EN 14307:2009

(Main)Thermal insulation products for building equipment and industrial installations - Factory made extruded polystyrene foam (XPS) products - Specification

Thermal insulation products for building equipment and industrial installations - Factory made extruded polystyrene foam (XPS) products - Specification

This European Standard specifies the requirements for factory made extruded polystyrene foam products which are used for the thermal insulation of building equipment and industrial installations with an operating temperature in the range of approximately - 180 °C to + 75 °C.

NOTE Below an operating temperature of - 50 °C, special tests regarding the suitability of the material in the intended application are advised (e.g. liquefaction of oxygen). Manufacturer's advice should be heeded in all cases.

The products are manufactured in the form of faced or unfaced boards, pipe sections, segments and prefabricated ware.

This standard describes product characteristics and includes procedures for testing, evaluation of conformity, marking and labelling.

Products covered by this standard are also used in prefabricated thermal insulating systems and composite panels; the performance of systems incorporating these products is not covered.

This standard does not specify the required level of a given property that shall be achieved by a product to demonstrate fitness for purpose in a particular application. The levels required for a given application can be found in regulations and invitations to tender.

Products with a declared thermal conductivity greater than 0,060 W/(m.K) at a mean temperature of 10 °C are not covered by this standard.

This standard does not cover products intended to be used for the insulation of the building structure nor for acoustical insulation.

Wärmedämmstoffe für die technische Gebäudeausrüstung und für betriebstechnische Anlagen in der Industrie - Werkmäßig hergestellte Produkte aus extrudiertem Polystyrolschaum (XPS) - Spezifikation

Diese Europäische Norm legt die Anforderungen für werkmäßig hergestellte Produkte aus extrudiertem Polystyrolschaum fest, die als Wärmedämmstoffe für die technische Gebäudeausrüstung und für betriebstechnische Anlagen in der Industrie im Temperaturbereich von etwa -180 °C bis +75 °C benutzt werden.

ANMERKUNG Unterhalb einer Betriebstemperatur von -50 °C sind besondere Prüfungen bezüglich der Eignung der Produkte für den beabsichtigten Anwendungsfall ratsam (z. B. Sauerstoffverflüssigung). In jedem Fall sollten die Empfehlungen des Herstellers beachtet werden.

Die Produkte werden mit oder ohne Kaschierung in der Form von Platten, Rohrschalen, Segmenten und vorgefertigten Produkten hergestellt.

Diese Europäische Norm beschreibt die Stoffeigenschaften und enthält die Prüfverfahren und Festlegungen für die Konformitätsbewertung, die Kennzeichnung und die Etikettierung.

In dieser Norm beschriebene Produkte werden auch in vorgefertigten Wärmedämmsystemen und Mehr¬schicht-Verbundplatten angewendet; die Eigenschaften von Systemen, in die diese Produkte integriert sind, werden nicht behandelt.

Diese Norm legt keine Leistungsstufen für eine vorgegebene Eigenschaft fest, die ein Produkt erreichen muss, um für einen bestimmten Anwendungsfall tauglich zu sein. Für bestimmte Anwendungen benötigte Stufen können Regelwerken oder Ausschreibungen entnommen werden.

Diese Norm gilt nicht für Produkte, deren Nennwert der Wärmeleitfähigkeit größer ist als 0,060 W/(m . K) bei 10 °C.

Diese Norm gilt nicht für Produkte, die zur Dämmung von Gebäuden bestimmt sind und Produkte, die zur Schalldämmung bestimmt sind.

Produits isolants thermiques pour l'équipement du bâtiment et les installations industrielles - Produits manufacturés en mousse de polystyrène extrudé (XPS) - Spécification

La présente norme spécifie les exigences relatives aux produits manufacturés en mousse de polystyrène extrudé, utilisés pour l’isolation thermique de l’équipement du bâtiment et des installations industrielles, dont la température de service est approximativement comprise entre - 180 °C et + 75 °C.

NOTE Pour une température de service inférieure à - 50 °C, des essais particuliers sont recommandés pour s'assurer de l'aptitude à l'emploi du produit dans l'application visée (p.ex. liquéfaction de l'oxygène). Il convient de se référer systématiquement aux conseils du fabricant.

Les produits sont manufacturés sous forme de panneaux, coquilles, segments et articles préfabriqués, avec ou sans parement.

