SIST EN 13141-4:2021

(Main)Ventilation for buildings - Performance testing of components/products for residential ventilation - Part 4: Aerodynamic, electrical power and acoustic performance of unidirectional ventilation units

Ventilation for buildings - Performance testing of components/products for residential ventilation - Part 4: Aerodynamic, electrical power and acoustic performance of unidirectional ventilation units

This document specifies aerodynamic, acoustic and electrical power performance test methods for unidirectional ventilation units used in residential ventilation systems.

This document is applicable to ventilation units:

- installed on a wall or in a window without any duct, A category;

- installed in the upstream of a duct, B category;

- installed in the downstream of a duct, C category;

- installed in a duct, or with duct connection upstream and downstream, D category;

- with one or several inlets/outlets;

- installed in a system with a heat pump for domestic hot water or water for cooling or heating;

- which can be used for supply or exhaust.

This document does not apply to:

- fan assisted cowls which are tested according to EN 13141-5;

- mechanical supply and exhaust units which are tested according to EN 13141-7:2021 or EN 13141 8:2021.

Lüftung von Gebäuden - Leistungsprüfungen von Bauteilen/Produkten für die Lüftung von Wohnungen - Teil 4: Aerodynamische, elektrische- und akustische Leistung von unidirektionalen Lüftungsgeräten

Dieses Dokument legt Verfahren zur Leistungsprüfung von in Wohnungs-Lüftungsanlagen eingesetzten unidirektionalen Lüftungsgeräten im Hinblick auf Aerodynamik, Akustik und elektrische Leistung fest.

Dieses Dokument ist auf Lüftungsgeräte anwendbar:

— die ohne Luftleitung an einer Wand oder in einem Fenster eingebaut sind (Kategorie A);

— die einer Luftleitung vorgeschaltet sind (Kategorie B);

— die im nachgeschalteten Teil einer Luftleitung eingebaut sind (Kategorie C);

— die in einer Luftleitung eingebaut sind oder denen eine Luftleitung vorgeschaltet und nachgeschaltet ist (Kategorie D);

— die eine oder mehrere Einström-/Ausströmöffnungen aufweisen;

— die in einem System mit einer Wärmepumpe für erwärmtes Trinkwasser bzw. für Kühl- oder Heizwasser eingebaut sind;

— die für Zuluft oder Fortluft verwendet werden können.

Dieses Dokument gilt nicht für:

— ventilatorunterstützte Fortluft-Hauben, die nach EN 13141 5 geprüft werden;

— mechanische Zuluft- und Ablufteinheiten, die nach EN 13141 7:2021 oder prEN 13141 8:2021 geprüft werden.

Ventilation des bâtiments - Essais des performances des composants/produits pour la ventilation des logements - Partie 4 : Performance aéraulique, de puissance électrique et acoustique des unités de ventilation simple flux

Le présent document spécifie les méthodes d’essai de performance aérauliques, acoustiques et électriques pour les unités de ventilation unidirectionnelle utilisées dans les systèmes de ventilation résidentielle.

Le présent document s'applique aux unités de ventilation :

- installées sur un mur ou une fenêtre sans aucun conduit, catégorie A ;

- installées en amont d'un conduit, catégorie B ;

- installées en aval d'un conduit, catégorie C ;

- installées dans un conduit, ou avec des raccordements de conduits en amont et en aval, catégorie D ;

- avec une ou plusieurs entrées/sorties ;

- installées dans un système doté d'une pompe à chaleur pour la production d'eau chaude sanitaire ou d'eau pour le refroidissement ou le chauffage ;

- qui peuvent être utilisées pour l'alimentation ou l'extraction.

Le présent document ne s'applique pas aux :

- extracteurs statiques assistés de ventilateurs soumis à essai selon l’EN 13141-5 ;

- unités de soufflage et d'extraction mécaniques qui sont soumises à essai selon l’EN 13141-7:2021 ou le prEN 13141-8:2021.

Prezračevanje stavb - Preskušanje lastnosti sestavnih delov/izdelkov za prezračevanje stanovanjskih stavb - 4. del: Aerodinamične, električne in akustične lastnosti enosmernih prezračevalnih enot

General Information

- Status

- Published

- Public Enquiry End Date

- 04-Nov-2018

- Publication Date

- 13-May-2021

- Technical Committee

- OGS - Heating for buildings

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 10-May-2021

- Due Date

- 15-Jul-2021

- Completion Date

- 14-May-2021

Relations

- Effective Date

- 01-Jun-2021

Overview

EN 13141-4:2021 (CEN) is the European test standard for the aerodynamic, electrical power and acoustic performance of unidirectional ventilation units used in residential ventilation systems. It specifies laboratory test methods to quantify airflow/pressure performance, leakages, electrical power consumption and acoustic emissions for units used as supply or exhaust devices - whether non‑ducted, ducted or connected upstream/downstream of ducting.

Key topics and requirements

Scope and applicability

- Covers unidirectional ventilation units installed: non‑ducted on a wall/window (A), upstream of a duct (B), downstream of a duct (C), or in a duct/with both upstream and downstream connections (D).

