EN 15232:2012

(Main)Energy performance of buildings - Impact of Building Automation, Controls and Building Management

Energy performance of buildings - Impact of Building Automation, Controls and Building Management

This European Standard specifies:

a structured list of Building Automation and Control System (BACS) and Technical Building Management (TBM) functions which have an impact on the energy performance of buildings;

a method to define minimum requirements regarding BACS and TBM functions to be implemented in buildings of different complexities;

a factor based method to get a first estimation of the impact of these functions on typical buildings;

detailed methods to assess the impact of these functions on a given building. These methods enable to introduce the impact of these functions in the calculations of energy performance ratings and indicators calculated by the relevant standards.

This European Standard is defined for:

building owners, architects or engineers, defining the functions to be implemented for a given new building or for the renovation of an existing building;

public authorities, defining minimum requirements for BACS and TBM functions for new buildings as well as for renovation, as defined in the relevant standard;

public authorities, defining inspection procedures of technical systems as well as inspectors applying these procedures to check if the level of BACS and TBM functions implemented is appropriate;

public authorities, defining calculation methods which take into account the impact of BACS and TBM functions on the energy performance of buildings as well as software developers implementing these calculation methods and designers using them;

designers, checking that the impact of all BACS and TBM functions are taken into account when assessing the energy performance of a building.

Energieeffizienz von Gebäuden - Einfluss von Gebäudeautomation und Gebäudemanagement

Diese Europäische Norm legt Folgendes fest:

- eine strukturierte Liste von Funktionen der Gebäudeautomation und des technischen Gebäudemanagements, die Auswirkungen auf die Energieeffizienz von Gebäuden haben;

- ein Verfahren zur Definition der Mindestanforderungen hinsichtlich der GA- und TGM-Funktionen, die in Gebäuden unterschiedlicher Komplexität umzusetzen sind;

- ein faktorbasiertes Verfahren für eine erste Abschätzung der Auswirkung dieser Funktionen auf typische Gebäude;

- ausführliche Verfahren zur Bewertung der Auswirkungen dieser Funktionen auf ein gegebenes Gebäude; Diese Verfahren erlauben es, die Auswirkungen dieser Funktionen in die Berechnungen der Kennzahlen und Leistungsindikatoren der Energieeffizienz nach den relevanten Normen aufzunehmen.

Diese Europäische Norm ist bestimmt für:

- Eigentümer von Gebäuden, Architekten oder Ingenieure, die die bei einem neuen Gebäude oder bei der Renovierung/Sanierung eines bestehenden Gebäudes umzusetzenden Funktionen definieren;

- öffentliche Behörden, die die Mindestanforderungen hinsichtlich der GA- und TGM-Funktionen für neue Gebäude sowie für die Renovierung/Sanierung nach den Festlegungen in den relevanten Normen definieren;

- öffentliche Behörden, die Inspektionsverfahren der technischen Anlagen definieren, sowie die Inspektoren, die diese Verfahren anwenden, um zu überprüfen, ob der Umsetzungsgrad der GA- und TGM-Funktionen angemessen ist;

- öffentliche Behörden, die Berechnungsverfahren definieren, die die Auswirkungen der GA- und TGM-Funktionen auf die Energieeffizienz von Gebäuden berücksichtigen, sowie Software-Entwickler, die diese Berechnungsverfahren umsetzen und Planer die sie anwenden;

- Planer, die überprüfen, ob die Auswirkungen aller GA- und TGM-Funktionen bei der Bewertung der Energieeffizienz eines Gebäudes berücksichtigt werden.

ANMERKUNG Die Begriffe BAC (Building Automation and Control) und BACS (Building Automation and Control System) sind von ihrer Bedeutung hinsichtlich energetischer Berechnung und Energieeffizienz äquivalent. In diesem Fall wird BACS in der englischen Fassung und BAC (Deutsche Entsprechung: GA Gebäudeautomation) in der deutschen Fassung verwendet.