La présente norme décrit les caractéristiques des produits et comporte des modes opératoires d’essai, d’évaluation de conformité, de marquage et d’étiquetage.

Les produits couverts par la présente norme sont également utilisés dans les systèmes d’isolation thermique préfabriqués et les panneaux composites ; les performances des systèmes incorporant ces produits ne sont pas traitées.

La présente norme ne spécifie pas le niveau requis pour une propriété donnée que doit posséder un produit pour démontrer son aptitude à une application particulière. Les niveaux requis pour une application donnée peuvent être trouvés dans les réglementations et les appels d’offre.

Les produits dont la conductivité thermique déclarée est supérieure à 0,060 W/(mK) à une température moyenne de 10 °C ne sont pas couverts par la présente norme.

La présente norme ne couvre ni les produits destinés à l’isolation des structures de bâtiment ni les produits d’isolation acoustique.

Toplotnoizolacijski proizvodi za opremo stavb in industrijske inštalacije - Proizvodi iz ekstrudiranega polistirena (XPS) - Specifikacija

Ta evropski standard določa zahteve za proizvode iz ekstrudiranega polistirena, ki se uporabljajo za toplotno izolacijo za opremo stavb in industrijske inštalacije z delovnim temperaturnim razponom med približno - 180°C in + 75°C. Proizvodi so narejeni v obliki površinsko obdelanih ali neobdelanih plošč, cevnih izolacij, segmentov in montažnih artiklov. Ta standard opisuje značilnosti proizvodov in vključuje postopke preskušanja, vrednotenja skladnosti, označevanja in uporabe nalepk.

General Information

- Status

- Withdrawn

- Publication Date

- 03-Nov-2009

- Withdrawal Date

- 29-Jan-2013

- Technical Committee

- CEN/TC 88 - Thermal insulating materials and products

- Drafting Committee

- CEN/TC 88/WG 10 - Building equipment and industrial installations

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 30-Jan-2013

- Completion Date

- 30-Jan-2013

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 824:2013 - Thermal insulating products for building applications - Determination of squareness - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Nonprofit organization that performs technical evaluations of building products.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

BBA (British Board of Agrément)

UK construction product certification.

Sponsored listings

Frequently Asked Questions

EN 14307:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Thermal insulation products for building equipment and industrial installations - Factory made extruded polystyrene foam (XPS) products - Specification". This standard covers: This European Standard specifies the requirements for factory made extruded polystyrene foam products which are used for the thermal insulation of building equipment and industrial installations with an operating temperature in the range of approximately - 180 °C to + 75 °C. NOTE Below an operating temperature of - 50 °C, special tests regarding the suitability of the material in the intended application are advised (e.g. liquefaction of oxygen). Manufacturer's advice should be heeded in all cases. The products are manufactured in the form of faced or unfaced boards, pipe sections, segments and prefabricated ware. This standard describes product characteristics and includes procedures for testing, evaluation of conformity, marking and labelling. Products covered by this standard are also used in prefabricated thermal insulating systems and composite panels; the performance of systems incorporating these products is not covered. This standard does not specify the required level of a given property that shall be achieved by a product to demonstrate fitness for purpose in a particular application. The levels required for a given application can be found in regulations and invitations to tender. Products with a declared thermal conductivity greater than 0,060 W/(m.K) at a mean temperature of 10 °C are not covered by this standard. This standard does not cover products intended to be used for the insulation of the building structure nor for acoustical insulation.

This European Standard specifies the requirements for factory made extruded polystyrene foam products which are used for the thermal insulation of building equipment and industrial installations with an operating temperature in the range of approximately - 180 °C to + 75 °C. NOTE Below an operating temperature of - 50 °C, special tests regarding the suitability of the material in the intended application are advised (e.g. liquefaction of oxygen). Manufacturer's advice should be heeded in all cases. The products are manufactured in the form of faced or unfaced boards, pipe sections, segments and prefabricated ware. This standard describes product characteristics and includes procedures for testing, evaluation of conformity, marking and labelling. Products covered by this standard are also used in prefabricated thermal insulating systems and composite panels; the performance of systems incorporating these products is not covered. This standard does not specify the required level of a given property that shall be achieved by a product to demonstrate fitness for purpose in a particular application. The levels required for a given application can be found in regulations and invitations to tender. Products with a declared thermal conductivity greater than 0,060 W/(m.K) at a mean temperature of 10 °C are not covered by this standard. This standard does not cover products intended to be used for the insulation of the building structure nor for acoustical insulation.

