prEN 17020-2

(Main)Extended application of test results on durability of self-closing for fire resistance and/or smoke control doorsets and openable windows - Part 2: Durability of self-closing of steel rolling shutters

Extended application of test results on durability of self-closing for fire resistance and/or smoke control doorsets and openable windows - Part 2: Durability of self-closing of steel rolling shutters

This European Standard covers steel rolling shutters as covered by EN 15269 10.

This document prescribes the methodology for extending the application of test results obtained from durability self-closing test(s) conducted in accordance with EN 1634 1.

Subject to the completion of the appropriate self-closing test or tests, the extended application may cover all or some of the following non-exhaustive list:

- Integrity only (E), radiation (EW) or insulated (EI1 or EI2) classifications;

- shutter curtain;

- wall/ceiling fixed elements (frame/suspension system);

- decorative finishes;

- intumescent, smoke, draught or acoustic seals;

- alternative supporting construction(s).

Erweiterter Anwendungsbereich von Prüfergebnissen zur Dauerhaftigkeit des Selbstschließens für Feuerschutz- und/oder Rauchschutztüren und zu öffnende Fenster - Teil 2: Dauerhaftigkeit der Selbstschließung von Rolltoren aus Stahl

Diese Europäische Norm befasst sich mit Rolltoren aus Stahl wie in EN 15269-10 beschrieben.

Dieses Dokument beschreibt die Methodik zur Erweiterung der Anwendung von Ergebnissen aus Dauerprüfung(en) des Selbstschließens, die nach EN 1634-1 durchgeführt wurden.

In Abhängigkeit von der Durchführung der entsprechenden Prüfung oder Prüfungen zum Selbstschließen darf der erweiterte Anwendungsbereich einige oder alle der nachstehend aufgeführten Bereiche abdecken, wobei diese Liste als unvollständig anzusehen ist:

Klassifizierungen des Raumabschlusses (E) sowie solche mit Anforderungen an die Strahlung (EW) oder an wärmegedämmte Abschlüsse (EI1 oder EI2);

Rollpanzer;

Wand-/Deckenbefestigungselemente (Rahmen/Aufhängungssysteme);

dekorative Oberflächenbeschichtungen;

dämmschichtbildende, Rauch-, Zugluft- oder Schallschutz-Dichtungen;

alternative Tragkonstruktion(en).

Application étendue des résultats d’essais de durabilité de la fermeture automatique des blocs-portes et fenêtres ouvrantes résistants au feu et/ou étanches à la fumée - Partie 2 : Durabilité de la fermeture automatique des rideaux à enroulement en acier

La présente Norme européenne couvre les rideaux à enroulement en acier visés par l’EN 15269-10.

Ce document établit la méthodologie d’extension de l’application des résultats d’essai obtenus suite aux essais de durabilité de la fermeture automatique réalisés conformément à l’EN 1634-1.

Sous réserve de la réalisation de l’essai ou des essais appropriés de fermeture automatique, l’application étendue peut couvrir tout ou partie des éléments de la liste non exhaustive suivante :

- classements d’étanchéité au feu uniquement (E), aux rayonnements (EW) ou à l’isolation thermique (EI1 ou EI2) ;

- tablier de rideau ;

- éléments fixes muraux/de plafond (structure/système de suspension) ;

- finitions décoratives ;

- joints intumescents, joints d’étanchéité aux fumées, joints d’étanchéité à l’air ou joints acoustiques ;

- autre(s) support(s).

Razširjena uporaba rezultatov preskusov trajnosti samozapiranja za požarno odporna in/ali dimotesna vrata in okna, ki se odpirajo - 2. del: Trajnost samozapiranja jeklenih valjanih zapiral

General Information

- Status

- Not Published

- Publication Date

- 04-Feb-2018

- Withdrawal Date

- 05-Aug-2018

- Technical Committee

- CEN/TC 127 - Fire safety in buildings

- Drafting Committee

- CEN/TC 33/WG 8 - Fire and smoke control

- Current Stage

- 4098 - Decision to abandon - Enquiry

- Start Date

- 18-Dec-2018

- Completion Date

- 21-Jan-2026

Overview

The prEN 17020-2:2016 European Standard, developed by CEN (European Committee for Standardization), defines a comprehensive methodology for the extended application of test results concerning the durability of self-closing steel rolling shutters. This standard complements existing European fire resistance and smoke control testing procedures and specifically addresses steel rolling shutters as covered under EN 15269-10.

Traditionally, durability testing for self-closing doors and shutters followed EN 1634-1, focusing on fire resistance and smoke control. prEN 17020-2 expands these results to cover a broader range of product variations while ensuring compliance with fire safety classifications. This document forms part of an essential framework supporting manufacturers and testing authorities to confidently extend test results to different shutter configurations without redundant testing.

Key Topics

- Durability of self-closing: Specifies evaluation criteria and extended application rules based on self-closing durability tests.

- Steel rolling shutters: Applies to rolling shutter assemblies including shutter curtains, frames, and suspension systems.

- Fire resistance classifications: Covers Integrity only (E), Radiation (EW), and Insulated (EI1, EI2) classifications according to EN 13501-2.