- Applies to units with one or several inlets/outlets and units integrated with heat-pump domestic systems.

- Excludes fan‑assisted cowls (see EN 13141-5) and mechanical supply/exhaust units tested to EN 13141-7 / EN 13141-8.

Aerodynamic performance

- Tests for external leakages, air flow vs. pressure curves, air flow sensitivity, and indoor/outdoor airtightness.

- Normative procedures to determine maximum and reference air volume flow and reference pressure.

Energy / electrical power

- Measurement of electrical power input at reference and maximum airflow.

- Includes operable and standby modes; part‑load energy efficiency assessment is provided as an informative annex.

Acoustic performance

- Methods for noise radiated through unit casing, radiated sound power in indoor/outdoor spaces, in‑duct sound power, and airborne sound insulation for non‑ducted units.

- References to other acoustic standards and updated acoustic test arrangements.

Documentation

- Standardized test report format and required product specification outputs. Normative annexes cover connection boxes and evaluation examples.

Practical applications & target users

- Manufacturers - to verify and declare aerodynamic, electrical and acoustic performance for product development and CE/national compliance.

- Independent test laboratories - to perform consistent, repeatable performance testing for certification and attestation.

- HVAC designers & consultants - to compare unit performance for system design, acoustic planning and ventilation sizing.

- Regulators & building certifiers - to assess compliance with residential ventilation requirements and building codes.

- Installers / specifiers - to select units appropriate for ducting configuration, noise limits and energy budgets.

Related standards

- EN 13141 series (other parts cover cowls, supply/exhaust units, system packages)

- EN 13141-5 (fan assisted cowls)

- EN 13141-7 / EN 13141-8 (mechanical supply and exhaust units)

EN 13141-4:2021 supersedes EN 13141-4:2011 and incorporates expanded aerodynamic tests (including external leakages), reorganized acoustic requirements, and clarified energy assessment procedures - making it the current reference for testing unidirectional residential ventilation units.

Frequently Asked Questions

SIST EN 13141-4:2021 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Ventilation for buildings - Performance testing of components/products for residential ventilation - Part 4: Aerodynamic, electrical power and acoustic performance of unidirectional ventilation units". This standard covers: This document specifies aerodynamic, acoustic and electrical power performance test methods for unidirectional ventilation units used in residential ventilation systems. This document is applicable to ventilation units: - installed on a wall or in a window without any duct, A category; - installed in the upstream of a duct, B category; - installed in the downstream of a duct, C category; - installed in a duct, or with duct connection upstream and downstream, D category; - with one or several inlets/outlets; - installed in a system with a heat pump for domestic hot water or water for cooling or heating; - which can be used for supply or exhaust. This document does not apply to: - fan assisted cowls which are tested according to EN 13141-5; - mechanical supply and exhaust units which are tested according to EN 13141-7:2021 or EN 13141 8:2021.

This document specifies aerodynamic, acoustic and electrical power performance test methods for unidirectional ventilation units used in residential ventilation systems. This document is applicable to ventilation units: - installed on a wall or in a window without any duct, A category; - installed in the upstream of a duct, B category; - installed in the downstream of a duct, C category; - installed in a duct, or with duct connection upstream and downstream, D category; - with one or several inlets/outlets; - installed in a system with a heat pump for domestic hot water or water for cooling or heating; - which can be used for supply or exhaust. This document does not apply to: - fan assisted cowls which are tested according to EN 13141-5; - mechanical supply and exhaust units which are tested according to EN 13141-7:2021 or EN 13141 8:2021.

SIST EN 13141-4:2021 is classified under the following ICS (International Classification for Standards) categories: 91.140.30 - Ventilation and air-conditioning systems. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13141-4:2021 has the following relationships with other standards: It is inter standard links to SIST EN 13141-4:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13141-4:2021 is associated with the following European legislation: EU Directives/Regulations: TP053. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13141-4:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2021

Nadomešča:

SIST EN 13141-4:2012

Prezračevanje stavb - Preskušanje lastnosti sestavnih delov/izdelkov za

prezračevanje stanovanjskih stavb - 4. del: Aerodinamične, električne in akustične

lastnosti enosmernih prezračevalnih enot

Ventilation for buildings - Performance testing of components/products for residential

ventilation - Part 4: Aerodynamic, electrical power and acoustic performance of

unidirectional ventilation units

Lüftung von Gebäuden - Leistungsprüfungen von Bauteilen/Produkten für die Lüftung

von Wohnungen - Teil 4: Aerodynamische, elektrische- und akustische Leistung von

unidirektionalen Lüftungsgeräten

Ventilation des bâtiments - Essais des performances des composants/produits pour la

ventilation des logements - Partie 4 : Performance aéraulique, de puissance électrique et

acoustique des unités de ventilation simple flux

Ta slovenski standard je istoveten z: EN 13141-4:2021

ICS:

91.140.30 Prezračevalni in klimatski Ventilation and air-

sistemi conditioning systems

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13141-4

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2021

EUROPÄISCHE NORM

ICS 91.140.30 Supersedes EN 13141-4:2011

English Version

Ventilation for buildings - Performance testing of

components/products for residential ventilation - Part 4:

Aerodynamic, electrical power and acoustic performance

of unidirectional ventilation units

Ventilation des bâtiments - Essais de performance des Lüftung von Gebäuden - Leistungsprüfungen von

composants/produits pour la ventilation des Bauteilen/Produkten für die Lüftung von Wohnungen -

logements - Partie 4 : Performance aéraulique, de Teil 4: Aerodynamische, elektrische und akustische

puissance électrique et acoustique des unités de Leistung von unidirektionalen Lüftungsgeräten

ventilation simple flux

This European Standard was approved by CEN on 25 January 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13141-4:2021 E

worldwide for CEN national Members.

