SIST EN 13655:2025

(Main)Plastics - Thermoplastic mulch films recoverable after use, for use in agriculture and horticulture

Plastics - Thermoplastic mulch films recoverable after use, for use in agriculture and horticulture

This document specifies the requirements related to dimensional, mechanical, optical and thermal characteristics of thermoplastic films for mulching applications in agriculture and horticulture.

These mulch films are intended to be removed after use and not incorporated in the soil.

These mulch films are not intended to be used for soil disinfection by fumigation. Films for soil disinfection are in the scope of EN 17098-1 [1] and EN 17098-2 [2].

The biodegradable mulch films intended to be incorporated in the soil after used are also not in the scope of this document. They are in the scope of EN 17033 [3].

This document specifies a classification for durability of mulching films and the test methods referred to in this document.

This document is applicable to thermoplastic mulch films, used for agriculture and horticulture in Europe, based on polyethylene and/or ethylene copolymers, of the following types:

- transparent films;

- black films;

- reflective films (e.g. white films, black/white films and black/silver films);

- films of other colour(s) for weed control (e.g. green, brown).

This document defines the criteria for design for recycling of mulch films and refer to EN 18109 for the product lifecycle, including installation, use, removal and collection for end of life for management of the product after its usage.

NOTE Mulch films can be highly soiled by organic and mineral residues at the end of their use life: the observed rates (or levels) of soilage of mulch films can vary from 70 % to 90 %, therefore the film thickness is a key factor on the rate of soilage, the thinnest films (e.g. less than 20 micron) will be the mostly soiled, difficult, expensive to remove, recover and recycle.

Kunststoffe - Nach Gebrauch rückbaubare thermoplastische Mulchfolien für den Einsatz in Landwirtschaft und im Gartenbau

Dieses Dokument legt die Anforderungen in Bezug auf Maßeigenschaften sowie die mechanischen, optischen und thermischen Merkmale thermoplastischer Folien für Mulchanwendungen in der Landwirtschaft und im Gartenbau fest.

Diese Mulchfolien sind dazu bestimmt, nach Gebrauch entfernt und nicht in den Boden eingearbeitet zu werden.

Diese Mulchfolien sind nicht für eine Nutzung im Rahmen einer Bodendesinfektion durch Begasung vorgesehen. Folien zur Desinfektion von Böden fallen in den Anwendungsbereich von EN 17098 1 [1] und EN 17098 2 [2].

Die biologisch abbaubaren Mulchfolien, die dafür vorgesehen sind, nach ihrer Verwendung in den Boden eingearbeitet zu werden, fallen ebenfalls nicht in den Anwendungsbereich dieses Dokuments. Sie fallen in den Anwendungsbereich von EN 17033 [3].

Dieses Dokument legt eine Klassifikation bezüglich der Beständigkeit von Mulchfolien und der in diesem Dokument in Bezug genommenen Prüfverfahren fest.

Dieses Dokument ist anwendbar für thermoplastische Mulchfolien der folgenden Typen, die aus Polyethylen und/oder Ethylen-Copolymeren bestehen und in Europa in der Landwirtschaft und im Gartenbau angewendet werden:

transparente Folien;

schwarze Folien;

reflektierende Folien (z. B. weiße Folien, schwarz/weiße Folien und schwarz/silberne Folien);

Folien in einer anderen Farbe bzw. in anderen Farben zur Unkrautbekämpfung (z. B. grün, braun).

Dieses Dokument definiert die Kriterien für das recyclinggerechte Design von Mulchfolien und verweist auf EN 18109 für den Produktlebenszyklus, einschließlich Installation, Nutzung, Entsorgung und Sammlung am Ende des Lebenszyklus für das Management des Produkts nach seiner Nutzung.

ANMERKUNG Mulchfolien können durch organische und mineralische Rückstände stark kontaminiert sein: Die beobachteten Grade (oder Niveaus) können von 70 % bis 90 % variieren. Daher ist die Foliendicke ein wichtiger Faktor für den Kontaminationsgrad, wobei die dünnsten Folien (z. B. weniger als 20 Mikron) am höchsten kontaminiert, schwierig und teuer zu entfernen, zu verwerten und zu recyceln sind.

Plastiques - Films de paillage thermoplastiques récupérables après usage, pour utilisation en agriculture et horticulture

Le présent document spécifie les exigences relatives aux caractéristiques dimensionnelles, mécaniques, optiques et thermiques des films thermoplastiques à utiliser pour les applications de paillage en agriculture et en horticulture.

Ces films de paillage sont destinés à être retirés après utilisation et ne sont pas incorporés dans le sol.

Ces films de paillage ne sont pas destinés à être utilisés pour la désinfection du sol par fumigation. Les films pour la désinfection du sol font partie du domaine d’application de l’EN 17098-1 [1] et de l’EN 17098-2 [2].

Les films de paillage biodégradables destinés à être incorporés dans le sol après utilisation ne sont également pas dans le domaine d’application du présent document. Ils sont couverts par l’EN 17033 [3].

Le présent document spécifie une classification pour la durabilité des films de paillage et les méthodes d’essai auxquelles il est fait référence dans le présent document.

Le présent document est applicable aux films de paillage thermoplastiques utilisés en agriculture et en horticulture en Europe, à base de polyéthylène et/ou de copolymères d’éthylène, des types suivants :

- films transparents ;

- films noirs ;

- films réfléchissants (par exemple films blancs, films noirs/blancs et films noirs/argentés) ;

- films d’autre(s) couleur(s) pour le contrôle des mauvaises herbes (par exemple verts, marrons).

Le présent document définit les critères pour la conception en vue du recyclage des films de paillage et fait référence à l’EN 18109 pour le cycle de vie du produit, incluant la mise en œuvre, l’utilisation, la dépose et la collecte pour la gestion en fin de vie du produit après usage.

NOTE Les films de paillage peuvent être fortement souillés par des résidus organiques et minéraux à la fin de leur vie : les taux (ou niveaux) de souillure observés sur les films de paillage peuvent varier de 70 % à 90 %. Par conséquent, l’épaisseur du film est un facteur clé pour le taux de souillure. Plus les films sont minces (par exemple moins de 20 microns), plus ils seront souillés et plus il sera difficile et coûteux de les éliminer, valoriser et recycler.

