EN 15734-2:2010

(Main)Railway applications - Braking systems of high speed trains - Part 2: Test methods

Railway applications - Braking systems of high speed trains - Part 2: Test methods

This European Standard specifies test methods and acceptance criteria for a brake system for use in high speed trains as described in the TSI Rolling Stock, operating on routes of the trans-European high-speed rail system.

The tests defined in this document have the purpose of verifying that the braking performance and functions of the train's brake system comply at least with the respective requirements of EN 15734-1.

This European Standard is applicable to:

- new vehicles of high speed trains;

- new constructions of existing vehicle types;

- major overhauls of the above-mentioned vehicles if they involve redesigning or extensive alteration to the brake system of the vehicle concerned.

The functional testing requirements set out in this document assume the vehicles are fitted with a brake system architecture that follows the UIC air brake pipe control principles.

High Speed Rolling Stock can be fitted with alternative brake system architectures that do not employ brake pipe control. In these cases equivalent testing requirements will need to be generated to test the functional performance of brake system fitted.

Bahnanwendungen - Bremssysteme für Hochgeschwindigkeitszüge - Teil 2: Prüfverfahren

Diese Europäische Norm legt die Prüfverfahren und Zulassungsbedingungen eines Bremssystems für den Einsatz in Hochgeschwindigkeitszügen fest, wie sie in der TSI Hochgeschwindigkeitsfahrzeuge beschrieben sind und welche auf Strecken des Transeuropäischen Hochgeschwindigkeitsnetzes betrieben werden.

Die in dieser Norm definierten Prüfungen haben den Zweck festzustellen, dass die Leistung und Funktion des Zugbremssystems mindestens die entsprechenden Anforderungen der EN 15734-1 erfüllt.

Diese Norm gilt für:

- alle neuen Fahrzeugbauarten von Hochgeschwindigkeitszügen;

- alle Nachbauten bereits bestehender Fahrzeugbaureihen;

- alle größeren Grundüberholungen der o. g. Fahrzeuge, wenn diese Neukonstruktionen oder umfassende Änderungen der Bremsanlage des betreffenden Fahrzeuges mit einschließt.

Die im vorliegenden Dokument enthaltenen funktionalen Prüfanforderungen gehen von der Annahme aus, dass die Architektur des Bremssystems der Fahrzeuge dem der UIC-Druckluftbremse entspricht.

Hochgeschwindigkeitsschienenfahrzeuge können mit einem alternativen Bremssystem ausgerüstet werden, welches nicht über eine Hauptluftleitung angesteuert wird. In diesen Fällen ist die Festlegung gleichwertiger Prüfanforderungen erforderlich, um die funktionalen Anforderungen des eingebauten Bremssystems zu prüfen.

Applications ferroviaires - Systèmes de freinage pour trains à grande vitesse - Partie 2 : Méthodes d'essai

La présente Norme européenne décrit les méthodes d’essai ainsi que les critères d’acceptation relatifs à un

système de freinage destiné à être utilisé sur des trains à grande vitesse décrits dans les spécifications

techniques d'interopérabilité (STI) Matériel roulant à grande vitesse, circulant sur des lignes du système

ferroviaire transeuropéen à grande vitesse.

Les essais définis dans le présent document ont pour objet de s’assurer que les performances de freinage et

les fonctions assurées par le système de freinage du train sont au moins conformes aux exigences

respectives de l’EN 15734-1.

La présente Norme européenne est applicable aux :

- véhicules neufs des trains à grande vitesse ;

- nouvelles constructions en ce qui concerne les types de véhicules existants ;

- grandes révisions des véhicules susmentionnés si celles-ci entraînent une reconception ou une

transformation majeure du système de freinage du véhicule concerné.

Les exigences d’essai fonctionnel définies dans le présent document supposent que les véhicules sont

équipés d’une architecture du système de freinage conforme aux principes UIC de commande par la conduite

générale de frein.

Le matériel roulant à grande vitesse peut être équipé d’autres architectures de système de freinage n’utilisant

par de commande par la conduite générale de frein. Dans ces cas, des exigences d’essai équivalentes

doivent être établies pour soumettre à essai les performances fonctionnelles du système de freinage installé.

