EN 16185-2:2014

(Main)Railway applications - Braking systems of multiple unit trains - Part 2: Test methods

Railway applications - Braking systems of multiple unit trains - Part 2: Test methods

This European Standard specifies test methods and acceptance criteria for a brake system for use in self propelling thermal and electric trains, in the following document called EMU/DMU, operating on routes of the European conventional rail system network.

This European Standard is applicable to:

- all new vehicles designs of self-propelling thermal and electric trains;

- all major overhauls of the EMU/DMU if they involve redesigning or extensive alteration to the brake system of the vehicle concerned.

This European Standard does not cover:

- locomotive hauled trains which are specified by EN 14198;

- mass transit rolling stock which is specified by EN 13452 (all parts);

- high speed trains being operated at speeds greater than 200 km/h which are specified by EN 15734-1 and tests in EN 15734-2.

The functional testing requirements set out in this European Standard assume the vehicles are fitted with brake system architecture as defined in prEN 16185 1.

The braking performance obtained by applying the tests defined in this European Standard can be used to assess compliance with the required braking performance as defined in prEN 16185-1.

Bahnanwendungen - Bremssysteme für Triebzüge - Teil 2: Prüfverfahren

Diese Europäische Norm legt Prüfverfahren und Annahmekriterien für ein Bremssystem für den Einsatz in selbstfahrenden Zügen mit thermischem oder elektrischem Antrieb — in diesem Dokument als EMU/DMU bezeichnet — fest, die auf Strecken des konventionellen transeuropäischen Eisenbahnsystems betrieben werden.

Diese Europäische Norm gilt für:

alle neuen Fahrzeugbauarten von selbstfahrenden Zügen mit thermischem oder elektrischem Antrieb;

alle größeren Grundüberholungen der EMUs/DMUs, wenn diese Neukonstruktionen oder umfassende Änderungen des Bremssystems des betreffenden Fahrzeugs mit einschließen.

Diese Europäische Norm gilt nicht für:

lokbespannte Züge, die in EN 14198 festgelegt sind;

Fahrzeuge des öffentlichen Nahverkehrs, die in EN 13452 (alle Teile) festgelegt sind;

Hochgeschwindigkeitszüge, die mit Geschwindigkeiten über 200 km/h betrieben werden, in EN 15734 1 festgelegt sind und nach EN 15734 2 geprüft werden.

Die in dieser Europäischen Norm enthaltenen Anforderungen an die Funktionsprüfungen gehen von der Annahme aus, dass die Architektur des Bremssystems der Fahrzeuge prEN 16185-1 entspricht.

Die mit den Prüfungen nach dieser Europäischen Norm erhaltene Bremsleistung kann zur Beurteilung der Einhaltung der erforderlichen Bremsleistung nach prEN 16185 1 genutzt werden.

Applications ferroviaires - Systèmes de freinage pour trains automoteurs - Partie 2 : Méthodes d'essai

La présente norme européenne décrit les méthodes d'essai ainsi que les critères d'acceptation relatifs à un système de freinage destiné à être utilisé sur les trains thermiques et électriques automoteurs, qui par la suite dans le document sont désignés par unités EMU/DMU (unité multiple électrique/unité multiple diesel), circulant sur des lignes du réseau de systèmes ferroviaires classiques européens.

La présente norme est applicable à :

- toutes les nouvelles conceptions de véhicules des trains automoteurs thermiques et électriques ;

- toutes les grandes révisions des unités EMU/DMU si celles-ci entraînent une nouvelle conception ou une transformation majeure du système de freinage du véhicule concerné.

La présente norme ne couvre pas :

- les trains tractés par locomotive qui sont spécifiés par l'EN 14198 ;

- les matériels roulants des transports publics et suburbains qui sont spécifiés par l'EN 13452(toutes les parties) ;

- les trains à grande vitesse circulant à des vitesses supérieures à 200km/h qui sont spécifiées par l’EN 15734-2.

Les exigences d'essai fonctionnel établies dans le présent document supposent que les véhicules sont équipés d'une architecture du système de freinage comme défini dans le prEN 16185-1.

Les performances de freinage obtenues par l'application des essais définis dans le présent document peuvent être utilisées pour évaluer la conformité aux performances de freinage requises comme défini dans le prEN 16185-1.

Železniške naprave - Zavorni sistemi motornih vlakov - 2. del: Preskusne metode

Ta standard opisuje preskusne metode in kriterije sprejemljivosti za delovanje zavornega sistema za uporabo pri motornih vlakih, ki vozijo po vseevropskem železniškem sistemu za visoke hitrosti.

