IEC 62896:2024

(Main)Hybrid insulators for AC and DC for high-voltage applications greater than 1 000 V AC and 1 500 V DC - Definitions, test methods and acceptance criteria

Hybrid insulators for AC and DC for high-voltage applications greater than 1 000 V AC and 1 500 V DC - Definitions, test methods and acceptance criteria

IEC 62896:2024 applies to hybrid insulators for AC and DC applications greater than 1 000 V AC and 1 500 V DC consisting of a load-bearing insulating solid or hollow core consisting of ceramic or glass, a housing (defined geometry, outside the insulating core) made of polymeric material and end fittings permanently attached to the insulating core.

Hybrid insulators covered by this document are intended for use as suspension/tension long rod and cap and pin type insulators, line post insulators, station post insulators and hollow core insulators for apparatus.

The object of this document is to:

- define the terms used;

- prescribe test methods;

- prescribe acceptance criteria

This document does not include requirements dealing with the choice of insulators for specific operating conditions. This first edition cancels and replaces the IEC TS 62896 published in 2015. This edition includes the following significant technical changes with respect to the previous edition:

- modifications of terms and definitions;

- modifications of tests procedures included in IEC TR 62039 and IEC 62217 (Hydrophobicity transfer test);

- harmonization of Table 1 (Tests to be carried out after design and type changes) with other product standards and IEC 62217.

Isolateurs hybrides pour applications haute tension en courant alternatif et en courant continu supérieures à 1 000 V en courant alternatif et 1 500 V en courant continu - Définitions, méthodes d’essai et critères d’acceptation

L’IEC 62896:2024 s’applique aux isolateurs hybrides pour applications en courant alternatif et en courant continu supérieures à 1 000 V en courant alternatif et 1 500 V en courant continu, constitués d’un noyau isolant supportant la charge mécanique, plein ou creux, fabriqué en matière céramique ou en verre, d’un revêtement (de géométrie définie, à l’extérieur du noyau isolant) en matériau polymère et d’armatures d’extrémité fixées de façon permanente au noyau isolant.

Les isolateurs hybrides couverts par le présent document sont destinés à être utilisés comme isolateurs de suspension/d’ancrage de type à long fût et de type capot et tige, isolateurs rigides à socle, isolateurs supports et isolateurs à noyau creux, pour l’appareillage.

Le présent document a pour objets:

- de définir les termes employés;

- de prescrire des méthodes d’essai;

- de prescrire les critères d’acceptation.

Cette première édition annule et remplace l’IEC TS 62896 parue en 2015. Cette édition inclut les modifications techniques majeures suivantes par rapport à l’édition précédente:

- modifications des termes et définitions;

- modifications des procédures d’essai incluses dans l’IEC TR 62039 et l’IEC 62217 (Essai de transfert d’hydrophobicité);

- harmonisation du Tableau 1 (Essais à réaliser après les modifications de conception et de type) avec d’autres normes de produit l’IEC 62217.

General Information

- Status

- Published

- Publication Date

- 13-May-2024

- Technical Committee

- TC 36 - Insulators

- Drafting Committee

- MT 24 - TC 36/MT 24

- Current Stage

- PPUB - Publication issued

- Start Date

- 14-May-2024

- Completion Date

- 10-May-2024

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62896:2024 is the latest international standard that defines specifications for hybrid insulators used in high-voltage AC and DC systems. Specifically designed for applications exceeding 1,000 V AC and 1,500 V DC, this standard establishes definitions, test methods, and acceptance criteria for hybrid insulators which combine ceramic or glass insulating cores with polymeric housings and end fittings.

Hybrid insulators play a critical role in electrical transmission and distribution systems, ensuring electrical insulation and mechanical support in high-voltage environments. This standard replaces the earlier IEC TS 62896 (2015) and incorporates significant technical updates to testing and terminology, harmonizing design and type tests with related IEC standards.

Key Topics

Scope and Application

- Applies to hybrid insulators comprising a load-bearing core (solid or hollow, ceramic or glass), polymeric housings with defined geometry, and end fittings permanently attached to the core.

- Covers various insulator types including suspension/tension long rod, cap and pin, line post, station post, and hollow core apparatus insulators.

- Addresses both AC and DC high-voltage uses greater than 1,000 V AC and 1,500 V DC.

Definitions and Terminology

- Provides standardized terms for clear communication among manufacturers, testing laboratories, and utilities.

- Updates and refines key definitions to reflect state-of-the-art designs and materials.

Test Methods

- Comprehensive test specifications divided into design tests, type tests, sample tests, and routine tests.

- Design tests ensure mechanical load-bearing core integrity and polymeric housing durability.

- Includes specific tests for interfaces, connections, hydrophobicity transfer, hardness, accelerated weathering, tracking and erosion resistance, and flammability.

- Harmonizes testing procedures with IEC 62217 (polymeric insulator standard) and IEC TR 62039 for hydrophobicity transfer.

