EN 923:2005+A1:2008

(Main + Amendment)Adhesives - Terms and definitions

Adhesives - Terms and definitions

This European Standard defines terms used in the adhesive industry and terms relating to adhesives in those industries that use adhesives.

Klebstoffe - Benennungen und Definitionen

Diese Europäische Norm definiert Begriffe, die in der Klebstoffindustrie verwendet werden, sowie Begriffe, die

sich in der klebstoffverarbeitenden Industrie auf Klebstoffe beziehen.

Adhésifs - Termes et définitions

La présente Norme européenne définit les termes utilisés dans l’industrie des adhésifs ainsi que ceux y afférant et qui sont usités dans les industries utilisatrices d’adhésifs.

Lepila - Izrazi in definicije

General Information

- Status

- Withdrawn

- Publication Date

- 04-Mar-2008

- Withdrawal Date

- 03-Feb-2026

- Technical Committee

- CEN/TC 193 - Adhesives

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 23-Dec-2015

- Completion Date

- 04-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 30-Dec-2015

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 1373:2015 - Adhesives - Test method for adhesives for floor and wall coverings - Shear test - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 923:2005+A1:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Adhesives - Terms and definitions". This standard covers: This European Standard defines terms used in the adhesive industry and terms relating to adhesives in those industries that use adhesives.

This European Standard defines terms used in the adhesive industry and terms relating to adhesives in those industries that use adhesives.

EN 923:2005+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 01.040.83 - Rubber and plastics industries (Vocabularies); 83.180 - Adhesives. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 923:2005+A1:2008 has the following relationships with other standards: It is inter standard links to EN 923:2005, EN 923:2015, EN ISO 24598:2019, EN ISO 18275:2012, EN ISO 18276:2006, EN ISO 3581:2016, EN ISO 17634:2006, EN ISO 17633:2010, EN 15275:2015, EN ISO 16834:2012, EN 1373:2015, EN 828:2013, EN 16254:2013+A1:2016, EN 1965-1:2011, EN 16254:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 923:2005+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 923:2005+A1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Adhesives - Terms and definitionsLepila - Izrazi in definicijeAdhésifs - Termes et définitionsKlebstoffe - Benennungen und DefinitionenTa slovenski standard je istoveten z:EN 923:2005+A1:2008SIST EN 923:2006+A1:2008en,fr,de83.18001.040.83ICS:SLOVENSKI

STANDARDSIST EN 923:2006+A1:200801-maj-2008

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 923:2005+A1

March 2008 ICS 83.180; 01.040.83 Supersedes EN 923:2005 English Version

Adhesives - Terms and definitions

Adhésifs - Termes et définitions

Klebstoffe - Benennungen und Definitionen This European Standard was approved by CEN on 12 September 2005 and includes Amendment 1 approved by CEN on 7 January 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 923:2005+A1:2008: E

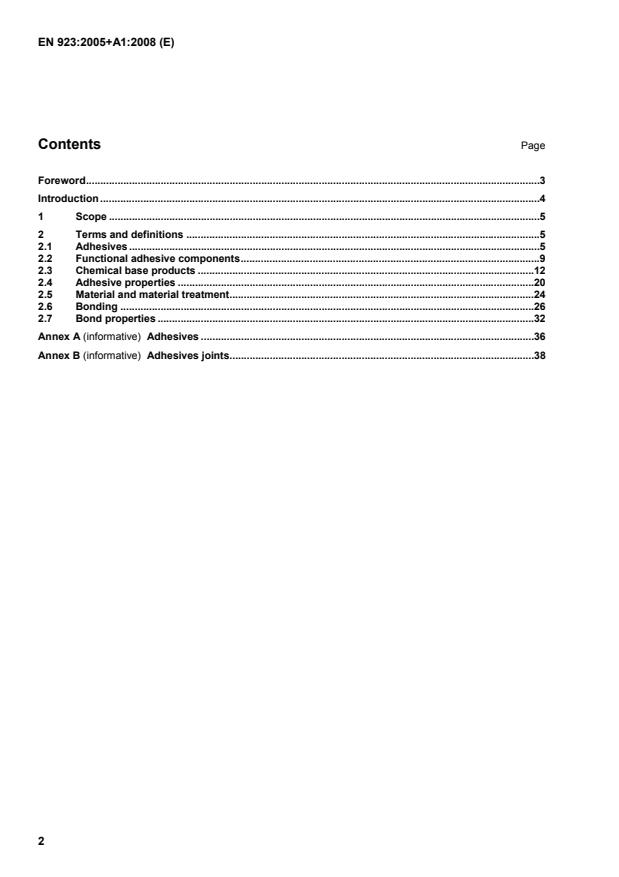

Adhesives.36 Annex B (informative)