EN 14307:2009 is classified under the following ICS (International Classification for Standards) categories: 91.100.60 - Thermal and sound insulating materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14307:2009 has the following relationships with other standards: It is inter standard links to EN 14307:2009+A1:2013, EN ISO 29469:2022, EN ISO 29466:2022, EN 12086:2013, EN ISO 29767:2019, EN 1605:2013, EN 13172:2024, EN 15715:2009, EN ISO 29468:2022, EN 824:2013, EN 12667:2001, EN ISO 12624:2022, EN ISO 18097:2022, EN 1604:2013, EN ISO 11925-2:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14307:2009 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/103. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14307:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Toplotnoizolacijski proizvodi za opremo stavb in industrijske inštalacije - Proizvodi iz ekstrudiranega polistirena (XPS) - SpecifikacijaWärmedämmstoffe für die technische Gebäudeausrüstung und für betriebstechnische Anlagen in der Industrie - Werkmäßig hergestellte Produkte aus extrudiertem Polystyrolschaum (XPS) - SpezifikationProduits isolants thermiques pour l'équipement du bâtiment et les installations industrielles - Produits manufacturés en mousse de polystyrene extrudé (XPS) - SpécificationThermal insulation products for building equipment and industrial installations - Factory made extruded polystyrene foam (XPS) products - Specification91.100.60Thermal and sound insulating materialsICS:Ta slovenski standard je istoveten z:EN 14307:2009SIST EN 14307:2010en,fr,de01-april-2010SIST EN 14307:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14307

November 2009 ICS 91.100.60 English Version

Thermal insulation products for building equipment and industrial installations - Factory made extruded polystyrene foam (XPS) products - Specification

Produits isolants thermiques pour l'équipement du bâtiment et les installations industrielles - Produits manufacturés en mousse de polystyrène extrudé (XPS) - Spécification

Wärmedämmstoffe für die technische Gebäudeausrüstung und für betriebstechnische Anlagen in der Industrie - Werkmäßig hergestellte Produkte aus extrudiertem Polystyrolschaum (XPS) - Spezifikation This European Standard was approved by CEN on 29 September 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14307:2009: ESIST EN 14307:2010

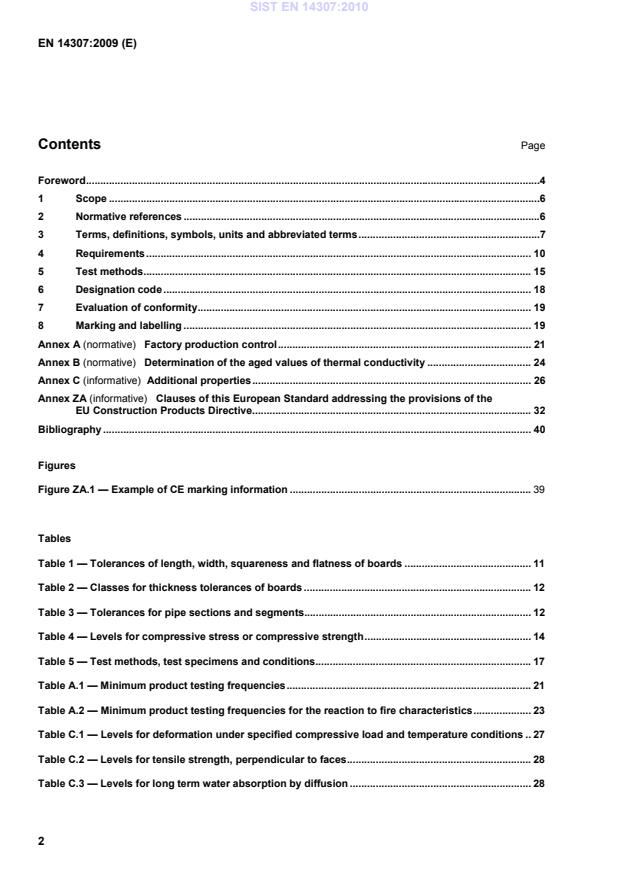

Factory production control . 21Annex B (normative)

