prEN 16759

(Main)Bonded Glazing for doors, windows and curtain walling - Verification of mechanical performance of bonding on aluminium and steel surfaces

Bonded Glazing for doors, windows and curtain walling - Verification of mechanical performance of bonding on aluminium and steel surfaces

This European Standard specifies the method to be used to verify the mechanical performance of the bonded glazing for doors, windows and curtain walling (see examples in Annex A) and its durability. The bonding covered is only that between the glass and the metal surface.

NOTE 1 Bonded glazing was formerly known as structural sealant glazing SSGS.

This European Standard covers bonded glazing incorporated into the product construction works as follows:

- either vertically; or

- up to 83° from the vertical (positive slope); or

- up to 15° from the vertical onto the building face (negative slope).

NOTE 2 A wall has a positive slope if its outer surface faces upwards.

NOTE 3 Specific additional safety provisions may apply nationally.

It gives information to the manufacturer to comply with requirements regarding design, factory production control and assembly rules.

The parts concerned in the testing are the metal surface (anodized and coated aluminium, stainless steel), the glass coated or not which shall be bonded, the bonding sealant and mechanical restraints when required.

This standard does not apply to:

- other surfaces materials;

- direct glazing;

- glass-to-glass bonding and edge seal of insulating glass units (which are covered by EN 13022 1 and EN 1279 5);

- adhesive tapes.

Geklebte Glaskonstruktionen für Türen, Fenster und Vorhangfassaden - Überprüfung der mechanischen Leistungseigenschaften der Verklebung auf Aluminium- und Stahloberflächen

Diese Europäische Norm legt das anzuwendende Verfahren zum Nachweis des mechanischen Leistungsverhaltens der geklebten Glaskonstruktionen für Türen, Fenster und Vorhangfassaden (siehe Beispiele in Anhang A) und deren Beständigkeit fest. Es werden nur die Verklebungen zwischen dem Glas und der Metalloberfläche erfasst.

ANMERKUNG 1 Geklebte Glaskonstruktionen wurden vorher als structural sealant glazing (SSGS) bezeichnet.

Diese Europäische Norm erfasst geklebte Glaskonstruktionen, die wie folgt im Bauwerksprodukt eingebaut sind:

- entweder vertikal angeordnet, oder

- bis zu 83° von der Vertikalen (positive Neigung), oder

- bis zu 15° von der Vertikalen auf der Gebäudefassade (negative Neigung).

ANMERKUNG 2 Eine Wand weist eine positive Neigung auf, wenn ihre Außenfläche nach oben zeigt.

ANMERKUNG 3 Auf nationaler Ebene können zusätzliche spezifische Sicherheitsbestimmungen gelten.

Sie liefert dem Hersteller Angaben zur Übereinstimmung mit Anforderungen bezüglich Ausführung, werkseigener Produktionskontrolle und Verglasungsvorschriften.

Die von der Prüfung betroffenen Teile sind die Metalloberflächen (anodisiertes und beschichtetes Aluminium, Edelstahl), beschichtetes oder unbeschichtetes Glas, das geklebt sein muss, der Klebedichtstoff und mechanische Halterungen, falls erforderlich.

Diese Norm gilt nicht für:

- andere Oberflächenmaterialien;

- Direktverglasung;

- den Glas/Glas-Verbund und Randverbund von Mehrscheiben-Isolierglaseinheiten (welche durch EN 13022-1 und EN 1279-5 erfasst werden);

- Klebebänder.

Vitrages extérieurs collés (VEC) pour portes, fenêtres et façades rideaux -Vérification des propriétés mécaniques de collage sur surfaces aluminium et acier

La présente Norme européenne spécifie la méthode à utiliser pour vérifier les performances mécaniques des vitrages extérieurs collés pour portes, fenêtres et façades rideaux (voir exemples à l’Annexe A) ainsi que leur durabilité. La présente norme ne traite que du collage entre le verre et la surface métallique.

NOTE 1 Les « vitrages extérieurs collés » étaient anciennement appelés « collages structurels de vitrage ».

La présente Norme européenne couvre les vitrages collés intégrés de l’une des manières suivantes dans les travaux de construction réalisés :

- verticalement ; ou

- inclinés jusqu’à 83° par rapport à la verticale (pente positive) ; ou

- inclinés jusqu’à 15° par rapport à la verticale sur la façade du bâtiment (pente négative).

NOTE 2 Une façade a une pente positive si sa surface extérieure est orientée vers le haut.