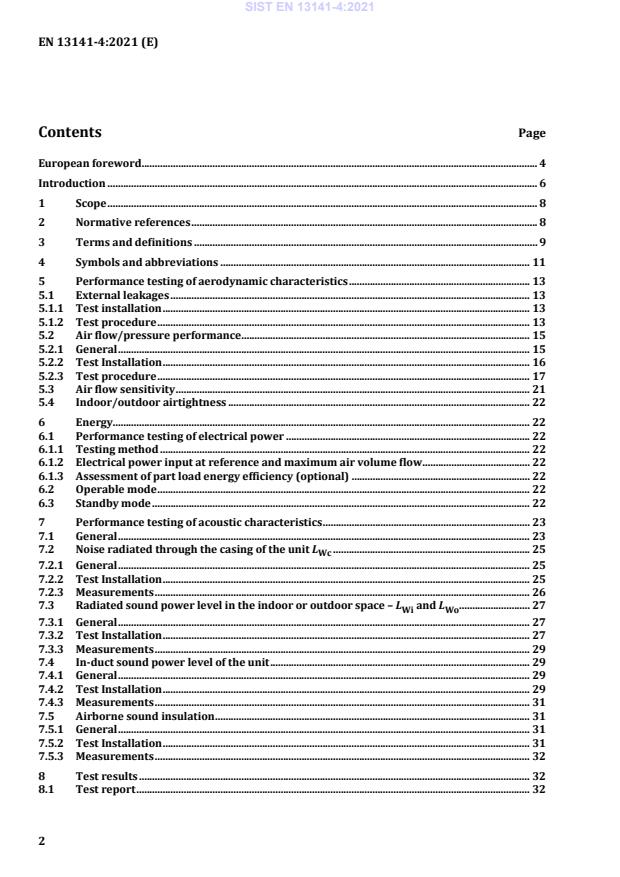

Contents Page

European foreword . 4

Introduction . 6

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 9

4 Symbols and abbreviations . 11

5 Performance testing of aerodynamic characteristics . 13

5.1 External leakages . 13

5.1.1 Test installation . 13

5.1.2 Test procedure . 13

5.2 Air flow/pressure performance . 15

5.2.1 General . 15

5.2.2 Test Installation . 16

5.2.3 Test procedure . 17

5.3 Air flow sensitivity . 21

5.4 Indoor/outdoor airtightness . 22

6 Energy. 22

6.1 Performance testing of electrical power . 22

6.1.1 Testing method . 22

6.1.2 Electrical power input at reference and maximum air volume flow . 22

6.1.3 Assessment of part load energy efficiency (optional) . 22

6.2 Operable mode . 22

6.3 Standby mode . 22

7 Performance testing of acoustic characteristics . 23

7.1 General . 23

7.2 Noise radiated through the casing of the unit L . 25

Wc

7.2.1 General . 25

7.2.2 Test Installation . 25

7.2.3 Measurements . 26

7.3 Radiated sound power level in the indoor or outdoor space – L and L . 27

Wi Wo

7.3.1 General . 27

7.3.2 Test Installation . 27

7.3.3 Measurements . 29

7.4 In-duct sound power level of the unit . 29

7.4.1 General . 29

7.4.2 Test Installation . 29

7.4.3 Measurements . 31

7.5 Airborne sound insulation . 31

7.5.1 General . 31

7.5.2 Test Installation . 31

7.5.3 Measurements . 32

8 Test results . 32

8.1 Test report . 32

8.2 Product specifications. 32

8.3 Leakages . 33

8.4 Air flow/pressure curve . 33

8.5 Air flow sensitivity for non-ducted ventilation units . 33

8.6 Indoor/outdoor airtightness for non-ducted ventilation units . 33

8.7 Energy . 33

8.8 Acoustic characteristics . 33

Annex A (normative) Connection box(es) . 36

Annex B (normative) Evaluation of maximum air volume flow and pressure . 38

Annex C (normative) Examples for the evaluation of reference pressure . 39

Annex D (informative) Assessment of part load energy efficiency . 40

Bibliography . 44

European foreword

This document (EN 13141-4:2021) has been prepared by Technical Committee CEN/TC 156 “Ventilation

for buildings”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2021, and conflicting national standards shall

be withdrawn at the latest by October 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 13141-4:2011.