Determination of the aged values of thermal conductivity . 24Annex C (informative)

Additional properties . 26Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive. 32Bibliography . 40 Figures

Figure ZA.1 — Example of CE marking information . 39

Tables Table 1 — Tolerances of length, width, squareness and flatness of boards . 11Table 2 — Classes for thickness tolerances of boards . 12Table 3 — Tolerances for pipe sections and segments . 12Table 4 — Levels for compressive stress or compressive strength . 14Table 5 — Test methods, test specimens and conditions. 17Table A.1 — Minimum product testing frequencies . 21Table A.2 — Minimum product testing frequencies for the reaction to fire characteristics . 23Table C.1 — Levels for deformation under specified compressive load and temperature conditions . 27Table C.2 — Levels for tensile strength, perpendicular to faces . 28Table C.3 — Levels for long term water absorption by diffusion . 28SIST EN 14307:2010

13823, Reaction to fire tests for building products — Building products excluding flooring exposed to the thermal attack by a single burning item EN 14706, Thermal insulating products for building equipment and industrial installations — Determination of maximum service temperature EN 15715:2009, Thermal insulating products — Instructions for mounting and fixing for reaction to fire testing — Factory made products EN ISO 8497, Thermal insulation — Determination of steady-state thermal transmission properties of thermal insulation for circular pipes (ISO 8497:1994) EN ISO 11925-2, Reaction to fire tests

— Ignitability of building products subjected to direct impingement of flame — Part 2: Single-flame source test (ISO 11925-2:2002) EN ISO 13787, Thermal insulation products for building equipment and industrial installations — Determination of declared thermal conductivity (ISO 13787:2003) 3 Terms, definitions, symbols, units and abbreviated terms 3.1 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1.1 Terms and definitions as given in EN ISO 9229:2007 3.1.1.1 extruded polystyrene foam rigid cellular plastic insulation material expanded and extruded with or without a skin from polystyrene or one of its co-polymers and that has a closed-cell structure 3.1.1.2 block (insulation) product generally of rectangular cross-section and with a thickness not significantly smaller than the width SIST EN 14307:2010

Boards may be supplied in tapered form. 3.1.1.4 lag

segment rigid or semi-rigid insulation product for application to large diameter cylindrical or spherical equipment 3.1.1.5 pipe section

section (insulation) product in the shape of a cylindrical annulus that may be split to facilitate application 3.1.1.6 production batch definite quantity of some commodity manufactured or produced under conditions that are presumed uniform 3.1.2 Additional terms and definitions 3.1.2.1 class combination of two levels of the same property between which the performance shall fall 3.1.2.2 level given value which is the upper or lower limit of a requirement

NOTE The level is given by the declared value of the characteristic concerned. 3.1.2.3 prefabricated ware pieces cut, abraded or otherwise formed from a board, a block or a billet of product, e.g. elbows, T-pieces, etc. 3.1.2.4 production line assemblage of equipment that produces products in a continuous process

3.1.2.5 production unit assemblage of equipment that produces products in a discontinuous process 3.2 Symbols, units and abbreviated terms 3.2.1 Symbols and units used in this standard b is the width mm DI is the inside diameter of pipe shell

mm d is the thickness mm dD is the declared thickness of the product mm ∆εb is the relative change in width mm SIST EN 14307:2010

stability under specified temperature and humidity conditions F is the symbol of the declared level of soluble fluoride ions MU is the symbol of the declared level for water vapour diffusion resistance factor NA is the symbol of the declared level of soluble sodium ions pH is the symbol of the declared level of the pH value SI is the symbol of the declared level of soluble silicate ions ST(+) is the symbol of the declared level for maximum service temperature ST(-) is the symbol of the declared level for minimum service temperature T is the symbol of the declared class for thickness tolerances WS is the symbol of the declared level for short term water absorption by partial immersion Z is the symbol of the declared value for water vapour resistance SIST EN 14307:2010

