ISO/TR 20118:2019

(Main)Plastics — Guidance on fire characteristics and fire performance of PVC materials used in building applications

Plastics — Guidance on fire characteristics and fire performance of PVC materials used in building applications

This document provides information on the fire characteristics and performance in fire tests of PVC materials and products for use in building applications. It illustrates a number of suitable applications incorporating primarily PVC materials, including unplasticized PVC (PVC-U), plasticized (or flexible) PVC (PVC-P) and chlorinated PVC (PVC-C) based products. Except where otherwise stated, there is no restriction with reference to the content of PVC (in terms of quantity and composition) in the products mentioned in this document. This document draws attention to the limits of applicability or the unsuitability of some standard fire test methods for certain applications of PVC based products in buildings. This document applies to products during their use phase in the building and does not apply to the manufacturing phase of plastic products. It neither applies to general safety measures applicable to the installation phase nor to the dismantling or the demolition phase of the building.

Plastiques — Lignes directrices relatives aux caractéristiques et aux performances au feu des matériaux en PVC utilisés dans les applications de construction

General Information

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 20118

First edition

2019-04

Plastics — Guidance on fire

characteristics and fire performance

of PVC materials used in building

applications

Plastiques — Lignes directrices relatives aux caractéristiques et

aux performances au feu des matériaux en PVC utilisés dans les

applications de construction

Reference number

©

ISO 2019

COPYRIGHT PROTECTED DOCUMENT

© ISO 2019

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2019 – All rights reserved

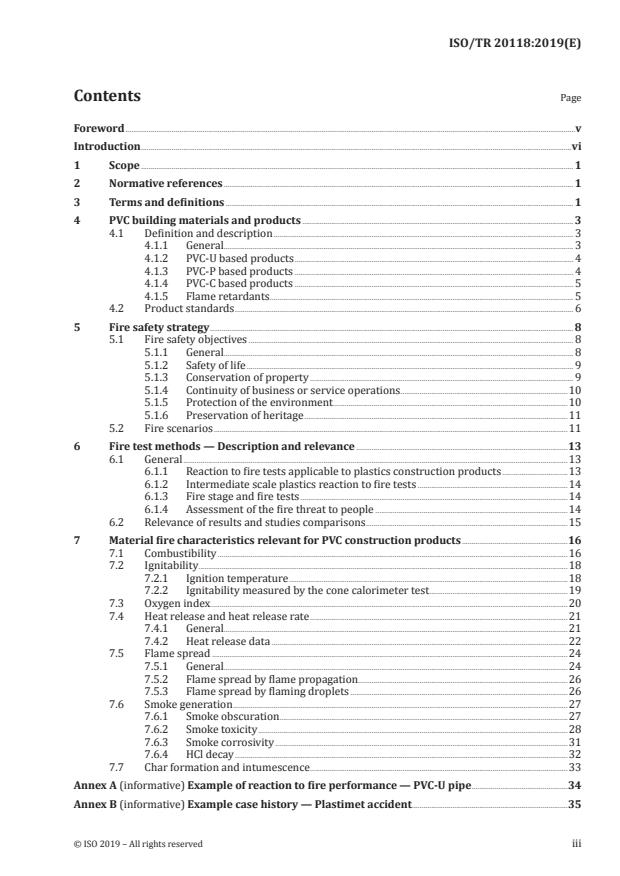

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 PVC building materials and products . 3

4.1 Definition and description . 3

4.1.1 General. 3

4.1.2 PVC-U based products . 4

4.1.3 PVC-P based products . 4

4.1.4 PVC-C based products . 5

4.1.5 Flame retardants . . 5

4.2 Product standards . 6

5 Fire safety strategy . 8

5.1 Fire safety objectives . 8

5.1.1 General. 8

5.1.2 Safety of life . 9

5.1.3 Conservation of property . 9

5.1.4 Continuity of business or service operations .10

5.1.5 Protection of the environment .10

5.1.6 Preservation of heritage .11

5.2 Fire scenarios .11

6 Fire test methods — Description and relevance .13

6.1 General .13

6.1.1 Reaction to fire tests applicable to plastics construction products .13

6.1.2 Intermediate scale plastics reaction to fire tests .14

6.1.3 Fire stage and fire tests .14

6.1.4 Assessment of the fire threat to people .14

6.2 Relevance of results and studies comparisons .15

7 Material fire characteristics relevant for PVC construction products .16

7.1 Combustibility .16

7.2 Ignitability .18

7.2.1 Ignition temperature .18

7.2.2 Ignitability measured by the cone calorimeter test .19

7.3 Oxygen index.20

7.4 Heat release and heat release rate .21

7.4.1 General.21

7.4.2 Heat release data .22

7.5 Flame spread .24

7.5.1 General.24

7.5.2 Flame spread by flame propagation.26

7.5.3 Flame spread by flaming droplets .26

7.6 Smoke generation .27

7.6.1 Smoke obscuration.27

7.6.2 Smoke toxicity .28

7.6.3 Smoke corrosivity .31

7.6.4 HCl decay .32

7.7 Char formation and intumescence .33

Annex A (informative) Example of reaction to fire performance — PVC-U pipe .34

Annex B (informative) Example case history — Plastimet accident .35

Bibliography .36

iv © ISO 2019 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso

.org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 61, Plastics, Subcommittee SC 4, Burning

behaviour.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

Introduction

Fire safety is an essential consideration in building design regardless of the type and nature of products

used. Effective measures should be taken to prevent or reduce the likelihood of fires that may result in

casualties, injuries or property damage.

National codes and regulations are the basis of such fire safety measures. Technical details are given

in standards and related documents, referred to as specific documents or incorporated in the said

codes or regulations. Such details are particularly important when performance-based behaviour

[77]

is concerned. A specific case is the European Construction Products Regulation , which specifies

that products need to be tested and classified regarding their fire performance according to the EU

harmonized classification systems for reaction to fire and for resistance to fire.

The construction industry makes significant efforts to protect society from the dramatic consequences

of fires. As a result, 1 % to 8 % of total construction costs are spent on fire safety measures. These costs

are directly dependent on the type of building and can increase considerably for sensitive buildings like

schools and theatres. In the case of shopping centres, fire safety measures can amount to 10 % of total

building costs.

Plastic products are increasingly specified by architects and used by builders. They contribute to

greater energy efficiency, cost savings and to a more comfortable and safer environment. The role

of plastics in fire safety should be addressed despite the fact that they are considered as a major

combustible contributor only in less than 15 % of fires.

Plastic materials or products can be tailored to meet specific needs and to reduce their contribution

to the propagation of a fire. Some families of plastics, such as halogen containing polymers like PVC,

inherently have superior fire performa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.