NOTE 3 Des dispositions de sécurité spécifiques complémentaires peuvent être en vigueur à l’échelle nationale.

La présente norme fournit des informations au fabricant lui permettant de satisfaire aux exigences relatives à la conception, au contrôle de la production en usine et aux règles d’assemblage.

Les parties concernées par les essais sont les surfaces métalliques (aluminium anodisé et thermolaqué, acier inoxydable), le verre revêtu ou non qui doit être collé, le joint de collage et les dispositifs de retenue mécanique, le cas échéant.

La présente norme ne s’applique pas :

- aux autres matériaux de surface ;

- au vitrage direct ;

- au collage verre sur verre ni aux assemblages par collage des vitrages isolants (qui sont couverts par l’EN 13022-1 et l’EN 1279-5) ;

- aux bandes adhésives.

Sistemi strukturne zasteklitve (SSGS)

General Information

- Status

- Not Published

- Publication Date

- 25-Nov-2018

- Withdrawal Date

- 26-May-2019

- Technical Committee

- CEN/TC 33 - Doors, windows, shutters and building hardware

- Drafting Committee

- CEN/TC 33/WG 6 - Curtain walling

- Current Stage

- 4098 - Decision to abandon - Enquiry

- Start Date

- 20-Dec-2018

- Completion Date

- 04-Feb-2026

Overview

prEN 16759 (CEN) defines the method to verify the mechanical performance and durability of bonded glazing (formerly known as Structural Sealant Glazing Systems, SSGS) where the bond is between glass and metal surfaces. The standard applies to bonded glazing for doors, windows and curtain walling with glazing installed vertically, up to a positive slope of 83° from vertical, or up to 15° negative slope onto the building face. It gives manufacturers guidance on design, factory production control (FPC) and assembly rules for bonded glazing on aluminium (anodized and coated) and stainless steel substrates.

Key topics and requirements

- Scope and exclusions: Covers glass-to-metal bonding only. Does not apply to other framing materials, direct glazing, glass-to-glass bonding, insulating glass edge seals (EN 13022-1 / EN 1279-5), or adhesive tapes.

- Components under test: Metal adhesion surfaces (anodised/coated aluminium, stainless steel), glass (coated or uncoated), structural sealant, and mechanical restraints when required.

- Mechanical performance verification: Specifies test methods and criteria to assess bond strength, retaining devices and self-weight support, plus durability through ageing tests.

- Surface and coating controls: Requirements for recording aluminium alloy composition, anodising characteristics (thickness and sealing), and coating inspection. Accepted measurement methods referenced include ISO 2360, ISO 2128, ISO 1463, ISO 2106 for thickness and ISO 2143, ISO 3210, ISO 2931 for sealing assessment.

- Design and FPC information: Information required for manufacturer documentation to demonstrate compliance with design resistance, production checks and assembly procedures.

- Annexes: Normative annexes define principles of SSGS, setting block material, testing protocols for coated aluminium and stainless steel, and verification rules for profiles with thermal barriers.

Applications and users

prEN 16759 is intended for:

- Façade and curtain walling manufacturers

- Window and door system suppliers

- Façade engineers, structural designers and architects specifying bonded glazing

- Test laboratories and certification bodies performing bond and durability testing

- Installers and quality managers implementing factory production control and assembly rules

Practical uses include qualifying structural sealant glazing systems for building envelopes, validating material combinations (glass + metal + sealant), and ensuring long-term performance under gravity, wind and environmental ageing.

Related standards

- EN 13022-1 / EN 13022-2 (Structural sealant glazing - glass & assembly rules)

- EN 15434 (Product standard for structural sealant)

- EN 1279-1 (Insulating glass units)

- EN 13830 (Curtain walling) and EN 14351-1 (Windows & doors)

- EN 14024 (Metal profiles with thermal barrier)

- EN 15651 series (Sealants), plus ISO standards for anodising and coating measurement