is Initial Type Test ML

is Manufacturer's Literature FPC is Factory Production Control SBI

is Single Burning Item 4 Requirements 4.1 General Product properties shall be assessed in accordance with Clause 5. To comply with this standard, products shall meet the requirements of 4.2, and the requirements of 4.3 as appropriate. NOTE 1 Information on additional properties is given in Annex C. One test result for a product property is the average of the measured values on the number of test specimens given in Table 5. NOTE 2 Apparent density is a useful parameter, among others, for the identification but it should not be used as a basis for the quality assessment of XPS products. Apparent density of XPS boards and billets, if voluntary declared by the manufacturer will be determined in accordance with EN 1602, Thermal insulating products for building applications – Determination of the apparent density. Apparent density of pipe sections, if voluntary declared by the manufacturer will be determined in accordance with EN 13470, Thermal insulating products for building equipment and industrial installations – Determination of the apparent density of preformed pipe insulation. Products manufactured from XPS can have the same thermal and mechanical properties at different densities. For this reason, product density is not quoted as requirement in this standard. 4.2 For all applications 4.2.1 Thermal conductivity For flat specimens, the thermal conductivity shall be based upon measurements carried out in accordance with EN 12667 or EN 12939 for thick products. For cylindrical specimens EN ISO 8497 shall be used as specified in 5.3.2.

In both cases, the thermal conductivity values shall be determined by the manufacturer and verified in accordance with EN ISO 13787, Subclause 5.3.1, and Annex B of this standard. They shall be declared by the manufacturer at reference mean temperatures covering the product service temperature range. The following conditions apply: the measured values shall be expressed with three significant figures; the declared conductivity curve shall be given as a limit curve, defined in EN ISO 13787; the value of the declared thermal conductivity, λD, shall be rounded upwards to the nearest

0,001 W/(m·K); SIST EN 14307:2010

0,000 1 W/(m.K) for λ values below 0,1 W/(m.K) and in 0,001 W/(m.K) for λ

values above 0,1 W/(m.K). This shall be used as a reference for the verification of the declaration. When thermal conductivity is declared as a table derived from the equation, rounding upwards to the next 0,001 W/(m.K) has to be done for the full range of the thermal conductivity. NOTE Determinations of the declared thermal conductivity of pipe sections, following EN ISO 8497, having joints in metering area, include the effects of these joints as defined in EN ISO 23993.

4.2.2 Dimensions and tolerances 4.2.2.1 Linear dimensions of boards The length, l, and width, b, shall be determined in accordance with EN 822, the squareness,Sb , in accordance with EN 824, and flatness, Smax, in accordance with EN 825. No test result shall deviate from the declared values by more than the tolerances given in Table 1. Table 1 — Tolerances of length, width, squareness and flatness of boards Length or width mm Tolerances Length or width

mm Squareness on length and width Sb mm/m Flatness Smax. mm Less than 1 000 1 000 to 2 000 > 2 000 to 4 000 > 4 000 ± 8 ± 10 ± 10 ± 10 5 5 5 5 7,0 14,0 28,0 35,0

4.2.2.2 Thickness of boards The thickness, d, shall be determined in accordance with EN 823. No test result shall deviate from the declared thickness, dD , by more than the tolerances given in Table 2 for the labelled class. SIST EN 14307:2010

4.2.2.3 Dimensions and tolerances of pipe sections and segments The length, l, thickness, d, inside diameter, Di, the deviation from the squareness, v, and the deviation from the linearity, L, of pipe sections and segments shall be tested in accordance with EN 13467. Products with a facing or natural skin shall be tested without removing them. No test result shall deviate from the declared values by more than the tolerances given in Table 3. Tolerances on prefabricated wares may be agreed between the parties. Table 3 — Tolerances for pipe sections and segments Length, l ± 10 mm Thickness, d a, ± 3 mm or ± 5% b Inside diameter, Di – 0 mm / + 4 mm or + 2 % b Squareness, v ± 6 mm or ± 2 % b Linearity, L ± 6 mm a

The tolerances only apply to unfaced products. The thickness of any facing exceeding 2 mm shall be indicated in the manufacturer’s literature. b

The greater value applies.