- Ensures tests address electrical performance under AC/DC stresses and mechanical robustness under service conditions.

Acceptance Criteria

- Sets clear benchmarks for pass/fail evaluation during manufacturing and design validation.

- Facilitates consistent quality assurance and performance reliability across different manufacturers and product lines.

Applications

IEC 62896:2024 applies to a wide range of hybrid insulator applications critical to modern electrical networks, including:

- Overhead power transmission lines: Suspension or tension insulators ensuring high-voltage line insulation and mechanical support.

- Substation equipment: Line post and station post insulators providing electrical isolation in outdoor switchyards and substations.

- Electrical apparatus: Hollow core insulators used within electrical devices requiring high dielectric strength and mechanical stability.

- High-pollution environments: Hybrid insulators with polymeric housing materials featuring hydrophobicity transfer mechanisms (HTM) to mitigate surface contamination and maintain insulation integrity.

By standardizing test requirements and acceptance criteria, IEC 62896 helps utilities and manufacturers ensure hybrid insulator reliability and durability, reducing failures and maintenance costs in high-voltage AC/DC systems worldwide.

Related Standards

IEC 62896:2024 works in conjunction with the following key IEC standards to provide a comprehensive framework for insulator design and testing:

- IEC 62217: Polymeric insulators for system voltages greater than 1,000 V – Covers polymeric housing materials and interface tests used in hybrid insulators.

- IEC TR 62039: Technical report including hydrophobicity transfer test methods relevant to polymeric materials.

- IEC 60168, IEC 60383 (Parts 1 & 2), IEC 62155: Ceramic and glass core insulator standards referenced for mechanical and electrical core material testing.

- IEC 60507, IEC 61245: Pollution test standards relevant to insulators (though specifically excluded from IEC 62896 for hybrid polymeric types).

Utilizing the IEC 62896:2024 standard ensures hybrid insulator manufacturers and system operators comply with universally accepted definitions and test methods, enhancing product quality and operational safety in high-voltage electrical infrastructure.

Keywords: IEC 62896, hybrid insulators, high-voltage AC, high-voltage DC, polymeric housing, ceramic core, glass core, electrical insulators, high-voltage applications, suspension insulators, post insulators, high-voltage testing, hydrophobicity transfer, insulator acceptance criteria, IEC standards, power transmission, electrical insulation.

Frequently Asked Questions

IEC 62896:2024 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Hybrid insulators for AC and DC for high-voltage applications greater than 1 000 V AC and 1 500 V DC - Definitions, test methods and acceptance criteria". This standard covers: IEC 62896:2024 applies to hybrid insulators for AC and DC applications greater than 1 000 V AC and 1 500 V DC consisting of a load-bearing insulating solid or hollow core consisting of ceramic or glass, a housing (defined geometry, outside the insulating core) made of polymeric material and end fittings permanently attached to the insulating core. Hybrid insulators covered by this document are intended for use as suspension/tension long rod and cap and pin type insulators, line post insulators, station post insulators and hollow core insulators for apparatus. The object of this document is to: - define the terms used; - prescribe test methods; - prescribe acceptance criteria This document does not include requirements dealing with the choice of insulators for specific operating conditions. This first edition cancels and replaces the IEC TS 62896 published in 2015. This edition includes the following significant technical changes with respect to the previous edition: - modifications of terms and definitions; - modifications of tests procedures included in IEC TR 62039 and IEC 62217 (Hydrophobicity transfer test); - harmonization of Table 1 (Tests to be carried out after design and type changes) with other product standards and IEC 62217.

IEC 62896:2024 applies to hybrid insulators for AC and DC applications greater than 1 000 V AC and 1 500 V DC consisting of a load-bearing insulating solid or hollow core consisting of ceramic or glass, a housing (defined geometry, outside the insulating core) made of polymeric material and end fittings permanently attached to the insulating core. Hybrid insulators covered by this document are intended for use as suspension/tension long rod and cap and pin type insulators, line post insulators, station post insulators and hollow core insulators for apparatus. The object of this document is to: - define the terms used; - prescribe test methods; - prescribe acceptance criteria This document does not include requirements dealing with the choice of insulators for specific operating conditions. This first edition cancels and replaces the IEC TS 62896 published in 2015. This edition includes the following significant technical changes with respect to the previous edition: - modifications of terms and definitions; - modifications of tests procedures included in IEC TR 62039 and IEC 62217 (Hydrophobicity transfer test); - harmonization of Table 1 (Tests to be carried out after design and type changes) with other product standards and IEC 62217.