Polimerni materiali - Termoplastične folije za mulčenje, primerne za nadaljnjo predelavo, za uporabo v kmetijstvu in vrtnarstvu

Ta dokument določa zahteve v zvezi z dimenzijskimi, mehanskimi, optičnimi in toplotnimi lastnostmi termoplastičnih folij za mulčenje, ki se uporabljajo v kmetijstvu in vrtnarstvu. Te folije za mulčenje je treba po uporabi odstraniti in jih ne zmešati v zemljino. Te folije niso namenjene razkuževanju zemlje z zaplinjevanjem. Folije za razkuževanje zemlje spadajo na področje uporabe standardov EN 17098-1 [1] in EN 17098-2 [2]. Biorazgradljive folije za mulčenje, ki po uporabi ostanejo v tleh, prav tako ne spadajo na področje uporabe tega dokumenta. Te folije spadajo na področje uporabe standarda EN 17033 [3]. Ta dokument določa razvrstitev za trajnost folij za mulčenje in preskusne metode, na katere se sklicuje ta dokument. Uporablja se za naslednje vrste termoplastičnih folij za mulčenje, ki se v Evropi uporabljajo v kmetijstvu in vrtnarstvu ter so izdelane iz polietilenskih in/ali etilenskih kopolimerov: – prosojne folije; – črne folije; – odsevne folije (npr. bele folije, črno/bele folije in črno/srebrne folije); – folije drugih barv za nadzor plevela (npr. zelene, rjave). Ta dokument opredeljuje merila za načrtovanje recikliranja folij za mulčenje in se sklicuje na standard EN 18109 glede življenjskega cikla izdelka, vključno z namestitvijo, uporabo, odstranitvijo in zbiranjem ob koncu življenjske dobe za ravnanje z izdelkom po njegovi uporabi. OPOMBA: Folije za mulčenje so lahko ob koncu življenjske dobe zelo onesnažene z organskimi in mineralnimi ostanki: ugotovljene stopnje (ali ravni) onesnaženja folij za mulčenje so v razponu od 70 % do 90 %. Zato je debelina folije ključen dejavnik pri stopnji onesnaženja. Najtanjše folije (npr. tanjše od 20 mikronov) bodo najbolj onesnažene, njihovo odstranjevanje, obnavljanje in recikliranje pa bo težavno in drago.

General Information

- Status

- Published

- Public Enquiry End Date

- 15-Oct-2024

- Publication Date

- 30-Sep-2025

- Technical Committee

- IPMA - Polimer materials and products

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 29-Sep-2025

- Due Date

- 04-Dec-2025

- Completion Date

- 01-Oct-2025

Relations

- Effective Date

- 28-Jan-2023

Overview

EN 13655:2025 - Plastics - Thermoplastic mulch films recoverable after use, for use in agriculture and horticulture - is a CEN standard that defines performance, testing and product-management requirements for thermoplastic mulching films that are intended to be removed and recovered after use. Approved 16 June 2025, it supersedes EN 13655:2018 and applies to polyethylene and ethylene‑copolymer based films (transparent, black, reflective and other colours) used across European agriculture and horticulture.

The standard covers dimensional, mechanical, optical and thermal characteristics, durability classification, test methods, roll acceptance, marking, storage/handling, instructions for installation/removal, and criteria for design for recycling and end‑of‑life management.

Key topics and technical requirements

- Scope limits: Not applicable to films for soil disinfection (see EN 17098‑1/2) or biodegradable films intended to be incorporated into soil (see EN 17033).

- Materials: Focus on polyethylene and ethylene copolymers; clause on materials extended in the 2025 revision.

- Durability classification: Defines service-life categories and associated test procedures.

- Dimensional & physical parameters: Requirements and test methods for thickness, width and roll length (ISO/EN methods referenced).

- Mechanical tests: Tensile properties, impact resistance (EN ISO 527 series; EN ISO 7765‑1).

- Optical & thermal tests: Total luminous transmittance, relative light transmission, solar reflectance, PAR/NIR radiation behaviour and resistance to artificial weathering (xenon‑arc exposure - EN ISO 4892‑2).

- Roll acceptance, storage & handling: Delivery checks and storage/handling guidance to preserve product integrity.

- Marking & instructions: Labelling, installation/use instructions and removal/collection guidance.

- Design for recycling: Criteria to support mechanical recycling and lifecycle management; reference to EN 18109 for product lifecycle and collection practice.

- Practical note: Mulch films can become highly soiled (observed soilage rates 70–90%); very thin films (< 20 µm) are more difficult and costly to recover and recycle.

Applications and who uses it

EN 13655:2025 is used for:

- Product specification and quality control by mulch film manufacturers

- Supplier selection and procurement by growers, nurseries and contractors

- Test laboratories performing mechanical, optical and weathering tests

- Recyclers and waste managers designing collection and mechanical recycling routes

- Certification bodies, agronomists and compliance teams assessing fitness for use, durability and recyclability

Benefits include standardized testing, clearer durability classes, improved design-for-recycling guidance and consistent labelling for end‑of‑life management.

Related standards

- EN 17098‑1 / EN 17098‑2 - films for soil disinfection

- EN 17033 - biodegradable mulch films incorporated in soil

- EN 18109 - product lifecycle and design-for-recycling guidance

- EN ISO 527‑1 / 527‑3, EN ISO 7765‑1, EN ISO 4892‑2, ISO 4591/2/3, ISO 9845‑1, ISO 22095, ASTM D1003 (referenced test methods)

Keywords: EN 13655:2025, thermoplastic mulch films, mulch film standards, agriculture mulching films, design for recycling, durability classification, mulch film test methods.