NOTE Smaller tolerances may be declared by a producer. 4.2.3 Dimensional stability Dimensional stability under specified temperature and humidity conditions shall be determined in accordance with EN 1604. The test shall be carried out after storage for 48 h at (23 ± 2) °C and (90 ± 5) % relative humidity. The relative changes in length, û0l, in width, û0b, and in thickness, û0d, shall not exceed 2 %. SIST EN 14307:2010

4.3.4 Compressive stress or compressive strength The compressive stress at 10 % deformation, σ10, or the compressive strength, σm, shall be determined in accordance with EN 826. No test result for either the compressive stress, σ10, or the compressive strength, σm, whichever is the greatest shall be less than the value given in Table 4, for the declared level. Table 4 — Levels for compressive stress or compressive strength Level Requirement kPa CS(10\Y) 100 ≥ 100 CS(10\Y) 150 ≥ 150 CS(10\Y) 200 ≥ 200 CS(10\Y) 250 ≥ 250 CS(10\Y) 300 ≥ 300 CS(10\Y) 400 ≥ 400 CS(10\Y) 500 ≥ 500 CS(10\Y) 600 ≥ 600 CS(10\Y) 700 ≥ 700 CS(10\Y) 800 ≥ 800 CS(10\Y) 1000 ≥ 1 000

4.3.5 Water vapour diffusion transmission properties Water vapour diffusion transmission properties shall be determined in accordance with EN 12086, and declared as the water vapour diffusion resistance factor, µ, for homogeneous products and as the water vapour resistance, Z, for faced or non-homogeneous products. No test result of µ shall be less than the declared level, MU, chosen from the following levels: 50; 80; 100; 150; 200; 250; 300. If Z is declared, no test result of Z shall be less than the declared value. Alternatively, for the declaration of water vapour transmission properties, the values quoted in EN ISO 10456 may be used. SIST EN 14307:2010

For pipe sections, segments and prefabricated wares fabricated from boards, the declared characteristics shall be determined on the boards from which they have been fabricated, except dimensions, squareness, flatness, pipe section linearity, thermal conductivity and reaction to fire.

EN 12939, provided it has been demonstrated that the results give safe (higher) values. The thermal conductivity shall be determined for the full temperature range of the product. For factory production control see Annex A. For XPS products for which ageing procedure applies, this procedure is described in Annex B. The results of ageing procedure performed on boards are also valid for pipe sections, segments and prefabricated wares fabricated from the same boards. For ITT, measurements of thermal conductivity made on two inside diameters of pipe sections at the greatest and smallest insulation thickness set of diameters are deemed to be representative of the total product range. For FPC, one dimension only is tested, i.e. one thickness of one diameter. NOTE Suitable sizes are e.g. 48 mm and 194 mm inside diameter. The guarded hot plate method EN 12667 or EN 12939 for thick products shall be deemed to be a suitable method for measurement of pipe sections having an inside diameter exceeding 500 mm. Flats products shall be prepared having the same thickness and density as the sections. If the guarded hot plate method is used the fact shall be stated in the test report. The thermal conductivity shall be determined directly at the measured thickness. If this is not possible it shall be determined by measurements on other thicknesses of the product providing that: the product is of similar chemical and physical characteristics and is produced on the same production line/unit; and it can be demonstrated that the thermal conductivity does not vary more than 2 % over the range of thicknesses where the calculation is applied. Where a product is manufactured in a range of thicknesses and the manufacturer chooses to characterise the entire range by declaring only one λ, he shall declare the highest λ of the range. If facings have been removed, this and the reason for the remove shall be stated in the test report. 5.3.3 Reaction to fire The tests shall be carried out in accordance with EN 13501-1. Rules for mounting and fixing are given in EN 15715:2009. Annex A of EN 15715:2009 gives tables for product and installation parameters for flat products and pipe insulation products as placed on the market. Installation parameters for standardized assemblies are only given for flat products. A conditioning period of six weeks applies before testing. SIST EN 14307:2010

Table 5 — Test methods, test specimens and conditions Dimensions in millimetres Clause Test method Test specimen dimensionsa Minimum

number of measurements to get one test result Specific conditions No. Title Flat / Board Cylindrical 4.2.1 Thermal conductivity EN 12667 or EN 12939 EN 12667 or EN 12939 for Di > 500 mm EN ISO 8497 for Di ≤ 500 See EN 12667, EN 12393 or EN ISO 8497 1

See Annex B 4.2.2.1 Board length and width EN 822

Full size 1

Board squareness EN 824

Full size 1 Where relevant the method to determine the squareness of the edge of boards with special edge treatment shall be agreed between parties. Board flatness EN 825

