IEC 61109:2025

(Main)Insulators for overhead lines – Composite suspension and tension insulators with AC voltage greater than 1 000 V and DC voltage greater than 1 500 V – Definitions, test methods and acceptance criteria

Insulators for overhead lines – Composite suspension and tension insulators with AC voltage greater than 1 000 V and DC voltage greater than 1 500 V – Definitions, test methods and acceptance criteria

IEC 61109:2025 applies to composite insulators for overhead lines consisting of a load-bearing cylindrical insulating solid core consisting of fibres - usually glass - in a resin-based matrix, a housing (surrounding the insulating core) made of polymeric material and metal end fittings permanently attached to the insulating core. Composite insulators covered by this document are intended for use as suspension/tension line insulators, but these insulators could occasionally be subjected to compression or bending, for example when used as interphase-spacers. Guidance on such loads is outlined in Annex C.

The object of this document is to:

- define the terms used,

- specify test methods,

- specify acceptance criteria.

This third edition cancels and replaces the second edition published in 2008. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

- extension of this document to apply both to AC and DC systems;

- modifications of Clause 3, Terms, definitions and abbreviations;

- removal of Clause 7, Hybrid insulators, from this document;

- modifications of tests procedures recently included in IEC 62217 (hydrophobicity transfer test, stress corrosion, water diffusion test on the core with housing);

- modifications on environmental conditions;

- modifications on classification of tests and include the relevance of the interfaces;

- clarification and modification of the parameters determining the need to repeat design and type tests;

- revision of Table 1;

- revision of electrical type tests;

- revision of re-testing procedure of sample test;

- addition of a new Annex D on electric field control for AC;

- addition of a new Annex E on typical sketch for composite insulators assembly;

- addition of a new Annex F on mechanical evaluation of the adhesion between core and housing;

- addition of a new Annex G on applicability of design- and type tests for DC applications.

Isolateurs pour lignes aériennes - Isolateurs composites de suspension et d'ancrage de tension supérieure à 1 000 v en courant alternatif et à 1 500 v en courant continu - Définitions, méthodes d'essai et critères d'acceptation

L'IEC 61109:2025 s'applique aux isolateurs composites pour lignes aériennes qui sont constitués d'un noyau isolant plein cylindrique réalisé en fibres - généralement de verre - qui supporte les charges. Ces isolateurs possèdent une matrice en résine, un revêtement (recouvrant le noyau isolant) en matériau élastomère et des armatures d'extrémité métalliques fixées au noyau isolant. Les isolateurs composites couverts par le présent document sont destinés à être utilisés pour la suspension ou l'ancrage de lignes, mais ces isolateurs peuvent parfois être sollicités en compression ou en flexion, par exemple lorsqu'ils sont utilisés comme entretoises interphases. L'Annexe C fournit des recommandations pour ces types de charges.

L'objet du présent document est de:

- définir les termes utilisés;

- spécifier les méthodes d'essai;

- spécifier les critères acceptation.

Cette troisième édition annule et remplace la deuxième édition parue en 2008. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- élargissement du présent document pour inclure les systèmes à courant alternatif et à courant continu;

- modifications de l'Article 3, Termes, définitions et abréviations;

- suppression de l'Article 7, Isolateurs hybrides, dans le présent document;

- modifications des procédures d'essai récemment incluses dans l'IEC 62217 (essai de transfert d'hydrophobie, essai de corrosion sous contrainte, essai de pénétration d'eau - sur le noyau avec le revêtement);

- modifications des conditions d'environnement;

- modifications de la classification des essais et ajout de la pertinence des interfaces;

- clarification et modification des paramètres qui déterminent la nécessité de répéter les essais de conception et de type;

- révision du Tableau 1;

- révision des essais électriques de type;

- révision de la procédure de contre-épreuve de l'essai sur prélèvement;

- ajout d'une nouvelle Annexe D sur la maîtrise des champs électriques pour les applications en courant alternatif;

- ajout d'une nouvelle Annexe E sur les croquis types pour l'assemblage des isolateurs composites;

- ajout d'une nouvelle Annexe F sur l'évaluation mécanique de l'adhérence entre le noyau et le revêtement;

- ajout d'une nouvelle Annexe G sur l'applicabilité des essais de conception et de type pour les applications en courant continu.

General Information

- Status

- Published

- Publication Date

- 25-Feb-2025

- Technical Committee

- TC 36 - Insulators

- Drafting Committee

- MT 18 - TC 36/MT 18

- Current Stage

- PPUB - Publication issued

- Start Date

- 26-Feb-2025

- Completion Date

- 28-Feb-2025

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61109:2025 - Insulators for overhead lines - Composite suspension and tension insulators with AC voltage greater than 1 000 V and DC voltage greater than 1 500 V - is the third edition (technical revision) of the international standard for composite insulators used on overhead lines. It defines terms, specifies test methods and acceptance criteria for composite insulators consisting of a fibre‑reinforced resin core, polymeric housing and permanently attached metal end fittings. The standard applies to suspension and tension insulators for both AC and DC systems and replaces the 2008 edition.