Železniške naprave - Zavorni sistemi na vlakih za velike hitrosti - 2. del: Preskusne metode

Ta evropski standard opisuje metode preskušanja in merila sprejemljivosti za zavorni sistem, ki se uporablja na vlakih za visoke hitrosti, kot je opisano v TSI Železniška vozila, ki obratujejo na progah transevropskega železniškega sistema za visoke hitrosti. Preskusi, opredeljeni v tem dokumentu, so namenjeni preverjanju, da so zavorno delovanje in funkcije zavornega sistema vlaka v skladu vsaj z ustreznimi zahtevami EN 15734-1. Ta evropski standard velja za: nova vozila vlakov za visoke hitrosti; nove konstrukcije obstoječih vrst vozil; večje prenove zgoraj navedenih vozil, če prenove vključujejo preoblikovanje in obširne spremembe zavornega sistema zadevnega vozila. Funkcionalne zahteve za preskušanje, ki jih določa ta dokument, predvidevajo, da so vozila opremljena z arhitekturo zavornega sistema, ki ustreza načelom UIC za krmiljenje zračnih zavornih vodov. Železniška vozila za visoke hitrosti so lahko opremljena z alternativno arhitekturo zavornega sistema, ki ne uporablja krmiljenja zračnih zavornih vodov. V takih primerih je treba pripraviti enakovredne zahteve za preskušanje funkcionalnega delovanja nameščenega zavornega sistema.

General Information

- Status

- Withdrawn

- Publication Date

- 23-Nov-2010

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 3/WG 47 - Braking

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 04-Mar-2022

- Completion Date

- 04-Mar-2022

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 01-Jan-2020

- Corrected By

EN 15734-2:2010/AC:2012 - Railway applications - Braking systems of high speed trains - Part 2: Test methods - Effective Date

- 17-Oct-2012

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish national quality association.

Sponsored listings

Frequently Asked Questions

EN 15734-2:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Braking systems of high speed trains - Part 2: Test methods". This standard covers: This European Standard specifies test methods and acceptance criteria for a brake system for use in high speed trains as described in the TSI Rolling Stock, operating on routes of the trans-European high-speed rail system. The tests defined in this document have the purpose of verifying that the braking performance and functions of the train's brake system comply at least with the respective requirements of EN 15734-1. This European Standard is applicable to: - new vehicles of high speed trains; - new constructions of existing vehicle types; - major overhauls of the above-mentioned vehicles if they involve redesigning or extensive alteration to the brake system of the vehicle concerned. The functional testing requirements set out in this document assume the vehicles are fitted with a brake system architecture that follows the UIC air brake pipe control principles. High Speed Rolling Stock can be fitted with alternative brake system architectures that do not employ brake pipe control. In these cases equivalent testing requirements will need to be generated to test the functional performance of brake system fitted.

This European Standard specifies test methods and acceptance criteria for a brake system for use in high speed trains as described in the TSI Rolling Stock, operating on routes of the trans-European high-speed rail system. The tests defined in this document have the purpose of verifying that the braking performance and functions of the train's brake system comply at least with the respective requirements of EN 15734-1. This European Standard is applicable to: - new vehicles of high speed trains; - new constructions of existing vehicle types; - major overhauls of the above-mentioned vehicles if they involve redesigning or extensive alteration to the brake system of the vehicle concerned. The functional testing requirements set out in this document assume the vehicles are fitted with a brake system architecture that follows the UIC air brake pipe control principles. High Speed Rolling Stock can be fitted with alternative brake system architectures that do not employ brake pipe control. In these cases equivalent testing requirements will need to be generated to test the functional performance of brake system fitted.