Ta standard vključuje:

– vsa nova vozila motornih vlakov;

– vse nove konstrukcije obstoječih tipov vozil;

– vse večje obnove zgoraj navedenih vozil, če obnova vključuje preoblikovanje ali obsežno spremembo zavornega sistema zadevnega vozila.

General Information

- Status

- Withdrawn

- Publication Date

- 16-Dec-2014

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 3/WG 47 - Braking

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 03-Jun-2020

- Completion Date

- 03-Jun-2020

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 15734-2:2010 - Railway applications - Braking systems of high speed trains - Part 2: Test methods - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 24-Jan-2018

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish national quality association.

Sponsored listings

Frequently Asked Questions

EN 16185-2:2014 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Braking systems of multiple unit trains - Part 2: Test methods". This standard covers: This European Standard specifies test methods and acceptance criteria for a brake system for use in self propelling thermal and electric trains, in the following document called EMU/DMU, operating on routes of the European conventional rail system network. This European Standard is applicable to: - all new vehicles designs of self-propelling thermal and electric trains; - all major overhauls of the EMU/DMU if they involve redesigning or extensive alteration to the brake system of the vehicle concerned. This European Standard does not cover: - locomotive hauled trains which are specified by EN 14198; - mass transit rolling stock which is specified by EN 13452 (all parts); - high speed trains being operated at speeds greater than 200 km/h which are specified by EN 15734-1 and tests in EN 15734-2. The functional testing requirements set out in this European Standard assume the vehicles are fitted with brake system architecture as defined in prEN 16185 1. The braking performance obtained by applying the tests defined in this European Standard can be used to assess compliance with the required braking performance as defined in prEN 16185-1.

This European Standard specifies test methods and acceptance criteria for a brake system for use in self propelling thermal and electric trains, in the following document called EMU/DMU, operating on routes of the European conventional rail system network. This European Standard is applicable to: - all new vehicles designs of self-propelling thermal and electric trains; - all major overhauls of the EMU/DMU if they involve redesigning or extensive alteration to the brake system of the vehicle concerned. This European Standard does not cover: - locomotive hauled trains which are specified by EN 14198; - mass transit rolling stock which is specified by EN 13452 (all parts); - high speed trains being operated at speeds greater than 200 km/h which are specified by EN 15734-1 and tests in EN 15734-2. The functional testing requirements set out in this European Standard assume the vehicles are fitted with brake system architecture as defined in prEN 16185 1. The braking performance obtained by applying the tests defined in this European Standard can be used to assess compliance with the required braking performance as defined in prEN 16185-1.

EN 16185-2:2014 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16185-2:2014 has the following relationships with other standards: It is inter standard links to EN 16185-2:2014+A1:2019, EN 15595:2018+A1:2023, EN 14478:2005, EN 15663:2017+A2:2024, EN 15734-2:2010, EN 16185-1:2014, EN 16334-1:2014+A1:2022, EN 16207:2014, EN 16185-2:2014/prA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16185-2:2014 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC; Standardization Mandates: M/334, M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16185-2:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Železniške naprave - Zavorni sistemi motornih vlakov - 2. del: Preskusne metodeBahnanwendungen - Bremssysteme für Triebzüge - Teil 2: PrüfverfahrenApplications ferroviaires - Systèmes de freinage pour trains automoteurs - Partie 2: Exigences et définitionsRailway applications - Braking systems of multiple unit trains - Part 2: Test methods45.040Materiali in deli za železniško tehnikoMaterials and components for railway engineeringICS:Ta slovenski standard je istoveten z:EN 16185-2:2014SIST EN 16185-2:2015en,fr,de01-marec-2015SIST EN 16185-2:2015SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16185-2

December 2014 ICS 45.040 English Version

Railway applications - Braking systems of multiple unit trains - Part 2: Test methods

Applications ferroviaires - Systèmes de freinage pour trains automoteurs - Partie 2 : Méthodes d'essai

Bahnanwendungen - Bremssysteme für Triebzüge - Teil 2: Prüfverfahren This European Standard was approved by CEN on 13 October 2014.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 16185-2:2014 ESIST EN 16185-2:2015

