IEC TS 61245:2015/COR1:2018

(Corrigendum)Corrigendum 1 - Artificial pollution tests on high-voltage ceramic and glass insulators to be used on d.c. systems

Corrigendum 1 - Artificial pollution tests on high-voltage ceramic and glass insulators to be used on d.c. systems

General Information

Relations

Standards Content (Sample)

IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

IEC TS 61245

Edition 2.0 2015-03

ARTIFICIAL POLLUTION TESTS ON HIGH-VOLTAGE CERAMIC AND GLASS INSULATORS TO BE USED ON

D.C. SYSTEMS

CO RRI G ENDU M 1

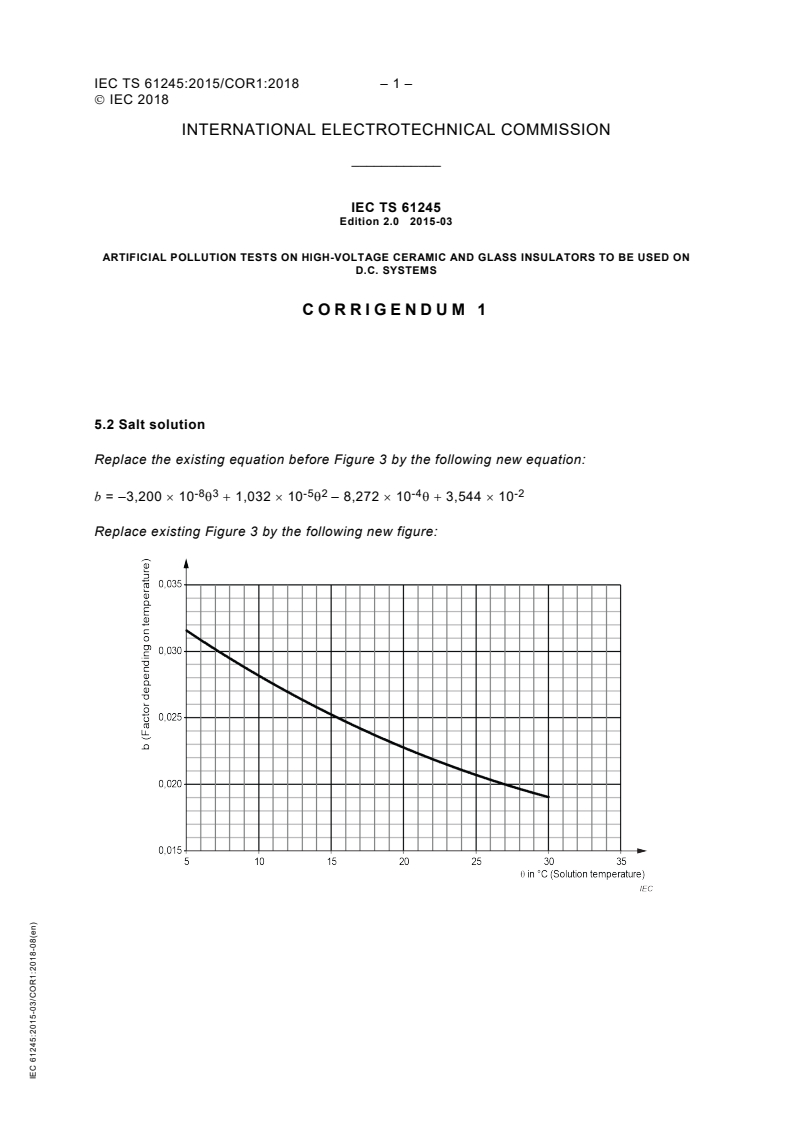

5.2 Salt solution

Repla

...

This May Also Interest You

IEC TS 63414:2025 is applicable for the determination of the AC and DC pollution flashover and withstand voltage characteristics of insulators with polymeric housing, to be used outdoors in HV applications and exposed to polluted environments. This is also applicable for insulators with hydrophobic coatings. This document refers to AC systems with a rated voltage greater than 1 000 V and DC systems with a rated voltage greater than 1 500 V.

The object of this technical specification is to prescribe standardized test methods, requirements and procedures for artificial pollution tests applicable to polymeric insulators for overhead lines including traction lines, station post and hollow insulators of equipment. Available test experience with polymeric station post and hollow insulators, especially for DC applications, is limited.

The proposed tests are not applicable to ceramic and glass insulators without polymeric housing, to greased insulators or to special types of insulators (e.g., insulators with semiconducting glaze).