EN 15734-2:2010 is classified under the following ICS (International Classification for Standards) categories: 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15734-2:2010 has the following relationships with other standards: It is inter standard links to EN 15734-2:2010+A1:2021, EN 15355:2019+A1:2023, EN 15595:2018+A1:2023, EN 15611:2020+A1:2022, EN 15663:2017+A2:2024, EN 15220:2025, EN 15734-1:2010, EN 16334-1:2014+A1:2022, EN 3750:2010, EN 16185-2:2014, EN 16185-2:2014+A1:2019, EN 15734-2:2010/prA1, EN 15734-2:2010/AC:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15734-2:2010 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC, 96/48/EC; Standardization Mandates: M/275. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15734-2:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Železniške naprave - Zavorni sistemi na vlakih za velike hitrosti - 2. del: Preskusne metodeBahnanwendungen - Bremssysteme für Hochgeschwindigkeitszüge - Teil 2: PrüfverfahrenApplications ferroviaires - Systèmes de freinage pour trains à grande vitesse - Partie 2 : Méthodes d'essaiRailway applications - Braking systems of high speed trains - Part 2: Test methods45.040Materiali in deli za železniško tehnikoMaterials and components for railway engineeringICS:Ta slovenski standard je istoveten z:EN 15734-2:2010SIST EN 15734-2:2011en,fr,de01-oktober-2011SIST EN 15734-2:2011SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15734-2

November 2010 ICS 45.060.01 English Version

Railway applications - Braking systems of high speed trains - Part 2: Test methods

Applications ferroviaires - Systèmes de freinage pour trains à grande vitesse - Partie 2 : Méthodes d'essai

Bahnanwendungen - Bremssysteme für Hochgeschwindigkeitszüge - Teil 2: Prüfverfahren This European Standard was approved by CEN on 23 October 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15734-2:2010: ESIST EN 15734-2:2011

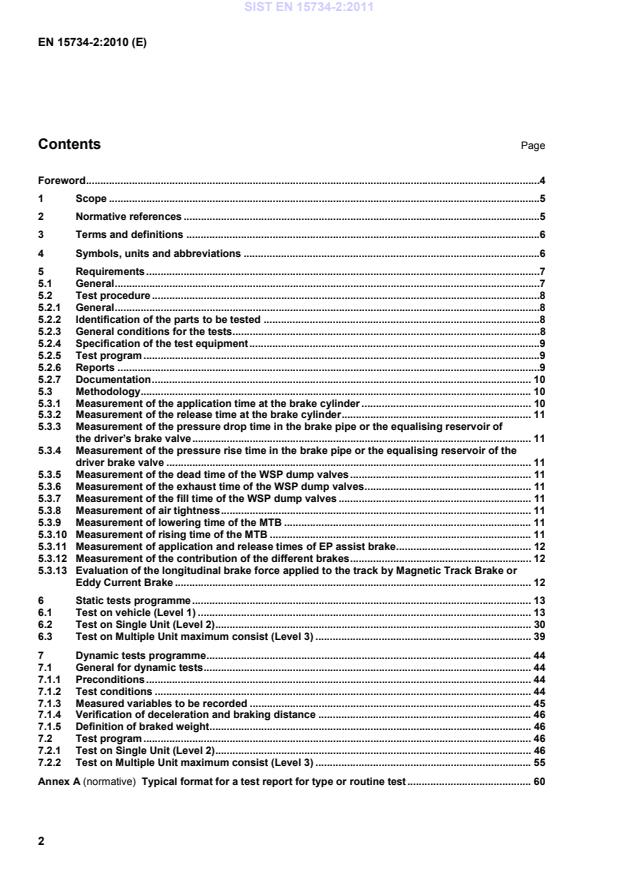

Typical format for a test report for type or routine test . 60SIST EN 15734-2:2011

Principle of the automatic function test . 61B.1 Purpose of the automatic function . 61B.2 Adjustment of the driver’s brake valve feed choke to comply with the automatic function . 61Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2008/57/EC . 62Bibliography . 64 SIST EN 15734-2:2011

This European Standard is applicable to: new vehicles of high speed trains; new constructions of existing vehicle types; major overhauls of the above-mentioned vehicles if they involve redesigning or extensive alteration to the brake system of the vehicle concerned.

The functional testing requirements set out in this document assume the vehicles are fitted with a brake system architecture that follows the UIC air brake pipe control principles. High Speed Rolling Stock can be fitted with alternative brake system architectures that do not employ brake pipe control. In these cases equivalent testing requirements will need to be generated to test the functional performance of brake system fitted. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 15220-1, Railway applications — Brake indicators — Part 1: Pneumatic operation brake indicators EN 15327-1, Railway applications — Passenger alarm subsystem — Part 1: General requirements and passenger interface for the passenger emergency brake system EN 15355, Railway applications — Braking — Distributor valves and distributor-isolating devices EN 15595, Railway applications — Braking — Wheel slide protection EN 15611, Railway applications — Braking — Relay valves EN 15663, Railway applications — Definition of vehicle reference masses EN 15734-1:2010, Railway applications — Braking systems of high speed trains — Part 1: Requirements and definitions EN 50125-1, Railway applications — Environmental conditions for equipment — Part 1: Equipment on board rolling stock EN 50128, Railway applications — Communications, signalling and processing systems — Software for railway control and protection systems UIC 544-1:2004, Brakes — Braking power SIST EN 15734-2:2011