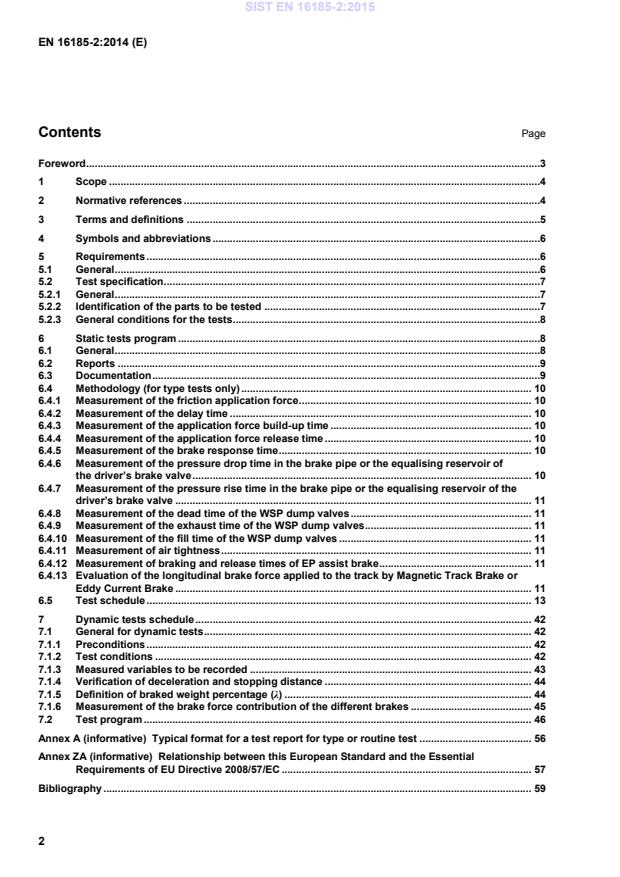

Typical format for a test report for type or routine test . 56 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2008/57/EC . 57 Bibliography . 59

1) This document is currently impacted by the corrigendum EN 15734-2:2010/AC:2012. SIST EN 16185-2:2015

Key 1 Level 1: Vehicle 2 Level 2: Single Multiple Unit 3 Level 3: Coupled Multiple Units NOTE This document addresses testing requirements to Level 2 and Level 3. Testing at Level 1 is not defined and is the responsibility of the manufacturer. Figure 1 — Type test and routine test levels 5.2 Test specification 5.2.1 General The test specification shall be agreed and shall include the following: — the test schedule; — the functions to be tested; — the conditions for the tests; — the procedures for carrying out the tests; — the test equipment to be used; — the pass/fail criteria. 5.2.2 Identification of the parts to be tested A list of the items of brake system equipment (and any associated equipment) to be tested shall be included, along with an appropriately detailed technical description of the items concerned and their intended interactions of relevance to the testing. It is recommended that pneumatic, electrical and/or electronic schematic diagrams and graphs etc. are also included as an aid to those carrying out the tests specified. SIST EN 16185-2:2015

Load condition according to 5.2.3.3 Level 2: Single Multiple Unit Level 3: Coupled Multiple Units Nr. Description of test procedure Type test Routine test Test condition Type test Test condition

Tare Normal Crush Measurement Test/ check Measurement Test/ check stat dyn Measurement Test/ check stat dyn 6.5.1 Basic inspection 6.5.1.1 The conformity of the vehicle data shall be verified concerning: — vehicle type and number; — vehicle inscriptions. — — — — X — X X — — X X — 6.5.1.2 The conformity of the pneumatic, mechanical, electric and electronic brake equipment regarding types, quantity and marking with the documentation shall be verified. — — — — X — X X — — X X — 6.5.1.3 A record of the serial number and configuration of the main brake system components (e.g. brake panels) should be compiled if not already part of existing documentation. — — — — X — X X — — X X — 6.5.1.4 The conformity of all the equipments/components in accordance with the applicable European Standard shall be verified. — — — — X — — X — — — — — 6.5.1.5 The correct connection (mechanical, pneumatic, electrical) of each Level 1 part of the unit shall be verified. — — — — X — X X — — — X — SIST EN 16185-2:2015

Load condition according to 5.2.3.3 Level 2: Single Multiple Unit Level 3: Coupled Multiple Units Nr. Description of test procedure Type test Routine test Test condition Type test Test condition