Keywords: bonded glazing, structural sealant glazing, SSGS, mechanical performance, anodised aluminium, coated aluminium, stainless steel, curtain walling, windows, doors, durability testing, factory production control.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

prEN 16759 is a draft published by the European Committee for Standardization (CEN). Its full title is "Bonded Glazing for doors, windows and curtain walling - Verification of mechanical performance of bonding on aluminium and steel surfaces". This standard covers: This European Standard specifies the method to be used to verify the mechanical performance of the bonded glazing for doors, windows and curtain walling (see examples in Annex A) and its durability. The bonding covered is only that between the glass and the metal surface. NOTE 1 Bonded glazing was formerly known as structural sealant glazing SSGS. This European Standard covers bonded glazing incorporated into the product construction works as follows: - either vertically; or - up to 83° from the vertical (positive slope); or - up to 15° from the vertical onto the building face (negative slope). NOTE 2 A wall has a positive slope if its outer surface faces upwards. NOTE 3 Specific additional safety provisions may apply nationally. It gives information to the manufacturer to comply with requirements regarding design, factory production control and assembly rules. The parts concerned in the testing are the metal surface (anodized and coated aluminium, stainless steel), the glass coated or not which shall be bonded, the bonding sealant and mechanical restraints when required. This standard does not apply to: - other surfaces materials; - direct glazing; - glass-to-glass bonding and edge seal of insulating glass units (which are covered by EN 13022 1 and EN 1279 5); - adhesive tapes.

This European Standard specifies the method to be used to verify the mechanical performance of the bonded glazing for doors, windows and curtain walling (see examples in Annex A) and its durability. The bonding covered is only that between the glass and the metal surface. NOTE 1 Bonded glazing was formerly known as structural sealant glazing SSGS. This European Standard covers bonded glazing incorporated into the product construction works as follows: - either vertically; or - up to 83° from the vertical (positive slope); or - up to 15° from the vertical onto the building face (negative slope). NOTE 2 A wall has a positive slope if its outer surface faces upwards. NOTE 3 Specific additional safety provisions may apply nationally. It gives information to the manufacturer to comply with requirements regarding design, factory production control and assembly rules. The parts concerned in the testing are the metal surface (anodized and coated aluminium, stainless steel), the glass coated or not which shall be bonded, the bonding sealant and mechanical restraints when required. This standard does not apply to: - other surfaces materials; - direct glazing; - glass-to-glass bonding and edge seal of insulating glass units (which are covered by EN 13022 1 and EN 1279 5); - adhesive tapes.

prEN 16759 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building; 91.060.10 - Walls. Partitions. Facades; 91.060.50 - Doors and windows. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 16759 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

oSIST prEN 16759:2014

01-september-2014

Sistemi strukturne zasteklitve (SSGS)

Structural Sealant Glazing Systems (SSGS)

Geklebte Glaskonstruktionen (SSGS)

Vitrages extérieurs collés (VEC)

Ta slovenski standard je istoveten z: prEN 16759

ICS:

81.040.20 Steklo v gradbeništvu Glass in building

91.060.10 Stene. Predelne stene. Walls. Partitions. Facades

Fasade

91.060.50 Vrata in okna Doors and windows

oSIST prEN 16759:2014 en,fr,de

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

oSIST prEN 16759:2014

oSIST prEN 16759:2014

EUROPEAN STANDARD

DRAFT

NORME EUROPÉENNE

EUROPÄISCHE NORM

June 2014

ICS 81.040.20; 91.060.10; 91.060.50

English Version

Structural Sealant Glazing Systems (SSGS)

Vitrages extérieurs collés (VEC) Geklebte Glaskonstruktionen (SSGS)

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 33.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other language

made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United

Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are aware and to

provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2014 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 16759:2014 E

worldwide for CEN national Members.