- Parameter variations: Addresses construction parameter variations such as shutter size, mounting position, seals, finishes, and supporting structures.

- Extended application process: Describes procedures to evaluate construction parameter changes that maintain fire classification and shutter durability without additional testing or indicate where further testing is necessary.

- Reports and classification: Defines requirements for producing extended application and classification reports aligned with EN 15269-1 and EN 13501-2.

Applications

- Manufacturers of steel rolling shutters can streamline product development by applying test results across multiple shutter configurations, reducing the need for repeated full-scale durability and fire resistance testing.

- Testing laboratories and certification bodies gain a standardized process to assess the feasibility of extending test results for different shutter variants while maintaining fire safety classifications.

- Building designers and specifiers benefit from harmonized classification reports confirming that variations in steel rolling shutter assemblies conform to European fire safety standards.

- Fire safety compliance: Supports fire safety engineers in ensuring rolling shutters’ integrity in fire and smoke control scenarios, contributing to safer building infrastructure.

- Quality assurance: Underpins durability guarantees for self-closing steel shutters across varied installation environments, finishes, and supporting constructions.

Related Standards

- EN 15269-10: Defines extended application of fire resistance test results specifically for steel rolling shutters.

- EN 1634-1: Fire resistance and smoke control tests for door and shutter assemblies, including durability self-closing testing.

- EN 13501-2: Provides criteria for fire classification of construction products, including doors and shutters.

- EN 12605: Specifies mechanical test methods for industrial, commercial, and garage doors and gates, including durability cycles.

- EN 1363-1 & EN 1363-2: General and alternative procedures for conducting fire resistance tests.

- EN 12433-1 & EN 12433-2: Terminology covering types and parts of industrial and commercial doors.

- EN ISO 13943: Fire safety vocabulary supporting clear and consistent terminology.

Keywords: prEN 17020-2, durability of self-closing, steel rolling shutters, fire resistance, smoke control doorsets, extended application, European Standard, EN 15269-10, EN 1634-1, fire door classification, self-closing test methodology, fire safety compliance, rolling shutter testing, shutter curtain durability, fire resistance classification.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Nonprofit organization that performs technical evaluations of building products.

NSF International

Global independent organization facilitating standards development and certification.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

prEN 17020-2 is a draft published by the European Committee for Standardization (CEN). Its full title is "Extended application of test results on durability of self-closing for fire resistance and/or smoke control doorsets and openable windows - Part 2: Durability of self-closing of steel rolling shutters". This standard covers: This European Standard covers steel rolling shutters as covered by EN 15269 10. This document prescribes the methodology for extending the application of test results obtained from durability self-closing test(s) conducted in accordance with EN 1634 1. Subject to the completion of the appropriate self-closing test or tests, the extended application may cover all or some of the following non-exhaustive list: - Integrity only (E), radiation (EW) or insulated (EI1 or EI2) classifications; - shutter curtain; - wall/ceiling fixed elements (frame/suspension system); - decorative finishes; - intumescent, smoke, draught or acoustic seals; - alternative supporting construction(s).

This European Standard covers steel rolling shutters as covered by EN 15269 10. This document prescribes the methodology for extending the application of test results obtained from durability self-closing test(s) conducted in accordance with EN 1634 1. Subject to the completion of the appropriate self-closing test or tests, the extended application may cover all or some of the following non-exhaustive list: - Integrity only (E), radiation (EW) or insulated (EI1 or EI2) classifications; - shutter curtain; - wall/ceiling fixed elements (frame/suspension system); - decorative finishes; - intumescent, smoke, draught or acoustic seals; - alternative supporting construction(s).

prEN 17020-2 is classified under the following ICS (International Classification for Standards) categories: 13.220.50 - Fire-resistance of building materials and elements; 91.060.50 - Doors and windows. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 17020-2 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2016

Razširjena uporaba rezultatov preskusov trajnosti samozapiranja za požarno

odporna in/ali dimotesna vrata in okna, ki se odpirajo - 2. del: Trajnost

samozapiranja jeklenih valjanih zapiral

Extended application of test results on durability of self-closing for fire resistance and/or

smoke control doorsets and openable windows - Part 2: Durability of self-closing of steel

rolling shutters

Application étendue des résultats d’essais de durabilité de la fermeture automatique des

blocs-portes et fenêtres ouvrantes résistants au feu et/ou étanches à la fumée - Partie 2 :

Durabilité de la fermeture automatique des rideaux à enroulement en acier

Ta slovenski standard je istoveten z: prEN 17020-2

ICS:

13.220.50 Požarna odpornost Fire-resistance of building

gradbenih materialov in materials and elements

elementov

91.060.50 Vrata in okna Doors and windows

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

June 2016

ICS 13.220.50; 91.060.50

English Version

Extended application of test results on durability of self-

closing for fire resistance and/or smoke control doorsets

and openable windows - Part 2: Durability of self-closing

of steel rolling shutters

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 33.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2016 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 17020-2:2016 E

worldwide for CEN national Members.

