EN 13684:2004+A2:2009

(Main + Amendment)Garden equipment - Pedestrian controlled lawn aerators and scarifiers - Safety

Garden equipment - Pedestrian controlled lawn aerators and scarifiers - Safety

This European Standard specifies safety requirements and their verification for the design and construction of pedestrian controlled integrally powered lawn aerators and scarifiers which are designed for re-generating lawns by, for instance, combing out grass, thatch and moss or cutting vertically into the lawn face using tines which rotate about a horizontal axis. It describes methods of elimination or reduction of hazards arising from their use. In addition, it specifies the type of information to be provided by the manufacturer on safe working practices.

Throughout this standard, the term "machine" applies to those machines known as aerators, scarifiers, corers, lawn rakes or grass rakes.

This standard does not apply to aerators/scarifiers made from a machine falling within the scope of EN 709:1997 when fitted with an aerating/scarifying implement, non-powered aerators, vertical axis aerators or those aerators which cut into the soil by means of a reciprocating motion or by water pressure. The electrical aspects of mains operated machines are covered by EN 60335-1. The safety aspects of batteries other than batteries for starting the engine and the electrical safety aspects of battery powered lawn aerators and scarifiers are not covered by this standard.

This standard deals with all significant hazards, hazardous situations and events relevant to scarifiers and aerators, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4).

Environmental hazards and EMC have not been considered in this standard.

This document is not applicable to aerators/scarifiers which are manufactured before the date of publication of this document by CEN.

Gartengeräte - Handgeführte Rasen-Bodenbelüfter und Vertikutierer - Sicherheit

Dieses Dokument ist eine Typ-C-Norm wie in EN 1070 angegeben.

Auf die betreffenden Maschinen und die behandelten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse wird im Anwendungsbereich dieses Dokuments hingewiesen.

Für Maschinen, die nach den Festlegungen dieser Typ-C-Norm konzipiert und gebaut worden sind, gilt: Wenn die Festlegungen in dieser Typ-C-Norm von den Festlegungen in Typ-A- oder Typ-B-Normen abweichen, haben die Festlegungen dieser Typ-C-Norm Vorrang gegenüber den Festlegungen der anderen Normen.

Matériel de jardinage - Aérateurs et scarificateurs à conducteur à pied - Sécurité

La présente Norme européenne spécifie les prescriptions de sécurité et leurs vérifications pour la conception et laconstruction des aérateurs de gazon et des scarificateurs à moteur intégré à conducteur à pied conçus pourpermettre au gazon d'être régénéré, par exemple par le ratissage de l'herbe, du chaume et de la mousse ou la coupeverticale de la surface du gazon par l'utilisation de dents qui tournent autour d'un axe horizontal. Elle décritlesméthodes pour éliminer ou réduire les phénomènes dangereux inhérents à leur utilisation. En outre, elle spécifiele type d’informations que le fabricant doit fournir sur les pratiques d’utilisation sûres.Dans toute cette norme, le terme «machine» s'applique aux machines connues comme étant des aérateurs,desscarificateurs, des extracteurs, des râteaux pour gazon ou herbe.La présente norme ne s'applique ni aux aérateurs/scarificateurs réalisés sur la base d’une machine relevantdudomaine d'application de l'EN 709:1997 lorsqu'ils sont équipés d'un outil d'aération/scarification, ni aux aérateurssans source de puissance, ni à ceux à axe vertical ou travaillant le sol au moyen d'un mouvement alternatif ou de lapression de l'eau. En ce qui concerne les aspects électriques des machines raccordées au secteur, se reporteràl'EN60335-1. Les aspects de sécurité des batteries autres que les batteries pour le démarrage du moteur et lesaspects de sécurité électrique des aérateurs de gazon et des scarificateurs alimentés par batteries ne sont pas couvertspar la présente norme. La présente norme traite tous les phénomènes dangereux, situations et événements dangereux significatifsengendrés par les scarificateurs et les aérateurs lorsqu’ils sont utilisés normalement et dans les conditions prévuespar le fabricant (voir Article 4).Les phénomènes dangereux liés à l’environnement et à la CEM ne sont pas couverts par la présente norme.

Oprema za nego vrta - Ročno upravljani prezračevalniki travne ruše in rahljalniki zemlje - Varnost

General Information

- Status

- Withdrawn

- Publication Date

- 07-Jul-2009

- Withdrawal Date

- 15-Dec-2009

- Technical Committee

- CEN/TC 144 - Tractors and machinery for agriculture and forestry

- Drafting Committee

- CEN/TC 144/WG 7 - Garden equipment

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 16-Dec-2009

- Completion Date

- 16-Dec-2009

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 24-Oct-2009

- Merged From

EN 13684:2004 - Garden equipment - Pedestrian controlled lawn aerators and scarifiers - Safety - Effective Date

- 20-May-2009

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Control Union Certifications

Global certification for agriculture and sustainability.