3.1 approval body Notified Body or National Railway Authority that conforms to EN ISO/IEC 17025 3.2 test(ing) institute test(ing) institute that conforms to EN ISO/IEC 17025 3.3 check test performed as a discrete measurement or visual inspection 3.4 record results recorded either graphically or electronically 3.5 type test test of one or more devices, system or complete vehicle demonstrating that the design meets the required specifications and the relevant standards NOTE (Type) tests are performed by a test institute.

3.6 routine test vehicle test that is performed during or after manufacture to confirm conformity to specified criteria 4 Symbols, units and abbreviations For the purpose of this document, the following symbols, units and abbreviations apply: ATC

Automatic Train Control ATP

Automatic Train Protection BC

Brake Control BP

Brake Pipe DP

Data Processing EP

Electro Pneumatic Brake ETCS

European Train Control System R+Mg

Brake mode R+Mg MRP

Main Reservoir Pipe MTB

Magnetic Track Brake R

Brake mode R SIST EN 15734-2:2011

Driver’s vigilance control (German: "Sicherheitsfahrschaltung") WRMS

Wheel Rotation Monitoring System WSP

Wheel Slide Protection System 1 bar = 1 000 mbar = 105 N/m2 = 105 Pa = 10-1 MPa 5 Requirements 5.1 General This document defines the content of the static and dynamic tests dedicated to the brakes, which are needed for the following phases: type tests which demonstrate that the brake system conforms to the requirements. They are done with a pre-serial unit or with the first unit of a serial production; routine tests which confirm the technical stability of the production process of the system and its subsystems. For this purpose the basic features and functions of the system and its subsystems are to be checked; verification that the braking performance and the functions of the train’s braking system comply at least with the respective requirements of EN 15734-1; identification of data for the verification of the brake performance and the functions of the train's braking system. The document also identifies relevant data to be recorded. The type and routine tests are as follows: tests with a single vehicle (Level 1); tests with one single unit (Level 2). These tests serve to check the common functions of the unit and the interfaces between the vehicles; tests with multiple units consisting of two to n units (Level 3) up to the maximum configuration. These tests serve to check the common functions of the train composition and the interfaces between the units. SIST EN 15734-2:2011

Key 1 Level 1: vehicle 2 Level 2: single unit 3 Level 3: multiple unit Figure 1 —Type test and routine test levels 5.2 Test procedure 5.2.1 General The procedures shall include the following items: identification of the parts to be tested; general conditions for the tests; specification of the test equipment; test program. 5.2.2 Identification of the parts to be tested A list of the parts to be tested shall be made, with a description starting from the total system or subsystem down to the single parts of the brake system. It is recommended to attach pneumatic, electric or electronic schemes, graphs, etc. The test stand and the procedure shall be documented with pneumatic, electric or electronic schemes, graphs, etc. 5.2.3 General conditions for the tests 5.2.3.1 Temperature The tests shall be run at a temperature within the range of the air temperature class in accordance with EN 50125-1, specified for the tested system. SIST EN 15734-2:2011

The recording apparatus shall have enough measurement tracks, in order that a record can include all the needed information for the test. Each measurement track shall be clearly identified. The records shall include the information listed in 5.2.6 and 8.1.3. The quality of the records shall enable the copy of them without quality loss. If a digital recording system is used, an open format shall be used for data files. 5.2.5 Test program The items listed in the following tables describe the minimum to be checked but do not define the testing procedure.

Additional tests shall be proposed to suit the specific configuration of the brake system architecture (e.g. automatic air brake, direct electro-pneumatic air brake, etc.) fitted on the rolling stock, or if specific requirements are mentioned in the functional specification. This list of tests shall be only considered as a basis for building up the dedicated test procedure for a given rolling stock.