Key topics and technical requirements

- Scope and definitions: Updated Clause 3 expands terms, definitions and abbreviations relevant to composite insulators and test classification.

- Test classification: Clear differentiation of design tests, type tests, sample tests and routine tests with criteria for when tests must be repeated after design changes.

- Electrical testing: Revised electrical type tests including dry lightning impulse, wet power‑frequency, wet switching impulse, corona/RIV and power arc tests for insulator strings and assemblies.

- Mechanical testing: Assembled core load‑time tests, damage‑limit proof tests, verification of specified mechanical load (SML) and mechanical routine tests.

- Materials and interfaces: Modified procedures for hydrophobicity transfer, stress corrosion and water diffusion tests on the core with housing (harmonized with IEC 62217); added mechanical evaluation methods for core-to-housing adhesion (Annex F: pull‑off, peel, shear).

- Environmental and installation: Revised environmental condition classifications, identification, transport, storage and installation guidance.

- New informative annexes:

- Annex D - Electric field control for AC;

- Annex E - Typical assembly sketches;

- Annex F - Mechanical evaluation of adhesion;

- Annex G - Applicability of design and type tests for DC applications.

- Other changes: Removal of hybrid insulators clause; clarification of interfaces and retesting procedures.

Applications and who uses it

IEC 61109:2025 is used by:

- Manufacturers of composite suspension/tension insulators for product design validation and production control.

- Test laboratories for type and routine testing to internationally accepted methods and acceptance criteria.

- Transmission and distribution utilities, engineers and asset owners for procurement specifications, acceptance testing and lifecycle assessment of overhead‑line insulators.

- Specification writers and consultants preparing tender documents and conformity statements for AC and DC overhead line projects.

Practical uses include qualification of new insulator designs, verification of mechanical and electrical performance, assessment of housing‑core adhesion, and guidance for DC applicability and electric field control.

Related standards

- IEC 62217 - referenced for composite insulating material tests (hydrophobicity transfer, stress corrosion, water diffusion).

REDLINE IEC 61109:2025 CMV - Insulators for overhead lines - Composite suspension and tension insulators for a.c. systems with a nominal voltage greater than 1 000 V - Definitions, test methods and acceptance criteria Released:26. 02. 2025 Isbn:9782832702864

Frequently Asked Questions

IEC 61109:2025 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Insulators for overhead lines – Composite suspension and tension insulators with AC voltage greater than 1 000 V and DC voltage greater than 1 500 V – Definitions, test methods and acceptance criteria". This standard covers: IEC 61109:2025 applies to composite insulators for overhead lines consisting of a load-bearing cylindrical insulating solid core consisting of fibres - usually glass - in a resin-based matrix, a housing (surrounding the insulating core) made of polymeric material and metal end fittings permanently attached to the insulating core. Composite insulators covered by this document are intended for use as suspension/tension line insulators, but these insulators could occasionally be subjected to compression or bending, for example when used as interphase-spacers. Guidance on such loads is outlined in Annex C. The object of this document is to: - define the terms used, - specify test methods, - specify acceptance criteria. This third edition cancels and replaces the second edition published in 2008. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - extension of this document to apply both to AC and DC systems; - modifications of Clause 3, Terms, definitions and abbreviations; - removal of Clause 7, Hybrid insulators, from this document; - modifications of tests procedures recently included in IEC 62217 (hydrophobicity transfer test, stress corrosion, water diffusion test on the core with housing); - modifications on environmental conditions; - modifications on classification of tests and include the relevance of the interfaces; - clarification and modification of the parameters determining the need to repeat design and type tests; - revision of Table 1; - revision of electrical type tests; - revision of re-testing procedure of sample test; - addition of a new Annex D on electric field control for AC; - addition of a new Annex E on typical sketch for composite insulators assembly; - addition of a new Annex F on mechanical evaluation of the adhesion between core and housing; - addition of a new Annex G on applicability of design- and type tests for DC applications.