oSIST prEN 16759:2014

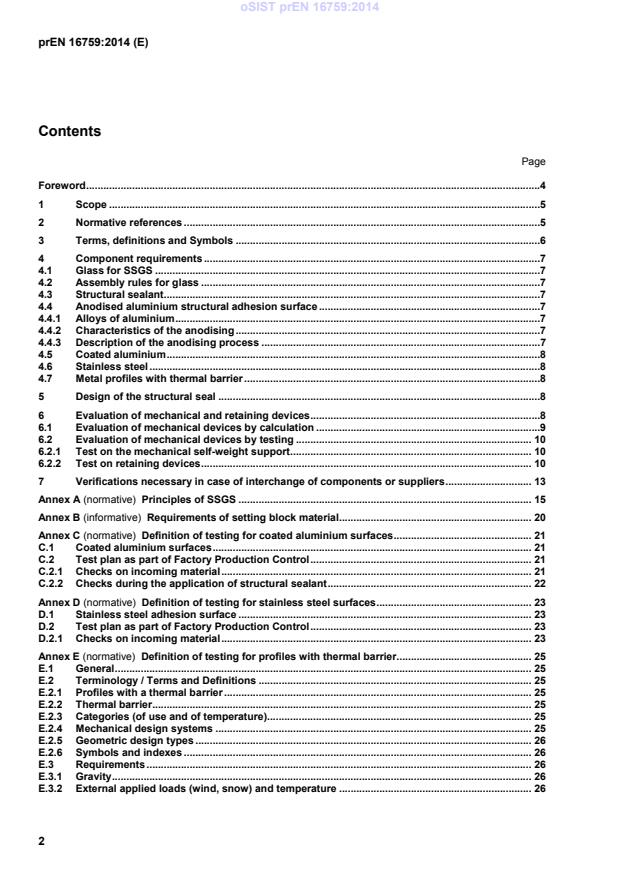

Contents

Page

Foreword .4

1 Scope .5

2 Normative references .5

3 Terms, definitions and Symbols .6

4 Component requirements .7

4.1 Glass for SSGS .7

4.2 Assembly rules for glass .7

4.3 Structural sealant.7

4.4 Anodised aluminium structural adhesion surface .7

4.4.1 Alloys of aluminium .7

4.4.2 Characteristics of the anodising .7

4.4.3 Description of the anodising process .7

4.5 Coated aluminium .8

4.6 Stainless steel .8

4.7 Metal profiles with thermal barrier .8

5 Design of the structural seal .8

6 Evaluation of mechanical and retaining devices .8

6.1 Evaluation of mechanical devices by calculation .9

6.2 Evaluation of mechanical devices by testing . 10

6.2.1 Test on the mechanical self-weight support . 10

6.2.2 Test on retaining devices . 10

7 Verifications necessary in case of interchange of components or suppliers . 13

Annex A (normative) Principles of SSGS . 15

Annex B (informative) Requirements of setting block material. 20

Annex C (normative) Definition of testing for coated aluminium surfaces . 21

C.1 Coated aluminium surfaces . 21

C.2 Test plan as part of Factory Production Control . 21

C.2.1 Checks on incoming material . 21

C.2.2 Checks during the application of structural sealant . 22

Annex D (normative) Definition of testing for stainless steel surfaces . 23

D.1 Stainless steel adhesion surface . 23

D.2 Test plan as part of Factory Production Control . 23

D.2.1 Checks on incoming material . 23

Annex E (normative) Definition of testing for profiles with thermal barrier. 25

E.1 General . 25

E.2 Terminology / Terms and Definitions . 25

E.2.1 Profiles with a thermal barrier . 25

E.2.2 Thermal barrier . 25

E.2.3 Categories (of use and of temperature). 25

E.2.4 Mechanical design systems . 25

E.2.5 Geometric design types . 26

E.2.6 Symbols and indexes . 26

E.3 Requirements . 26

E.3.1 Gravity . 26

E.3.2 External applied loads (wind, snow) and temperature . 26

oSIST prEN 16759:2014

E.3.3 Effects of water and relative humidity . 26

E.3.4 Ageing . 26

E.3.5 Durability of materials used as a thermal barrier . 27

E.3.6 Mechanical resistance . 28

E.3.7 Static proof . 28

E.4 Methods of verification . 28

E.4.1 Ageing method: Permanent shear tension and high temperature . 28

E.4.2 Requirements . 28

E.5 Static proof . 28

E.6 Extrapolation rules . 28

Bibliography . 29

oSIST prEN 16759:2014

Foreword

This document (prEN 16759:2014) has been prepared by Technical Committee CEN/TC 33 “Doors, windows,

shutters, building hardware and curtain walling”, the secretariat of which is held by AFNOR.

This document is currently submitted to the CEN Enquiry.

EN 13830 Curtain walling - EN 14351-1 Windows and

Product standard doors Product standard,

(Harmonized standard) performance characteristics -

Part 1: Windows and external

pedestrian doorsets without

resistance to fire and/or smoke

leakage characteristics

(Harmonized standard)

Glazing Systems (SSGS)

EN 13022-1 Glass in

EN 15434 Glass in building EN 1279-5 Glass in

building - Structural sealant

- Product standard for building - Insulating

glazing - Part 1: Glass

structural and/or ultraviolet glass units - Part 5:

products for structural

resistant sealant (for use Evaluation of

sealant glazing systems for

with structural sealant conformity

supported and

glazing and/or insulating

unsupported monolithic

glass units with exposed

and multiple glazing

seals)

EN 13022-2 Glass in

building - Structural sealant

glazing - Part 2: Assembly

rules

oSIST prEN 16759:2014

1 Scope

This European Standard specifies the method to be used to verify the mechanical performance of Structural

Sealant Glazing Systems.

It applies to any window/doorset or curtain walling application (see Annex A).