Performance énergétique des bâtiments - Impact de l'automatisation, de la régulation et de la gestion technique

La présente Norme européenne spécifie :

- une liste structurée des fonctions d’automatisation, de régulation BACS et de gestion technique du bâtiment (GTB) qui ont un impact sur la performance énergétique des bâtiments,

- un procédé pour définir les exigences minimales concernant les fonctions d’automatisation, de régulation et de gestion technique du bâtiment (GTB) à mettre en œuvre dans des bâtiments de différentes complexités,

- une méthode basée sur des facteurs pour obtenir une première estimation de l'impact de ces fonctions sur les bâtiments classiques,

- des méthodes détaillées pour estimer l'impact de ces fonctions sur un bâtiment donné. Ces méthodes permettent de tenir compte de l'impact de ces fonctions dans les calculs des indices de performance énergétique et des indicateurs calculés par les normes appropriées.

La présente Norme européenne est destinée :

- aux propriétaires de bâtiments, architectes ou ingénieurs, qui spécifient les fonctions devant être mises en œuvre pour un bâtiment neuf donné ou pour la rénovation d'un bâtiment existant,

- aux pouvoirs publics qui définissent les spécifications minimales pour les fonctions d’automatisation, de régulation et de gestion technique du bâtiment GTB pour les bâtiments neufs comme pour la rénovation, comme défini dans la norme appropriée,

- aux pouvoirs publics qui définissent les procédures d'inspection des systèmes techniques ainsi qu'aux inspecteurs qui appliquent ces procédures pour vérifier si le niveau des fonctions d’automatisation, de régulation et de gestion technique du bâtiment GTB mis en œuvre est adapté,

- aux pouvoirs publics qui définissent les méthodes de calcul qui tiennent compte de l'impact des fonctions d’automatisation, de régulation et de gestion technique du bâtiment sur la performance énergétique des bâtiments ainsi qu'aux développeurs des logiciels qui implémentent ces méthodes de calcul et aux concepteurs qui les utilisent,

- aux concepteurs qui vérifient que l'impact de toutes les fonctions d’automatisation, de régulation et de gestion technique du bâtiment GTB sont bien prises en compte dans l'évaluation de la performance énergétique d'un bâtiment.

Energijske lastnosti stavb - Vpliv avtomatizacije stavb in izvršnih elementov ter upravljanja stavb

Ta evropski standard določa:

– strukturiran seznam funkcij sistema za avtomatizacijo in izvršne elemente stavb (BACS) ter tehničnega upravljanja stavb (TBM), ki vplivajo na energetsko učinkovitost stavb;

– metodo za opredelitev minimalnih zahtev v zvezi s funkcijami sistema za avtomatizacijo in izvršne elemente stavb ter tehničnega upravljanja stavb, ki morajo biti izpolnjene v različno kompleksnih stavbah;

– metodo, ki temelji na faktorju, za prvo oceno učinka teh funkcij na običajne stavbe;

– natančne metode za oceno učinka teh funkcij na določeno stavbo. Te metode omogočajo upoštevanje učinka teh funkcij pri ocenah in indikatorjih energetske učinkovitosti, izračunanih v skladu z zadevnimi standardi.

Ta evropski standard velja za:

– lastnike stavb, arhitekte ali inženirje, ki določajo funkcije, ki morajo biti izpolnjene pri neki novi stavbi ali obnovi obstoječe stavbe;

– javne organe, ki določajo minimalne zahteve za funkcije sistema za avtomatizacijo in izvršne elemente stavb ter tehničnega upravljanja stavb za nove stavbe in obnovo, kot je opredeljeno v ustreznem standardu;

– javne organe, ki določajo postopke nadzora tehničnih sistemov, ter nadzorne organe, ki uporabljajo te postopke pri preverjanju, ali je raven izpolnjenih funkcij sistema za avtomatizacijo in izvršne elemente stavb ter tehničnega upravljanja stavb primerna;

– javne organe, ki določajo metode izračuna, pri katerih se upošteva učinek funkcij sistema za avtomatizacijo in izvršne elemente stavb ter tehničnega upravljanja stavb na energetsko učinkovitost stavb, ter razvijalce programske opreme, ki izvajajo te metode izračuna, in projektante, ki te metode uporabljajo;

– projektante, ki preverjajo, ali se učinek funkcij sistema za avtomatizacijo in izvršne elemente stavb ter tehničnega upravljanja stavb upošteva pri oceni energetske učinkovitosti stavbe.