Frequently Asked Questions

SIST EN 13655:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Plastics - Thermoplastic mulch films recoverable after use, for use in agriculture and horticulture". This standard covers: This document specifies the requirements related to dimensional, mechanical, optical and thermal characteristics of thermoplastic films for mulching applications in agriculture and horticulture. These mulch films are intended to be removed after use and not incorporated in the soil. These mulch films are not intended to be used for soil disinfection by fumigation. Films for soil disinfection are in the scope of EN 17098-1 [1] and EN 17098-2 [2]. The biodegradable mulch films intended to be incorporated in the soil after used are also not in the scope of this document. They are in the scope of EN 17033 [3]. This document specifies a classification for durability of mulching films and the test methods referred to in this document. This document is applicable to thermoplastic mulch films, used for agriculture and horticulture in Europe, based on polyethylene and/or ethylene copolymers, of the following types: - transparent films; - black films; - reflective films (e.g. white films, black/white films and black/silver films); - films of other colour(s) for weed control (e.g. green, brown). This document defines the criteria for design for recycling of mulch films and refer to EN 18109 for the product lifecycle, including installation, use, removal and collection for end of life for management of the product after its usage. NOTE Mulch films can be highly soiled by organic and mineral residues at the end of their use life: the observed rates (or levels) of soilage of mulch films can vary from 70 % to 90 %, therefore the film thickness is a key factor on the rate of soilage, the thinnest films (e.g. less than 20 micron) will be the mostly soiled, difficult, expensive to remove, recover and recycle.

This document specifies the requirements related to dimensional, mechanical, optical and thermal characteristics of thermoplastic films for mulching applications in agriculture and horticulture. These mulch films are intended to be removed after use and not incorporated in the soil. These mulch films are not intended to be used for soil disinfection by fumigation. Films for soil disinfection are in the scope of EN 17098-1 [1] and EN 17098-2 [2]. The biodegradable mulch films intended to be incorporated in the soil after used are also not in the scope of this document. They are in the scope of EN 17033 [3]. This document specifies a classification for durability of mulching films and the test methods referred to in this document. This document is applicable to thermoplastic mulch films, used for agriculture and horticulture in Europe, based on polyethylene and/or ethylene copolymers, of the following types: - transparent films; - black films; - reflective films (e.g. white films, black/white films and black/silver films); - films of other colour(s) for weed control (e.g. green, brown). This document defines the criteria for design for recycling of mulch films and refer to EN 18109 for the product lifecycle, including installation, use, removal and collection for end of life for management of the product after its usage. NOTE Mulch films can be highly soiled by organic and mineral residues at the end of their use life: the observed rates (or levels) of soilage of mulch films can vary from 70 % to 90 %, therefore the film thickness is a key factor on the rate of soilage, the thinnest films (e.g. less than 20 micron) will be the mostly soiled, difficult, expensive to remove, recover and recycle.

SIST EN 13655:2025 is classified under the following ICS (International Classification for Standards) categories: 65.040.30 - Greenhouses and other installations; 83.140.10 - Films and sheets. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13655:2025 has the following relationships with other standards: It is inter standard links to SIST EN 13655:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13655:2025 is associated with the following European legislation: Standardization Mandates: M/584. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13655:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2025

Polimerni materiali - Termoplastične folije za mulčenje, primerne za nadaljnjo

predelavo, za uporabo v kmetijstvu in vrtnarstvu

Plastics - Thermoplastic mulch films recoverable after use, for use in agriculture and

horticulture

Kunststoffe - Nach Gebrauch rückbaubare thermoplastische Mulchfolien für den Einsatz

in Landwirtschaft und im Gartenbau

Plastiques - Films de paillage thermoplastiques récupérables après usage, pour

utilisation en agriculture et horticulture

Ta slovenski standard je istoveten z: EN 13655:2025

ICS:

65.040.30 Rastlinjaki in druge naprave Greenhouses and other

installations

83.140.10 Filmi in folije Films and sheets

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13655

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2025

EUROPÄISCHE NORM

ICS 83.140.10 Supersedes EN 13655:2018

English Version

Plastics - Thermoplastic mulch films recoverable after use,

for use in agriculture and horticulture

Plastiques - Films de paillage thermoplastiques Kunststoffe - Nach Gebrauch rückbaubare

récupérables après usage, pour utilisation en thermoplastische Mulchfolien für den Einsatz in

agriculture et horticulture Landwirtschaft und im Gartenbau

This European Standard was approved by CEN on 16 June 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13655:2025 E

worldwide for CEN national Members.