IEC 61109:2025 applies to composite insulators for overhead lines consisting of a load-bearing cylindrical insulating solid core consisting of fibres - usually glass - in a resin-based matrix, a housing (surrounding the insulating core) made of polymeric material and metal end fittings permanently attached to the insulating core. Composite insulators covered by this document are intended for use as suspension/tension line insulators, but these insulators could occasionally be subjected to compression or bending, for example when used as interphase-spacers. Guidance on such loads is outlined in Annex C. The object of this document is to: - define the terms used, - specify test methods, - specify acceptance criteria. This third edition cancels and replaces the second edition published in 2008. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - extension of this document to apply both to AC and DC systems; - modifications of Clause 3, Terms, definitions and abbreviations; - removal of Clause 7, Hybrid insulators, from this document; - modifications of tests procedures recently included in IEC 62217 (hydrophobicity transfer test, stress corrosion, water diffusion test on the core with housing); - modifications on environmental conditions; - modifications on classification of tests and include the relevance of the interfaces; - clarification and modification of the parameters determining the need to repeat design and type tests; - revision of Table 1; - revision of electrical type tests; - revision of re-testing procedure of sample test; - addition of a new Annex D on electric field control for AC; - addition of a new Annex E on typical sketch for composite insulators assembly; - addition of a new Annex F on mechanical evaluation of the adhesion between core and housing; - addition of a new Annex G on applicability of design- and type tests for DC applications.

IEC 61109:2025 is classified under the following ICS (International Classification for Standards) categories: 29.080.10 - Insulators. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61109:2025 has the following relationships with other standards: It is inter standard links to IEC 61109:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61109:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61109 ®

Edition 3.0 2025-02

COMMENTED VERSION

INTERNATIONAL

STANDARD

Insulators for overhead lines – Composite suspension and tension insulators

with AC voltage greater than 1 000 V and DC voltage greater than 1 500 V –

Definitions, test methods and acceptance criteria

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a

Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and

containing more than 22 500 terminological entries in English

once a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61109 ®

Edition 3.0 2025-02

COMMENTED VERSION

INTERNATIONAL

STANDARD

Insulators for overhead lines – Composite suspension and tension insulators

with AC voltage greater than 1 000 V and DC voltage greater than 1 500 V –

Definitions, test methods and acceptance criteria

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.080.10 ISBN 978-2-8327-0286-4