Each test in the following tables includes a short and basic description of the function to be tested. The complete and detailed description shall be included into the test procedure to be presented to the approval body. The type tests shall include the degraded modes tests, with special attention to the redundant functions. The tests shall start only if the software of the brake function / brake system has been successfully validated in advance in accordance with EN 50128. 5.2.6 Reports The tests shall be presented in a report and transmitted to the approval body that assesses the vehicle. This report shall at least include: a) reference of the test (type test or routine test); b) date and location of the test; SIST EN 15734-2:2011

5.2.7 Documentation The parameters as follows shall be recorded irrespective from the type of testing: software versions of all brake-relevant components (all software-controlled systems, contributing directly or indirectly to the braking performance: drive units, anti-skid protection systems, brake modules, etc.); batch numbers of the friction materials (blocks, inserts, pads, etc.) and results of bench tests in dry and wet conditions; brake cylinder pressures in the case of an emergency brake application for at least one motor bogie and one trailer bogie; wheel diameter. It is assumed that the documentation conforms to the relevant standards and that conformity with these requirements shall be established before performing the tests. 5.3 Methodology 5.3.1 Measurement of the application time at the brake cylinder The application time is to be measured from 0 % to 95 % of the maximum stabilized pressure at the brake cylinder. This is measured at the brake cylinder which is the furthest from of the brake panel which controls it. It is accepted to add a T-connection for the type test. SIST EN 15734-2:2011

5.3.9 Measurement of lowering time of the MTB The lowering time of the MTB shall be measured between the activation command and the impact of the magnets on the rail.

5.3.10 Measurement of rising time of the MTB The rising time of the MTB shall be measured between the deactivation command and reaching their upper position.

5.3.12 Measurement of the contribution of the different brakes During dynamic tests the contribution of the different brakes installed on the rolling stock shall be measured as follows: for the friction brake by recording the pressure in the brake cylinders; for the dynamic brake by recording the brake force information provided by the traction equipment; for the eddy current brake by recording the brake force information provided by the control equipment; for the magnetic track brake by recording their state and using design data. 5.3.13 Evaluation of the longitudinal brake force applied to the track by Magnetic Track Brake or Eddy Current Brake The longitudinal force shall be evaluated for emergency brake application and if applicable also for full service brake application from maximum speed under operational mass in working order. If there a load dependent brake force is applied for the Eddy Current Brake, then the design mass under exceptional payload shall also be considered. The longitudinal force for the magnetic track brake shall be calculated from the deceleration which is raised by the Magnetic track brake. These deceleration shall be calculated as the difference between the deceleration which is measured for brake applications with and without acting Magnetic Track Brake. For the Eddy Current Brake the recorded brake force information provided by the control equipment shall be evaluated. SIST EN 15734-2:2011

Record Check Record Check6.1.1 Basic visual inspection 6.1.1.1 The conformity of the vehicle data shall be checked concerning vehicle type and number; vehicle inscriptions.

9 6.1.1.2 The conformity of the pneumatic, mechanical, electric and electronic brake equipment regarding types, quantity and marking with the documentation shall be checked.

9 6.1.2 General safety related assessment of the installation 6.1.2.1 The installation of the brake system parts in the vehicle (e.g. installation position, clearances and safety features as defined in the installation documentation) shall be checked.

9 6.1.2.2

The correct installation of piping and flexible connections shall be checked.

9 6.1.2.3

The clearance of the friction brake components as defined in the installation documentation shall be checked.

9 6.1.2.4 The accessibility, by maintenance staff, to the wear conditions of the friction partners, especially brake discs, brake blocks or pads and running surface of the wheels shall be checked.

9 SIST EN 15734-2:2011

Record Check Record Check6.1.2.5 The conformity of the position of the friction materials regarding brake discs and/or running surface of the wheel with the installation documentation shall be checked.