General Information

- Status

- Withdrawn

- Publication Date

- 24-Jan-2012

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 247 - Controls for mechanical building services

- Drafting Committee

- CEN/TC 247 - Controls for mechanical building services

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 24-May-2017

- Completion Date

- 28-Jan-2026

Relations

- Effective Date

- 30-Oct-2010

- Effective Date

- 31-May-2017

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

ICC Evaluation Service

Nonprofit organization that performs technical evaluations of building products.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 15232:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Energy performance of buildings - Impact of Building Automation, Controls and Building Management". This standard covers: This European Standard specifies: a structured list of Building Automation and Control System (BACS) and Technical Building Management (TBM) functions which have an impact on the energy performance of buildings; a method to define minimum requirements regarding BACS and TBM functions to be implemented in buildings of different complexities; a factor based method to get a first estimation of the impact of these functions on typical buildings; detailed methods to assess the impact of these functions on a given building. These methods enable to introduce the impact of these functions in the calculations of energy performance ratings and indicators calculated by the relevant standards. This European Standard is defined for: building owners, architects or engineers, defining the functions to be implemented for a given new building or for the renovation of an existing building; public authorities, defining minimum requirements for BACS and TBM functions for new buildings as well as for renovation, as defined in the relevant standard; public authorities, defining inspection procedures of technical systems as well as inspectors applying these procedures to check if the level of BACS and TBM functions implemented is appropriate; public authorities, defining calculation methods which take into account the impact of BACS and TBM functions on the energy performance of buildings as well as software developers implementing these calculation methods and designers using them; designers, checking that the impact of all BACS and TBM functions are taken into account when assessing the energy performance of a building.

This European Standard specifies: a structured list of Building Automation and Control System (BACS) and Technical Building Management (TBM) functions which have an impact on the energy performance of buildings; a method to define minimum requirements regarding BACS and TBM functions to be implemented in buildings of different complexities; a factor based method to get a first estimation of the impact of these functions on typical buildings; detailed methods to assess the impact of these functions on a given building. These methods enable to introduce the impact of these functions in the calculations of energy performance ratings and indicators calculated by the relevant standards. This European Standard is defined for: building owners, architects or engineers, defining the functions to be implemented for a given new building or for the renovation of an existing building; public authorities, defining minimum requirements for BACS and TBM functions for new buildings as well as for renovation, as defined in the relevant standard; public authorities, defining inspection procedures of technical systems as well as inspectors applying these procedures to check if the level of BACS and TBM functions implemented is appropriate; public authorities, defining calculation methods which take into account the impact of BACS and TBM functions on the energy performance of buildings as well as software developers implementing these calculation methods and designers using them; designers, checking that the impact of all BACS and TBM functions are taken into account when assessing the energy performance of a building.