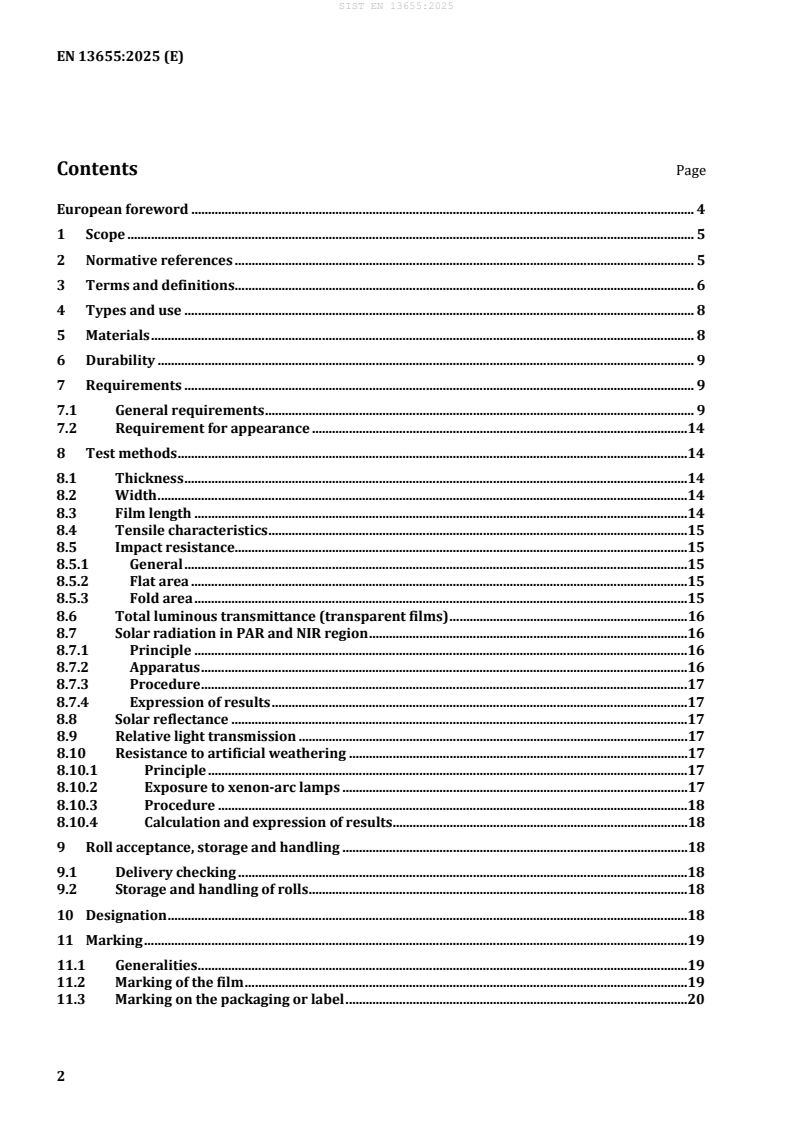

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Types and use . 8

5 Materials . 8

6 Durability . 9

7 Requirements . 9

7.1 General requirements . 9

7.2 Requirement for appearance .14

8 Test methods .14

8.1 Thickness .14

8.2 Width .14

8.3 Film length .14

8.4 Tensile characteristics .15

8.5 Impact resistance.15

8.5.1 General .15

8.5.2 Flat area .15

8.5.3 Fold area .15

8.6 Total luminous transmittance (transparent films) .16

8.7 Solar radiation in PAR and NIR region .16

8.7.1 Principle .16

8.7.2 Apparatus .16

8.7.3 Procedure .17

8.7.4 Expression of results .17

8.8 Solar reflectance .17

8.9 Relative light transmission .17

8.10 Resistance to artificial weathering .17

8.10.1 Principle .17

8.10.2 Exposure to xenon-arc lamps .17

8.10.3 Procedure .18

8.10.4 Calculation and expression of results .18

9 Roll acceptance, storage and handling .18

9.1 Delivery checking .18

9.2 Storage and handling of rolls .18

10 Designation .18

11 Marking .19

11.1 Generalities .19

11.2 Marking of the film .19

11.3 Marking on the packaging or label .20

12 Instructions for storage, installation and use of mulch films. 20

13 Design for mechanical recycling and end of life of mulch films . 21

14 Removal and collection instructions of used mulch films . 22

15 Functions and factors of degradability of mulch films . 22

Annex A (informative) Exposure to other light sources . 23

Annex B (informative) Numerical correlation between durations of mulching films exposed to

artificial weathering and natural exposure . 27

Annex C (normative) Determination of solar reflectance . 30

Annex D (normative) Determination of the relative light transmission . 32

Annex E (informative) Guidance main functions of mulch films factors influencing degradability

........................................................................................................................................................................................... 33

Bibliography . 34

European foreword

This document (EN 13655:2025) has been prepared by Technical Committee CEN/TC 249 “Plastics”, the

secretariat of which is held by SIS.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2026, and conflicting national standards shall

be withdrawn at the latest by February 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 13655:2018.

— Clause 5 on materials has been extended;

— Clause 10, Clause 11 and Clause 12 on designation, marking and instructions for storage, installation

and use of mulch films, respectively, have been modified;

— Clause 13 on the design-for-recycling of end of life of mulch films has been added;

— Clause 14 on removal and collection instructions of used mulch films has been modified, referring to

EN 18109 for additional information;

— the informative Annex E has been modified, and previous Clauses E.3 and E.4 have been transferred

to EN 18109;

— Details on functions and factors of degradability of mulch films have been transferred to Clause 15 in

this document;

— the previous Annex E on the guidance for conditions for installation, use and removal of mulch films

has been transferred to EN 18109.

This document (EN 13655) has been prepared under a standardization request addressed to CEN by the

European Commission. The Standing Committee of the EFTA States subsequently approves these

requests for its Member States.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Under preparation

1 Scope

This document specifies the requirements related to dimensional, mechanical, optical and thermal

characteristics of thermoplastic films for mulching applications in agriculture and horticulture.

These mulch films are intended to be removed after use and not incorporated in the soil.

These mulch films are not intended to be used for soil disinfection by fumigation. Films for soil

[1] and EN 17098-2 [2].

disinfection are in the scope of EN 17098-1

The biodegradable mulch films intended to be incorporated in the soil after used are also not in the scope

of this document. They are in the scope of EN 17033 [3].

This document specifies a classification for durability of mulching films and the test methods referred to

in this document.

This document is applicable to thermoplastic mulch films, used for agriculture and horticulture in Europe,

based on polyethylene and/or ethylene copolymers, of the following types:

— transparent films;

— black films;

— reflective films (e.g. white films, black/white films and black/silver films);

— films of other colour(s) for weed control (e.g. green, brown).

This document defines the criteria for design for recycling of mulch films and refer to EN 18109 for the

product lifecycle, including installation, use, removal and collection for end of life for management of the

product after its usage.

NOTE Mulch films can be highly soiled by organic and mineral residues at the end of their use life: the observed

rates (or levels) of soilage of mulch films can vary from 70 % to 90 %, therefore the film thickness is a key factor on

the rate of soilage, the thinnest films (e.g. less than 20 micron) will be the mostly soiled, difficult, expensive to

remove, recover and recycle.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 527-1, Plastics — Determination of tensile properties — Part 1: General principles (ISO 527-1)

EN ISO 527-3, Plastics — Determination of tensile properties — Part 3: Test conditions for films and sheets

(ISO 527-3)

EN ISO 7765-1:2004, Plastics film and sheeting — Determination of impact resistance by the free-falling

dart method — Part 1: Staircase methods (ISO 7765-1:1988)

EN ISO 4892-2:2013, Plastics — Methods of exposure to laboratory light sources — Part 2: Xenon-arc lamps

(ISO 4892-2:2013)

ISO 4591, Plastics — Film and sheeting — Determination of average thickness of a sample, and average

thickness and yield of a roll, by gravimetric techniques (gravimetric thickness)

ISO 4592, Plastics — Film and sheeting — Determination of length and width

ISO 4593, Plastics — Film and sheeting — Determination of thickness by mechanical scanning

ISO 9845-1, Solar energy — Reference solar spectral irradiance at the ground at different receiving

conditions — Part 1: Direct normal and hemispherical solar irradiance for air mass 1,5

ISO 22095, Chain of custody — General terminology and models

ASTM D 1003-13, Standard Test Method for Haze and Luminous Transmittance of Transparent Plastics

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

width

total width of a film when laid flat

Note 1 to entry: It is expressed in millimetres, mm.