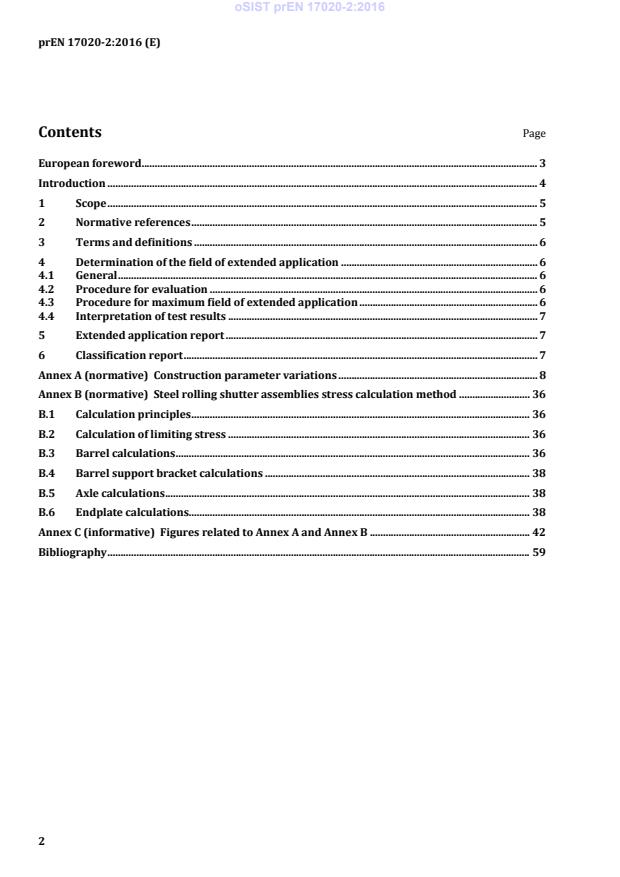

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Determination of the field of extended application . 6

4.1 General . 6

4.2 Procedure for evaluation . 6

4.3 Procedure for maximum field of extended application . 6

4.4 Interpretation of test results . 7

5 Extended application report . 7

6 Classification report . 7

Annex A (normative) Construction parameter variations . 8

Annex B (normative) Steel rolling shutter assemblies stress calculation method . 36

B.1 Calculation principles . 36

B.2 Calculation of limiting stress . 36

B.3 Barrel calculations . 36

B.4 Barrel support bracket calculations . 38

B.5 Axle calculations . 38

B.6 Endplate calculations. 38

Annex C (informative) Figures related to Annex A and Annex B . 42

Bibliography . 59

European foreword

This document (prEN 17020-2:2016) has been prepared by Technical Committee CEN/TC 33 “Doors,

windows, shutters, building hardware and curtain walling”, the secretariat of which is held by AFNOR.

This document is currently submitted to the CEN Enquiry.

Introduction

The EN 15269 series of standards covering extended application of test results for fire resistance

and/or smoke control for door, shutter and openable window assemblies, including their elements of

building hardware, does not include the durability of self-closing of the doorsets following an extended

application process. This document is one of a series of standards intended to be used for the purpose

of producing an extended application report based on the evaluation of one or more durability self-

closing tests. These European Standards may also be used to identify the best selection of test

specimens required to cover a wide range of product variations.

Before there can be any consideration for extended application, the doorset will need to have been

tested in accordance with EN 1634-1 resp. EN 1634-3 and EN 12605 to achieve a test result which could

generate a classification in accordance with EN 13501-2 at least equal to the classification subsequently

required from extended application considerations.

1 Scope

This European Standard covers steel rolling shutters as covered by EN 15269-10.

This document prescribes the methodology for extending the application of test results obtained from

durability self-closing test(s) conducted in accordance with EN 1634-1.

Subject to the completion of the appropriate self-closing test or tests, the extended application may

cover all or some of the following non-exhaustive list:

— Integrity only (E), radiation (EW) or insulated (EI1 or EI2) classifications;

— shutter curtain;

— wall/ceiling fixed elements (frame/suspension system);

— decorative finishes;

— intumescent, smoke, draught or acoustic seals;

— alternative supporting construction(s).

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 1363-1, Fire resistance tests - Part 1: General Requirements

EN 1363-2, Fire resistance tests - Part 2: Alternative and additional procedures

EN 1634-1, Fire resistance and smoke control tests for door and shutter assemblies, openable windows and

elements of building hardware - Part 1: Fire resistance test for door and shutter assemblies and openable

windows

EN 12433-1, Industrial, commercial and garage doors and gates - Terminology - Part 1: Types of doors

EN 12433-2, Industrial, commercial and garage doors and gates - Terminology - Part 2: Parts of doors

EN 12605, Industrial, commercial and garage doors and gates - Mechanical aspects - Test methods

EN 13501-2:2007+A1:2009, Fire classification of construction products and building elements — Part 2:

Classification using data from fire resistance tests, excluding ventilation services

EN 15269-1, Extended application of test results for fire resistance and/or smoke control for door, shutter

and openable window assemblies, including their elements of building hardware - Part 1: General

requirements

EN ISO 13943, Fire safety - Vocabulary (ISO 13943)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 1363-1, EN 1363-2,

EN 1634-1, EN 15269-1, EN 12433-1, EN 12433-2 and EN ISO 13943 and the following apply.