In addition to a number of editorial revisions, the following main changes have been made with respect

to EN 13141-4:2011:

— the scope has been changed, and concerns now all unidirectional ventilation units (ducted or non-

ducted units, supply or exhaust units), excluding cowls with fans (see EN 13141-5);

— the terms and definitions have been updated in accordance with the parameters used in the

document;

— performance testing of aerodynamic characteristics clause includes new testing of external leakages;

— description of the connection box has been moved in a normative annex;

— determination of the maximum and reference air flow has been added;

— assessment of part load energy efficiency has been moved in an informative annex;

— tests of air flow sensitivity and indoor/outdoor airtightness have been added;

— in the energy part, the characterization of SPI has been added;

— the whole acoustic clause has been reorganized and references to acoustic standard updated;

— testing of noise radiated by the casing for ducted units has been added;

— testing of radiated sound power in the indoor or outdoor space and the airborne sound insulation of

non-ducted units have been added;

— the safety clause has been deleted;

— a new clause dealing with all test results has been created.

A list of all parts in the EN 13141 series, published under the general title Ventilation for buildings —

Performance testing of components/products for residential ventilation can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document specifies methods for the performance testing of components used in residential

ventilation systems to establish the performance characteristics as identified in EN 13142:2021 [1].

This document incorporates many references to other European and International Standards, especially

on characteristics other than the aerodynamic characteristics, for instance on acoustic characteristics.

In most cases, some additional tests or some additional conditions are given for the specific use in

residential ventilation systems.

This document can be used for the following applications:

— laboratory testing;

— attestation purposes.

The position of this document in the field of standards for the mechanical building services is shown in

Figure 1.

Mechanical Building Services

Control systems Ventilation and air conditioning systems Heating systems

Air terminal Air handling Mechanical and natural Design criteria for the System

Ductwork Installation

devices units residential ventilation indoor environment performance

Components/products for

Performance testing and

residential ventilation Performance testing of Simplified calculation Design and dimensioning for

installation checks for

Required and optional components/products for methods for residential residential ventilation

residential ventilation

performance residential ventilation ventilation systems systems

systems

characteristics

Part 1: Externally and internally mounted air transfer devices

Part 2: Exhaust and supply air terminal devices

Part 3: Range hoods for residential use without fan

Part 4: Aerodynamic, electrical power and acoustic performance of unidirectional

ventilation units

Part 5: Cowls, assisted cowls and roof outlet terminal devices

Part 6: Exhaust ventilation system packages used in a single dwelling

Part 7: Performance testing of ducted mechanical supply and exhaust ventilation units

(including heat recovery)

Part 8: Performance testing of non-ducted mechanical supply and exhaust ventilation

units (including heat recovery)

Part 9: Externally mounted humidity controlled air transfer device

Part 10: Humidity controlled extract air terminal device

Part 11: Supply ventilation units

Figure 1 — Position of EN 13141-4 in the field of the mechanical building services

1 Scope

This document specifies aerodynamic, acoustic and electrical power performance test methods for

unidirectional ventilation units used in residential ventilation systems.

This document is applicable to ventilation units:

— installed on a wall or in a window without any duct, A category;

— installed in the upstream of a duct, B category;

— installed in the downstream of a duct, C category;

— installed in a duct, or with duct connection upstream and downstream, D category;

— with one or several inlets/outlets;

— installed in a system with a heat pump for domestic hot water or water for cooling or heating;

— which can be used for supply or exhaust.

This document does not apply to:

— fan assisted cowls which are tested according to EN 13141-5;

— mechanical supply and exhaust units which are tested according to EN 13141-7:2021 or

prEN 13141-8:2021.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12792, Ventilation for buildings — Symbols, terminology and graphical symbols

EN ISO 717-1, Acoustics — Rating of sound insulation in buildings and of building elements — Part 1:

Airborne sound insulation (ISO 717-1)

EN ISO 5801:2017, Industrial fans — Performance testing using standardized airways (ISO 5801:2017)

EN ISO 5135, Acoustics — Determination of sound power levels of noise from air-terminal devices, air-

terminal units, dampers and valves by measurement in a reverberation room (ISO 5135)

EN ISO 5136, Acoustics — Determination of sound power radiated into a duct by fans and other air-moving

devices — In-duct method (ISO 5136)

EN ISO 10140-1, Acoustics — Laboratory measurement of sound insulation of building elements — Part 1:

Application rules for specific products (ISO 10140-1)

EN ISO 10140-2, Acoustics — Laboratory measurement of sound insulation of building elements — Part 2:

Measurement of airborne sound insulation (ISO 10140-2)

EN ISO 10140-5, Acoustics — Laboratory measurement of sound insulation of building elements — Part 5:

Requirements for test facilities and equipment (ISO 10140-5)

EN ISO 16890 (all parts), Air filters for general ventilation (ISO 16890 (all parts))

ISO 13347-2, Industrial fans — Determination of fan sound power levels under standardized laboratory

conditions — Part 2: Reverberant room method

ISO 13347-3, Industrial fans — Determination of fan sound power levels under standardized laboratory

conditions — Part 3: Enveloping surface methods

ISO 13347-4, Industrial fans — Determination of fan sound power levels under standardized laboratory

conditions — Part 4: Sound intensity method

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 12792, EN ISO 5801:2017 and

the following apply.