3.2

nominal width

width of a film, as declared by the manufacturer/supplier

Note 1 to entry: It is expressed in millimetres, mm.

3.3

nominal thickness

thickness of a film, as declared by the manufacturer/supplier

Note 1 to entry: It is expressed in micrometres, μm.

3.4

roll length

largest dimension of the film corresponding to the length of the unwinded roll

Note 1 to entry: It is expressed in metres, m.

3.5

longitudinal direction of the film

MD

direction parallel to the roll length corresponding to the extrusion direction

3.6

transverse direction of the film

TD

direction parallel to the width, at right angles to the length

3.7

radiant exposure

H

time integral of irradiance

−2

Note 1 to entry: It is measured in joules per square metre (J ⋅ m ).

[SOURCE: ISO 9370:2017, 3.27] [4]

3.8

design for recycling

design of product, including the related accessories, in order to ensure its recyclability under the current

practices of removal, sorting, collection and recycling systems

Note 1 to entry: The purpose with the design for recycling criteria is to be able to use the recyclates back in the

same product, independent of producer of material.

[SOURCE: EN 18109:2024, 3.1.13, modified without DFR]

3.9

mechanical recycling

processing of plastic waste into secondary raw materials or products without significantly changing the

chemical structure of the material

Note 1 to entry: Plastic secondary raw material is a synonym of recyclate.

[SOURCE: EN ISO 472:2013, 2.1697, modified — Note 1 to entry changed; “plastics waste” changed to

read “plastic waste”.] [5]

3.10

post-consumer plastic

plastic, generated by the end-users of products, that has fulfilled its intended purpose and can no longer

be used for its intended purpose (including material returned from within the distribution chain)

Note 1 to entry: The term “post-use” is sometimes used synonymously.

Note 2 to entry: Often abbreviated as PCR.

3.11

pre-consumer plastic

plastic diverted from the manufatcuring process

Note 1 to entry: Excluded is reutilization of materials such as rework, regrind or scrap generated in a process and

capable of being reclaimed within the same process that generated it.

3.12

recycled content

proportion, by mass, of recycled plastic in a product or packaging

Note 1 to entry: Only pre consumer and post consumer materials shall be considered as recycled content,

consistent with the following usage of terms.

3.13

controlled blending model

chain of custody model in which materials or products with a set of specified characteristics are mixed

according to certain criteria with materials or products without that set of characteristics resulting in a

known proportion of the specified characteristics in the final output

Note 1 to entry: The adhered claim may refer to a certain percentage, at batch-level and /or site-level.

[SOURCE: ISO 22095: 2020, 3.3.3]

3.14

national collection scheme

NCS

voluntary or mandatory national collection system of defined plastic fractions used in agriculture or

horticulture applications

3.15

specular

indicates that the flux leaves a surface or medium at an angle that is numerically equal to the angle of

incidence, lies in the same plane as the incident ray and the perpendicular, but is on the opposite side of

the perpendicular to the surface

[SOURCE: ISO 16378:2022, 3.16] [6]

4 Types and use

The different types of mulch films, their optical characteristics and use are given in Table 1.

Table 1 — Types and use of mulching films

Type Optical characteristic Use

Transparent film Transparent to sunlight To warm up the soil

radiation

Not used for weed growth control

Black film Very low sunlight transmission When prevention of weeds growth is requested

in with a warming effect of the soil

a

Reflective film Very low sunlight transmission When prevention of weeds growth is requested

and sunlight reflection prevent young leaves

burning and improves photosynthesis by light

reflection

Film of other Selective sunlight transmission When prevention of weeds growth and warming

colour(s) for in PAR (photosynthesis active up of soil are needed

b

weed control radiation) and in near IR

a

E.g. white, black/white and black/silver.

b

E.g. green, brown, etc.

5 Materials

Mulch films according to this document are usually manufactured from polyethylene and polyethylene

copolymers and additives in accordance with requirement in Clause 14. If requested, the density shall be

declared by the film manufacturer in order to calculate the nominal thickness value.

The product shall be suitable for mechanical recycling as a PE fraction, according to the design for

recycling defined in Clause 12.

Recycled content in the film shall be verified with ratio of post-consumer plastic recyclates and/or pre-

consumer plastic recyclates following a controlled blending model according to ISO 22095.

The core, which is a part of the mulch film product, enables unrolling film on field. The core shall be

recyclable and clearly marked for which material fraction to be sorted.

6 Durability

The durability of mulch films is characterized by the class N, A, B, C and D. This classification, given in

Table 2, is depending on the duration of exposure of the film to an artificial weathering using xenon-arc

lamps according to 8.10, which induces a decrease of the value of tensile strain at break equal or less than

50 % of the initial value.

The class of durability shall be declared by the manufacturer/supplier.

Table 2 — Classification according to artificial weathering

Class Minimum duration of exposure

H

At irradiance At irradiance

(narrowband – 340 nm) (narrowband – 340 nm)

2 2

0,35 W/(m ·nm) 0,51 W/(m ·nm)

N 400 280

A 2 000 1 400

B 3 500 2 450

C 5 900 4 070

D 8 160 5 600

Other light sources may be used provided that a correlation between the test results obtained with these

light sources and these obtained after a natural exposure can be demonstrated. This can be useful when

the durations of the exposure to xenon-arc lamps as defined in Table 2 are too long. Details of these

methods are given in Annex A.

In case of dispute the choice of exposure equipment will be decided by the parties. If no agreement can

be found the exposure to xenon-arc lamps with 0,35 W/(m ·nm) at 340nm according to 8.10 and the

classification according to Table 2 shall be used.

NOTE A numerical correlation between durability of mulch films exposed to artificial weathering and natural

exposure is given in Annex B.

7 Requirements

7.1 General requirements

Transparent films, black films, reflective films and films of other colour(s) for weed control shall fulfil the

requirements of Tables 3, 4, 5 and 6, respectively.