3.1

full scale test

test of a full size doorset or rolling shutter in accordance with EN 12605

4 Determination of the field of extended application

4.1 General

4.1.1 Before there can be any consideration for extended application the steel rolling shutter

assemblies shall have been tested and classified in accordance with EN 12605 and EN 13501-2

respectively in order to establish a classification for the doorset.

4.1.2 A review of the construction parameters can indicate that one or more characteristics may be

improved by a particular parameter variation. All evaluations shall be made on the basis of retaining the

classifications obtainable from testing to EN 12605, including those with a lower number of opening

and closing cycles. However, this shall never lead to an increased classification for any specific

parameter beyond that achieved during any one test unless specifically identified in the relevant

Construction Parameter Variation tables.

4.1.3 All evaluations shall be made on the basis of retaining the classification obtained from testing to

EN 1634-1 or EN 1634-3 and EN 12605.

4.1.4 If, by following the extended application procedure, any part of the classified product cannot be

achieved by extended application rules, that part shall be omitted from the subsequent extended

application report and classification report.

4.2 Procedure for evaluation

4.2.1 Identify the variations from the original test specimen(s) which are required to be covered by

an extended application report. Ensure that the variation(s) do(es) not prevent the shutter from self-

closing.

4.2.2 Locate the variations in the appropriate parameter variation by reference to columns (1) and

(2) of Table A.1.

4.2.3 Establish from the contents of column (4) of Table A.1 whether any extended application is

available without the need for further testing.

4.2.4 Where this is deemed to be possible this can be recorded in the extended application report

together with any appropriate restrictions and the stated rules from column (4) in Table A.1.

4.2.5 Where the variations required can only be achieved from additional testing according to

column (5), the additional test can be made on a similar specimen type to the original test against which

the extended application is sought. Alternatively, column (5) identifies an option for alternative testing

and relevant test parameters.

4.3 Procedure for maximum field of extended application

4.3.1 It is possible to provide a limited field of extended application from the results of a single test.

However, where a manufacturer intends to produce a range of steel rolling shutters assemblies

incorporating manual and power drives, insulated and uninsulated version, with alternative elements of

construction etc. it is recommended that careful consideration is given to the complete range of designs

and options in order to minimize the testing required before testing commences.

4.3.2 Establish all the parameter variations which are required to be part of the product range.

4.3.3 Determine which are the most important specification requirements and incorporate as many

as possible into the specimen(s) for the first tests in the series.

4.3.4 Conduct the first durability test or a series of tests and then establish which of the original

desired parameter variations have not been covered by this test(s).

4.3.5 Identify these parameter variations in Table A.1 and establish if any extended application is

possible without further testing.

4.3.6 Record this for the extended application report together with any restrictions and rules given in

column (4) in Table A.1.

4.3.7 Evaluate which, if any, of the desired parameter variations have not been covered by the initial

field of extended application derived from 4.3.6 above.

4.3.8 Select the required outstanding parameter variations from column (1) and column (2) of

Table A.1 and observe from column (5) of Table A.1 which are the most appropriate weakest specimen

options for further testing.

4.3.9 If the complete selection of required parameter variations has not been covered by the tests

completed in accordance with 4.3.8 and 4.3.9 above, then an appropriate test or tests may be repeated

with the additional product variations incorporated.

4.4 Interpretation of test results

4.4.1 In order to maximize the field of extended application, it is important that the test reports shall

record details of any failures throughout the test duration.

4.4.2 Where a series of tests have been conducted, the field of extended application shall be based on

the lowest performance achieved from the complete series of tests unless premature failure has been

attributed to one or more specific construction parameter variation.

4.4.3 Where it has been possible to identify specific parameter failures, the extended application for

all other construction parameter variations can be based on the performance achieved after isolating

the premature failure(s).

5 Extended application report

Prepare an extended application report in accordance with the requirements of EN 15269-1, based on

the results of evaluations in accordance with the above.

6 Classification report

The classification report shall be determined from the results of the extended application report and

shall be presented in accordance with EN 13501-2:2007+A1:2009, Annex A.

Annex A

(normative)

Construction parameter variations

Table A.1 below is designed to be used by experts competent in the field of fire resistance and self-

closing durability testing of steel rolling shutter assemblies.

The table shall only be used to assess a field of extended application when at least one positive self-

closing durability test to EN 12605 has generated a classification according to EN 13501-2.

The first two columns identify possible variations to the construction details of the specimen tested. It is

presupposed that the variation does not restrain the door closing.

Column (4) leads to the judgement of the possibility of extending the field of application.

Where additional tests are deemed to be necessary, the type of specimen approved for incorporation of

the changed parameter is defined in column (5). Where it is possible to use information from tests

performed on one configuration for evidence on a different configuration, this allowance has been made

in order to reduce the overall number of tests required for extended application evaluation.