ISO and IEC maintain terminological databases for the use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

unit pressure

p

u

pressure increase induced by the ventilation unit given as difference between the total pressures at the

unit outlet and the unit inlet

Note 1 to entry: In case of equal cross-section areas of the inlet and outlet, the total pressure difference is equal

to the static pressure difference.

Note 2 to entry: The parameter p for a ventilation unit is defined as the parameter p described in EN ISO 5801

u f

for a stand alone fan.

3.2

unit static pressure

p

us

pressure increase induced by the ventilation unit given as difference between the static pressure at the

unit outlet and the total pressure at the unit inlet

Note 1 to entry: The parameter p for a ventilation unit is defined as the parameter p described in

us fs

EN ISO 5801 for a stand alone fan.

3.3

external static pressure difference

p

s,ext

pressure increase induced by the ventilation unit given as difference between the static pressures at the

unit outlet and the unit inlet

Note 1 to entry: The external static pressure difference, p , is used to determine the maximum air volume flow

s,ext

and the reference air volume flow.

3.4

maximum air volume flow at zero pressure

q

vmax,0

measured air volume flow corresponding to the maximum achievable fan curve setting of the unit, at 0 Pa

unit static pressure, p

us

3.5

pressure at maximum air volume flow

p

qvmax

external static pressure difference, p , corresponding to the maximum air volume flow

s,ext

3.6

declared maximum air volume flow

q

vmax,d

declared maximum air volume flow of the unit

3.7

maximum air volume flow

q

vmax

air volume flow corresponding to the maximum achievable fan curve setting of the unit at the pressure

p , either declared or measured

qvmax

Note 1 to entry: To determine maximum air volume flow, see 5.2.3.3, Table 5.

3.8

reference air volume flow

q

vref

air volume flow corresponding to the reference pressure

Note 1 to entry: To determine reference air volume flow, see 5.2.3.4, Table 6.

3.9

reference pressure

p

ref

external static pressure difference, p , corresponding to the reference air volume flow

s,ext

3.10

ventilation unit

casing incorporating at least a fan, and that may include duct connections, filters, coils, electrical heating,

or any other air treatment component

3.11

external leakage

q

ve

leakage to or from the air flowing inside the casing of the ventilation unit to or from the surrounding air

3.12

air flow sensitivity

v

maximum relative deviation of the maximum air volume flow q of a non-ducted ventilation unit due

vmax

to a static pressure difference of + 20 Pa and – 20 Pa

3.13

indoor/outdoor airtightness

q

vio

maximum of air volume flow through a non-ducted ventilation unit at static pressure difference of − 20 Pa

and + 20 Pa corresponding to the setting when the fans are “OFF” and all additional shutters are closed

Note 1 to entry: Indoor/outdoor airtightness is not the external leakage.

3.14

non-ducted ventilation units

ventilation unit intended to be used without external ductwork (Cat. A)

3.15

electrical power input

P

E

average overall electrical power input to the equipment within a defined interval of time for standard air

conditions obtained from:

— the power input of the fans;

— controller(s), compressor(s), safety devices of the equipment(s) excluding additional electrical

heating devices not used for defrosting

3.16

electrical power input at the reference air volume flow

P

E,ref

electrical power input at reference air volume flow, q , and reference pressure, p

vref ref

3.17

maximum electrical power input

P

E,max

electrical power input at maximum air volume flow, q , and its corresponding pressure, p

vmax qvmax

4 Symbols and abbreviations

For the purpose of this document, the symbols and abbreviations given in EN 12792 and those listed in

Table 1 apply.

Table 1 — Symbols

Symbol Designation Unit

D airborne sound insulation dB

n,e

D (Ctr) global airborne sound insulation index dB

n,e,w

L sound power level dB

W

L A-weighted sound power level dB(A)

WA

L casing emitted sound dB

Wc

Symbol Designation Unit

L inside emitted sound dB

Wi

L outside emitted sound dB

Wo

p unit pressure Pa

u

p unit static pressure Pa

us

p pressure at maximum air volume flow Pa

qvmax

p reference pressure Pa

ref

p external static pressure difference Pa

s,ext

P electrical power input W

E

P maximum electrical power input W

E,max

P electrical power input at the reference air volume flow W

E,ref

q external leakage 3 a

ve m /s

q indoor/outdoor airtightness 3 a

vio m /s

q maximum air volume flow 3 a

vmax m /s

q maximum air volume flow at zero pressure 3 a

vmax,0 m /s

q declared maximum air volume flow 3 a

vmax,d m /s

q reference air volume flow 3 a

vref m /s

v air flow sensitivity %

— test voltage V

ρ density of ambient air 3

kg/m

a 3

l/s or m /h can be used for measurement of air flow but it shall be verified that all parameters are

consistent with the chosen unit.

5 Performance testing of aerodynamic characteristics

5.1 External leakages

5.1.1 Test installation

The external leakage test shall be carried out by connecting an adjustable fan to the exhaust/supply air

side of the tested ventilation unit as shown in Figure 2.