Table 3 — Requirements for transparent films

Characteristics Unit Nominal thickness Test method

a

≥ 20 μm ≥ 35 μm Subclause

7.2

Appearance - Shall conform to 7.2

Dimensional characteristics

Tolerance of average

thickness/nominal % ±5 8.1

thickness

Tolerance of single

point % from - 20 to 25 from −15 to 25

8.1

thickness/nominal

b

thickness

%

Max. Tolerance of single 8.1

point

+100

thickness/nominal

thickness at gel

Width tolerance/

% ±2 8.2

nominal width

Tolerances of the roll

% −1 8.3

length/nominal length

Mechanical characteristics of unexposed film

Tensile stress at yield

MPa ≥ 9

(MD, TD)

Tensile stress at break

≥ 20

MPa

(MD, TD) 8.4

Tensile strain at break

≥ 250

%

MD

%

≥ 350

TD

Impact resistance

g ≥ 75 ≥ 80

Flat area 8.5

g ≥ 50 ≥ 60

Fold area

Optical characteristic of unexposed film

Total luminous

% ≥ 90 8.6

transmittance

a

20 μm ≤ nominal thickness < 35 μm.

b

Measurement shall be performed outside of any defects, e.g. gel from recycling material

Table 4 — Requirements for black films

Characteristics Unit Nominal thickness Test

method

a b

≥ 20 μm ≥ 50 μm ≥ 100 μm Subclause

Appearance - Shall conform to 7.2 7.2

Dimensional characteristics

Tolerance of average % 8.1

thickness/nominal ±5

thickness

Tolerance of single point % 8.1

from - 20 to

thickness/nominal ±15 ±15

c

thickness

Max. Tolerance of single % 8.1

point

+100

thickness/nominal

thickness at gel

Width tolerance/ nominal % 8.2

±2

width

Tolerances of the roll

% −1 8.3

length/nominal length

Mechanical characteristics of unexposed film

Tensile stress at yield (MD,

MPa ≥ 9

TD)

Tensile stress at break (MD,

MPa ≥ 20

TD)

8.4

Tensile strain at break

MD % ≥ 250

TD % ≥ 350

Impact resistance

flat area g ≥ 75 ≥ 120 ≥ 250 8.5

fold area g ≥ 50 ≥ 60 ≥ 120

Optical characteristic of unexposed film

−2 −2 −3

Relative light transmission % ≤ 10 ≤ 10 ≤ 10 8.9

a

20 μm ≤ nominal thickness < 50 μm.

b

50 μm ≤ nominal thickness < 100 μm.

c

Measurement shall be performed outside of any defects, e.g. gel from recycling material

Table 5 — Requirements for reflective films (white, black/white, black/silver)

Test

Characteristics Unit Nominal thickness

method

a

≥ 25 μm ≥ 60 μm Subclause

Appearance - Shall conform to 7.2 7.2

Dimensional characteristics

Tolerance of average

% ±5 8.1

thickness/nominal thickness

Tolerance of single point

% from - 20 to 25 ±15 8.1

b

thickness/nominal thickness

Max. Tolerance of single point % 8.1

+100

thickness/nominal thickness at gel

Width tolerance/ nominal width % ±2 8.2

Tolerances of the roll length/nominal

% −1 8.3

length

Mechanical characteristics on unexposed film

Tensile stress at yield

MPa ≥ 9

(MD, TD)

Tensile stress at break

MPa ≥ 20

(MD, TD)

8.4

Tensile strain at break

MD % ≥ 250

TD % ≥ 350

Impact resistance

Flat area g ≥ 80 ≥ 150 8.5

fold area g ≥ 40 ≥ 80

Optical characteristic of unexposed film

Relative light transmission

% ≤ 1 ≤ 0,1 8.9

(for film with at least one black layer)

Relative light transmission

% ≥ 60 ≥ 50 8.9

(for film without black layers)

Solar reflectance

% ≥ 55 ≥ 60 8.8

(for film with at least one white

layer)

To be declared

Solar reflectance

To be declared by

% by the 8.8

the manufacturer

(for film without white layers)

manufacturer

a

25 μm ≤ nominal thickness < 60 μm.

b

Measurement shall be performed outside of any defects, e.g. gel from recycling material

Table 6 — Requirements for films of other colour(s) for weed control

Characteristics Unit Nominal thickness Test method

≥ 25 μm Subclause

Appearance - Shall conform to 7.2 7.2

Dimensional characteristics

Tolerance of average thickness/nominal

% ±5 8.1

thickness

Tolerance of single point

% from - 20 to 25 8.1

a

thickness/nominal thickness

Max. Tolerance of single point % 8.1

+100

thickness/nominal thickness at gel

Width tolerance/ nominal width % ±2 8.2

Tolerances of the roll length/nominal −1

% 8.3

length

Mechanical characteristics of unexposed film

Tensile stress at yield (MD, TD) MPa ≥ 9

Tensile stress at break (MD, TD) MPa ≥ 20

Tensile strain at break 8.4

MD % ≥ 250

TD % ≥ 350

Impact resistance on flat area g ≥ 80 8.5

Optical characteristic of unexposed film

Transmission of solar radiation in the

photosynthesis active radiation (PAR)

Range 400 nm to 500 nm % < 25 8.7

Range 600 nm to 700 nm % < 20

Transmission of solar radiation in the

near-infrared region (NIR)

% > 55 8.7

Range 850 nm to 1 100 nm

a

Measurement shall be performed outside of any defects, e.g. gel from recycling material

7.2 Requirement for appearance

The last turn of the roll shall be sealed with adhesive tape or by some other similar means, in order to

prevent its unwinding before use

The edges shall be properly in line and there shall be sufficient tension to prevent the layers of the roll

from transversal slipping when it is handled.

The film shall be homogeneous for the purpose of the application and checked by unrolling at least 2 m

of the film and examining it against the light, holding it tight at arm’s length.

8 Test methods

8.1 Thickness

The minimum thickness of the single points of the film shall be determined in accordance with ISO 4593.

The average thickness of the film shall be determined in accordance with ISO 4591. Testing is performed

using one strip of film cut in transverse direction of the roll (TD).