EN 15232:2012 is classified under the following ICS (International Classification for Standards) categories: 35.240.99 - IT applications in other fields; 91.120.10 - Thermal insulation of buildings; 91.140.10 - Central heating systems; 97.120 - Automatic controls for household use. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15232:2012 has the following relationships with other standards: It is inter standard links to EN 15232:2007, EN 15232-1:2017, EN 15242:2007, EN 15500:2008, EN 15316-3-3:2007, EN 15316-3-2:2007, EN 15316-4-3:2017, EN ISO 52017-1:2017, EN 15378-1:2017, EN 15316-2-1:2007, EN 15603:2008, EN 15316-1:2007, EN ISO 13790:2008, EN 15316-4-2:2017, EN 15243:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15232:2012 is associated with the following European legislation: Standardization Mandates: M/343. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15232:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Energijske lastnosti stavb - Vpliv avtomatizacije stavb in izvršnih elementov ter upravljanja stavbEnergieeffizienz von Gebäuden - Einfluss von Gebäudeautomation und GebäudemanagementPerformance énergétique des bâtiments - Impact de l'automatisation, de la régulation et de la gestion techniqueEnergy performance of buildings - Impact of Building Automation, Controls and Building Management97.120Avtomatske krmilne naprave za domAutomatic controls for household use91.120.10Toplotna izolacija stavbThermal insulation of buildings27.015VSORãQREnergy efficiency. Energy conservation in generalICS:Ta slovenski standard je istoveten z:EN 15232:2012SIST EN 15232:2012en,fr,de01-maj-2012SIST EN 15232:2012SLOVENSKI

STANDARDSIST EN 15232:20071DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15232

January 2012 ICS 35.240.99; 91.120.10; 97.120 Supersedes EN 15232:2007English Version

Energy performance of buildings - Impact of Building Automation, Controls and Building Management

Performance énergétique des bâtiments - Impact de l'automatisation, de la régulation et de la gestion technique Energieeffizienz von Gebäuden - Einfluss von Gebäudeautomation und Gebäudemanagement This European Standard was approved by CEN on 27 November 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15232:2012: ESIST EN 15232:2012

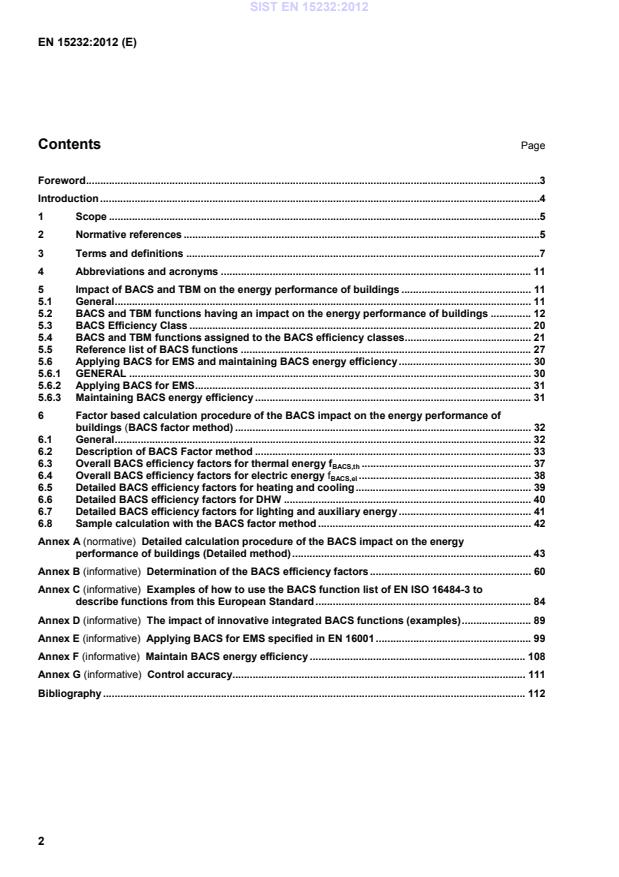

Detailed calculation procedure of the BACS impact on the energy performance of buildings (Detailed method) . 43Annex B (informative)

Determination of the BACS efficiency factors . 60Annex C (informative)

Examples of how to use the BACS function list of EN ISO 16484-3 to describe functions from this European Standard . 84Annex D (informative)

The impact of innovative integrated BACS functions (examples) . 89Annex E (informative)

Applying BACS for EMS specified in EN 16001 . 99Annex F (informative)

Maintain BACS energy efficiency . 108Annex G (informative)