During the pressurization tests for external leakages, the fan in the unit under test shall be switched off.

The static pressure tapping is located on a blanking off plate and the tap is connected to a pressure

measuring instrument. The external leakage flow rates at over and/or under pressure in the casing are

established with suitable air flow measuring equipment.

The accuracy of the measured values shall be kept within ± 5 % for the flow rates and ± 3 % for the static

pressures of the casing.

Key

1 adjustable fan

2 air flow measuring equipment

3 ventilation unit

4 static pressure measuring equipment

Figure 2 — External leakage test configuration

5.1.2 Test procedure

5.1.2.1 General

External leakages of ventilation units may impact ventilation efficiency of the system if the extract/supply

air flow of the building is not the intended one. The impact will depend on ventilation unit category

according to EN ISO 5801, the location of the unit, inside or outside the building, and the location of the

air flow measurement device during the air flow/pressure test, according to 5.2. Table 2 and Table 3 refer

cases where external leakages shall be reported, and cases where external leakages measurements are

optional because external leakages don't affect building air flows and are already taken into account in

electrical power consumption measurements.

Table 2 — External Leakage for exhaust ventilation unit

External leakage

Category of the

Unit inside the building Unit outside the building

exhaust ventilation

unit, according to

a

Air flow measurement location

EN ISO 5801

Extract side Exhaust side Extract side Exhaust side

Category A (non- Leakage at Leakage at

Optional Optional

ducted) + 250 Pa + 250 Pa

Category B (ducted Leakage at Leakage at

Optional Optional

outlet) + 250 Pa + 250 Pa

Category C (ducted Leakage at Leakage at Leakage at

Optional

inlet) + 250 Pa - 250 Pa - 250 Pa

Category D (both

Leakage Leakage Leakage

ducted inlet and Optional

at ± 250 Pa at ± 250 Pa at ± 250 Pa

outlet)

a

Air flow measurement device location during the air flow/pressure test according to 5.2.

Table 3 — External Leakage for supply ventilation unit

External leakage

Category of the

Unit inside the building Unit outside the building

supply ventilation

unit, according to

Air flow measurement location

EN ISO 5801

Supply side Outdoor side Supply side Outdoor side

Category A (non- Leakage at Leakage at

Optional Optional

ducted) - 250 Pa + 250 Pa

Category B (ducted Leakage at Leakage at Leakage at

Optional

outlet) - 250 Pa + 250 Pa + 250 Pa

Category C (ducted Leakage at Leakage at

Optional Optional

inlet) - 250 Pa + 250 Pa

Category D (both

Leakage Leakage Leakage

ducted inlet and Optional

at ± 250 Pa at ± 250 Pa at ± 250 Pa

outlet)

5.1.2.2 Specificity for units with ducted inlet and/or outlet (Category B, C or D)

At least three different measurement points evenly distributed shall be made between 100 Pa and 300 Pa,

and reported by means of a curve. The external leakage air volume flow rate at 250 Pa shall not be a result

of an extrapolation.

5.1.2.3 Specificity for units with free inlet and outlet (Category A)

For non-ducted units, the external leakage air volume flow, q , shall be measured at over and under-

ve

pressure of 50 Pa. The external leakage at 250 Pa shall then be calculated according to Formula (1).

0,65

qq=

ve,250 ve,50

(1)

5.1.2.4 Result

The external leakage air volume flow q at over and/or under pressure of 250 Pa, shall be reported as

ve

such and also compared to the reference air volume flow q of the unit as a percentage.

vref

5.2 Air flow/pressure performance

5.2.1 General

The test shall be carried out in accordance with EN ISO 5801 and in regards with the specifications given

in 5.2.2 and 5.2.3.

In order to convert the measured values of unit pressure, p , unit static pressure, p , external static

u us

pressure difference, p and electrical power input, P , to the standard conditions (20 °C, 101 325 Pa)

s,ext E

the measured values shall be corrected by the density according to:

— Formula (2), correction of the unit pressure, p ;

u

— Formula (3), correction of the unit static pressure, p ;

us

— Formula (4), correction of the external static pressure difference, p ;

s,ext

— Formula (5), correction of the electrical power input, P .

E

ρ

st

pp⋅

u u,T

e

ρ

T

e

(2)

ρ

st

p p⋅

us us,T

e

ρ

T

e

(3)

ρ

st

pp ⋅

s,ext s,ext,T

e

ρ

T

e

(4)

ρ

st

PP⋅

E E,T

e

ρ

T

e

(5)

=

=

=

=

where

p is the unit pressure under test conditions measured at the density ρ ;

u,T Te

e

p is the unit static pressure under test conditions measured at the density ρ ;

us,T Te

e

p

is the external static pressure difference of the unit under test conditions measured at the

s,ext,T

e

density ρ ;

Te

P is the electrical power input under test conditions measured at the density ρ ;

E,Te Te

ρ

is the density of the ambient air at the test enclosure;

Te

ρ 3

st is the density of 1,2 kg/m corresponding to the air under standard conditions (20 °C and

101 325 Pa).