Tare Normal Crush Measurement Test/ check Measurement Test/ check stat dyn Measurement Test/ check stat dyn 6.5.1.6 The continuity of the main brake pipe shall be verified. — — — — X — X X — — X X — 6.5.1.7 The continuity of the main reservoir pipe shall be verified. — — — — X — X X — — X X — 6.5.1.8 The continuity of the safety loop shall be verified. — — — — X — X X — — X X — 6.5.1.9 The installation of the brake system parts in the vehicle (e.g. installation position, movements and clearances of flexible connections, etc. and safety features as defined in the installation documentation) shall be verified. — — — — X — — X — — — — — 6.5.2 General safety related assessment of the installation 6.5.2.1 The conformity of the position of the friction materials regarding brake discs and/or running surface of the wheel with the installation documentation shall be verified. — — — — X — — X — — — — — 6.5.3 Air tightness 6.5.3.1 The air tightness of the main reservoir system with the ancillary components connected shall be verified. All ancillary devices supplied by the main reservoir pipe shall be connected but not in operation; it is permissible to isolate devices that have a permanent — — — X — — X X — X — X — SIST EN 16185-2:2015

Load condition according to 5.2.3.3 Level 2: Single Multiple Unit Level 3: Coupled Multiple Units Nr. Description of test procedure Type test Routine test Test condition Type test Test condition

Tare Normal Crush Measurement Test/ check Measurement Test/ check stat dyn Measurement Test/ check stat dyn air consumption e.g. precision pressure regulators etc. Air supply shall be deactivated. A brake release command shall be propagated along the brake command line (brake pipe pressure shall be 5 bar for trains equipped with air brake pipe). Hoses are to be isolated by dummy couplings and end cocks shall be opened. The main reservoir pipe shall be filled at nominal pressure. Acceptable pressure reduction shall be 0 bar to 0,2 bar in 3 min. 6.5.3.2 For trains equipped with a brake pipe, its air tightness shall be verified. All devices supplied by the brake pipe shall be connected: brake panels, emergency valves, driver’s brake valve, etc. The brake pipe shall be filled to normal release pressure and stabilized. The driver’s brake valve shall be in neutral position. The connection between main reservoir pipe and auxiliary reservoirs shall be isolated. Hoses are to be isolated by dummy couplings and end cocks shall be opened. Acceptable pressure reduction shall be 0 bar to 0,1 bar in — — — X — — X X — X — X — SIST EN 16185-2:2015

Load condition according to 5.2.3.3 Level 2: Single Multiple Unit Level 3: Coupled Multiple Units Nr. Description of test procedure Type test Routine test Test condition Type test Test condition

Tare Normal Crush Measurement Test/ check Measurement Test/ check stat dyn Measurement Test/ check stat dyn 3 min from 5 bar. 6.5.3.3 For systems incorporating a brake pipe and brake distributors, the stability of the brake command shall be tested. A service brake shall be applied. Acceptable pressure variation in brake cylinder shall be less than 0,2 bar in 10 min. This test shall be carried out in normal train operation as well as in back-up and in rescue configurations of the brake system. — — — X — — X X — — — — — 6.5.3.4 The air tightness of the brake cylinders shall be verified. With the auxiliary reservoir isolated from the main reservoir pipe, an emergency brake shall be applied. The brake cylinder pressure shall be constant with a tolerance of +0,2 bar and −0,15 bar, acceptable auxiliary reservoir pressure reduction shall be less than 0,2 bar in 10 min. — — — X — — X X — — — — — 6.5.4 Gauging and pressure gauges 6.5.4.1 The functionality of the gauges on the desk (MRP, BP if present, BC, etc.) shall be verified with regard to: — the correct connection; — the correct marking; — — — — X — X X — — — — — SIST EN 16185-2:2015

Load condition according to 5.2.3.3 Level 2: Single Multiple Unit Level 3: Coupled Multiple Units Nr. Description of test procedure Type test Routine test Test condition Type test Test condition

Tare Normal Crush Measurement Test/ check Measurement Test/ check stat dyn Measurement Test/ check stat dyn — the precision in accordance with EN 16185–1. 6.5.5 Auxiliary reservoir 6.5.5.1 The functionality of filling of the auxiliary reservoirs from the main reservoir pipe shall be verified. The test shall be performed with the air compressor of the unit in accordance with 5.2.3.2. — — — X — — — X — — — — — 6.5.5.2 The functionality of filling of the auxiliary reservoirs from the brake pipe alone (if present) shall be verified. The test shall be done with the air compressor of the unit in accordance with 5.2.3.2. — — — X — — — X — — — — — 6.5.6 Local control of the brake/distributor valve 6.5.6.1 For direct EP-Brakes verify that it acts in accordance with the design specification (including trans-characteristic, hysteresis, sensitivity, repeatability, application and release times). — — — X — X — X — X — X — 6.5.6.2 If the train is fitted with a brake pipe, it is to be verified that the total volume associated with each distributor is less than 25 l. This verification can be carried out on documentation. — — — — X — — X — — — — — SIST EN 16185-2:2015