Adhesives joints.38

the physical nature of

the adhesive. Table A.1 lists main binders, temperature and mode of setting of these adhesives and the number of parts that have to be mixed before use. Some other names refer to the method of application, or mode of setting. Furthermore adhesives are named according to points of less significance: field of application (e.g. footwear adhesive, construction adhesive, packaging adhesive), material to bond (e.g. paper adhesive, wood adhesive, wall paper adhesive, rubber adhesive), place of application (e.g. in situ adhesive), speed of setting (e.g. instant adhesive), bond properties (e.g. structural adhesive), shape (e.g. powder adhesive, pearl glue, table glue for solid glue, adhesive film for shaped adhesive, or stick adhesive for stick shaped adhesives), or aspect (e.g. white glue). 2.1.2 water-borne adhesive; aqueous adhesive adhesive in which the solvent, or the continuous phase is water 2.1.3 glue aqueous adhesive specifically designed for bonding of wood and other porous substrates NOTE A glue can be based on a natural product like protein or synthetic resins (UF, PF or PVAC, see 2.3.51, 2.3.52 and 2.3.30 respectively) 2.1.4 paste adhesive adhesive of a non-stringy, highly viscous nature

2.2.10 crosslinking agent substance that causes, promotes or regulates the formation of intermolecular, covalent or ionic bonds between polymer chains resulting in a three dimensional molecular network NOTE Crosslinking can occur either between polymer chains or by reaction of simple functional molecules (e.g. two part polyurethane or epoxy adhesives). Crosslinking can also be produced by radiation or oxidation. The terms "hardener" and "curing agent" are often used synonymously with crosslinking agent. 2.2.11 adhesion promotor; coupling agent substance used in small proportions to increase the adhesion to specific substrates 2.2.12 accelerator substance used in small proportions to increase the reaction rate of a chemical system (reactants, plus additives) 2.2.13 catalyst substance used in small proportion, that augments the rate of a chemical reaction, and in theory remains unchanged chemically at the end of the reaction

Two classes of fillers are used: chemically inert fillers, e.g. china clay or woodflour; "reinforcing fillers" like silicates, carbon black, fibrous materials or

aluminium powder

that markedly enhance the per-formance of a polymer. NOTE 2 A filler only used to reduce cost is termed “extender”. An extender can be a liquid.

then grinding to a fine powder; “slag cement“, consisting mostly of an intimate and uniform blend of granulated blast-furnace slag and hydrated lime in which the slag constituent is more than a specified minimum percentage. Blast-furnace slag is the non-metallic product consisting essentially of silicates and aluminosilicates of calcium and other bases that is developed in a molten condition simultaneously with iron in a blast furnace; “Portland-Pozzolan cement“, consisting of an intimate and uniform blend of Portland cement or Portland blast-furnace slag cement and fine pozzolan, in which the amount of the pozzolan constituent is within specified limits. Pozzolan is a siliceous and aluminous material which in itself possesses little or no cementitious value but which will, in finily divided form and in the presence of moisture, chemically react with calcium hydroxide at ordinary temperatures to form compounds possessing cementitious properties.