ECOCERT

Organic and sustainability certification.

Rainforest Alliance Certification

Sustainable agriculture and forestry certification.

Sponsored listings

Frequently Asked Questions

EN 13684:2004+A2:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Garden equipment - Pedestrian controlled lawn aerators and scarifiers - Safety". This standard covers: This European Standard specifies safety requirements and their verification for the design and construction of pedestrian controlled integrally powered lawn aerators and scarifiers which are designed for re-generating lawns by, for instance, combing out grass, thatch and moss or cutting vertically into the lawn face using tines which rotate about a horizontal axis. It describes methods of elimination or reduction of hazards arising from their use. In addition, it specifies the type of information to be provided by the manufacturer on safe working practices. Throughout this standard, the term "machine" applies to those machines known as aerators, scarifiers, corers, lawn rakes or grass rakes. This standard does not apply to aerators/scarifiers made from a machine falling within the scope of EN 709:1997 when fitted with an aerating/scarifying implement, non-powered aerators, vertical axis aerators or those aerators which cut into the soil by means of a reciprocating motion or by water pressure. The electrical aspects of mains operated machines are covered by EN 60335-1. The safety aspects of batteries other than batteries for starting the engine and the electrical safety aspects of battery powered lawn aerators and scarifiers are not covered by this standard. This standard deals with all significant hazards, hazardous situations and events relevant to scarifiers and aerators, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). Environmental hazards and EMC have not been considered in this standard. This document is not applicable to aerators/scarifiers which are manufactured before the date of publication of this document by CEN.

This European Standard specifies safety requirements and their verification for the design and construction of pedestrian controlled integrally powered lawn aerators and scarifiers which are designed for re-generating lawns by, for instance, combing out grass, thatch and moss or cutting vertically into the lawn face using tines which rotate about a horizontal axis. It describes methods of elimination or reduction of hazards arising from their use. In addition, it specifies the type of information to be provided by the manufacturer on safe working practices. Throughout this standard, the term "machine" applies to those machines known as aerators, scarifiers, corers, lawn rakes or grass rakes. This standard does not apply to aerators/scarifiers made from a machine falling within the scope of EN 709:1997 when fitted with an aerating/scarifying implement, non-powered aerators, vertical axis aerators or those aerators which cut into the soil by means of a reciprocating motion or by water pressure. The electrical aspects of mains operated machines are covered by EN 60335-1. The safety aspects of batteries other than batteries for starting the engine and the electrical safety aspects of battery powered lawn aerators and scarifiers are not covered by this standard. This standard deals with all significant hazards, hazardous situations and events relevant to scarifiers and aerators, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). Environmental hazards and EMC have not been considered in this standard. This document is not applicable to aerators/scarifiers which are manufactured before the date of publication of this document by CEN.

EN 13684:2004+A2:2009 is classified under the following ICS (International Classification for Standards) categories: 65.060.70 - Horticultural equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13684:2004+A2:2009 has the following relationships with other standards: It is inter standard links to EN 13684:2004+A3:2009, EN 13684:2004, EN ISO 13628-4:2010, EN ISO 10424-2:2007, EN ISO 10407-2:2008, EN ISO 10423:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13684:2004+A2:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13684:2004+A2:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Gartengeräte - Handgeführte Rasen-Bodenbelüfter und Vertikutierer - SicherheitMatériel de jardinage - Aérateurs et scarificateurs à conducteur à pied - SécuritéGarden equipment - Pedestrian controlled lawn aerators and scarifiers - Safety65.060.70Vrtnarska opremaHorticultural equipmentICS:Ta slovenski standard je istoveten z:EN 13684:2004+A2:2009SIST EN 13684:2004+A2:2009en,fr,de01-november-2009SIST EN 13684:2004+A2:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13684:2004+A2

July 2009 ICS 65.060.70 Supersedes EN 13684:2004English Version

Garden equipment - Pedestrian controlled lawn aerators and scarifiers - Safety

Matériel de jardinage - Aérateurs et scarificateurs à conducteur à pied - Sécurité

Gartengeräte - Handgeführte Rasen-Bodenbelüfter und Vertikutierer - Sicherheit This European Standard was approved by CEN on 1 April 2004 and includes Amendment 2 approved by CEN on 6 June 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13684:2004+A2:2009: ESIST EN 13684:2004+A2:2009