IEC 62896:2024 is classified under the following ICS (International Classification for Standards) categories: 29.080.10 - Insulators. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62896:2024 has the following relationships with other standards: It is inter standard links to IEC TS 62896:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62896:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62896 ®

Edition 1.0 2024-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Hybrid insulators for AC and DC for high-voltage applications greater than

1 000 V AC and 1 500 V DC – Definitions, test methods and acceptance criteria

Isolateurs hybrides pour applications haute tension en courant alternatif et en

courant continu supérieures à 1 000 V en courant alternatif et 1 500 V en courant

continu – Définitions, méthodes d’essai et critères d’acceptation

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications, symboles

en utilisant différents critères (numéro de référence, texte, graphiques et le glossaire. Avec un abonnement, vous aurez

comité d’études, …). Elle donne aussi des informations sur les toujours accès à un contenu à jour adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 500 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 25 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 62896 ®

Edition 1.0 2024-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Hybrid insulators for AC and DC for high-voltage applications greater than

1 000 V AC and 1 500 V DC – Definitions, test methods and acceptance criteria

Isolateurs hybrides pour applications haute tension en courant alternatif et en

courant continu supérieures à 1 000 V en courant alternatif et 1 500 V en courant

continu – Définitions, méthodes d’essai et critères d’acceptation

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.080.10 ISBN 978-2-8322-8755-2