Load condition according to 5.2.3.3 Level 2: Single Multiple Unit Level 3: Coupled Multiple Units Nr. Description of test procedure Type test Routine test Test condition Type test Test condition

Tare Normal Crush Measurement Test/ check Measurement Test/ check stat dyn Measurement Test/ check stat dyn 6.5.6.3 It is to be verified that it is possible to properly release the control pressures of the direct and indirect brakes. — — — X — — — X — — — — — 6.5.7 Main relay valve 6.5.7.1 It is to be verified: — whether the brake cylinder pressure(s) for an emergency application conforms/conform to the design specification (tolerances +0,2 bar; −0,15 bar); — for double stage relay valves (if any) the change-over between the “high” and “low” pressure stage and whether the brake cylinder pressures for both stages comply with the specification (tolerances +0,2 bar; −0,15 bar). X — — X — X — X — — — — — 6.5.7.2 The brake cylinders pressure shall be gradually controllable and proportional to the brake demand signal. The brake cylinder pressure values, for both the increasing and decreasing brake demand, and sensitivity shall be measured and verified against the design specifications. It shall be possible to obtain a number of different brake cylinder pressure levels in X — — X — — — X — — — — — SIST EN 16185-2:2015

Load condition according to 5.2.3.3 Level 2: Single Multiple Unit Level 3: Coupled Multiple Units Nr. Description of test procedure Type test Routine test Test condition Type test Test condition

Tare Normal Crush Measurement Test/ check Measurement Test/ check stat dyn Measurement Test/ check stat dyn accordance with EN 16185–1. 6.5.7.3 The relationship between the actual weight of the vehicle (obtained after weighing) and the load pressure shall be verified against the design specifications. NOTE This test can be done, for normal and crush loads, when loading the train for dynamic tests. X X X X — — — X — — — — — 6.5.7.4 For the variable load relay valves, the pairs load pressure/brake cylinder pressures for the three load states tare, normal, crush shall be verified for an emergency brake application and for an appropriate number of brake demand levels. The low pressure point is measured by increasing the pressure and high pressure point is measured by decreasing the pressure. NOTE Load pressures can be simulated. X X X X — X — X — — — — — 6.5.7.5 Tests listed in 6.5.7.1, 6.5.7.2, 6.5.7.3 and 6.5.7.4 shall be repeated one time with the main air supply isolated during the test (refilling reservoirs before starting the next test). X X X X — — — X — — — — — SIST EN 16185-2:2015

Load condition according to 5.2.3.3 Level 2: Single Multiple Unit Level 3: Coupled Multiple Units Nr. Description of test procedure Type test Routine test Test condition Type test Test condition

Tare Normal Crush Measurement Test/ check Measurement Test/ check stat dyn Measurement Test/ check stat dyn In addition, for variable load relay valves, the brake cylinders pressure shall be verified for load pressures below the tare value. 6.5.7.6 The application and release times at the brake cylinders during full service and emergency brake applications shall be measured. If the brake system is fitted with a variable load relay valve the measurement shall be performed for two load states. NOTE Load pressures can be simulated. X — X X — X — X — — — — — 6.5.8 Emergency brake 6.5.8.1 The functionality of all emergency control devices fitted on the vehicle, including the emergency position of the brake controllers, shall be verified. The reaction of the systems fitted on the vehicle to the emergency brake commands, shall also be verified. In the above tests, both electrical and pneumatic (if applicable) paths shall be verified. — — — — X — X X — — — — — 6.5.8.2 The forces to move any manual device into the emergency position shall be varified — — — — X — — X — — — — — SIST EN 16185-2:2015

Load condition according to 5.2.3.3 Level 2: Single Multiple Unit Level 3: Coupled Multiple Units Nr. Description of test procedure Type test Routine test Test condition Type test Test condition

Tare Normal Crush Measurement Test/ check Measurement Test/ check stat dyn Measurement Test/ check stat dyn according to the design specifications. 6.5.8.3 The functionality of all emergency control devices fitted on the vehicle, including the emergency position of the brake controllers, shall be verified: — the brake delay and brake force build-up times of the friction brake shall be measured during application and release as close as is possible to a brake cylinder, at the front and far end of the unit; — the brake delay time (the brake force application and release times are established during dynamic testing) of the electro-dynamic brake (if applicable) shall be measured for all vehicles; — the brake application and release times of the Magnetic Track Brake and of the Eddy Current Brake (if applicable) shall be measured. This test shall be performed for all paths (electrical, pneumatic) that propagates the emergency brake command along the MU. — — — X — X — X — X — X — 6.5.9 Driver’s brake valve/brake controller 6.5.9.1 The integration of the driver’s — — — — X — X X — — — — — SIST EN 16185-2:2015