Full size 1

4.2.2.2 Board thickness EN 823

Full size 1 Load (250 ± 5) Pa 4.2.2.3 Pipe section dimensions and tolerances

EN 13467 Full size 1

4.2.3 Dimensional stability EN 1604

200 x 200 2 Condition specimens for 45 days. Test conditions: 23 °C, 90 % RH. 4.2.4 Reaction to fire ofthe product asplaced on themarket See EN 13501-1, EN ISO 11925-2 and EN 13823 See EN 15715:2009 4.3.2 Maximum service temperature EN 14706

Boards (100 × 100) × dd = 50 or 100

3 Temperature gradient

50 K/h maximum Condition specimen

45 days 4.3.4 Compressive stress or compressive strength EN 826

100 × 100

5 Condition specimen for

45 days, specimen shall be a cube when > 150 mm × 150 mm 150 × 150 3 SIST EN 14307:2010

number of measurements to get one test result Specific conditions No. Title Flat Cylindrical 4.3.5 Water vapour transmission properties EN 12086

See 6.1 of EN 12086 3 Conditions, Set A 4.3.6 Short term water absorption by partial immersion EN 1609

200 × 200 4 Method A 4.3.7 Trace quantities of water soluble ions and the pH-value EN 13468

3 7,5 g 4.3.8 Release of dangerous substances b

4.3.9 Continuous glowing combustion b

a

Full size product thickness, except for 4.2.3. b

Not yet available.

6 Designation code A designation code for the product shall be given by the manufacturer. The following shall be included except when there is no requirement for a property described in 4.3: The extruded polystyrene foam abbreviated term

XPS This EN standard number

EN 14307 Thickness tolerances

Ti Maximum service temperature

ST(+) Compressive stress or strength

CS(10\Y)i Water vapour diffusion resistance factor

MUi Short term water absorption by partial immersion

WSi

Trace quantities of water soluble chloride ions

Cli Level of the pH

pHi where “i” shall be used to indicate the relevant class or level. The designation code for an extruded polystyrene foam board is illustrated by the following example: XPS – EN 14307 – T2 – ST(+)(75) –

CS(10\Y)300 – MU(110) – WS(0,5) – CL(5) SIST EN 14307:2010

(normative)

Factory production control Table A.1 — Minimum product testing frequencies Subclause Minimum testing frequency a No. Title 4.2.1 Thermal conductivity 1 per 2 years

and indirect testing: Manufacturer’s methods and thermal conductivity of non sliced boards used to cut pipe sections:1 per 24 h where there are being production.

4.2.2.1 Dimensions and tolerances / board:

Length and width 1 per 2 h Squareness 1 per 4 h Flatness 1 per 8 h 4.2.2.2 Thickness / board 1 per 2 h 4.2.2.3 Dimensions and tolerances – pipe sections 1 per batch 4.2.3 Dimensional stability ITTb / 5 years 4.2.4 Reaction to fire of the product as placed to the market See Table A.2 4.3.2 Maximum service temperature ITTb / 5 years 4.3.4 Compressive stress or compressive strength/ board 1 per 24 h 4.3.5 Water vapour diffusion resistance factor ITTb / 5 years 4.3.6 Short term water absorption by partial immersion ITTb / 5 years 4.3.7 Trace quantities of water soluble ions and the pH- value ITTb / 5 years 4.3.8 Dangerous substances c 4.3.9 Continuous glowing combustion c

For mechanical properties, the testing frequencies given are independent of the change of product. In addition the manufacturer shall establish internal rules for process adjustments related to these properties when changing the product.

For initial type testing of long lasting tests, e.g. aged value of thermal resistance or conductivity, mechanical and freeze-thaw properties, test results of similar products produced at different plants or production line will be recognized until testing for a new plant/production line is completed. b ITT, see EN 13172. c Frequencies are not given.

and

EN ISO 11925-2 [Ignitability] Exposure = 30 s 1 per month or — — — — — — 1 per 2 years and indirect testing Manufacturer's method 1 per week Manufacturer's method 1 per week Manufacturer's method 1 per week 1 per week or

— — — — — —

1 per 2 years and indirect testing Manufacturer's method 1 per week Manufacturer's method 1 per week Manufacturer's method 1 per w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...