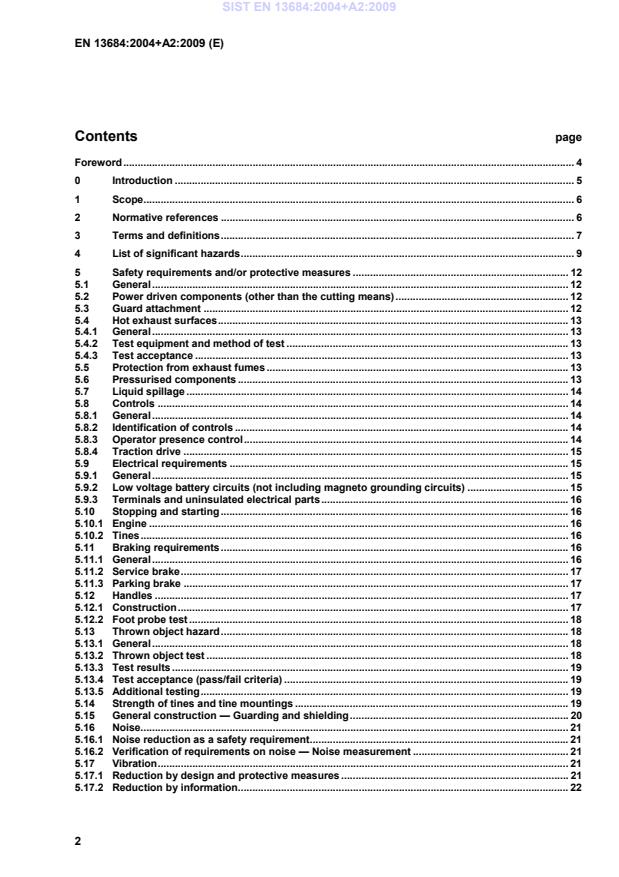

Symbols/pictorials . 33A.1General . 33A.2Pictograms . 33Annex B (informative)

Safety instructions . 35B.1General . 35B.2Safe operation practices. . 35B.2.1Training . 35B.2.2Preparation . 35B.2.3Operation . 36B.2.4Maintenance and storage . 37Annex C (normative)

Noise test code — Engineering method (grade 2) . 38C.1Scope. 38C.2A-weighted sound power level determination . 38C.3A-weighted emission sound pressure level measurement . 40C.4Requirements for test floor . 40C.4.1Artificial surface . 40C.4.2Natural grass . 41C.5Installation, mounting and operating conditions . 41C.6Measurement uncertainties and declaration of noise emission values . 42C.7Information to be recorded and reported . 42Annex D (informative)

Example of a material and construction fulfilling the requirements for an artificial surface. 43D.1Material . 43D.2Construction . 43Annex E (normative)

Vibration . 45E.1Quantities to be measured . 45E.2Instrumentation . 45E.2.1General . 45E.2.2Fastening of transducer . 45E.2.3Calibration . 45E.3Measurement direction and measurement location . 45E.3.1Measurement direction . 45E.3.2Measurement location . 46E.4Determination of working procedure . 46E.5Measurement procedure . 46E.6Determination of the measurement result . 47Annex ZA (informative)

####Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC$$$$ . 48Annex ZB (informative)

####Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC$$$$ . 49Bibliography . 50 SIST EN 13684:2004+A2:2009

Its is the responsibility of the manufacturer to check whether or not the safety requirements specified in this standard apply to each significant hazards presented by its specific machine and to validate that the risk assessment is complete with particular attention to: the intended use of the machine including maintenance, setting and cleaning and its reasonably foreseeable misuse; the identification of all significant hazards associated with the machine. SIST EN 13684:2004+A2:2009

— machine parts or work pieces, e.g.:

e) inadequacy of mechanical strength; Tine failure/strength 5.14

— accumulation of energy inside the machinery e.g.:

g) liquids and gases under pressure; Hydraulic fluid leakage/burst 5.6, 6.1 1.2 Shearing hazard Contact with moving parts 5.2, 5.3, 5.10.2, 5.15, 6.1, 6.2 and annex A 1.3 Cutting or severing hazard Contact with moving parts 5.2, 5.3, 5.10.2, 5.15, 6.1, 6.2 and annex A 1.4 Entanglement hazard Contact with moving parts 5.2, 5.3, 5.10.2, 5.15, 6.1, 6.2 and annex A 1.5 Drawing-in or trapping hazard Contact with moving parts 5.2, 5.3, 5.10.2, 5.15, 6.1, 6.2 and annex A 1.6 Impact hazard Hit by thrown objects 5.3, 5.13 1.9 High pressure fluid injection or ejection hazard Penetration by high pressure fluid 5.6, 6.1 2 Electrical hazards due to: 2.1 Contact of persons with live parts (direct contact) Contact with live parts 5.9.3 2.3 Approach to live parts under high voltage Contact with HT ignition parts 5.9.3 2.5 Thermal radiation or other phenomena such as the projection of molten particles and chemical effects from short circuits, overloads, etc. Protection against circuit overload 5.9.2.3 3 Thermal hazards, resulting in: 3.1 Burns, scalds and other injuries by a possible contact of persons with objects or materials with an extreme high or low temperature, by flames or explosions and also by the radiation of heat sources Contact with hot parts 5.4 4 Hazards generated by noise, resulting in: 4.1 Hearing loss (deafness), other physiological disorders (e.g. loss of balance, loss of awareness) Hearing damage 5.16, 6.1, 6.2 and annex A, annex C 5 Hazards generated by vibration 5.1 Use of hand-held machines resulting in a variety of neurological and vascular disorders Vibration white finger 5.17, 6.1, annex E