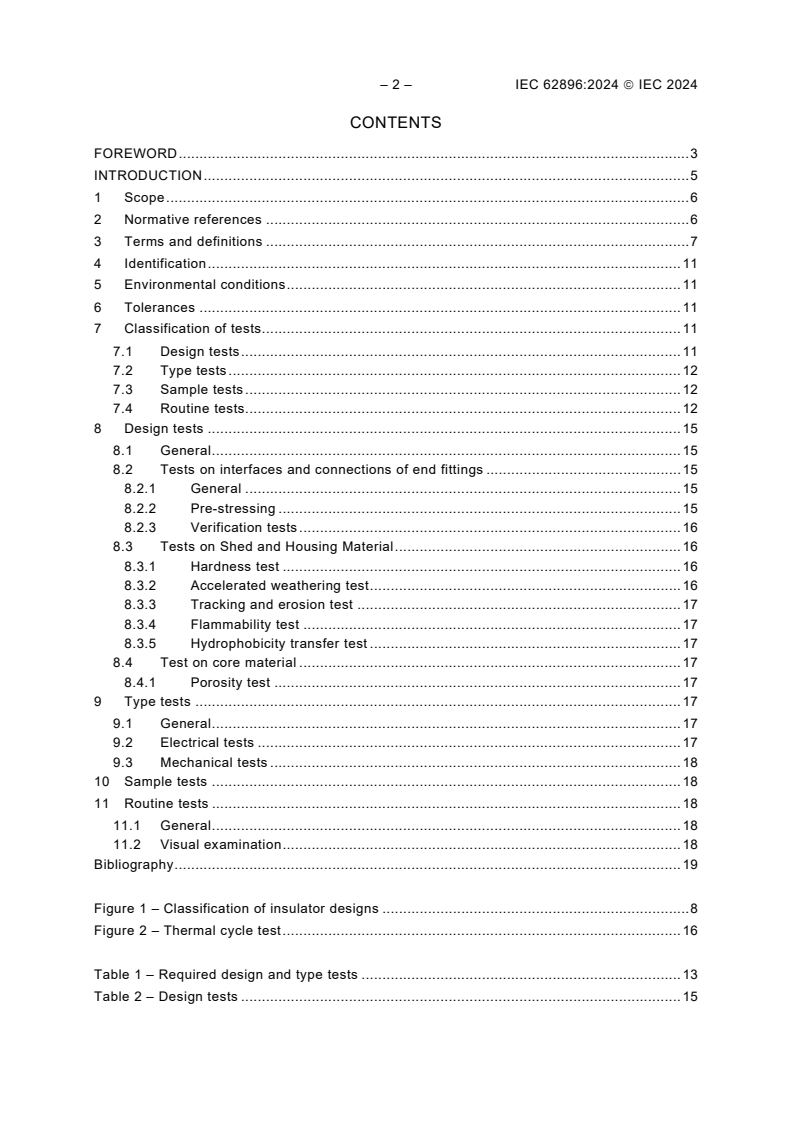

– 2 – IEC 62896:2024 IEC 2024

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Identification . 11

5 Environmental conditions . 11

6 Tolerances . 11

7 Classification of tests. 11

7.1 Design tests . 11

7.2 Type tests . 12

7.3 Sample tests . 12

7.4 Routine tests. 12

8 Design tests . 15

8.1 General . 15

8.2 Tests on interfaces and connections of end fittings . 15

8.2.1 General . 15

8.2.2 Pre-stressing . 15

8.2.3 Verification tests . 16

8.3 Tests on Shed and Housing Material . 16

8.3.1 Hardness test . 16

8.3.2 Accelerated weathering test . 16

8.3.3 Tracking and erosion test . 17

8.3.4 Flammability test . 17

8.3.5 Hydrophobicity transfer test . 17

8.4 Test on core material . 17

8.4.1 Porosity test . 17

9 Type tests . 17

9.1 General . 17

9.2 Electrical tests . 17

9.3 Mechanical tests . 18

10 Sample tests . 18

11 Routine tests . 18

11.1 General . 18

11.2 Visual examination . 18

Bibliography . 19

Figure 1 – Classification of insulator designs . 8

Figure 2 – Thermal cycle test . 16

Table 1 – Required design and type tests . 13

Table 2 – Design tests . 15

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HYBRID INSULATORS FOR AC AND DC HIGH-VOLTAGE

APPLICATIONS GREATER THAN 1 000 V AC AND 1 500 V DC –

DEFINITIONS, TEST METHODS AND ACCEPTANCE CRITERIA

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 62896 has been prepared by IEC technical committee 36: Insulators. It is an International

Standard.

This first edition cancels and replaces the IEC TS 62896 published in 2015. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) modifications of terms and definitions;

b) modifications of tests procedures included in IEC TR 62039 and IEC 62217 (Hydrophobicity

transfer test);

c) harmonization of Table 1 (Tests to be carried out after design and type changes) with other

product standards and IEC 62217.

– 4 – IEC 62896:2024 IEC 2024

The text of this International Standard is based on the following documents:

Draft Report on voting

36/594/FDIS 36/597/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

INTRODUCTION

Hybrid insulators consist of an insulating core, bearing the mechanical load protected by a

polymeric housing, the load being transmitted to the core by end fittings. Despite these common

features, the materials used and the construction details employed by different manufacturers

may be quite different. The core is made of ceramic or glass material.

Hybrid insulators are applied as overhead line, post or hollow core equipment insulators. In

order to perform the design tests, IEC 62217 is intended to be applied for the polymeric housing

and the interfaces between core and the housing. For the core, the test standards for the

respective ceramic product (IEC 60168, IEC 60383-1 and −2 and IEC 62155) are intended to

be applied.

Some tests have been grouped together as "design tests", to be performed only once on

insulators which satisfy the same design conditions. For all design tests of hybrid insulators,

the common clauses defined in IEC 62217 are applied. As far as practical, the influence of time

on the electrical and mechanical properties of the components (core material, housing,

interfaces etc.) and of the complete hybrid insulators has been considered in specifying the

design tests to ensure a satisfactory life-time under normally known stress conditions in service.

Polymeric housing materials that show the hydrophobicity transfer mechanism (HTM) are

preferred for hybrid insulators. These housing materials are applied as a countermeasure

against severely polluted service conditions.

Pollution tests according to IEC 60507 or IEC 61245 are not included in this document since

they are designed for non-polymeric items. Specific pollution tests for polymeric insulators are

still under consideration.

– 6 – IEC 62896:2024 IEC 2024

HYBRID INSULATORS FOR AC AND DC HIGH-VOLTAGE

APPLICATIONS GREATER THAN 1 000 V AC AND 1 500 V DC –

DEFINITIONS, TEST METHODS AND ACCEPTANCE CRITERIA

1 Scope

This document applies to hybrid insulators for AC and DC applications greater than 1 000 V AC

and 1 500 V DC consisting of a load-bearing insulating solid or hollow core consisting of ceramic

or glass, a housing (defined geometry, outside the insulating core) made of polymeric material

and end fittings permanently attached to the insulating core.

Hybrid insulators covered by this document are intended for use as suspension/tension long

rod and cap and pin type insulators, line post insulators, station post insulators and hollow core

insulators for apparatus.

The object of this document is to:

• define the terms used;

• prescribe test methods;

• prescribe acceptance criteria.

Silicone or other functional coatings (CIGRE Technical Brochure No. 478), booster sheds, shed

extenders and rain deflectors are not within the scope of this document. CIGRE B2.69 published

two Technical Brochures, TB 837 and TB 838, in June 2021 with the scope of practical

applications and collection of experiences for anti-pollution coatings for insulators.

This document does not include requirements dealing with the choice of insulators for specific

operating conditions.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050-471:2007, International Electrotechnical Vocabulary (IEV) – Part 471: Insulators

IEC 60168, Tests on indoor and outdoor post insulators of ceramic material or glass for systems

with nominal voltages greater than 1000 V

IEC 60383-1:2023, Insulators for overhead lines with a nominal voltage above 1000 V – Part 1:

Ceramic or glass insulator units for a.c. systems – Definitions, test methods and acceptance

criteria

IEC 60383-2, Insulators for overhead lines with a nominal voltage above 1000 V – Part 2:

Insulator strings and insulator sets for a.c. systems – Definitions, test methods and acceptance

criteria

IEC 62155, Hollow pressurized and unpressurized ceramic and glass insulators for use in

electrical equipment with rated voltages greater than 1 000 V

IEC 62217, Polymeric HV insulators for indoor and outdoor use – General definitions, test

methods and acceptance criteria

IEC 61211, Insulators of ceramic material or glass for overhead lines with a nominal voltage

greater than 1 000 V – Impulse puncture testing in air

IEC 61325, Insulators for overhead lines with a nominal voltage above 1000 V – Ceramic or

glass insulator units for d.c. systems – Definitions, test methods and acceptance criteria

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-471:2007 and

the following apply (some definitions from IEC 62217 are reproduced here for ease of

reference).