Control accuracy. 111Bibliography . 112 SIST EN 15232:2012

detailed methods to assess the impact of these functions on a given building. These methods enable to introduce the impact of these functions in the calculations of energy performance ratings and indicators calculated by the relevant standards. This European Standard is defined for: building owners, architects or engineers, defining the functions to be implemented for a given new building or for the renovation of an existing building; public authorities, defining minimum requirements for BACS and TBM functions for new buildings as well as for renovation, as defined in the relevant standard; public authorities, defining inspection procedures of technical systems as well as inspectors applying these procedures to check if the level of BACS and TBM functions implemented is appropriate; public authorities, defining calculation methods which take into account the impact of BACS and TBM functions on the energy performance of buildings as well as software developers implementing these calculation methods and designers using them; designers, checking that the impact of all BACS and TBM functions are taken into account when assessing the energy performance of a building. NOTE The terms BAC (Building Automation and Control) and BACS (Building Automation and Control System) are equivalent in view of energy calculation and energy efficiency. In this case BACS will be used in the English version and BAC (German term: "GA Gebäudeautomation") in the German version. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 12098-1, Controls for heating systems — Part 1: Outside temperature compensated control equipment for hot water heating systems EN 12098-2, Controls for heating systems — Part 2: Optimum start-stop control equipment for hot water heating systems EN 12098-3, Controls for heating systems — Part 3: Outside temperature compensated control equipment for electrical heating systems EN 12098-4, Controls for heating systems — Part 4: Optimum start-stop control equipment for electrical systems SIST EN 15232:2012

EN 15316-3-3:2007, Heating systems in buildings — Method for calculation of system energy requirements and system efficiencies — Part 3-3: Domestic hot water systems, generation EN 15316-4-1, Heating systems in buildings — Method for calculation of system energy requirements and system efficiencies — Part 4-1: Space heating generation systems (boilers) EN 15316-4-2, Heating systems in buildings — Method for calculation of system energy requirements and system efficiencies — Part 4-2: Space heating generation systems, heat pump systems EN 15316-4-3, Heating systems in buildings — Method for calculation of system energy requirements and system efficiencies — Part 4-3: Heat generation systems, thermal solar systems EN 15316-4-4, Heating systems in buildings — Method for calculation of system energy requirements and system efficiencies — Part 4-4: Heat generation systems, building-integrated cogeneration systems EN 15316-4-5, Heating systems in buildings — Method for calculation of system energy requirements and system efficiencies — Part 4-5: Space heating generation systems, the performance and quality of district heating and large volume systems SIST EN 15232:2012

Both input and output need to be accurately defined in quantity and quality, and be measurable. NOTE 2

Energy efficiency is commonly used with the meaning of “Optimum Energy Efficiency”, namely: “to operate (an entity) with minimum energy consumption”. NOTE 3

Commonly used sense of energy efficiency is doing at least the same with less energy. [CEN/CLC/TR 16103] 3.11 energy efficiency improvement increase in energy efficiency as a result of technological, behavioural and/or economic changes [CEN/CLC/TR 16103] 3.12 energy use manner or kind of application of energy EXAMPLE Lighting, ventilation, heating, processes, transport. NOTE The quantity of the energy applied is expressed as energy consumption. [CEN/CLC/TR 16103] 3.13 control function BACS effect of programs and parameters NOTE 1 Functions within a BACS are referred to as control functions, I/O, processing, optimization, management and operator functions. They are listed in the BACS FL (function list) for a specification of work. NOTE 2 Function is a program unit that delivers exactly one data element, which can be a multiple value (i.e. an array or a structure). Functions can be an operand in a program. [IEC 61131-3:2003] [EN ISO 16484-2:2004] SIST EN 15232:2012