Differently to ceramic and glass insulators without polymeric housing:

- The pollution performance of insulators with polymeric housing varies with the hydrophobicity condition of the surface. The specific conditions simulated by standardized tests might not represent the actual dynamic field conditions.

- The determination of the flashover and/or withstand voltage under pollution conditions is not enough for dimensioning. Additional constraints related to possible ageing are also to be considered.

- If the Hydrophobicity Transfer Material (HTM) test according to IEC TR 62039 confirms that an insulator is non-HTM, it can be tested according to IEC 60507 or IEC TS 61245.

- Technical specification39 pagesEnglish languagesale 15% off

IEC TS 60815-2:2025, which is a technical specification, is applicable for the selection of ceramic and glass insulators for AC systems, and the determination of their relevant dimensions, to be used in high-voltage systems with respect to pollution. This document applies to insulators for outdoor installation only.

This document gives specific guidelines and principles to arrive at an informed judgement on the probable behaviour of a given insulator in certain pollution environments.

The basis for the structure and approach of this document is fully explained in IEC TS 60815-1.

The objective of this document is to give the user means to:

- determine the reference unified specific creepage distance (RUSCD) from site pollution severity (SPS) value or class;

- evaluate the suitability of different insulator profiles;

- determine the necessary USCD by applying corrections for insulator shape, size, position, etc. to the RUSCD;

- if required, determine the appropriate test methods and parameters to verify the performance of the selected insulators.

This second edition of IEC TS 60815-2, together with IEC TS 60815-1, cancels and replaces the first edition of IEC TS 60815-2 published in 2008. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) Some terms and definitions are modified or introduced in this document, such as USCD, nominal creepage distance, RUSCD, creepage factor, insulator trunk, etc.;

b) From RUSCD of reference insulator to USCD of candidate insulator, the correction factors are introduced and revised, such as altitude correction, diameter correction, shed profile correction and parallel insulator number correction;

c) Profile suitability on ceramic and glass insulators was simplified.

- Technical specification22 pagesEnglish languagesale 15% off

IEC TS 60815-3:2025, which is a technical specification, is applicable for the selection of polymeric insulators for AC systems, and the determination of their relevant dimensions, to be used in high voltage systems with respect to pollution. The specification applies to insulators for outdoor installation only.

This document gives specific guidelines and principles to arrive at an informed judgement on the probable behaviour of a given insulator in certain pollution environment.

The contents of this document are based on CIGRE TB 158 and CIGRE TB 361, which form a useful complement to this document for those wishing to study in greater depth the performance of insulators under pollution.

This document does not deal with the effects of snow or ice on polluted insulators. Although this subject is dealt with by CIGRE TB 158, current knowledge is very limited and practice is too diverse.

The objective of this document is to give the user means to

- determine the reference unified specific creepage distance (RUSCD) from site pollution severity (SPS) value or class,

- choose appropriate profiles,

- apply correction factors for altitude, insulator shape, size and position, etc. to the RUSCD.

This second edition of IEC TS 60815-3, together with IEC TS 60815-1, cancels and replaces the first edition of IEC TS 60815-3:2008. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) Terms and definitions are modified or introduced in this document;

b) From RUSCD of reference insulator to USCD of candidate insulator, the correction factors are introduced and revised, such as altitude correction, diameter correction, shed profile correction and - parallel insulator number correction;

d) The general guidance on materials is revised. The concept of hydrophobicity transfer and hydrophobicity transfer material (HTM) are introduced, recognising that a reduced creepage distance may be used for HTM insulators.

- Technical specification23 pagesEnglish languagesale 15% off

IEC TS 60815-1:2025 is applicable to the selection of insulators, and the determination of their relevant dimensions, to be used in outdoor high-voltage systems with respect to pollution. For the purposes of this technical specification series, the insulators are divided into the following broad categories, each dealt with in a specific part as follows:

- IEC TS 60815-2 – Ceramic and glass insulators for AC systems;

- IEC TS 60815-3 – Polymer insulators for AC systems;

- IEC TS 60815-4 – Insulators for DC systems.

This document provides general definitions, gives methods for the evaluation of site pollution severity (SPS) and outlines the principles to arrive at an informed judgement on the probable behaviour of a given insulator in certain pollution environments. The general principles described are applicable to both AC and DC systems. However, the applicability part mainly refers to AC. More information about DC can be found in IEC TS 60815-4.

This document is applicable to all types of external insulation, including insulation forming part of other apparatus. The term "insulator" is used hereafter to refer to any type of insulator.