9 6.1.3 Air tightness 6.1.3.1

The air tightness of the main reservoir pipe with the ancillary components connected shall be checked. All ancillary devices supplied by the main reservoir pipe shall be connected but not in operation: electro- magnetic track brake, permanent magnetic track brake, eddy current brake suspension, doors, etc. Air supply shall be deactivated and brake pipe vented. Pressure reduction shall be 0 bar to 0,2 bar in 3 min. Hoses are to be isolated by dummy couplings and end cocks shall be opened. 9

6.1.3.2

The air tightness of the brake pipe shall be checked. All devices supplied by the brake pipe shall be connected: brake panels, emergency valves, driver brake valve, etc. The driver’s brake valve shall be switched out. Pressure reduction shall be 0 bar to 0,1 bar in 3 min. Hoses are to be isolated by dummy couplings and end cocks shall be opened. 9

6.1.3.3

The air tightness of the control reservoirs (A-Chamber) of the distributor valves shall be checked. A service brake shall be applied with a brake pipe pressure reduction of about 0,5 bar and this pressure level shall be maintained. Pressure reduction in brake cylinder shall be less than 0,2 bar in 10 min. 9

Record Check Record Check6.1.3.4

The air tightness of the brake cylinders shall be checked. With the auxiliary reservoir isolated from the main reservoir pipe, an emergency brake shall be applied. The brake cylinder pressure shall be constant with a tolerance of + 0,2 bar and - 0,15 bar, auxiliary reservoir pressure reduction shall be less than 0,2 bar in 10 min. 9

6.1.4 Gauging and pressure gauges

The accuracy of the gauges on the desk (MRP, BP, BC, etc.) shall be checked with regard to: the correct connection; the correct marking; the precision in accordance with EN 15734-1 using a calibrated instrument.

9 6.1.5 Auxiliary reservoir 6.1.5.1

The functionality of filling of the auxiliary reservoirs from the main reservoir pipe alone shall be checked. The test shall be performed with the air compressor of the unit or with external air supply in accordance with 5.2.3.2.

9 6.1.5.2

The functionality of filling of the auxiliary reservoirs from the brake pipe alone shall be checked. The test shall be done with the air compressor of the unit or with external air supply in accordance with

5.2.3.2.

9 SIST EN 15734-2:2011

Record Check Record Check6.1.6 Local control of the brake/distributor valve 6.1.6.1

It is to be checked that the distributor has been tested and conforms to EN 15355.

9 6.1.6.2

It is to be checked that the total brake pipe volume associated with each distributor is less than 25 l.

6.1.6.3

It is to be checked that the control chamber’s release valve function of the distributor.

6.1.6.4

For direct EP-Brakes it is to be checked whether the brake demand signal characteristics comply with the design specification (including hysteresis, sensitivity, repeatability). 9

6.1.7 Main relay valve 6.1.7.1 The conformity of the relay valve with EN 15611 shall be checked.

9 6.1.7.2

It is to be checked: whether the brake cylinder pressure(s) for an emergency application conforms to the design specification (tolerances + 0,2; - 0,15 bar); for double stage relay valves the change over between the "high" and "low" pressure stage and whether the brake cylinder pressures for both stages comply with the specification (tolerances + 0,2 bar; - 0,15 bar). The brake cylinders pressure shall be gradually controllable and proportional to the brake demand signal. The brake cylinder pressure values for both the increasing and decreasing brake demand and sensitivity shall be measured and checked against the design specifications. 9

Record Check Record Check6.1.7.3

For the variable load relay valves, check the conformance to the design specification: actual weight of the vehicle (obtained after weighing) / measured load pressure / brake cylinder pressures (including hysteresis) for the design masses in working order, under normal payload and under exceptional payload (as defined in EN 15663). NOTE This test can be performed, for normal and exceptional loads, when loading the train for dynamic tests.

6.1.7.4 For the variable load relay valves, the pairs load pressure/brake cylinder pressures for the three load states operational mass in working order, design mass under normal payload, design mass under exceptional payload shall be checked for an emergency brake application. NOTE Load pressures are simulated.

9 6.1.7.5 With filling of auxiliary reservoirs by brake pipe pressure only. For the variable load relay valves, the pairs load pressure/brake cylinder pressures for the three load states operational mass in working order, design mass under normal payload, design mass under exceptional payload shall be checked for an emergency brake application. The maximum brake cylinder pressure during an emergency brake application shall be checked in accordance with the design specification.

6.1.7.6

The application and release times during an emergency brake application shall be measured. If the brake system is fitted with a variable load relay valve the measurement shall be performed for the three load states.