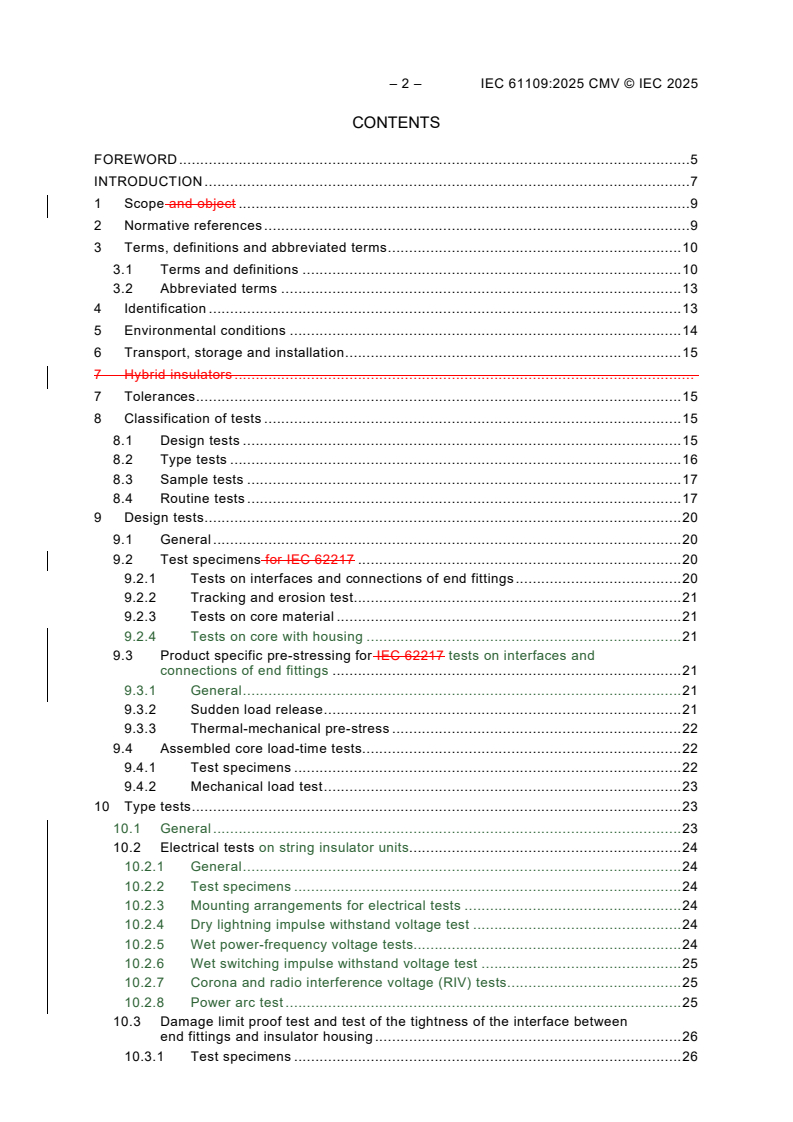

– 2 – IEC 61109:2025 CMV © IEC 2025

CONTENTS

FOREWORD .5

INTRODUCTION .7

1 Scope and object .9

2 Normative references .9

3 Terms, definitions and abbreviated terms . 10

3.1 Terms and definitions . 10

3.2 Abbreviated terms . 13

4 Identification . 13

5 Environmental conditions . 14

6 Transport, storage and installation . 15

7 Hybrid insulators .

7 Tolerances . 15

8 Classification of tests . 15

8.1 Design tests . 15

8.2 Type tests . 16

8.3 Sample tests . 17

8.4 Routine tests . 17

9 Design tests . 20

9.1 General . 20

9.2 Test specimens for IEC 62217 . 20

9.2.1 Tests on interfaces and connections of end fittings . 20

9.2.2 Tracking and erosion test . 21

9.2.3 Tests on core material . 21

9.2.4 Tests on core with housing . 21

9.3 Product specific pre-stressing for IEC 62217 tests on interfaces and

connections of end fittings . 21

9.3.1 General . 21

9.3.2 Sudden load release . 21

9.3.3 Thermal-mechanical pre-stress . 22

9.4 Assembled core load-time tests . 22

9.4.1 Test specimens . 22

9.4.2 Mechanical load test . 23

10 Type tests . 23

10.1 General . 23

10.2 Electrical tests on string insulator units. 24

10.2.1 General . 24

10.2.2 Test specimens . 24

10.2.3 Mounting arrangements for electrical tests . 24

10.2.4 Dry lightning impulse withstand voltage test . 24

10.2.5 Wet power-frequency voltage tests. 24

10.2.6 Wet switching impulse withstand voltage test . 25

10.2.7 Corona and radio interference voltage (RIV) tests . 25

10.2.8 Power arc test . 25

10.3 Damage limit proof test and test of the tightness of the interface between

end fittings and insulator housing . 26

10.3.1 Test specimens . 26

10.3.2 Performance of the test . 26

10.3.3 Evaluation of the test . 28

11 Sample tests . 28

11.1 General rules. 28

11.2 Verification of dimensions (E1 + E2) . 29

11.3 Verification of the end fittings (E2) . 29

11.4 Verification of tightness of the interface between end fittings and insulator

housing (E2) and of the specified mechanical load, SML (E1) . 29

11.5 Galvanizing test (E2) . 30

11.6 Minimum sheath thickness (E1) . 30

11.7 Re-testing procedure . 30

12 Routine tests . 32

12.1 Mechanical routine test . 32

12.2 Visual examination . 33

Annex A (informative) Principles of the damage limit, load coordination and testing for

composite suspension and tension insulators . 34

A.1 Introductory remark . 34

A.2 Load-time behaviour and the damage limit. 34

A.3 Service load coordination . 35

A.4 Verification tests . 37

Annex B (informative) Example of two possible devices for sudden release of load . 39

B.1 Device 1 (Figure B.1) . 39

B.2 Device 2 (Figure B.2) . 39

Annex C (informative) Guidance on non-standard mechanical stresses and dynamic

mechanical loading of composite tension/suspension insulators . 41

C.1 Introductory remark . 41

C.2 Torsion loads. 41

C.3 Compressive (buckling) loads . 41

C.4 Bending loads . 42

C.5 Dynamic mechanical loads . 42

C.6 Limits . 43

Annex D (informative) Electric field control for AC . 44

Annex E (informative) Typical sketches for composite insulator assemblies . 46

Annex F (informative) Mechanical evaluation of the adhesion between core and

housing . 47

F.1 General . 47

F.2 Method A: Pull-off test . 48

F.2.1 General . 48

F.2.2 Specimens . 48

F.2.3 Procedure . 48

F.3 Method B: Peel test . 50

F.3.1 General . 50

F.3.2 Specimens . 50

F.3.3 Procedure . 51

F.4 Method C: Shear test . 52

F.4.1 General . 52

F.4.2 Specimens . 52

F.4.3 Procedure . 52

Annex G (informative) Applicability of design and type tests for DC applications. 53

– 4 – IEC 61109:2025 CMV © IEC 2025

Bibliography . 55

List of comments . 57

Figure 1 – Thermal-mechanical pre-stressing . 22

Figure 2 – Examples for 1 min SML withstand test . 27

Figure 3 – Location for minimum sheath thickness measurement . 30

Figure 4 – Method of re-testing at different stages . 32

Figure A.1 – Load-time strength and damage limit of a core assembled with fittings . 35

Figure A.2 – Graphical representation of the relationship of the damage limit to the

mechanical characteristics and service loads of an insulator with a 16 mm diameter

core and an SML rating of 133 kN . 36

Figure A.3 – Applied specific force relationship, example 1 . 36

Figure A.4 – Applied specific force relationship, example 2 . 37

Figure A.5 – Test loads . 38

Figure B.1 – Example of possible device 1 for sudden release of load. 39

Figure B.2 – Example of possible device 2 for sudden release of load. 40

Figure C.1 – Example of compression loads in V-string assemblies . 42

Figure C.2 – Buckling of composite insulator in a phase-to-phase configuration . 42