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

high-voltage

HV

voltage over 1 000 V AC or over 1 500 V DC or over 1 500 V peak value

3.2

polymeric insulator

insulator whose insulating body consists of at least one organic based material

Note 1 to entry: Polymeric insulators are also known as non-ceramic insulators.

Note 2 to entry: Coupling devices may be attached to the ends of the insulating body.

[SOURCE: IEC 60050-471:2007, 471-01-13]

3.3

resin insulator

polymeric insulator whose insulating body consists of a solid insulator trunk and sheds

protruding from the insulator trunk made from only one organic based housing material (e.g.

cycloaliphatic epoxy)

3.4

composite insulator

polymeric insulator made of at least two polymeric insulating parts, namely a core and a

housing, equipped with metal fittings

Note 1 to entry: Composite insulators, for example, can consist either of individual sheds mounted on the core, with

or without an intermediate sheath, or alternatively, of a housing directly moulded or cast in one or several pieces on

to the core.

[SOURCE: IEC 60050-471:2007, 471-01-02, modified (addition of "polymeric", replacement of

"end fittings" by "metal fittings"]

– 8 – IEC 62896:2024 IEC 2024

3.5

hybrid insulator

insulator that consists of a ceramic core and a polymeric housing, equipped with one or more

metal fittings

See Figure 1.

Note 1 to entry: According to IEC TS 62896.

Note 2 to entry: The mechanical functions are mainly characterised by the core, the external electrical functions

are mainly characterised by the polymeric housing. The housing may cover the core completely or partly. In the latter

case the exposed portions of the ceramic core are usually covered by glaze.

Figure 1 – Classification of insulator designs

3.6

core

central insulating part of an insulator which provides the mechanical characteristics

Note 1 to entry: The housing and sheds are not part of the core.

[SOURCE: IEC 60050-471:2007, 471-01-03]

3.7

insulator trunk

central insulating part of an insulator from which the sheds project

Note 1 to entry: Also known as shank on smaller insulators.

[SOURCE: IEC 60050-471:2007, 471-01-11]

3.8

housing

external insulating part of a composite insulator providing the necessary creepage distance and

protecting core from environment

Note 1 to entry: An intermediate sheath made of insulating material may be part of the housing.

[SOURCE: IEC 60050-471:2007, 471-01-09]

3.9

shed (of an insulator)

insulating part, projecting from the insulator trunk, intended to increase the creepage distance

Note 1 to entry: The shed can be with or without ribs.

[SOURCE: IEC 60050-471:2007, 471-01-15]

3.10

creepage distance

shortest distance or the sum of the shortest distances along the surface on an insulator between

two conductive parts which normally have the operating voltage between them

[SOURCE: IEC 60050-471:2007, 471-01-04]

3.11

arcing distance

shortest distance in air external to the insulator between the metallic parts which normally have

the operating voltage between them

[SOURCE: IEC 60050-471:2007, 471-01-01]

3.12

sheath

uniform and continuous tubular covering made of insulating material

[SOURCE: IEC 60050-151, 151-12-41, modified (removal of "conductive or")]

3.13

interfaces

surface between the different materials

Note 1 to entry: Various interfaces can be found in most composite insulators, e.g.:

– between housing and end fittings;

– between various parts of the housing; e.g. between sheds, or between sheath and sheds;

– between core and housing.

3.14

end fitting

integral component or formed part of an insulator, intended to connect it to a supporting

structure, or to a conductor, or to an item of equipment, or to another insulator

Note 1 to entry: Where the end fitting is metallic, the term "metal fitting" is normally used.

[SOURCE: IEC 60050-471:2007, 471-01-06]

3.15

connection zone

zone where the mechanical load is transmitted between the insulating body and the end fitting

3.16

coupling

part of the end fitting which transmits load to the hardware external to the insulator

– 10 – IEC 62896:2024 IEC 2024

3.17

tracking

progressive degradation of the surface of a solid insulating material by local discharges to form

conducting or partially conducting paths

Note 1 to entry: Tracking paths are conductive even under dry conditions.

3.18

erosion

loss of material due to leakage current or electrical discharge

Note 1 to entry: Light surface traces, commonly tree-shaped, can occur on composite insulators as on ceramic

insulators, after partial discharge. These traces are not considered to be objectionable as long as they are

nonconductive. When they are conductive, they are classified as tracking.