The objective of this technical specification series is to:

- understand and identify parameters of the system, application, equipment and site influencing the pollution behaviour of insulators,

- understand and choose the appropriate approach to the design and selection of the insulator solution, based on available data, time and resources.

- characterise the type of pollution at a site and determine the site pollution severity (SPS) value and the SPS class,

- determine the reference unified specific creepage distance (RUSCD) of "reference" insulator based on the SPS class,

- select candidate insulators and determine corrections to apply to RUSCD to arrive at the USCD of the "candidate" insulators by taking into account their specific properties (notably their shed profiles), conditions of the site, the application and the type of system,

- evaluate the relative advantages and disadvantages of the possible solutions, using HTM or non-HTM insulators,

- assess the need and merits of "hybrid" solutions or mitigative measures.

The IEC 60815 series does not deal with the effects of ice and snow on polluted insulators.

CIGRE documents form a useful complement to this technical specification for those wishing to study in greater depth the performance of insulators under pollution.

This second edition cancels and replaces the first edition of IEC TS 60815‑1 published in 2008. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) In the Scope, it is clarified that this specification is applicable to AC and DC conditions while it mainly refers to AC conditions. Detailed application indications refer to AC only. The RUSCD is determined based on the SPS class of reference insulators, and this document does not deal with the effects of ice and snow on polluted insulators;

b) Some terms and definitions are modified or introduced in this document, such as RUSCD, creepage factor, average diameter, SPS value and SPS class, hydrophobicity transfer and HTM, etc.;

c) Clause 5 is re-organized and revised regarding input parameters for the selection and dimensioning of insulators, including system requirements and environmental conditions;

d) Clause 6 "Determination of site pollution severity (SPS) class" is re-organized and re-written. A distinction was made between SPS value and SPS class. The measurement of pollution that is made on the de-energized reference insulator is valid for AC only;

e) A new pollution class, extremely heavy class f, is added. It is applicable only to the special situations of extremely heavy pollution when the RUSCD of class e cannot meet the requirements. The RUSCD value for class f is not specified;

f) The parameters of reference insulators were defined;

g) The pro

- Technical specification60 pagesEnglish languagesale 15% off

IEC 62217:2025 is applicable to polymeric insulators for AC systems with a nominal voltage greater than 1 000 V (frequency less than 100 Hz) and DC systems with a nominal voltage greater than 1 500 V whose insulating body consists of one or various organic materials. Polymeric insulators covered by this document are intended for use both on HV overhead lines and in substations, in both indoor and outdoor applications. They include composite insulators with solid and hollow core and resin insulators. Hybrid insulators with ceramic core and polymeric housing are also included, while coated insulators (e.g. with RTV silicone rubber coatings) are not included in this standard. Electrical tests described in this document are done under AC voltage and are in general applicable to insulators to be used in DC systems too. Tests under DC voltage are intended to reflect up-to-date knowledge and experience. Only polymeric housing materials of hybrid insulators are specified in this document. Tests for core materials and the interfaces between housing and core of hybrid insulators are not included.

The object of this document is

- to define the common terms used for polymeric insulators;

- to prescribe common test methods for design tests on polymeric insulators;

- to prescribe acceptance or failure criteria, if applicable;

These tests, criteria and recommendations are intended to ensure a satisfactory lifetime under normal operating and environmental conditions. This document includes design tests intended to reject materials or designs which are inadequate under normal operating and environmental conditions. This document defines test methods and acceptance criteria. The applicable tests are given in the relevant product standard. This third edition cancels and replaces the second edition published in 2012. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) The scope of the document is specified to comprise composite insulators with solid and hollow core and resin insulators used for both AC and DC systems in indoor and outdoor applications of HV overhead lines and substations; hybrid insulators (defined in IEC TS 62896) with ceramic core and polymeric housing are also included, while coated insulators (e.g. with Room Temperature Vulcanized (RTV) silicone rubber coatings) are not considered in this document;

b) Steep-front impulse voltage test is modified to avoid unwanted flashovers between the leads of the electrodes;

c) Differences between hydrophobicity transfer material (HTM) and non-HTM housing materials are specified and relevant test methods and acceptance criteria for polymeric insulators with HTM housing are introduced;

d) The previous water diffusion test on core materials with or without housing is split into two tests. One is on core materials without housing, the other is on core materials with housing. The acceptance criteria are modified;

e) Stress corrosion test for core materials is introduced;

f) Annex B summarizes the test application for evaluating the quality of interfaces and connections of end fittings, housing materials and core materials;

g) Annex E is introduced to emphasize the need for control of electric fields of polymeric insulators for AC. The control of electric fields of polymeric insulators for DC is still under consideration.