Structural Sealant Glazing can be incorporated into the product as follows:

either vertically; or

up to 83° from the vertical (positive slope)

up to 15° from the vertical onto the building face (negative slope).

NOTE A wall has a positive slope if its outer surface faces upwards.

It gives information to the manufacturer to comply with requirements regarding design, factory production

control and assembly rules.

The parts concerned in the testing are the metal profile (anodized and coated aluminium, stainless steel), the

glass coated or not which shall be bonded, the sealant and mechanical restraints when required.

The testing does not apply to other framing materials.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

EN 573-3, Aluminium and aluminium alloys - Chemical composition and form of wrought products - Part 3:

Chemical composition and form of products

EN 1279-1, Glass in building - Insulating glass units - Part 1: Generalities, dimensional tolerances and rules

for the system description

EN 1990, Eurocode - Basis of structural design

EN 1991 (all parts), Eurocode 1: Actions on structures

EN 12206-1, Paints and varnishes - Coating of aluminium and aluminium alloys for architectural purposes -

Part 1: Coatings prepared from coating powder

EN 13022-1, Glass in building - Structural sealant glazing - Part 1: Glass products for structural sealant

glazing systems for supported and unsupported monolithic and multiple glazing

EN 13022-2:2006, Glass in building - Structural sealant glazing - Part 2: Assembly rules

EN 13119, Curtain walling – Terminology

EN 13830, Curtain walling – Product standard

EN 14024:2004 Metal profiles with thermal barrier - Mechanical performance - Requirements, proof and tests

for assessment

oSIST prEN 16759:2014

EN 14351-1 Windows and doors - Product standard, performance characteristics - Part 1: Windows and

external pedestrian doorsets without resistance to fire and smoke leakage characteristics

EN 15434:2006, Glass in building - Product standard for structural and/or ultraviolet resistant sealant (for use

with structural sealant glazing and/or insulating glass units with exposed seals)

EN 15651-1, Sealants for non-structural use in joints in buildings and pedestrian walkways - Part 1: Sealants

for facade elements

EN 15651-2, Sealants for non-structural use in joints in buildings and pedestrian walkways - Part 2: Sealants

for glazing

EN ISO 2813, Paints and varnishes - Determination of specular gloss of non-metallic paint films at 20

degrees, 60 degrees and 85 degrees

ISO 1463 Metallic and oxide coatings -- Measurement of coating thickness -- Microscopical method

ISO 2106 Anodizing of aluminium and its alloys - Determination of mass per unit area (surface density) of

anodic oxidation coatings - Gravimetric method

ISO 2128 Anodizing of aluminium and its alloys - Determination of thickness of anodic oxidation coatings -

Non-destructive measurement by split-beam microscope

ISO 2143 Anodizing of aluminium and its alloys - Estimation of loss of absorptive power of anodic oxidation

coatings after sealing - Dye-spot test with prior acid treatment

ISO 2360 Non-conductive coatings on non-magnetic electrically conductive basis materials - Measurement of

coating thickness - Amplitude-sensitive eddy-current method

ISO 2931 Anodizing of aluminium and its alloys - Assessment of quality of sealed anodic oxidation coatings by

measurement of admittance

ISO 3210 Anodizing of aluminium and its alloys - Assessment of quality of sealed anodic oxidation coatings by

measurement of the loss of mass after immersion in phosphoric acid/chromic acid solution

ISO 3668, Paints and varnishes -- Visual comparison of the colour of paints

3 Terms, definitions and Symbols

For the purposes of this European Standard, the terms and definitions given in EN 1279-1, EN 13022-1,

EN 13022-2, EN 13119, EN 13830, EN 15434 and the following symbols apply.

F

design resistance

des

F

characteristic force giving 75 % confidence that 95 % of the test results will be higher than

u,5

this value

F average breaking force

mean

eccentricity of 5 % with a 75 % confidence

τ

αß

s standard deviation of the series under consideration

P breaking/rupture pressure, initial state

br,n

P breaking pressure, after ageing test

br,c

safety factor

γ

oSIST prEN 16759:2014

4 Component requirements

4.1 Glass for SSGS

Glass used in SSGS shall conform to EN 13022-1.

4.2 Assembly rules for glass

The assembling of the glass elements into or onto the window, door or curtain-walling framework shall be in

accordance with EN 13022-2, clause 4.

For requirements of the setting block material see Annex B.

4.3 Structural sealant

The structural sealant shall be identified and assessed according to EN 15434.