Where an additional test is required in column (5), the test is a full scale test unless otherwise specified.

In order to maximize the possible field of application from a minimum number of tests, the parameter

changes have been spread over a series of test specimens. The recommended tests for each parameter

is depending upon the classification required and the preferred direction of testing as indicated in

column (5).

Where more than a single parameter variation is required, the influence on other variations shall also

be taken into account.

Table A.1 — Construction parameters

Influence of variation on Additional evidence

Construction parameter Variation Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

A General (See Figure C.1 for an example of a General Arrangement of rolling shutter construction)

A.1 Size variations / construction

A.1.1 Width between vertical Possible providing tightness and clearances are not

Decrease ≥

guides (See Figure C.2) changed

Possible providing the static requirements to fixings,

A.1.2 Distance between

barrel and load-bearing constructions are fulfilled

vertical guides Increase =

and the requirements of Annex B are satisfied (at

(See Figure C.2)

room temperature)

A.1.3 Height from floor level

to centre line of barrel Decrease ≥ Possible

(See Figure C.3)

Possible providing the static requirements to fixings,

A.1.4 Height from floor level

barrel and load-bearing constructions are fulfilled

to centre line of barrel Increase =

and the requirements of Annex B are satisfied (at

(See Figure C.3)

room temperature)

Possible providing a minimum gap of 10 mm will

A.1.5 Expansion allowances

remain during opening/closing

between the end of the Decease > = <

lath and guide

Otherwise not possible without an additional test

A.1.6 Expansion allowances

between the end of the Increase = Possible

lath and guide

Face fixed on

A.1.7 Mounting furnace side to = Possible

within opening

Within opening

A.1.8 Mounting to face fixed on = Possible

furnace side

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

A.2 Materials and constructions

Possible providing no abrasion will occur (in general

this is given if no moving part touches the insulation

A.2.1 Insulation material

material during opening/closing)

whether intumescent Change > = <

or not Otherwise

Not possible without an additional test

Possible providing no moving part touches the

A.2.2 Density of insulation

insulation material during opening/closing)

Increase > = <

material

Otherwise not possible without an additional test

Possible providing no moving part touches the

A.2.3 Density of insulation

insulation material during opening/closing)

Decrease > = <

material

Otherwise not possible without an additional test

Possible but only for an identical composition or if no

Change of

moving part touches the insulation material during

A.2.4 Intumescent material supplier and/or > = <

opening/closing)

manufacturer

Otherwise not possible without an additional test

Possible providing no moving part touches the

Alternative

insulation material during opening/closing)

A.2.5 Intumescent material > = <

material

Otherwise not possible without an additional test

Possible providing no moving part touches the

A.2.6 Thickness of insulation

insulation material during opening/closing)

material other than Increase > = <

curtains

Otherwise not possible without an additional test

A.2.7 Thickness of insulation

material other than Decrease = Possible

curtains

B Curtain

B.1 Laths

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

Possible providing interlock remains the same and

the interaction with parts touching the curtain (e.g.

press rollers) remains the same

B.1.1 Size (height of lath)

Decrease > = <

(See Figure C.4) Or a test has been passed (with a similar type of

rolling shutter assembly) with this type of laths

Otherwise not possible without an additional test

Possible providing a test has been passed (with a

similar type of rolling shutter assembly) with this

B.1.2 Size (height of lath)

Increase ≥

type of laths with the same or lower barrel diameter

(See Figure C.5)

Otherwise not possible without an additional test

Possible providing a test has been passed (with

another type of rolling shutter assembly) with this

B.1.3 Thickness of steel Decrease > = <

type of laths with the same or lower barrel diameter

Otherwise not possible without an additional test

Possible providing a test has been passed (with

another type of rolling shutter assembly) with this

type of laths with the same or smaller barrel

B.1.4 Thickness of steel Increase > = <

diameter

Otherwise not possible without an additional test

Possible providing a test has been passed (with

another type of rolling shutter assembly) with this

B.1.5 Thickness of insulation

type of laths with the same or smaller barrel

material Decrease > = <

diameter

(See Figure C.6)

Otherwise not possible without an additional test

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

Possible providing a test has been passed (with

another type of rolling shutter assembly) with this

type of laths with the same or smaller barrel

B.1.6 Thickness of insulation

diameter and assuming that the gap between the

material Increase > = <

skins is full of insulating material and that the

(See Figure C.7)

thickness of lath creates a corresponding increase in

the width of the guides

Otherwise not possible without an additional test

Possible providing the material is not loaded

mechanically (e.g. fulled or bended) or a test has been

passed (with another type of rolling shutter

B.1.7 Density of insulation assembly) with this type of insulation material with

Increase > = <

material the same or smaller barrel diameter and the

requirements of Annex B are satisfied (at room

temperature) otherwise not possible without an

additional test

Possible providing the material is not loaded

mechanically (e.g. fulled or bended) or a test has been

passed (with another type of rolling shutter

B.1.8 Density of insulation

Decrease > = <

assembly) with this type of insulation material with

material

the same or smaller barrel diameter

Otherwise not possible without an additional test

Mild steel to

B.1.9 Material = Possible

stainless steel

Stainless steel to

B.1.10 Material = Possible

mild steel

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

Possible providing half the circumference of the

barrel is covered or a test has been passed (with

B.1.11 Number of laths on

another type of rolling shutter assembly) with this

barrel when door is in Decrease > = <

type of insulation material with the same or smaller

closed position

barrel diameter

Otherwise not possible without an additional test

B.1.12 Number of laths on

barrel when door is in Increase = Possible

closed position

Possible providing interlock remains the same and

the interaction with parts touching the curtain (e.g.