Load condition according to 5.2.3.3 Level 2: Single Multiple Unit Level 3: Coupled Multiple Units Nr. Description of test procedure Type test Routine test Test condition Type test Test condition

Tare Normal Crush Measurement Test/ check Measurement Test/ check stat dyn Measurement Test/ check stat dyn brake valve/brake controller in the vehicle system shall be verified, e.g. electric wiring, pneumatic connection. 6.5.9.2 Verify the correct transmission of the brake release command along the M.U. If the train is equipped with a brake pipe, verify the pressure with the brake pipe control system(s) in running position. Target value shall be set value ± 0,1 bar and for UIC systems shall be: 5,0 bar ± 0,1 bar. — — — X — X — X — X — X — 6.5.9.3 For trains equipped with a brake pipe, the minimum brake step (pressure drop for first brake step) shall be verified. The brake pipe pressure shall be measured. Target value shall be: pressure reduction 0,4 bar + 0,1 bar. — — — X — X — X — X — X — 6.5.9.4 The output of the brake controller (driver’s brake valve for trains equipped with a brake pipe) shall be gradually controllable and proportional to the driver’s brake demand. The output values, for both the increasing and decreasing brake demand, and sensitivity shall be measured and verified against the design specifications. — — — X — X — X — X — X — SIST EN 16185-2:2015

Load condition according to 5.2.3.3 Level 2: Single Multiple Unit Level 3: Coupled Multiple Units Nr. Description of test procedure Type test Routine test Test condition Type test Test condition

Tare Normal Crush Measurement Test/ check Measurement Test/ check stat dyn Measurement Test/ check stat dyn It shall be possible to obtain a number of different brake demand levels (brake pipe pressure levels for trains equipped with a brake pipe) in accordance with EN 16185–1. 6.5.9.5 For trains equipped with a brake pipe, it is to be verified whether the other functions of the driver’s brake valve/brake controller conforms to the design specification (e.g. neutral valve, overcharging…). — — — X — X — X — — — — — 6.5.9.6 The inexhaustibility of the brake shall be proven by testing as follows. With the air supply isolated, the specified emergency brake cylinder pressure in full loaded conditions shall be obtained while carrying out the number of consecutive emergency brake application and release cycles specified in EN 16185–1. The local brake control systems shall not release the brake unless enough pressure is contained in the auxiliary reservoirs. This pressure level shall be indicated in the design specifications and is the same that allows the previous test. NOTE Load pressures can be simulated. — — X — X — — X — — — — — SIST EN 16185-2:2015

Load condition according to 5.2.3.3 Level 2: Single Multiple Unit Level 3: Coupled Multiple Units Nr. Description of test procedure Type test Routine test Test condition Type test Test condition

Tare Normal Crush Measurement Test/ check Measurement Test/ check stat dyn Measurement Test/ check stat dyn 6.5.9.7 The supply cut-off function (if available) or the brake pipe cut-off shall be verified with regard to the following: — the light up of the “neutral” light indicator if available; — the emergency position of the driver’s brake valves/brake controllers activates the supply cutoff function or the brake pipe cut-off; — the brake application in service position if available; — the brakes cannot be released. For trains not equipped with a brake pipe, in the emergency position of the brake controller, a brake command shall be propagated along the brake command line and no brake release command can be propagated by any mean. — — — — X — X X — — — — — 6.5.9.8 The isolation functionality of the driver’s brake valve/brake controller shall be verified. — — — — X — X X — — — — — SIST EN 16185-2:2015

Load condition according to 5.2.3.3 Level 2: Single Multiple Unit Level 3: Coupled Multiple Units Nr. Description of test procedure Type test Routine test Test condition Type test Test condition

Tare Normal Crush Measurement Test/ check Measurement Test/ check stat dyn Measurement Test/ check stat dyn 6.5.9.9 For trains equipped with a brake pipe, the automatic function shall be verified in accordance with EN 15734-2:2010, Annex B2). The test shall be performed using the compressors on the unit. — — — — X — X X — — — — —

2) This document is currently impacted by the co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...