3.19

crack

any internal fracture or surface fissure of depth greater than 0,1 mm

3.20

puncture

permanent loss of dielectric strength due to a disruptive discharge passing through the solid

insulating material of an insulator

[SOURCE: IEC 60050-471:2007, 471-01-14, modified to define puncture as the result of a

discharge, rather than the discharge itself]

3.21

lot

group of insulators or insulator bodies offered for acceptance from the same manufacturer, of

the same design and manufactured under similar conditions of production

Note 1 to entry: One or more lots may be offered together for acceptance; the lot(s) offered may consist of the

whole, or part, of the quantity ordered.

3.22

hydrophobicity

behaviour of the surface of a solid insulating material to repel to water or aqueous electrolyte

solutions; hydrophobicity of a polymeric insulating material is, in general, a volume property by

means of the chemical composition of a material at its surface

Note 1 to entry: Nonetheless, hydrophobicity is strongly affected by surface effects such as:

– surface structure (i. e. roughness);

– chemical interaction between water and the solid surface (adsorption, absorption, swelling of the solid material

in contact with water);

– an accumulated pollution layer.

Note 2 to entry: Furthermore, the conditions during an evaluation of hydrophobicity (climatic (temperature,

pressure, humidity), method for cleaning or electrostatic charges) may affect the measured degree of hydrophobicity.

3.23

hydrophobicity transfer

hydrophobicity transfer is the phenomenon of a transfer of hydrophobicity from the bulk of the

housing material to pollution layer on its surface

3.24

hydrophobicity transfer material (HTM)

polymeric material which exhibits hydrophobicity and the capability to transfer hydrophobicity

onto the layer of pollution, which is a combined dynamic behaviour of retention and transfer of

hydrophobicity specific to different insulator materials

[SOURCE: IEC TS 60815-4:2016, 3.1.4, modified – addition of text following "pollution"].

4 Identification

Each insulator shall be marked with the name or trademark of the manufacturer and the year of

manufacture. In addition, each insulator shall be marked with the rated characteristics specified

in the applicable IEC product standards for ceramic or glass insulators. These markings shall

be legible, indelible and their fixings (if any) weather- and corrosion-proof.

5 Environmental conditions

The normal environmental conditions to which insulators are submitted in service are defined

in IEC 62217.

6 Tolerances

Unless otherwise agreed, a tolerance of

• ±(0,04 × d + 1,5) mm when d ≤ 300 mm,

• ±(0,025 × d + 6 ) mm when d > 300 mm with a maximum tolerance of ±50 mm,

shall be allowed on all dimensions for which specific tolerances are not requested or given on

the insulator drawing (d being the dimension in millimetres).

The measurement of creepage distances shall be related to the design dimensions and

tolerances as determined from the insulator drawing, even if this dimension is greater than the

value originally specified. When a minimum creepage is specified, the negative tolerance is

also limited by this value.

7 Classification of tests

7.1 Design tests

These tests are intended to verify the suitability of the design, materials and method of

manufacture (technology). A hybrid insulator design is defined by:

• materials of the core, housing and their manufacturing method;

• material of the end fittings, their design and method of attachment (excluding the coupling);

• layer thickness of the housing over the core (including a sheath where used);

• diameter of the core.

Design tests shall be performed in accordance with Table 1. Sampling, test procedures and

acceptance criteria shall apply as in the standards referenced in Table 1.

When changes in the design occur, re-qualification shall be carried out in accordance with

Table 1.

– 12 – IEC 62896:2024 IEC 2024

When a hybrid insulator is submitted to the design tests, it becomes a parent insulator for a

given design and the results shall be considered valid for that design only. This tested parent

insulator defines a particular design of insulators which have all the following characteristics:

a) same materials for the core and housing and same manufacturing method;

b) same material of the fittings, the same design, and the same method of attachment;

c) same or greater minimum layer thickness of the housing over the core (including a sheath

where used);

d) same or smaller stress under mechanical loads;

e) same or greater cross-diameter of the core;

f) equivalent housing profile parameters, see Note (a) of Table 1.

7.2 Type tests

The type tests are intended to verify the main characteristics of a hybrid insulator, which depend

mainly on its materials, shape and size. Type tests in accordance with Table 1 shall be applied

to hybrid insulators, the class of which has passed the design tests. They shall be repeated

only when the type or material of the hybrid insulator is changed (see Table 1). The type tests

shall be performed, depending on type and application, according to the type tests defined in:

• IEC 60168 for solid core station post insulators,

• IEC 60383-1 and −2 for AC overhead transmission line insulators (cap and pin and long rod

and line post type)

• IEC 61325 for DC overhead transmission line insulators (cap and pin and long rod and line

post type)

• IEC 62155 for hollow core insulators

7.3 Sample tests

The sample tests are for the purpose of verifying other characteristics of hybrid insulators,

including those which depend on the quality of manufacture and on the materials used. They

are made on insulators taken at random from lots offered for delivery. Sample tests shall be

applied in accordance with IEC 60168, IEC 60383-1 or IEC 62155 for the respective kind of

products.