The simplified calculation method for fans supplying a pressure lower than 2 000 Pa with a Mach number

of less than 0,15 according to EN ISO 5801 can be applied.

5.2.2 Test Installation

5.2.2.1 General

A ventilation unit is specified to supply a given air flow rate to an installation. In order to choose the

appropriate unit, it is necessary to know its aerodynamic performance characteristics, given as the

volume flow rate as a function of unit pressure p or unit static pressure p .

u us

These characteristics are strongly influenced by upstream flow conditions (velocity profile, possible

presence of a swirl and wind). Downstream conditions do not usually affect the unit operation, but the

nature of flow downstream from the unit, especially the swirl, can have an effect on losses in the circuit

and should be taken into account during installation design.

Four categories of installations are defined in EN ISO 5801:

— category A: free inlet and free outlet;

— category B: free inlet and ducted outlet;

— category C: ducted inlet and free outlet;

— category D: ducted inlet and outlet.

For each category, EN ISO 5801 defines the installation in the immediate proximity of the unit, as well as

the position of the pressure measurement.

The test shall be performed according to the intended use of the unit:

— for an extract unit, air flow measurement shall be located at the extract side;

— for a supply unit, air flow measurement shall be located at the supply side.

If the measure can’t be done at the correct side, then:

— if the external leakage, q ≤ 7 % q , then the air volume flow can be measured on the other side

ve vref

of the unit (because the unit can be considered as almost airtight);

— if the external leakage, q > 7 % q , then a correction shall be applied to the results in order to

ve vref

take into account leakages, using the function determined by the three points measurement of

external leakage.

Unidirectional ventilation units which are able to change automatically their direction (alternating units),

can be tested and rated according to this document, for each air directions, if switches ensure that the

test can be proceed with one direction only. For such unit, each air directions shall be tested.

5.2.2.2 Specificity for exhaust or supply ventilation units with multi-inlets or multi-outlets

This type of unit corresponds to a fan mounted in a casing having several inlets or outlets (all ducted) and

only one outlet or inlet which discharges into the open air or into a duct.

These units shall be tested using a category B, C or D installation, but due to the presence of more than

one inlet or outlet, each inlet or outlet shall be connected to the test installation according to the

category B or C. Where for practical reasons (insufficient distance between inlet or outlet ducts placed on

the same side of casing) it is not possible to place two test installations side by side, then apply Annex A.

The test shall be carried out for the maximum configuration: all the inlets or outlets connected.

In case of products that include self-regulating dampers in spigot, the dampers shall be removed in order

to assess the product only. If it is not possible, then the dampers shall be switched in a fixed maximum

opening position (this position can be more or less opened, depending of the technology of regulation).

The presence of the self-regulation dampers during the test and the methodology to fix them in a

maximum opening position shall be described in the test report.

5.2.2.3 Specificity for roof exhaust fans

This type of ventilation unit, normally installed at the downstream end of a duct, shall be tested using a

category C or D installation.

Ventilation units with gravity controlled shutters shall be tested under their correct mounting conditions.

If the discharge can be adjusted (i.e. between vertical and radial), then extreme discharge configurations

shall be tested.

5.2.3 Test procedure

5.2.3.1 General

Where a single value is assigned by the manufacturer as rated voltage, this shall be the test voltage. Where

a voltage range is assigned to the product by the manufacturer that includes 1 ∼ 230 V / 3 ∼ 400 V, the

test voltage shall be 230 VAC.

This voltage shall be maintained to ± 1 % throughout the testing.

The performance characteristics of a unit shall be determined according to the following procedure for

the relevant settings:

a) choose the appropriate installation category according to the intended use of the unit;

b) choose a method for flow rate measurement taking into account in particular the relatively low

pressure supplied by these devices (the use of an auxiliary fan might be necessary);

c) proceed to the test according to EN ISO 5801 using simplified calculation method for fans supplying

a pressure lower than 2 000 Pa with a Mach number of less than 0,15.

5.2.3.2 Determination of external static pressure difference

The relevant pressure parameter determining the maximum air volume flow and reference air volume

flow is the external static pressure difference between unit outlet and unit inlet. It can be measured

directly or derived from the measured unit static pressure curve p considering the installation category

us

according to Table 4.

Table 4 — Determination of the external static pressure difference

External static pressure difference

p

s,ext

Determina- Ducted unit

Non-ducted unit

tion

a a a

Cat A

Cat B Cat C Cat D

Direct

−p p

p −p pp−

3 4

4 3 43

or

measurement

Calculated

based on unit

ρ ρ

2 2

st st

p p p +⋅ v p +⋅ v

us us us 3 us 3

static pressure

2 2

p

us

Calculated

ρ ρ

2 22

st st

based on unit

— p − ⋅ v — p − ⋅ vv−

( )

u4 u 4 3

2 2

pressure p

u

Key

p : Static pressure at inlet side (pressure difference against ambient pressure, in Pa)

p : Static pressure at outlet side (pressure difference against ambient pressure, in Pa)

ρ : Density of 1,2 kg/m corresponding to the air under standard conditions (20 °C, 101 325 Pa)

st

v: Average calculated air flow velocity in the duct, in m/s

a

Duct equipped with pressure tap shall have same section as ventilation unit inlet or outlet (the one

connected). For other section, correction shall applied according to EN ISO 5801.