Figure D.1 – Example for electrical field vectors on a composite insulator . 45

Figure E.1 – Interface description for insulator with housing made by modular

assembly and external sealant . 46

Figure E.2 – Interface description for insulator with housing made by injection molding

and overmolded end fitting . 46

Figure F.1 – Example for type of housing separation . 47

Figure F.2 – Example of specimen mounted in a tensile test machine . 49

Figure F.3 – Example of test object for pull-off test and application clamping and force . 49

Figure F.4 – Relevant dimensions for the calculation of the area of the pull-off section . 50

Figure F.5 – Example of test specimen for peel test . 51

Figure F.6 – Method of peel test and tested specimens after peel test . 51

Figure F.7 – Method of shear test and tested samples after shear test with cohesive

bonding, sample passed the test. 52

Table 1 – Normal environmental conditions . 14

Table 2 – Tests to be carried out after design changes . 17

Table 3 – Design tests . 20

Table 4 – Application and mounting arrangements for electrical tests . 26

Table 5 – Sample sizes . 29

Table G.1 – Design and type tests for DC applications . 53

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INSULATORS FOR OVERHEAD LINES

COMPOSITE SUSPENSION AND TENSION INSULATORS

FOR A.C. SYSTEMS WITH A NOMINAL AC VOLTAGE GREATER THAN

1 000 V AND DC VOLTAGE GREATER THAN 1 500 V 1 –

DEFINITIONS, TEST METHODS AND ACCEPTANCE CRITERIA

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

This commented version (CMV) of the official standard IEC 61109:2025 edition 3.0 allows

the user to identify the changes made to the previous IEC 61109:2008 edition 2.0.

Furthermore, comments from IEC TC 36 experts are provided to explain the reasons of

the most relevant changes, or to clarify any part of the content.

A vertical bar appears in the margin wherever a change has been made. Additions are in

green text, deletions are in strikethrough red text. Experts' comments are identified by a

blue-background number. Mouse over a number to display a pop-up note with the

comment.

This publication contains the CMV and the official standard. The full list of comments is

available at the end of the CMV.

– 6 – IEC 61109:2025 CMV © IEC 2025

IEC 61109 has been prepared by subcommittee 36B: Insulators for overhead lines, of IEC

technical committee 36: Insulators. It is an International Standard.

This third edition cancels and replaces the second edition published in 2008. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) extension of this document to apply both to AC and DC systems;

b) modifications of Clause 3, Terms, definitions and abbreviations;

c) removal of Clause 7, Hybrid insulators, from this document;

d) modifications of tests procedures recently included in IEC 62217 (hydrophobicity transfer

test, stress corrosion, water diffusion test on the core with housing);

e) modifications on environmental conditions;

f) modifications on classification of tests and include the relevance of the interfaces;

g) clarification and modification of the parameters determining the need to repeat design and

type tests;

h) revision of Table 1;

i) revision of electrical type tests;

j) revision of re-testing procedure of sample test;

k) addition of a new Annex D on electric field control for AC;

l) addition of a new Annex E on typical sketch for composite insulators assembly;

m) addition of a new Annex F on mechanical evaluation of the adhesion between core and

housing;

n) addition of a new Annex G on applicability of design- and type tests for DC applications.

The text of this International Standard is based on the following documents:

Draft Report on voting

36/609/FDIS 36/611/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

This International Standard is to be used in conjunction with IEC 62217:2012.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

INTRODUCTION

Composite suspension and tension 2 insulators (in the following the term "composite insulator"

is used) consist of fibreglass insulating core, bearing the mechanical load protected by a

polymeric housing, the load being transmitted to the core by metallic end fittings. Despite these

common features, the materials used and the construction design details and manufacturing

process used by different manufacturers may differ.

Some tests have been grouped together as "Design tests", to be performed only once on

insulators which satisfy the same design conditions. For all design tests of these composite

suspension and tension insulators, the appropriate common clauses defined in IEC 62217 are

applied. As far as practical, the influence of time on the electrical and mechanical properties of

its components (core material, housing, interfaces etc.) and of the complete composite

insulators has been considered in specifying the design tests to ensure a satisfactory lifetime

under normally known stress conditions of transmission lines. Explanation of the principles of

the damage limit, load coordination and testing are presented in Annex A.