For ceramic cores the porosity test according to IEC 60383-1:2023, Clause 25, shall be

performed.

7.4 Routine tests

The aim of these tests is to eliminate hybrid insulators with manufacturing defects. They are

made on every hybrid insulator offered for acceptance. Routine tests shall be applied in

accordance with IEC 60168, IEC 60383-1 or −2 or IEC 62155 for the respective kind of

products.

Table 1 – Required design and type tests

Then the following tests shall be repeated

Type tests

Design tests

IEC 60168 IEC 60381-1/-2,

IEC 62217

IEC 61325 IEC 60168,

IEC 62217 IEC 62772

Tests on housing material

IF the change in

IEC 62155

insulator design

Interfaces

concerns:

Tracking

and Assembled Accelerated

Mechanical

Hardness and Flammability Hydrophobicity Porosity Electrical

connections core load test, weathering

type tests

test erosion test transfer test test type tests

of end only 8.3.1 test

test

fittings

1 Housing

Materials or

formulation and

1a X X X X X X

manufacturing

process

2 a)e)

1b Assembly process X X

a)e)

1c Profile X X

2 Core

Material or

c) c) b)c)

2a manufacturing X X X X

process

c) b)c)

2b Design X

X X

3 End fitting

Material or

f) f)

3a X

X X

assembly process

End fitting

3b connection zone X X

design

4 Interface

Primer material

4a and application X

method

– 14 – IEC 62896:2024 IEC 2024

Then the following tests shall be repeated

Type tests

Design tests

IEC 60168 IEC 60381-1/-2,

IEC 62217

IEC 61325 IEC 60168,

IEC 62217 IEC 62772

Tests on housing material

IF the change in IEC 62155

insulator design

concerns: Interfaces

Tracking

and Assembled Accelerated

Mechanical

Hardness and Flammability Hydrophobicity Porosity Electrical

connections core load test, weathering

type tests

test erosion test transfer test test type tests

of end only 8.3.1 test

test

fittings

Core and end-

4b fitting assembly X X X

process

Core/housing/end

4c fitting interface X X X X

design

d)

5 Type of insulator X

X

NOTE 1 Housing manufacturing process: General manufacturing method such as injection moulding, modular process etc.

NOTE 2 Housing assembly process: If shed and sheath are mounted separately to the tube, incl. type and method of bonding shed-sheath.

a)

Not necessary if thickness of the housing surrounding the core (including a sheath where used) is equal or greater. The previous edition of this document provided relative

numbers as tolerances, which do not constitute a change of the profile. These have been

– overhang: ±10 %

– thickness at base and tip: ±15 %

– spacing: ±15 %

– shed inclinations: ±3°

– shed repetition: identical.

These relatively small tolerances can serve as reference, however, cause a high test demand due to the variety of today`s profiles. Alternatively, a technical agreement between

manufacturer and user in agreement with 9.1 is possible if the equivalence of the profile evaluated in the interface test as well as the tracking and erosion test to the profile in

question can be shown. A possible method is the interpolation of results with different profiles.

b)

Porosity test acc. to IEC 60168 (for ceramic only)

c)

Variations of the core diameter within ±20 % do not constitute a change. However, the type tests shall be performed in case of change of core diameter

d)

Mechanical and electrical type tests shall be carried out according to product test standards for ceramic or glass Insulators. It is permissible to perform the mechanical type

tests without the polymeric housing.

e)

Higher severity design in electric performance can be representative in similar design, if layer thickness of the housing over the core is the same or higher

f)

Not necessary if it can be demonstrated that the change has no influence on "interfaces and connection of end fittings".

8 Design tests

8.1 General

These tests consist of the tests specified in IEC 62217 as listed in Table 2. The design tests

are performed only once, and the results are recorded in a test report. Each part can be

performed independently on new test specimens. The hybrid insulator of a particular design will

be qualified only when all insulators or test specimens pass the design tests.

Table 2 – Design tests

Tests on interfaces and connections of end fittings

thermal-cycle pre-stressing

water immersion pre-stressing

Verification tests:

visual examination

steep-front impulse voltage test

dry power frequency voltage test

Tests on shed and housing material

hardness test

accelerated weathering test

tracking and erosion test – see 8.3.3 for specimens

flammability test

hydrophobicity transfer test

Tests on core material

porosity test

8.2 Tests on interfaces and connections of end fittings

8.2.1 General

One insulator assembled on the production line shall be tested. The insulation length (metal to

metal spacing) shall be not less than 800 mm. Both metal fittings shall be the same as on

standard production insulators. The end fittings shall be assembled so that the insulating part

from the fitting to the closest shed shall be identical to that of the production line insulator.