8.2 Width

The width of the film shall be determined in accordance with ISO 4592.

8.3 Film length

The length of the film shall be determined by unwinding the roll by means of a calibrated reel in contact

continuously with its outside surface (see Figure 1). The calibrated reel is connected to a revolution

counter. The diameter of the calibrated reel shall be measured with an accuracy of ± 0,2 %. The roll shall

be totally unwound at a speed of 100 m/min ± 10 m/min.

The value of the length of the film is calculated by using Formula (1):

ln=⋅π⋅ d

(1)

where

l is the value of the length of the film, expressed in metres (m);

n is the number of revolutions of the calibrated reel during the total unwinding of the roll;

d is the diameter of the calibrated reel, expressed in metres (m).

Key

1 film roll

2 calibrated reel with a revolution counter

3 collection reel

4 deflection reel

d diameter of the calibrated reel

Figure 1 — Apparatus for the determination of the film length

8.4 Tensile characteristics

The tensile characteristics shall be determined according to EN ISO 527-1 and EN ISO 527-3 using five

test pieces type 2 (see Figure 1 of EN ISO 527-3:2018) with a width of 10 mm, cut in each direction of the

film [longitudinal direction (MD) and transverse direction (TD)], at a testing speed of 500 mm/min.

Calculate the arithmetic average value of the five measurements.

8.5 Impact resistance

8.5.1 General

In case of a folded film, a distinction shall be made between the test pieces taken from the folds (fold area)

and test pieces taken from areas which have not been folded (flat area).

NOTE Films which are wider than 2 000 mm are usually folded lengthwise at least once before winding on a

reel. These folds are retained even when the film is laid out flat, and this can affect test results.

8.5.2 Flat area

The impact resistance (dart drop test) in flat area shall be determined in accordance with

EN ISO 7765-1:2004, method A.

Calculate the impact failure mass m , in grams, in accordance with EN ISO 7765-1.

f

8.5.3 Fold area

The impact resistance (dart drop test) in fold area shall be determined using the apparatus specified in

EN ISO 7765-1:2004, method A.

Spread out the film with the marked face onto the apparatus and test every fold tangentially twice,

alternately internal and external folds, with a mass as specified in Table 3 to Table 6, as applicable. The

tangential test is obtained by shifting forward the fold of 13 mm from the vertical axle of the specimen

clamp (see Figure 2).

If no failure occurs, the result is declared “pass”.

If one failure occurs, carry out two additional tests on the fold which failed in the same position (internal

or external fold). Then, if no failure occurs, the result is declared “pass” and if one or two failure(s)

occur(s), the result is declared “fail”.

If two failures occur, the result is declared “fail”.

Key

1 external fold

2 internal fold

3 film

4 vertical axle of the specimen clamps

d = 13 mm

Figure 2 — Position of impact on folds

8.6 Total luminous transmittance (transparent films)

The total luminous transmittance shall be determined in accordance with ASTM D 1003-13 on five test

pieces cut from the film.

Calculate the arithmetic average value of the five measurements.

8.7 Solar radiation in PAR and NIR region

8.7.1 Principle

The Visible-NIR transmission spectrum within the wavelength range 400 nm to 1 100 nm of a film is

measured by means of spectrophotometer.

8.7.2 Apparatus

8.7.2.1 UV-Visible-Near-IR spectrophotometer equipped with an integrating sphere, capable of

measuring and recording continuously the transmittance at least between 300 nm and 1 200 nm.

8.7.2.2 Software, capable of integrating the transmittance.

8.7.3 Procedure

Carry out the measurement on five test pieces cut from the film.

Set up a test piece on the specimen holder of the integrating sphere and record the transmittance at least

between 300 nm and 1 200 nm.

Determine for each range of wavelength (i.e. 400 nm to 500 nm, 600 nm to 700 nm and 850 nm to

1 100 nm), by using the software, Formula (2):

s

R = (2)

ij−

s

where

s is the area between the line corresponding to a transmittance of 0 % and the curve of the

spectrum;

s is the area between the line corresponding to a transmittance of 0 % and the line

corresponding to a transmittance of 100 %.

These three different ratios correspond to different ranges of wavelengths (λ) on the recorded spectrum:

— R and R in the visible region of the spectrum:

400-500 600-700

— for R the limits of the spectrum are: λ = 400 nm and λ = 500 nm;

400-500

— for R600-700 the limits of the spectrum are: λ = 600 nm and λ = 700 nm.

— R in the Near-IR region of the spectrum:

850-1100

— for R the limits of the spectrum are: λ = 850 nm and λ = 1 100 nm.

850-1100

8.7.4 Expression of results

For each ratio calculate the arithmetic average value of the five measurements.

8.8 Solar reflectance

The solar reflectance shall be determined according to Annex C on five test pieces cut from the film.

8.9 Relative light transmission

The relative light transmission shall be determined in accordance with Annex D on five test pieces cut

from the film.

Calculate the arithmetic average value of the five measurements.

8.10 Resistance to artificial weathering

8.10.1 Principle

The variation of the tensile strain at break of specimens shall be determined before and after an exposure

to xenon-arc lamps.

8.10.2 Exposure to xenon-arc lamps

Carry out the artificial weathering according to EN ISO 4892-2 using the test conditions given in Table 7.

Table 7 — Exposure cycle and test conditions

Irradiance

Exposure Black-

Broadband Narrowband Chamber Relative

standard

conditions

(300 nm to 400 nm) (340 nm) Temperature humidity

Temperature

2 2

W/m W/(m⋅nm) °C %

°C

A 102 min dry 40 ± 2 0,35 ± 0,02 65 ± 3 38 ± 3 50 ± 5

18 min water spray 40 ± 2 0,35 ± 0,02 — — —

B 102 min dry 60 ± 2 0,51 ± 0,02 65 ± 3 38 ± 3 50 ± 5

18 min water spray 60 ± 2 0,51 ± 0,02 — — —

8.10.3 Procedure

Expose the specimens with a backing made of matt aluminium plate according to 8.10.2 during the

minimum duration of exposure specified in Table 2, corresponding to the class of durability of the film.