It has not been considered useful to specify a power arc test as a mandatory test. The test

parameters are manifold and can have very different values depending on the configurations of

the network and the supports and on the design of arc-protection devices. The heating effect of

power arcs should need to be considered in the design of metal fittings. Critical damage to the

metal fittings resulting from the magnitude and duration of the short-circuit current can be

avoided by properly designed arc-protection devices. This document, however, does not

exclude the possibility of a power arc test by agreement between the user and manufacturer

and customer. IEC 61467 gives details on AC power arc testing of complete insulator sets, that

match their configuration with actual protective and string fittings, to recreate the real

electromagnetic field affecting the arc movement.

Composite insulators are used in both a.c. and d.c. applications. In spite of this fact, a specific

tracking and erosion test procedure for d.c. applications as a design test has not yet been

defined and accepted. The 1 000 h a.c. tracking and erosion test of IEC 62217 is used to

establish a minimum requirement for the tracking resistance of the housing material.

The mechanism of brittle fracture has been investigated by CIGRE B2.03 and conclusions are

published in [2, 3]. Brittle fracture is a result of stress corrosion induced by internal or external

acid attack on the resin bonded glass fibre core. CIGRE D1.14 has developed a test procedure

for core materials based on time-load tests on assembled cores exposed to acid, along with

chemical analysis methods to verify the resistance against acid attack [4]. In parallel IEC

TC36WG 12 is studying preventive and predictive measures.

This document covers both AC and DC composite insulators. Before the appropriate standard

for DC applications is issued, the majority of tests listed in this document can also be applicable

for DC (Annex G). Due to the difference in AC and DC tracking performance, a specific tracking

and erosion test procedure for DC applications as a design test is planned to be developed.

The 1 000 h AC tracking and erosion test of IEC 62217 can be used only to establish a minimum

requirement for the tracking and erosion resistance. This 1 000 h salt fog tracking and erosion

test is considered as a screening test intended to reject materials in combination with the design

which are inadequate. Tracking and erosion tests are not intended to evaluate long term

performance of insulators. Such tests, e.g. the 5 000 h multiple stress test and wheel test in

IEC TR 62730 [1] , or other tests intended for research or sometimes used as a supplementary

design test, are not considered in this document.

Composite suspension and tension insulators are, in general, not intended for torsion or other

non-tensile loads. However, due to consideration to non-standard applications (interphase

___________

International Council on Large High Voltage Electric Systems: Working Group B2.03.

Numbers in square brackets refer to the bibliography.

– 8 – IEC 61109:2025 CMV © IEC 2025

spacers etc.) loads during handling and installation have to be considered in the design.

Guidance on non-standard loads is given in Annex C.

Wherever possible, IEC Guide 111 [2] has been followed for the drafting of this document.

INSULATORS FOR OVERHEAD LINES

COMPOSITE SUSPENSION AND TENSION INSULATORS

FOR A.C. SYSTEMS WITH A NOMINAL AC VOLTAGE GREATER THAN

1 000 V AND DC VOLTAGE GREATER THAN 1 500 V –

DEFINITIONS, TEST METHODS AND ACCEPTANCE CRITERIA

1 Scope and object

This International Standard applies to composite suspension/tension insulators for overhead

lines consisting of a load-bearing cylindrical insulating solid core consisting of fibres – usually

glass – in a resin-based matrix, a housing (outside surrounding the insulating core) made of

polymeric material and metal end fittings permanently attached to the insulating core.

Composite insulators covered by this document are intended for use as suspension/tension line

insulators, but it should be noted that these insulators can could occasionally be subjected to

compression or bending, for example when used as phase interphase-spacers. Guidance on

such loads is outlined in Annex C.

This standard can be applied in part to hybrid composite insulators where the core is made of

a homogeneous material (porcelain, resin), see Clause 8.

The object of this document is to

– define the terms used,

– prescribe specify test methods,

– prescribe specify acceptance criteria.

This document does not include requirements dealing with the choice of insulators for specific

operating conditions or environments beyond normal environmental conditions defined in

Table 1.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60060-1, High-voltage test techniques – Part 1: General definitions and test requirements

IEC 60383-1, Insulators for overhead lines with a nominal voltage above 1000 V – Part 1:

Ceramic or glass insulator units for AC systems – Definitions, test methods and acceptance

criteria

IEC 60383-2, Insulators for overhead lines with a nominal voltage above 1 000 V – Part 2:

Insulator strings and insulator sets for AC systems – Definitions, test methods and acceptance

criteria

IEC 60437, Radio interference test on high-voltage insulators

IEC 61284, Overhead lines – Requirements and tests for fittings

– 10 – IEC 61109:2025 CMV © IEC 2025

IEC 61466-1, Composite string insulator units for overhead lines with a nominal voltage greater

than 1 000 V – Part 1: Standard strength classes and end fittings

IEC 61467, Insulators for overhead lines – Insulator strings and sets for lines with a nominal

voltage greater than 1 000 V – AC power arc tests

IEC 62217:2005— , Polymeric HV insulators for indoor and outdoor use with a nominal voltage

> 1 000 V – General definitions, test methods and acceptance criteria

IEC 62231, Composite station post insulators for substations with AC voltages greater than

1 000 V up to 245 kV – Definitions, test methods and acceptance criteria

ISO 3452 (all parts), Non-destructive testing – Penetrant testing

3 Terms, definitions and abbreviated terms

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

Note 1 to entry: Certain terms from IEC 62217:2012 are reproduced here for ease of reference. Additional

definitions applicable to insulators can be found in IEC 60050-471 [3].