5.2.3.3 Determination of maximum air volume flow and corresponding pressure

The maximum air volume flow and pressure shall be evaluated on the basis of the measured maximum

achievable air volume flow/pressure curve of the unit according to Table 5 (for example diagrams, see

Annex B).

The maximum air volume flow q shall either be measured or determined by an interpolation

vmax

between the measured points.

Table 5 — Maximum air volume flow and pressure

p

s,ext

p q

Type of unit

qvmax vmax

at 0,7 · q

vmax,0

q

Non-ducted unit (Cat A) — 0 Pa

vmax,0

q at 100 Pa

≥ 100 Pa 100 Pa

v

Ducted unit (Cat B, C, D)

p at 0,7 · q 0,7 · q

< 100 Pa

s,ext vmax,0 vmax,0

NOTE q is limited to 70 % of the maximum air volume flow at zero pressure, q , as minimum in

vmax vmax,0

order to ensure that ducted units are assessed within their characteristic operating range.

If the declared maximum air volume flow q is equal to the measured maximum air volume flow,

vmax,d

in a tolerance of ± MAX(3 m /h ; 10 % q ), then the declared maximum air volume flow shall be used

vmax

as the maximum air volume flow. If not, the measured maximum air volume flow shall be used instead.

5.2.3.4 Determination of reference air volume flow and reference pressure

The reference pressure and reference air volume flow shall be determined from the maximum air volume

flow and corresponding pressure (see 5.2.3.3) and on the basis of measured air volume flow/pressure

curves of the unit, according to Table 6 (for example diagrams, see Annex B). The reference pressure,

p , shall be either measured or determined by an interpolation between the measured points for the

ref

same setting which intends to meet the reference air flow.

Table 6 — Reference air volume flow and reference pressure

Type of unit p p q

s,ext ref vref

at 0,7 · q

vmax,0

Non-ducted unit (CAT A) — 0 Pa a

≥ 0,7 · q

qvmax

≥ 100 Pa c b

≥ 50 Pa 0,7 · q

qvmax

Ducted unit (CAT B, C, D)

< 100 Pa d b

≥ 0,5 · p 0,7 · q

qvmax qvmax

a

The reference air volume flow corresponds to 0,7 · q . If this air flow is not achievable with

vmax

the available settings, then the reference air volume flow corresponds to the air flow at zero pressure

at the next setting that exceeds 0,7 · q (for example diagrams, see Annex C).

vmax

b

For units with constant air flow control, if the reference air volume flow is not achievable at p

ref

with the available settings, then the reference air volume flow corresponds to the air flow at p at

ref

the next setting that exceeds 0,7 · q .

vmax

c

The reference pressure corresponds to 50 Pa. If the reference pressure is not achievable with the

available settings, then the reference pressure corresponds to the pressure at q at the next setting

vref

that exceeds 50 Pa (for example diagrams, see Annex C).

d

The reference pressure corresponds to 0,5 · p . If the reference pressure is not achievable

qvmax

with the available settings, then the reference pressure corresponds to the pressure at q at the

vref

next setting that exceeds 0,5 · p (example diagrams, see Annex C).

qvmax

5.2.3.5 Measurement of air flow/pressure curves for ducted ventilation units

The air volume flow/pressure curves shall be determined according to 5.2.1, 5.2.2 and 5.2.3.1.

Installation categories B, C or D shall be chosen according to the intended use.

A minimum of 3 curves per unit shall be measured and reported for minimum setting, maximum setting

and an intermediate setting. If the ventilation unit has less than 3 settings, then all curves shall be

measured.

A minimum of 8 test points equally distributed shall be measured and reported on each curve.

5.2.3.6 Measurement of air flow for non-ducted ventilation units

The air volume flow shall be determined according to 5.2.2.1, 5.2.3.1 and Figure 3.

Installation category A shall be applied.

Measurements shall be carried out with the maximum fan speed setting at least for the following settings

of external static pressure difference, p :

s,ext

— + 20 Pa;

— - 20 Pa;

— 0 Pa (q ). This point shall not be an interpolation between the two measurements at + 20 Pa and

vmax

− 20 Pa.

For ventilation units with 2 or more settings, the following set points on external static pressure

difference p shall be measured in addition:

s,ext

— 0 Pa with minimum fan speed (q );

vmin

— 0 Pa with an intermediate fan speed (q ) if available, and if possible at 0,7 · q .

vin vmax

Key

p external static pressure difference

s,ext

q maximum air volume flow

vmax

q minimum air volume flow

vmin

q air volume flow at intermediate fan speed setting

vin

dq / dq absolute deviation of maximum air volume flow due to over/under pressure of 20 Pa

v,over v,u

nder

Figure 3 — Air flow measurements (installation category A)

5.3 Air flow sensitiv

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...