to higher application rates will be assumed to be Class INT1. c

For EN 13823 according to 5.2.2.2.2, the relevant classification criteria according to EN 13501–1 shall be used. At least the same classification level as initially shall be reached. d Criteria for small scale fire testing according to 5.2.2.2.3 after weather exposure:

- Class B products (according to EN 13501–1): Heat Release Rate, HRR30s ave

150 kW/m2 during 600 s after ignition and Total Heat Release THR600s increase < 20 % compared to fire testing before the weather exposure.

- Class C products (according to EN 13501–1): HRR 30s ave

220 kW/m2 during 600 s after ignition and THR600s increase < 20 % compared to fire testing before the weather exposure. e For DRF Class EXT, the Durability of Reaction to Fire performance classification is only valid for the type of coating system (with an ordinary paint) to be verified. f Verification of DRF Class EXT obtained without a coating system (with an ordinary paint) is valid also for the same product coated, provided that the coating does not reduce the reaction to fire performance according to 5.2.1. NOTE 2 Heat Release Rate, HRR30s ave is calculated as the sum of the HRR peak value and three values before and after the peak (totally seven values) divided by seven. 5.3.5 Practise to use DRF classes Practices to use the DRF classification system: — DRF INT1 and INT2 classifications apply for the lifetime of the wood product provided the product is only used in the intended service class. — DRF Class EXT is complex with a number of factors to be considered. The manufacturers should be consulted regarding service life. SIST EN 16755:2017

Figure 2 — Proposed labels to be used for DRF classes INT1, INT2 and EXT with year of initial testing according to this standard 6 Classification report Classification report according to this document shall be issued by accredited institutes and approval bodies. The classification report shall include the following items: — name and address of the accredited institute or approval body; — name and address of the organization or person stating the classification; — name and address of the manufacturer or supplier of the tested product; — identification of the wood product including type of fire-retardant treatment, retention level and coating details; — a general description of the product including density and thickness; — initial reaction to fire class obtained according to e.g. EN 13501-1 or IMO Code FTP, incl. details on mounting and fixing; — identification and number of the test reports referred to; — accelerated weathering method used for DRF Class EXT; — information if any maintenance shall be performed during use; — hygroscopicity and weathering tests, including test method employed; — performance according to the criteria for the actual DRF class; — reference to this Standard and the fire classification standard used. The format for a classification report is given in Annex C. SIST EN 16755:2017

Hygroscopic properties of fire-retardant treated wood products including those with fire-retardant coatings A.1 General This test method prescribes the procedure for determining the equilibrium moisture content after exposure to standard high relative humidity conditions of (90 ± 5) % at (27 ± 2)°C, depending on DRF class. The method is based on NT Build 504 [16], with changes in A.3 and an additional humid climate included for testing. It is a modified and extended version of ASTM D3201-94 (with the same title) [10]. The extension aims at more repeatable and reproducible results by requiring conditioning to equilibrium moisture content (instead of a specified time, one week, without specifying the sample size or air velocities in the climate chamber in the ASTM version). In this European Standard, some further modifications are included, mainly testing for two interior cases, dry and humid. A.2 Field of application — The method is applicable for assessing the hygroscopic properties of fire-retardant treated wood products (with the fire-retardant incorporated during the manufacturing of the wood product). It is also applicable for wood products with fire-retardant coatings, including film-forming, non-film-forming and intumescent coatings. The hygroscopic properties of wood and wood products treated with fire-retardant chemicals may be greater than for untreated products. This is particularly true at the higher relative humidity conditions. This higher hygroscopicity may cause staining, decay, poor paint adhesion, migration and exuding of chemicals and moisture at the high humidities. Corrosion of metal fasteners may also occur. The results obtained with this Standard are important in determining if the fire-retardant treated wood or wood product has undesirable hygroscopic properties, i.e. reaches an equilibrium moisture content that exceeds that for untreated wood and the maximum prescribed level for the applicable DRF Class. — Two test options are included, one general option and one specific option for end use products. — The general test option (A.3.1) for impregnation treatments and fire-retardant coatings is carried out using Scots pine (Pinus sylvestris) sapwood, in an uncoated manner (without ordinary paint) since this will give c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...