3.1 Terms and definitions

3.1.1

polymeric insulator

insulator whose insulating body consists of at least one organic based material

Note 1 to entry: Polymeric insulators are also known as non-ceramic insulators.

Note 2 to entry: Coupling devices may be attached to the ends of the insulating body.

[SOURCE: IEC 60050-471:2007, 471-01-13]

3.1.2

composite insulator

insulator made of at least two insulating parts, namely a core and a housing equipped with

metal end fittings

Note 1 to entry: Composite insulators can consist either of individual sheds mounted on the core, with or without

an intermediate sheath, or alternatively, of a housing directly moulded or cast in one or several pieces on to the core.

[SOURCE: IEC 60050-471:2007, 471-01-02]

3.1.3

core (of a composite an insulator)

internal insulating part of a composite insulator which is designed to ensure the mechanical

characteristics

NOTE The core usually consists of either fibres (e.g. glass) which are positioned in a resin-based matrix or a

homogeneous insulating material (e.g. porcelain or resin).

___________

Under preparation. Stage at the time of publication: IEC/RFDIS 62217:2025.

[IEV 471-01-03, modified]

central insulating part of an insulator which provides the mechanical characteristics

Note 1 to entry: The housing and sheds are not part of the core.

[SOURCE: IEC 60050-471:2007, 471-01-03]

3.1.4

insulator trunk

central insulating part of an insulator from which the sheds project

Note 1 to entry: Also known as shank on smaller insulators.

[SOURCE: IEC 60050-471:2007, 471-01-11]

3.1.5

housing

external insulating part of composite insulator providing the necessary creepage distance and

protecting protects the core from the environment

Note 1 to entry: An intermediate sheath made of insulating material may be part of the housing.

[SOURCE: IEC 60050-471:2007, 471-01-09]

3.1.6

shed (of an insulator)

insulating part, projecting from the insulator trunk, intended to increase the creepage distance

Note 1 to entry: The shed can be with or without under-ribs.

[SOURCE: IEC 60050-471:2007, 471-01-15]

3.1.7

interface

contact surface between the different materials

Note 1 to entry: Various interfaces exist in composite insulators, e.g.:

– between housing and fixing devices end fittings;

– between various parts of the housing; e.g. between separately manufactured sheds, or between sheath and

sheds;

– between core and housing;

– between sealant and core;

– between sealant and end fittings.

(Annex E: Typical sketches for composite insulator assemblies)

[Definition 3.10 of IEC 62217]

[SOURCE: IEC 62217:—, 3.11, modified – "contact" added in definition, Note 1 to entry

modified]

3.1.8

end fitting

integral component or formed part of an insulator intended to connect it to a supporting

structure, or to a conductor, or to an item of equipment, or to another insulator

Note 1 to entry: Where the end fitting is metallic, in general the term "metal fitting" is used.

Note 2 to entry: Standard end fittings are defined in IEC 61466-1.

– 12 – IEC 61109:2025 CMV © IEC 2025

[SOURCE: IEC 60050-471:2007, 471-01-06]

3.1.9

connection zone

zone where the mechanical load is transmitted between the insulating body core and the end

fitting

[Definition 3.12 of IEC 62217]

[SOURCE: IEC 62217:2012, 3.13, modified – "insulating body and the fixing device" replaced

by "core and the end fitting"]

3.1.10

coupling

part of the end fitting which transmits the load to the accessories external to the insulator

[Definition 3.13 of IEC 62217, modified]

[SOURCE: IEC 62217:2012, 3.14, modified – "fixing device" replaced by "end fitting",

"hardware" replaced by "accessories"]

3.1.11

creepage distance

shortest distance or the sum of the shortest distances along the surface on an insulator between

two conductive parts which normally have the operating voltage between them

[SOURCE: IEC 60050-471:2007, 471-01-04]

3.1.12

arcing distance

shortest distance in the air external to the insulator between the metallic parts which normally

have the operating voltage between them

Note 1 to entry: The term "dry arcing distance" is also used.