4.4 Anodised aluminium structural adhesion surface

4.4.1 Alloys of aluminium

The chemical composition of the aluminium alloy shall be recorded.

4.4.2 Characteristics of the anodising

The aluminium structural adhesion surface on which the tests in EN 15434 are to be performed, are identified

as follows.

4.4.2.1 Measurement of the thickness

At least one of the following methods shall be used:

Eddy current test method to ISO 2360

Split-beam optical method to ISO 2128

Micro-section method to ISO 1463

Gravimetric method to ISO 2106.

4.4.2.2 Sealing tests

At least one of the following methods shall be used:

Stain test to ISO 2143

Immersion test to ISO 3210

Measurement of admittance test at 1000 Hz to ISO 2931.

4.4.3 Description of the anodising process

The following information of the anodising process shall be recorded:

4.4.3.1 Scouring

Composition of the bath

oSIST prEN 16759:2014

Time of immersion of aluminium in the bath

4.4.3.2 Anodic oxidation

Composition of the bath

Time of immersion of aluminium in the bath

Temperature of the bath

4.4.3.3 Sealing of the anodised layer

Composition of the bath or reference name

Time of immersion of aluminium in the bath

Temperature of the bath

NOTE 1 A misunderstanding can arise from the word "sealing" which is a post-treatment of the anodising. The

equivalent in French is "colmatage" and in German "Verdichtung".

Where cold sealing is proposed additional proof must be provided

NOTE 2 Details are prescribed on Qualanod ‘Sealing by hydrothermal treatment’ or ‘Cold impregnation/Cold sealing

(CI-CS) based on nickel fluoride’.

4.5 Coated aluminium

For coated aluminium the relevant information regarding testing, inspection and factory production control

shall be taken from EN 13022-2, 6.2.

For coated aluminium surfaces see Annex C.

4.6 Stainless steel

For stainless steel the relevant information regarding testing, inspection and factory production control shall be

taken from Annex D.

4.7 Metal profiles with thermal barrier

For metal profiles with thermal barrier the relevant information regarding testing, inspection and factory

production control shall be taken from EN 14024 and Annex E.

5 Design of the structural seal

The design of the glass elements into or onto the window, door or curtain-walling framework shall be in

accordance with of EN 13022-2, Annex B.

6 Evaluation of mechanical and retaining devices

Devices are used to reduce danger in the event of bond failure and they may be required by national

regulations. Functions of devices are illustrated in Figure 1.

Type I: Mechanical transfer of the self-weight of the infill to the sealant-support frame and thence to the

structure. The structural seal transfers all other actions. Devices are used to reduce danger in the event of a

bond failure.

oSIST prEN 16759:2014

Type II: Mechanical transfer of the self-weight of the infill to the sealant-support frame and thence to the

structure. The structural seal transfers all other actions and no devices are used to reduce danger in the event

of bond failure.

Type III: The structural seal transfers all actions including the self-weight of the infill to the sealant support

frame and thence to the structure. Devices are used to reduce danger in the event of a bond failure.

Type IV: The structural seal transfers all actions, including self-weight of the infill to the sealant support frame

and thence to the structure. No devices are used to reduce danger in the event of bond failure.

Key

1 retaining device to reduce danger in case of bond failure

2 mechanical self-weight support

3 structural sealant support frame

4 structural bonding

Figure 1 — Examples of the different types of SSGS

The performance of the devices shall be assessed either from the results of tests or from calculations which

shall allow for the method of attachment to the frame and also consider a variety of designs. The devices shall

not themselves cause damage to the glazing.

NOTE Some provisions may require mechanical retaining devices, e.g. for negative sloping surfaces.

6.1 Evaluation of mechanical devices by calculation

The structural adequacy of such supports is assessed using conventional calculations based upon the

strength of materials and testing will not be required.

The design principles are based on the structural Eurocode EN 1990. The actions are determined in

accordance with the structural Eurocode series EN 1991, including the National annexes.

The engineering stresses shall be calculated in accordance with the appropriate Eurocodes taking into

account the nationally determined parameters relevant to the place of use. The engineering stresses induced

oSIST prEN 16759:2014

into mechanical devices shall be no greater than those specified within the appropriate materials standard

from which mechanical devices are made.

6.2 Evaluation of mechanical devices by testing

Where the design incorporates novel features the following test can be used.

6.2.1 Test on the mechanical self-weight support

Key

1 load application

2 structural sealant support frame

3 mechanical self-weight support

Figure 2 — Test on mechanical self-weight support

The test piece comprises

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...