-CH2 -C(CH3)2 - NOTE Polyisobutylene is sometimes used as the basis of solvent-borne adhesives giving films with pressure sensitive or self-sealing properties, and as a modifier. 2.3.28 polystyrene (PS) thermoplastic polymer produced by the polymerization of styrene NOTE Polystyrene is used amongst others in solution in organic solvent as an adhesive for polystyrene and certain porous materials. 2.3.29 vinyl resin thermoplastic polymer based on vinyl compounds CH2 = CH-R in which the main chain repeating unit is

-CH2 -CH-R- NOTE The term "vinyl resin" is normally used for polymers based on vinyl chloride, vinyl acetate and the theoretical vinyl alcohol. Strict polymer science nomenclature would include any polymer derived from other vinyl compounds, e.g. polystyrene. 2.3.30 poly(vinyl acetate) (PVAC) thermoplastic polymer in either dispersion, resinous or solid form produced by the polymerization of vinyl acetate as sole or principal monomer NOTE Polyvinyl acetate is used as a versatile adhesive for porous materials, particularly for wood and paper, and for general packaging work. 2.3.31 polyethylene-vinyl acetate (EVAC) thermoplastic polymer produced by copolymerization of ethylene and vinyl acetate NOTE Polyethylene-vinyl acetate can be used as a solid in hot-melt adhesives or as dispersion in water-borne adhesives. 2.3.32 poly(vinyl alcohol) (PVAL) water soluble thermoplastic polymer produced by the hydrolysis of poly(vinyl acetate) NOTE Commercial poly(vinyl alcohol) usually contains some residual acetate groups. The uses of poly(vinyl alcohol) are as follows: as a water-soluble adhesive for porous materials; as an additive in other adhesives to improve adhesion and as a stabilizer etc.; as a heat seal or moisture reactivation adhesive.

poly(vinyl alcohol) by

the reaction of its hydroxyl groups with acetaldehyde NOTE The term poly(vinyl acetal) is also generically used for a class of polymers derived from polyvinyl esters in which some or all the ester groups have been hydrolysed to hydroxyl groups and some or all of these hydroxyl groups have been reacted with aldehydes to form acetal groups. It includes also 2.2.34 and 2.2.35. 2.3.34 poly(vinyl formal) (PVFM) thermoplastic polymer of the poly(vinyl acetal) type made from poly(vinyl alcohol) by the reaction of its hydroxyl groups with formaldehyde (see also 2.3.33, NOTE) NOTE The main use of poly(vinyl formal) is as a constituent of two polymer systems to provide high strength structural adhesives. 2.3.35 poly(vinyl butyral) (PVB) thermoplastic polymer of the poly(vinyl acetal) type made from poly(vinyl alcohol) by the reaction of its hydroxyl groups with butyraldehyde (see also 2.3.33, NOTE) NOTE the main uses of poly(vinyl butyral) are as follows: as a constituent of two polymer systems which provide high strength structural adhesives; as a main component of certain hot-melt adhesives used in particular for laminated safety glass and packaging applications. 2.3.36 poly(vinyl chloride) (PVC) thermoplastic polymer produced by polymerization of vinyl chloride NOTE When compounded with suitable plasticizers, adhesion promoting materials, stabilizers etc., certain types of PVC form plastisols which can be used as flexible hot setting adhesives with gap-filling and shock-absorbing properties. 2.3.37 chlorinated poly(vinyl chloride) poly(vinyl chloride) modified by the controlled chlorination of the polymer NOTE Chlorinated PVC is soluble in a wide range of organic solvents and used in adhesives for bonding plastics, particularly for bonding un-plasticized polyvinyl chloride. 2.3.38 polyacrylate; polyacrylates polymers and copolymers where at least one constitutional unit is derived from acrylic acid CH2 = CH - COOH or its esters CH2 = CH - COOR NOTE Polymers of this class find outlets as constituent of many types of solvent-borne adhesives and emulsion adhesives. 2.3.39 polymethacrylates polymers and copolymers where at least one constitutional unit is derived from methacrylic acid

CH2 = C(CH3) - COOH or its esters CH2 = C(CH3) - COOR 2.3.40 cyanoacrylate monomer special type of acrylic monomer esters having the general formula CH2 = C(CN) - COOR NOTE Cyanoacrylate monomers are capable of polymerizing rapidly in form of thin films and are used for certain fast-setting polymerizing adhesives.

the repeating linkage in the chain is urethane -NH-CO-O- NOTE Different polyurethane products are used for adhesives: hydroxyl polyurethanes for solvent-borne adhesives;

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...