[SOURCE: IEC 60050-471:2007, 471-01-01]

3.1.13

specified mechanical load

SML

withstand load, specified by the manufacturer, which is used for mechanical tests in this

document

3.1.14

routine test load

RTL

load applied to all assembled composite insulators during a routine mechanical test

3.1.15

mechanical failing load

maximum load that is reached when the insulator is tested under the prescribed standard

conditions

[SOURCE: IEC 60050-471:2007, 471-01-12, modified – "prescribed" replaced by "standard",

Note 1 to entry removed]

3.1.16

insulator set

assembly of one or more insulator strings suitably connected together, complete with end

fittings and protective devices as required in service

Note 1 to entry: The terms "arcing and field grading devices" is also used for protective devices.

[SOURCE: IEC 60050-471:2007, 471-03-02]

3.1.17

string insulator unit

cap and pin insulator or long rod insulator of which the end fittings are suitable for flexible

attachment to other similar string insulator units or to connecting accessories

Note 1 to entry: Cap and pin insulators are not composite insulators and are not part of this document.

[SOURCE: IEC 60050-471:2007, 471-03-08]

3.1.18

sealing

method for providing the ability of a component to resist the ingress of contaminants

Note 1 to entry: Contaminants include pollution and moisture.

[SOURCE: IEC 60050-581:2008, 581-23-16]

3.1.19

sealant

additional material used for sealing

Note 1 to entry: Typically RTV-silicones are used for composite insulators.

Note 2 to entry: See sealant in Annex E: Typical principles sketch for composite insulators assembly.

3.1.20

grading/corona ring

protective devices made from metal attached to the composite insulator end fitting or

intermediate string fitting intended to keep the electric field anywhere along the surface of

composite insulator below the specified maximum value

3.2 Abbreviated terms

The following abbreviated terms are used in this document:

E1, E2 Sample sets for sample tests

M Average 1 min failing load of the core assembled with fittings

AV

RTL Routine test load

RTV Room-temperature-vulcanizing silicone

SML Specified mechanical load

4 Identification

In addition to the requirements of IEC 62217, each insulator shall be marked with the SML.

It is recommended that each insulator is marked or labelled by the manufacturer to show that it

has passed the routine mechanical test.

– 14 – IEC 61109:2025 CMV © IEC 2025

5 Environmental conditions 3

The normal environmental conditions to which insulators are submitted in service are defined

in IEC 62217 and shown in Table 1. Terms are defined as follows:

• Indoor environment: installation within a building or other construction where the insulators

are protected against wind, rain, snow, periodical fast-built pollution deposits, abnormal

condensation, ice and hoar frost.

• Outdoor environment: installation in open air outside any building or shelter, where the

insulators are submitted to wind, rain, snow, periodical fast-built pollution deposits, high

condensation, ice and hoar frost.

If service conditions of polymeric insulators deviate significantly from the parameters in Table 1,

the insulator is to be designed or evaluated according to agreement between the customer and

manufacturer. Alternatively, if positive service experience ("i.e. no failures") is available for a

specific environment and specific insulator design (including material and profile), the insulator

can be used for this specific environment, deviating from normal environmental conditions.

Table 1 – Normal environmental conditions

Indoor insulation Outdoor insulation

a

Does not exceed 40 °C and its average value measured over a period of

Maximum ambient air temperature

24 h does not exceed 35 °C

b

−25 °C −40 °C

Minimum ambient air temperature

Vibration Negligible vibration due to causes external to the insulators or to earth

c

tremors .

d 2

Not applicable

Solar radiation Up to a level of 1 120 W/m

e

No significant pollution by dust, Pollution by dust, smoke, corrosive

Site pollution severity

smoke, corrosive and/or

gases, vapours or salt occurs.

flammable gases, vapours, or salt. Pollution does not exceed SPS class

"heavy" as defined in

IEC TS 60815-1 [5].

f

No rain, snow, abnormal humidity, Rain, snow, abnormal humidity,

Humidity

condensation, ice and hoar frost condensation, ice and hoar frost

occur.

a

If exceeded, follow the recommendations of IEC TR 62039 [5] for the core and adhesive materials (like glue) in

"glass transition temperature" section.

b

In general, temperatures below −40 °C are non-critical for service. However, for handling and installation the

crystallization temperature of the polymeric housing is to be considered. For line installations with temperatures

below −20 °C, special steel grades with low ductile transition temperature can be specified.

c

Vibration due to external causes can be dealt with in accordance to IEC 60721-1 [6].

d 2

For outdoor application, the influence of deviation from the assumed level of 1 120 W/m .

depends on the insulator material. If service conditions of polymeric insulators deviate significantly from the

parameters in Table 1, the insulator is to be designed/evaluated taking into account relevant service experience.

In the absence of significant service experience, special tests simulating the solar radiation condition of the

installation area have to be carried out.

e

In general, pollution is not an issue for indoor insulators. In particular cases, such as DC.

indoor conditions, the insulators can accumulate some contamination due to DC electrical field. However, the

pollution flashover phe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...