press rollers) remains the same

B.1.13 Shape (single skin)

Change > = <

(See Figure C.8) Or a test has been passed (with a similar type of

rolling shutter assembly) with this type of laths

Otherwise not possible without an additional test

Possible providing a test has been passed (with a

similar type of rolling shutter assembly) with this

B.1.14 Single skin to double

type of insulation material with the same or smaller

skin or double skin to

Change > = <

barrel diameter and the requirements of Annex B are

single skin

satisfied (at room temperature)

(See Figure C.9)

Otherwise not possible without an additional test

B.2 Endlocks (see Figure C.10 for example of endlock)

Possible providing the endlocks do not touch the

ground of the side guides during opening/closing

B.2.1 Size and shape Decrease > = <

Otherwise not possible without an additional test

Possible providing requirements in respect of

clearances and interlock remain unchanged

B.2.2 Size and shape Increase > = <

Otherwise not possible without an additional test

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

Possible providing the endlocks do not touch the

B.2.3 Thickness

ground of the side guides during opening/closing

Decrease > = <

(See Figure C.10)

Otherwise not possible without an additional test

Possible providing requirements in respect of

expansion clearances and interlock remain

B.2.4 Thickness

Increase > = <

unchanged

(See Figure C.10)

Otherwise not possible without an additional test

Steel to

B.2.5 Material = Possible

malleable iron

Malleable iron to

B.2.6 Material = Possible

steel

Possible providing the endlocks do not touch the

ground of the side guides during opening/closing

B.2.7 Material Steel to plastic ≤

Otherwise not possible without an additional test

Possible providing the endlocks do not touch the

ground of the side guides during opening/closing

B.2.8 Material Plastic to steel > = <

Otherwise not possible without an additional test

Possible providing the endlocks do not touch the

Steel to

ground of the side guides during opening/closing

B.2.9 Material > = <

aluminium

Otherwise not possible without an additional test

Possible providing the endlocks do not touch the

Aluminium to

ground of the side guides during opening/closing

B.2.10 Material > = <

steel

Otherwise not possible without an additional test

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

B.3 Endlock Fixings

Possible providing a test has been passed (with a

similar type of rolling shutter assembly) with this

diameter of endlock fixing with the same or smaller

B.3.1 Size (diameter) Decrease ≤

barrel diameter

Otherwise not possible without an additional test

B.3.2 Size (diameter) Increase ≥ Possible

Possible providing a test has been passed (with a

similar type of rolling shutter assembly) with this

type of endlock fixing with the same or smaller barrel

B.3.3 Type Change > = <

diameter

Otherwise not possible without an additional test

Possible providing a test has been passed (with a

similar type of rolling shutter assembly) with this

type of endlock fixing with the same or smaller barrel

B.3.4 Material Change > = <

diameter

Otherwise not possible without an additional test

Possible providing a test has been passed (with a

similar type of rolling shutter assembly) with the

required (or a lower) number of endlock fixings with

B.3.5 Number Decrease ≤

the same or smaller barrel diameter

Otherwise not possible without an additional test

B.3.6 Number Increase ≥ Possible

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

B.4 Bottom Rail

Possible providing a test has been passed (with a

similar type of rolling shutter assembly) with this

type of bottom rail with the same or smaller barrel

B.4.1 Size (See Figure C.11) Decrease > = <

diameter

Otherwise not possible without an additional test

Possible if requirements of Annex B are satisfied (at

B.4.2 Size (See Figure C.12) Increase ≥

room temperature)

Possible providing a test has been passed (with a

similar type of rolling shutter assembly) with this

type of bottom rail with the same or smaller barrel

B.4.3 Thickness of steel Decrease ≤

diameter

Otherwise not possible without an additional test

Possible if requirements of Annex B are satisfied (at

B.4.4 Thickness of steel Increase ≥

room temperature)

Stainless steel to

B.4.5 Material = Possible

mild steel

Mild steel to

B.4.6 Material = Possible

stainless steel

Possible providing a test has been passed (with a

similar type of rolling shutter assembly) with this

bottom rail material with the same or smaller barrel

B.4.7 Material of safety edge Change > = <

diameter

Otherwise not possible without an additional test

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

Possible providing a test has been passed (with a

similar type of rolling shutter assembly) with this

B.4.8 Construction Change from T-

type of bottom rail with the same or smaller barrel

> = <

(See Figure C.13) section to flat

diameter

Otherwise not possible without an additional test

Possible. If the weight of the T-section bottom bar is

B.4.9 Construction Change from flat

> = < higher the requirements of Annex B shall be satisfied

(See Figure C.14) to T-section

(at room temperature)

B.4.10 Expansion allowances

Possible providing a minimum gap of 10 mm will

between the end of

remain during opening/closing

Decrease ≤

the bottom rail and

Otherwise not possible without an additional test

guide

B.4.11 Expansion allowances

between the end of

Increase ≥ Possible

the bottom rail and

guide

Possible providing the bending stiffness and weight

Change from T-

will be the same or higher. In case of a higher weight

B.4.12 Construction

section to double > = <

the requirements of Annex B shall be satisfied.