(continued)

Over-speed of engine 5.8.1 Leaving unattended machine running 5.8.3 16 Break-up during operation Broken tines 5.14 17 Falling or ejected objects or fluids Thrown objects 5.3, 5.13

Additional hazards, hazardous situations and hazardous events due to mobility 20 Relating to the travelling function

20.1 Movement when starting the engine Movement of the machine 5.8.1, 5.8.3, 5.8.4 20.2 Movement without a driver at the driving position Operator presence control — tines Operator presence control — traction 5.8.3 5.8.4 20.6 Insufficient ability of machinery to be slowed down, stopped and immobilised Stopping from travelling Keeping stationary 5.11.1, 5.11.2 5.11.3 21 Linked to the work position (including driving station) on the machine 21.4 Mechanical hazards at the work position: c) fall of objects, penetration by objects e) contact of persons with machine parts or tools (pedestrian controlled machines)

Thrown objects Feet in contact with tines

5.3, 5.13 5.12

(continued) SIST EN 13684:2004+A2:2009

5.7 Liquid spillage When filled to the maximum according to the manufacturer's instructions liquid containers, batteries, fuel systems, oil reservoirs, and coolant systems shall be constructed to prevent spillage for 1 min whilst the machine is tilted at 20 ° lateral and 30 ° longitudinal. Weeping at vent systems shall not be considered as spillage. Compliance shall be checked by inspection.

5.8 Controls 5.8.1 General Except as indicated in the following list operator controls shall be located within, and have a range of movement which remains within, the anthropometric dimensions given in Figure 1: controls for setting the depth of penetration of the tines; catcher discharge arrangements; engine starting controls, on condition that starting can only be accomplished with the drive to the tines disengaged. The operating range of less frequently used operator controls may be extended by allowing the operator's trunk, when standing with both feet on the ground, to articulate within the confines of the operator zone (e.g. lean forward until contacting the handle in any of the operating positions). It shall not be possible to sustain an engine/motor speed greater than the maximum operating engine/motor speed by use of any control or by simple adjustments made by using standard tools. Compliance shall be checked by inspection. 5.8.2 Identification of controls Controls, whose purpose is not obvious to the user, shall have the function, direction and/or method of operation clearly identified by a durable label or mark. Operator control symbols shall comply with ISO 3767-1:1998, and ISO 3767-3:1995, and ISO 3864-1:2002 for signs and colours. Detailed instructions on the operation of all controls shall be provided in an instruction handbook. Compliance shall be checked by inspection. 5.8.3 Operator presence control Machines shall be fitted with a device on the control handle which will automatically stop tine rotation when the operator's hands are removed from the handle. This may be accomplished, for example, by stopping the drive motor or by an intermediate tine clutch/brake mechanism.

5.9 Electrical requirements 5.9.1 General These electrical requirements apply only to battery starter and ignition circuits. 5.9.2 Low voltage battery circuits (not including magneto grounding circuits) 5.9.2.1 Electrical cables Electrical cables shall be protected if located in potentially abrasive contact with metal surfaces and shall be resistant to, or protected against, contact with lubricant and fuel. The wiring assembly shall, where possible, be grouped together, be supported and be located so that no portion is in contact with the carburettor, metallic fuel lines, the exhaust system, moving parts or sharp edges. Any edges of metal members likely to be in contact with the cables shall be rounded or protected to prevent damage to the cables by cutting or abrasion. Compliance shall be checked by inspection. 5.9.2.2 Battery installation The compartment for a vented storage battery shall have openings to provide ventilation and drainage. When the battery is in the operating position, acid shall not leak onto parts that would be critically affected to the extent that a hazard would be created from corrosion. Compliance shall be checked by inspection. 5.9.2.3 Overload protection All circuits, except starter motor and high tension ignition circuits, shall be provided with overload protection devices in the ungrounded line near the battery terminal. The overload protection may be located in either wire of a 2 wire system. Compliance shall be checked by inspection. SIST EN 13684:2004+A2:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...