Record Check Record Check6.1.7.7

If a direct EP brake is used, the application and release times during a full service brake application shall be measured. If the brake system is fitted with a variable load relay valve the measurement shall be performed for the three load states. 9

6.1.7.8

The application and release times shall be measured (see 5.3) for brake cylinder for the operational mass in working order for an emergency brake application).

6.1.8 Emergency brake 6.1.8.1

The exhaust flow rate of the brake pipe pressure shall be checked through each emergency device, including the emergency position of the brake controllers. When testing the emergency brake an additional reservoir of 400 l shall be added to the brake pipe. Pressure shall drop by 1,5 bar, from the normal working pressure, in less than 2,5 s. The pressure reduction shall finally drop to a value of less than 2,5 bar. 9

6.1.8.2

The forces to move any manual device into the emergency position shall be checked in accordance with the design specifications. 9

6.1.9 Driver’s brake valve/brake controller 6.1.9.1

The functionality after activation of the driver’s brake valve/brake controller shall be checked. The integration of the driver’s brake valve/brake controller in the vehicle system shall be checked, e.g. electric wiring, pneumatic connection.

Record Check Record Check6.1.9.2

Check the normal working pressure of the brake pipe in the running position of the brake pipe control system(s). The brake pipe pressure shall be measured. Target value shall be : (5,0 ± 0,05) bar 9

6.1.9.3 The minimum brake step (pressure drop for first brake step) of the brake pipe control system shall be checked. The brake pipe pressure shall be measured. Target value shall be: Pressure reduction 0,4 bar + 0,1 bar 9

6.1.9.4 The brake pipe pressure reduction time by the brake pipe control system shall be measured for a full service application and checked in accordance with the design specifications. 9

6.1.9.5

The brake pipe pressure build-up time by the brake pipe control system shall be measured from a full service application to normal working pressure and checked in accordance with the design specifications.9

6.1.9.6

The output of the driver’s brake valve/brake controller shall be gradually controllable and proportional to the brake demand signal. The output values, for both the increasing and decreasing brake demand, and sensitivity shall be measured and checked against the design specifications.

6.1.9.7 It is to be checked whether the function of the driver’s brake valve/brake controller conforms to the design specification.

Record Check Record Check6.1.9.8

When releasing the brake, the brake pipe shall automatically return to the normal working pressure if the difference between the control pressure and the normal working pressure is within 0,25 bar to 0,35 bar. 9

6.1.9.9 The "inexhaustibility" function shall be checked. After reducing the brake pipe pressure below 3 bar, it shall be stabilized at about 3 bar and the equalising reservoir shall be checked.

9 6.1.9.10 The supply cut-off function (if available) or the brake pipe cut-off shall be checked with regard to the following: the light up of the "neutral" light indicator if available; the emergency position of the driver’s brake valves/brake controllers activates the supply cut-off function or the brake pipe cut-off; the brake application in service position if available; the brakes cannot be released.

9 6.1.9.11

Isolation of the driver’s brake valve/brake controller

The isolation functionality of the driver’s brake valve/brake controller shall be checked. In a non active cab the brake application in emergency shall be checked.

9 6.1.10 Additional/auxiliary for driver's brake valve/controller 6.1.10.1

The functionality after activation of the driver’s additional/auxiliary valve/controller shall be checked.

9 SIST EN 15734-2:2011

Record Check Record Check6.1.10.2

The brake pipe pressure in the running position shall be checked. The brake pipe pressure shall be measured. Target value shall be: (5,0 ± 0,05) bar. 9

6.1.10.3

The brake pipe pressure reduction time by the additional/auxiliary driver’s brake valve/controller shall be measured for a full service application demand and checked in accordance with the design specifications. 9

6.1.10.4

The brake pipe pressure build-up time by the additional/auxiliary driver’s brake valve/controller shall be measured from a full service application to running demand and checked in accordance with the design specifications. 9

6.1.10.5

The output of the driver’s additional/auxiliary brake valve/controller shall be gradually controllable and proportional to the brake demand. The output values, for both the increasing and decreasing brake demand, and sensitivity shall be measured and checked against the design specifications.