(See Figure C.15)

angles

Otherwise not possible without an additional test

Possible providing the bending stiffness and weight

Change from

will be the same or higher. In case of a higher weight

B.4.13 Construction

double angles to > = <

the requirements of Annex B shall be satisfied.

(See Figure C.16)

T-section

Otherwise not possible without an additional test

Possible providing the bending stiffness and weight

Change from

will be the same or higher. In case of a higher weight

B.4.14 Construction

insulated to T- > = <

the requirements of Annex B shall be satisfied.

(See Figure C.17)

section

Otherwise not possible without an additional test

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

Possible providing the bending stiffness and weight

Change from T-

will be the same or higher. In case of a higher weight

B.4.15 Construction

section to > = <

the requirements of Annex B shall be satisfied.

(See Figure C.18)

insulated

Otherwise not possible without an additional test

B.5 Bottom rail fixings

Possible subject to total cross-section of fixings not

B.5.1 Size Decrease > = <

being reduced

B.5.2 Size Increase ≥ Possible

Possible subject to total cross-section of fixings not

B.5.3 Type Change > = <

being reduced

Possible providing the material has equal or better

B.5.4 Material Change > = < mechanical properties (yield stress, Young’s modulus,

creep behaviour)

B.5.5 Number Decrease ≤ Not possible

B.5.6 Number Increase ≥ Possible

C. Guides

C.1 Section

C.1.1 Shape from channel to

wind-lock type Change = Possible

(See Figure C.19)

C.1.2 Shape from wind-lock

type to channel Change = Possible providing no wind-locks are used

(See Figure C.20)

C.1.3 Depth

Decrease ≤ Not possible

(See Figure C.21)

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

C.1.4 Depth Possible providing tightness and clearances are not

Increase ≥

(See Figure C.22) reduced

C.1.5 Width Possible providing tightness and clearances are not

Decrease > = <

(See Figure C.23) reduced

C.1.6 Width

Increase ≥ Possible

(See Figure C.24)

C.1.7 Material thickness Decrease ≤ Not possible

C.1.8 Material thickness Increase ≥ Possible

Stainless steel to

C.1.9 Material = Possible

mild steel

Mild steel to

C.1.10 Material = Possible

stainless steel

Possible providing a minimum gap of 10 mm will

remain during opening/closing

C.1.11 Expansion allowances Decrease ≤

Otherwise not possible without an additional test

C.1.12 Expansion allowances Increase ≥ Possible

C.2 Guide fixing section

C.2.1 Size (See Figure C.25) Decrease ≤ Not possible

C.2.2 Size (See Figure C.26) Increase ≥ Possible

C.2.3 Thickness Decrease ≤ Not possible

C.2.4 Thickness Increase ≥ Possible

Stainless steel to

C.2.5 Material = Possible

mild steel

Mild steel to

C.2.6 Material = Possible

stainless steel

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

C.2.7 Expansion allowances Decrease = Possible

C.2.8 Expansion allowances Increase = Possible

Possible providing thickness and section modulus is

C.2.9 Shape

same or greater

Change > = <

(See Figure C.27)

Otherwise not possible without an additional test

C.2.10 Continuous section to

Change = Possible

short sections

C.2.11 Short sections to

Change = Possible

continuous sections

C.2.12 Flag type including

Possible providing clearances (between shutter and

endplate Separate =

guides) are not reduced

(See Figure C.28)

C.2.13 Separate Possible providing clearances (between shutter and

Flag type > = <

(See Figure C.29) guides) are not reduced

C.3 Fixings to supporting construction

Possible subject to more fixings being used so that

C.3.1 Size Decrease > = <

the total cross-section of the fixings is not decreased

C.3.2 Size Increase ≥ Possible

C.3.3 Spacing Decrease ≥ Possible

Possible by 10 % and providing that the position

C.3.4 Spacing Increase ≤

uppermost fixing (of each side) is not lowered

C.3.5 Number Decrease ≤ Not possible

C.3.6 Number Increase ≥ Possible

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

Possible providing the fixings have been shown by

Alternative

test to have an equal or better pullout strength (at

C.3.7 Material or Type material and/or > = < .

room temperature); see Annex B, otherwise not

type

possible without an additional test

D Barrel

D.1 Tube

Possible providing a test has been passed (with a

similar type of rolling shutter assembly) with the

D.1.1 Outside diameter

same or smaller tube diameter and the requirements

Decrease > = <

(See Figure C.30)

in Annex B are satisfied (at room temperature)