After the exposure, determine the tensile strain at break according to EN ISO 527-1 and EN ISO 527-3,

using five type 2 test pieces, (see Figure 1 of EN ISO 527-3:2018), 10 mm wide, 150 mm long, taken

longitudinally in the film (MD), at a test speed of 500 mm/min.

8.10.4 Calculation and expression of results

Calculate the arithmetic mean value of the five measurements performed on the test pieces cut from the

exposed specimens and the arithmetic mean value of the five measurements performed on the test pieces

cut from the unexposed specimens in longitudinal direction (MD) (see 8.4). Compare these two values.

The test is considered successful when the value calculated for specimens exposed to artificial weathering

is equal or greater than 50 % of the value calculated for unexposed specimens.

9 Roll acceptance, storage and handling

9.1 Delivery checking

Carefully examine the rolls upon delivery in order to find any apparent damage or anomalies.

If a defect is found, take the necessary actions for the case.

Whenever possible, it is recommended to take a photograph of the damage.

9.2 Storage and handling of rolls

The rolls shall be carried, not dragged over the ground or any other surface.

Keep the films in their original packaging and store them in a location protected from the elements (e.g.

sunlight, heat, rain).

It is recommended that the films be used within six months of delivery.

It is recommended that rolls delivered with a cardboard core be stored in a dry location.

Handling of rolls should be performed horizontally.

10 Designation

The designation of the film shall include the following information:

a) manufacturer’s trademark

b) reference to this document, i.e. EN 13655;

c) use of the film: MULCHING FILM with the type according to Table 1 of this document;

d) nominal width of the film in millimetres;

e) nominal roll length in metres;

f) nominal thickness of the film in micrometres (μm), if required;

g) colour when applicable;

h) class of durability according to Table 2;

i) declared minimum content of recycled post-consumer plastic (percentage of total mass) when post-

consumer plastic is integrated.

NOTE Content of recycled pre-consumer material can also be declared separately.

EXAMPLE The marking of a black mulch film, 5 000 mm wide, in roll of length 1 000 m, 30 μm thickness, and

with a duration of exposure to an artificial weathering, conforming to 8.10 of 1 700 h, manufactured with at least

50 % of recycled material by TRADEMARK:

TRADEMARK, EN 13655 BLACK FILM 5000 1000 30 A 50 % PCR

External documentary evidence may be requested by the purchaser or interested third parties as

collection schemes for used products.

11 Marking

11.1 Generalities

The purpose of marking is to ensure traceability of the product, conformity to this document and possibly

additional instructions for installation, use and removal.

11.2 Marking of the film

A marking shall be printed along the edges of the film and shall include at least the following information:

a) manufacturer's trademark;

b) reference to this document, i.e. EN 13655;

c) class of durability according to Table 2;

d) manufacturing code, including traceability to define manufacturing date;

Optional information:

e) nominal width, in millimetres (mm);

f) nominal length in meters (m);

g) thickness in micrometres (µm);

h) recovery logo;

i) declared minimum content of recycled post-consumer plastic (percentage of total mass) when post-

consumer plastic is integrated.

NOTE Content of recycled pre-consumer plastic can also be declared separately.

EXAMPLE The marking of a black mulch film, 5 000 mm wide, in roll of length 1 000 m, 30 μm thickness, and

with a duration of exposure to an artificial weathering, conforming to 8.10 of 1 700 h, manufactured with at least

50 % of recycled material by TRADEMARK:

TRADEMARK, EN 13655 BLACK FILM 2014-06 RXX d9XX 5000 1000 30 A 50 % PCR

11.3 Marking on the packaging or label

Marking on the packaging or label shall include at least the following information:

a) manufacturer's trademark;

b) reference to this document, i.e. EN 13655;

c) type of film see Table 1;

d) nominal width, in millimetres (mm);

e) nominal length in metres (m);

f) nominal thickness in micrometres (µm);

g) class of durability according to Table 2;

h) declared minimum content of recycled post-consumer plastic (percentage of total mass) when post-

consumer plastic is integrated.

NOTE Content of recycled pre-consumer plastic can also be declared separately.

i) manufacturing code, including traceability to define manufacturing date;

Optional information:

j) recovery logo.

EXAMPLE The marking of a black mulch film, 5 000 mm wide, in roll of length 1 000 m, 50 μm thickness, and

with a duration of exposure to an artificial weathering, conforming to 8.10 of 500 h, manufactured with at least

30 % of recycled material by TRADEMARK in June 2014:

TRADEMARK, EN 13655 BLACK FILM 5000 1000 30 A 30 % PCR 2014-06 RXX d9XX

12 Instructions for storage, installation and use of mulch films

The impact of the installation, use, removal and preparation for recycling should be considered when

preparing for the most effective end-of-life for the product.

Appropriate information and training should be given to all the users of plastic for agricultural purposes,

including manufacturer’s staff, agronomic advisers, retailers and final users given in EN 18109.

For the conditions of installation and use, including durability aspects, the instructions of the

manufacturer shall be followed. These instructions can be given in paper form accompanying the film

and/or with a QR code or via internet link printed on labels. In the absence of such instructions, guidance

is given in EN 18109:2025, Clause 5.

In order to ensure traceability, the labels accompanying films or their packaging up to end-of-use shall

be kept. Keeping only the pallet label for homogeneous pallet deliveries is acceptable.

13 Design for mechanical recycling and end of life of mulch films

The purpose with the design for recycling criteria is to be able to use the recyclates from mulch film back

in the same product, independent of producer of material.

The design for mechanical recycling criteria for mulch film are described in Table 8. The material can be

recycled with other processes but criteria need to be defined for e.g. chemical recycling or physical

recycling.

The design for mechanical recycling criteria for related components to mulch film is described in Table 9.

The material can be recycled with other processes but criteria need to be defined for e.g. chemical

recycling or physical recycling.

It is recommended to use recyclates coming from plastic collected by an NCS dedicated to agriculture.

Table 8 — Guideline design for recycling of a mulching film

Full compatibility with PE mulch No compatibility with PE mulch film

film recycling recycling

Materials PE (PE-LD, PE-LLD); PE-HD, polar PP, PET; PVC; PS; biodegradable,

ethylene copoly

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...