- Standard113 pagesEnglish languagesale 15% off

IEC 61109:2025 applies to composite insulators for overhead lines consisting of a load-bearing cylindrical insulating solid core consisting of fibres - usually glass - in a resin-based matrix, a housing (surrounding the insulating core) made of polymeric material and metal end fittings permanently attached to the insulating core. Composite insulators covered by this document are intended for use as suspension/tension line insulators, but these insulators could occasionally be subjected to compression or bending, for example when used as interphase-spacers. Guidance on such loads is outlined in Annex C.

The object of this document is to:

- define the terms used,

- specify test methods,

- specify acceptance criteria.

This third edition cancels and replaces the second edition published in 2008. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

- extension of this document to apply both to AC and DC systems;

- modifications of Clause 3, Terms, definitions and abbreviations;

- removal of Clause 7, Hybrid insulators, from this document;

- modifications of tests procedures recently included in IEC 62217 (hydrophobicity transfer test, stress corrosion, water diffusion test on the core with housing);

- modifications on environmental conditions;

- modifications on classification of tests and include the relevance of the interfaces;

- clarification and modification of the parameters determining the need to repeat design and type tests;

- revision of Table 1;

- revision of electrical type tests;

- revision of re-testing procedure of sample test;

- addition of a new Annex D on electric field control for AC;

- addition of a new Annex E on typical sketch for composite insulators assembly;

- addition of a new Annex F on mechanical evaluation of the adhesion between core and housing;

- addition of a new Annex G on applicability of design- and type tests for DC applications.

- Standard165 pagesEnglish languagesale 15% off

IEC/TR 62730:2012(E) is applicable to polymeric insulators whose insulating body consists of one or various organic materials. Polymeric insulators covered by this technical report include both solid core and hollow insulators. They are intended for use on overhead lines and in indoor and outdoor equipment with a rated voltage greater than 1 000 V. The object of this technical report is:

- to define the common terms used;

- to give the background behind the development and use of the 5 000 h multiple stress test and the tracking wheel test;

- to describe the test methods for the 5 000 h multiple stress test and the tracking wheel tests on polymeric insulators;

- to describe possible acceptance or failure criteria, if applicable. Key words: polymeric insulators, multiple stress test, 5000 h

- Technical report19 pagesEnglish languagesale 15% off

- Technical report38 pagesEnglish languagesale 15% off

- Technical report4 pagesEnglish languagesale 15% off

IEC 62896:2024 applies to hybrid insulators for AC and DC applications greater than 1 000 V AC and 1 500 V DC consisting of a load-bearing insulating solid or hollow core consisting of ceramic or glass, a housing (defined geometry, outside the insulating core) made of polymeric material and end fittings permanently attached to the insulating core.

Hybrid insulators covered by this document are intended for use as suspension/tension long rod and cap and pin type insulators, line post insulators, station post insulators and hollow core insulators for apparatus.

The object of this document is to:

- define the terms used;

- prescribe test methods;

- prescribe acceptance criteria

This document does not include requirements dealing with the choice of insulators for specific operating conditions. This first edition cancels and replaces the IEC TS 62896 published in 2015. This edition includes the following significant technical changes with respect to the previous edition:

- modifications of terms and definitions;

- modifications of tests procedures included in IEC TR 62039 and IEC 62217 (Hydrophobicity transfer test);

- harmonization of Table 1 (Tests to be carried out after design and type changes) with other product standards and IEC 62217.

- Standard42 pagesEnglish and French languagesale 15% off

IEC 60437:2023 specifies the procedure for a radio interference (RI) test carried out in a laboratory on clean and dry insulators at a frequency of 0,5 MHz or 1 MHz or, alternatively, at other frequencies between 0,5 MHz and 2 MHz.

This document applies to insulators for use on AC or DC overhead power lines and overhead traction lines with a nominal voltage greater than 1 000 V.

This third edition cancels and replaces the second edition published in 1997. This third edition cancels and replaces the second edition published in 1997. This edition includes the following significant technical changes with respect to the previous edition:

a) Composite station post and composite hollow core station post insulators have been included;

b) All paragraphs of Samples test were actualized;

c) Sample test fast procedure was introduced.

- Standard41 pagesEnglish languagesale 15% off

- Standard25 pagesEnglish and French languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...