If the manufacturer only has facilities to produce insulators shorter than 800 mm, the design

tests may be performed on insulators of those lengths available to him, but the results are only

valid for up to the lengths tested.

8.2.2 Pre-stressing

8.2.2.1 Thermal cycle test

The specimen is submitted to temperature cycles under no mechanical load as described in

Figure 2, the 24 h temperature cycle being repeated four times. Each 24 h cycle has two

temperature levels with a duration of at least 8 h, one at +50 °C ± 5 K, the other at –35 °C ± 5 K.

The cold period shall be at a temperature at least 85 K below the value actually applied in the

hot period. The pre-stressing can be conducted in air or any other suitable medium.

– 16 – IEC 62896:2024 IEC 2024

Figure 2 – Thermal cycle test

The cycles may be interrupted for maintenance of the test equipment for a total duration of 2 h.

The starting point after any interruption shall be the beginning of the interrupted cycle.

8.2.2.2 Water immersion pre-stressing

Shall be performed according to IEC 62217.

8.2.3 Verification tests

8.2.3.1 General

Shall be performed according to IEC 62217.

8.2.3.2 Visual examination

Shall be performed according to IEC 62217.

8.2.3.3 Steep-front impulse voltage test

Shall be performed according to IEC 62217.

If necessary for insulators with a nominal length < 500 mm, the test arrangement only of

IEC 61211 may be used.

8.2.3.4 Dry power frequency voltage test

Shall be performed according to IEC 62217.

8.3 Tests on Shed and Housing Material

8.3.1 Hardness test

Shall be performed according to IEC 62217.

8.3.2 Accelerated weathering test

Shall be performed according to IEC 62217.

8.3.3 Tracking and erosion test

Shall be performed according to IEC 62217.

IEC 62217 specifies that the creepage distance shall be between 500 mm and 800 mm. If the

manufacturer only has facilities to produce insulators with creepage shorter than 500 mm, the

design tests may be performed on insulators of those lengths he has available, but the results

are only valid for up to the tested lengths.

If the insulator design does not allow samples with this creepage distance requirement, (e.g.

insulators with one shed) then the original insulator shall be used as test sample and the

line-to-earth voltage as specified by the manufacturer shall be applied as test voltage.

The acceptance criteria for composite insulators defined in IEC 62217 apply.

NOTE Tracking and erosion has no significant impact on the mechanical performance for hybrid insulators.

8.3.4 Flammability test

Shall be performed according to IEC 62217.

8.3.5 Hydrophobicity transfer test

Shall be performed according to IEC 62217.

8.4 Test on core material

8.4.1 Porosity test

Shall be performed according to IEC 60168.

9 Type tests

9.1 General

An insulator type is electrically defined by the arcing distance, creepage distance, shed

inclination, shed diameter and shed spacing. The electrical type tests shall be performed only

once on insulators satisfying the above criteria for one type and shall be performed with arcing

and/or corona devices, if they are an integral part of the insulator type.

An insulator type is mechanically defined by the core diameter and the method of attachment

of the metal fittings. The mechanical type tests shall be performed only once on insulators

satisfying the above criteria for each type.

The electrical and/or mechanical type tests shall be repeated only when one or more of the

above-mentioned characteristics are changed.

9.2 Electrical tests

The electrical tests for line insulators shall be performed according to IEC 60383-1 and

IEC 60383-2 to confirm the specified values. Electrical tests for station post insulators shall be

performed according to IEC 60168. No electrical type tests are required for hollow core

insulators.

Interpolation of electrical test results may be used for insulators of intermediate length, provided

that the factor between the arcing distances of the insulators whose results form the end points

of the interpolation range is less than or equal to 1,5. Extrapolation is not allowed.

– 18 – IEC 62896:2024 IEC 2024

9.3 Mechanical tests

The mechanical type tests shall be performed according to the respective product standard for

the kind of ceramic or glass insulator (e.g. IEC 60383-1, IEC 60168, IEC 62155 etc.).

10 Sample tests

The sample tests shall be performed according to the respective product standard for the kind

of insulator (e.g. IEC 60383-1, IEC 60168, IEC 62155 etc.).

For the verification of dimensions, in the case of repetitive shed profile and uniform diameter,

it is permissible to measure a short section (approximately 1 m in length) of the insulator and

then to extrapolate.

11 Routine tests

11.1 General

The general routine tests shall be performed according to the respective product standard for

the kind of insulator (e.g., IEC 60383-1, IEC 60168, IEC 62155 etc.).

11.2 Visual examination

Each insulator shall be examined. The mounting of metallic parts on the insulator assembly

shall be in accordance with the drawings. The colour of the insulator shall approximately be as

specified in the drawing.

The following defects are not permitted:

– on the housing, superficial defects of an area greater than 25 mm (the total defective area

shall not exceed 0,2 % of the total insulator surface) or depth or height greater than 1 mm;

– crack at the roo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...