9 SIST EN 15734-2:2011

Record Check Record Check6.1.10.6

The supply cut-off function (if available) or the brake pipe cut-off shall be checked with regard to the following:

the lighting on of the "neutral" light indicator if available; that the emergency position of the back-up driver’s brake valve/controller operates the supply cut-off function or brake pipe cut-off; the brake application in service position if available; that the brakes cannot be released. NOTE Simulation of signals could be necessary.

9 6.1.10.7 Turning off control

9 6.1.11 Blending, Interlock or Combination ED brake/pneumatic brake 6.1.11.1

The integration of the blending system in the vehicle, e.g. electric wiring, pneumatic connection shall be checked.

9 6.1.11.2

The functional operation of the blending system shall be checked for conformance to the design specification with regard to the following: The functional operation of the local blending system shall be checked for conformance to the design specification with regard to the following: measurement of the response times; check the effort limitation rates; measurement of the pilot pressures for the different load states; check the transition behaviour blending control / distributor valve control. NOTE Simulation of signals could be necessary. 9 9

9 SIST EN 15734-2:2011

Record Check Record Check6.1.12 Wheel slide protection (WSP) NOTE If during the dynamic tests the brake cylinder pressures are altered, it will be necessary to repeat all the tests regarding this item. 6.1.12.1

The integration of the WSP into the brake system shall be checked, e.g. concerning electric wiring, pneumatic connection, self test run. The correct correlation of the speed sensors to the corresponding dump valves shall be checked. All the input/output shall be tested, including the check of the operation for conformance to the design specification.

9 6.1.12.2

The exhaust and filling times at the brake cylinders in operational mass in working order (see 5.3) shall be measured for conformance to the design specification. The test shall be done for each dump valve.

6.1.12.3

The exhaust and filling times at the brake cylinders in simulated maximum load (see Clause 6) shall be measured for conformance to the design specification. The test shall be done for each dump valve. 9

6.1.13 Wheel rotation monitoring system (WRMS) 6.1.13.1

The integration of the WRMS in the vehicle shall be checked, e.g. concerning electric wiring, self test run. All the input/output shall be tested in accordance with the design specification.

Record Check Record Check6.1.13.2 The independency of WRMS from WSP shall be demonstrated (test program to be specified in accordance with the design specification).

9 6.1.14 Magnetic track brake (MTB) 6.1.14.1

The conformance of the MTB should comply with the future European Standard on this subject. NOTE Magnetic track brake European Standard is drafted by CEN/TC 256/SC 3/WG 22 under WI 00256376.

9 6.1.14.2

The MTB's position when not active (upper position) shall be checked.

9 6.1.14.3

Lowering and switching on of the MTB during an emergency brake application shall be checked. Activation of MTB only above the speed threshold, in accordance with the design specifications, shall be checked.

9 6.1.14.4

If present, the manual application of MTB shall be checked in accordance with the design specifications.

6.1.14.5 The correct filling of the MTB supply reservoirs shall be checked.

9 6.1.14.6

The filling and exhaust times of the MTB’s lowering actuators shall be measured for conformance to the design specification. 9

6.1.14.7

The lowering and raising up times shall be measured for conformance to the design specification. 9

Record Check Record Check6.1.14.8

The lowering and raising up times with a low main reservoir pipe pressure shall be measured for

conformance to the design specification. 9

6.1.14.9

Measurement of the magnetizing current for the electrical MTB when operating on battery power only

for conformance to the design specification. 9

6.1.14.10

It is to be checked that MTB is not acting in R position but only in R+Mg.

9 6.1.15 Eddy current track brake

6.1.15.1

The integration of the eddy current track brake in the vehicle shall be checked, e.g. concerning electric wiring, pneumatic connection, mechanical interface.

9 6.1.15.2

It is to be checked that the eddy current track brake suspension system is well seated in the upper position.

6.1.15.3

It is to be checked whether the eddy current track brake’s distance to the rail conforms to the design specification in the operational position.

9 6.1.15.4

It is to be checked whether the lifting and lowering times are compliant with the design specification. 9

6.1.16 Parking brake 6.1.16.1

It is to be checked whether the parking brake applies due to a reduction of the supply system pressure.

9 SIST EN 15734-2:2011

Record Check Record Check6.1.16.2

The pneumatic release and application values (times, pressures, etc.) shall be checked and measured if it is a remote controlled parking brake. 9

6.1.16.3

It is to be checked whether the mechanical u

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...