Otherwise not possible without an additional test

D.1.2 Outside diameter Possible providing requirements in Annex B are

Increase ≥

(See Figure C.31) satisfied (at room temperature)

D.1.3 Wall thickness Possible providing requirements in Annex B are

Decrease ≤

(See Figure C.32) satisfied (at room temperature)

D.1.4 Wall thickness Possible providing requirements in Annex B are

Increase ≥

(See Figure C.33) satisfied (at room temperature)

Possible requirements in Annex B are satisfied (at

room temperature) or a test has been passed (with a

Alternative

similar type of rolling shutter assembly) with the

D.1.5 Material material and/or > = <

same or smaller tube diameter

manufacturer

Otherwise not possible without an additional test

D.1.6 Expansion allowances Decrease = Possible

D.1.7 Expansion allowances Increase = Possible

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

Possible providing half the tube is minimum

octagonal and requirements in Annex B are satisfied

Change from

(at room temperature) or a test has been passed

D.1.8 Shape

circular to ≤

(with a similar type of rolling shutter assembly) with

(See Figure C.34)

angular

this type of tube with the same or smaller diameter,

Otherwise not possible without an additional test.

Change from

D.1.9 Shape Possible providing the requirements in Annex B are

angular to ≥

(See Figure C.34) satisfied (at room temperature).

circular

D.2 Shaft

D.2.1 Outside diameter Possible providing requirements in Annex B are

Decrease ≤

(See Figure C.35) satisfied (at room temperature).

D.2.2 Outside diameter Possible providing requirements in Annex B are

Increase ≥

(See Figure C.36) satisfied (at room temperature).

D.2.3 Type Possible providing requirements in Annex B are

Solid to hollow ≤

(See Figure C.37) satisfied (at room temperature).

D.2.4 Type

Hollow to solid ≥ Possible

(See Figure C.38)

Possible providing requirements in Annex B are

D.2.5 Material Alternative > = <

satisfied (at room temperature).

D.2.6 Expansion allowances

Decrease ≤ Not possible

(lateral)

D.2.7 Expansion allowances

Increase ≥ Possible

(lateral)

Possible providing requirements in Annex B are

D.2.8 Shape

Change = satisfied (at room temperature), otherwise not

(See Figure C.39)

possible without an additional test.

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

Possible providing a test has been passed (with a

similar type of rolling shutter assembly) with this

D.2.9 Stub shafts

Continuous axle ≤

type of shaft with the same or smaller diameter,

(See Figure C.40)

Otherwise not possible without an additional test.

D.2.10 Continuous axle

Stub shafts ≥ Possible

(See Figure C.41)

D.2.11 Shaft end retention Remove < Not possible

D.2.12 Shaft end retention Add ≥ Possible

D.3 Endcaps (Infill at end of tube usually mild steel or casting which sometimes carries a bearing if the shaft is fixed).

D.3.1 Thickness Decrease < Not possible

D.3.2 Thickness Increase ≥ Possible

Alternative Possible providing requirements in Annex B are

D.3.3 Material material and/or > = < satisfied (at room temperature). otherwise not

manufacturer possible without an additional test

D.4 Curtain to barrel fixings

Possible providing the fixings are positioned closer

together so that the total cross-section of the fixings

D.4.1 Size Decrease > = <

is not decreased, otherwise not possible without an

additional test

D.4.2 Size Increase ≥ Possible

D.4.3 Number Decrease < Not possible

D.4.4 Number Increase ≥ Possible

Possible providing the material has equal or better

Alternative

mechanical properties (yield stress, Young’s modulus,

D.4.5 Material material and/or > = <

creep behaviour), otherwise not possible without an

manufacturer

additional test

Influence of variation on Additional evidence

Construction parameter Variation

Possibility of extension

performance characteristic required

(1) (2) (3) (4) (5)

D.4.6 Spacing Decrease ≥ Possible

D.4.7 Spacing Increase ≤ Not possible

D.5 Springs either inside barrels or externally mounted

D.5.1 Delete > = < Possible providing closing speed will not increase

Possible providing requirements in Annex B are

D.5.2 Add > = <

satisfied (at room temperature)

D.5.3 Size Decrease > = < Possible providing closing speed will not increase

Possible providing requirements in Annex B are

D.5.4 Size Increase > = <

satisfied (at room temperature)

D.5.5 Number Decrease > = < Possible providing closing speed will not increase

Possible providing requirements in Annex B are

D.5.6 Number Increase > = <

satisfied (at room temperature)

Alternative Possible providing closing speed will not increase

D.5.7 Material material and/or > = < and the requirements in Annex B are satisfied (at

manufacturer room temperature)

E Barrel/shaft end supports

E.1 Support brackets/endplates

Possible providing requirements in

E.1.1 Size (See Figure C.42) Decrease > = <

Annex B are satisfied (at room temperature)

E.1.2 Size (See Figure C.43) Increase > Possible

Possible providing requirements in Annex B are

E.1.3 Material thickness Decrease > = <

satisfied (at room temperature)

E.1.4 Material thickness Increase > Possible

oSIST prEN 17

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...