Building Management DHW Domestic Hot Water EMS Energy Management System HVAC Heating, Ventilation and Air Conditioning TABS Thermo-active Building Systems TBM Technical Building Management 5 Impact of BACS and TBM on the energy performance of buildings 5.1 General Building Automation and Control Systems (BACS) provide effective control functions of heating, ventilating, cooling, hot water and lighting appliances etc., that lead to improve operational and energy efficiencies. Complex and integrated energy saving functions and routines can be configured based on the actual use of a building, depending on real user needs, to avoid unnecessary energy use and CO2 emissions. Technical Building Management (TBM) functions as part of Building Management (BM) provide information about operation, maintenance, services and management of buildings, especially for energy management – measurement, recording trending, and alarming capabilities and diagnosis of unnecessary energy use. Energy management provides requirements for documentation, controlling, monitoring, optimisation, determination and to support corrective action and preventive action to improve the energy performance of buildings. The BACS functions described in Table 1 are based on the energy demand and supply model for a building in Figure 1. SIST EN 15232:2012

Figure 1 — Energy demand and supply model (Example: Heating plant) Rooms represent the source of the energy demand. Suitable equipment should ensure comfortable conditions in the rooms with regard to temperature, humidity, air quality and light as needed and with due consideration of minimum or maximum requirements specified in local regulations. Supply media is provided to the consumer according to energy demand keeping losses in distribution and generation to an absolute minimum. The building automation and control functions described in Table 1 are aligned in accordance with the energy demand and supply model. The relevant energy-efficiency functions are handled starting with the room, via distribution up through generation. 5.2 BACS and TBM functions having an impact on the energy performance of buildings The most common BACS and TBM functions having an impact on the energy performance of buildings have been described and summarized in Table 1. SIST EN 15232:2012

1.1 Emission control

The control system is installed at the emitter or room level, for case 1 one system can control several rooms

0 No automatic control of the room temperature

1 Central automatic control: There is only central automatic control acting either on the distribution or on the generation. This can be achieved for example by an outside temperature controller conforming to EN 12098-1 or EN 12098-3

2 Individual room control: By thermostatic valves or electronic controller

3 Individual room control with communication and demand control: Communication between controllers and to BACS; Demand control performed by occupancy 1.2 Emission control for TABS

0 No automatic control of the room temperature

1 Central automatic control: The central automatic control for a TABS zone (which comprises all rooms which get the same supply water temperature) typically is a supply water temperature control loop whose set-point is dependant on the filtered outside temperature, e.g. the average of the previous 24 hours.

2 Advanced central automatic control: This is an automatic control of the TABS zone that fulfils the following conditions: – If the TABS is used only for heating: The central automatic control is designed and tuned to achieve an optimal self-regulating of the room temperature within the required comfort range (specified by the room temperature heating set-point). "Optimal" means that the room temperatures of all rooms of the TABS zone remain during operation periods in the comfort range, to meet comfort requirements, but also is as low as possible to reduce the energy demand for heating. – If the TABS is used for heating and cooling: The central automatic control is designed and tuned to achieve an optimal self-regulating of the room temperature within the required comfort range (specified by room temperature heating and cooling set-points). "Optimal" means that the room temperatures of all rooms of the TABS zone remain during operation periods in the comfort range, to meet comfort requirements, but also uses as far as possible the full range to reduce the energy demand for heating and cooling. – If the TABS is used for heating and cooling: the automatic switching between heating and cooling is not done only dependent on the outside temperature, but also taking at least indirectly the heat gains (internal and solar) into account.

3 Advanced central automatic control with intermittent operation and/or room temperature feedback control: a) Advanced central automatic control with intermittent operation. This is an advanced central automatic control according to 2) with the following supplement: The pump is switched off regularly to save electrical energy, either with a fast frequency - typically 6 hours on/off cycle time - or with a slow frequency, corresponding to 24 hours on/off cycle time. If the TABS is used for cooling, intermittent operation with 24 hours on/off cycle time can also be used to reject the heat to the outside air if the outside air is cold.

b) Advanced central automatic control with room temperature feedback control. This is an advanced central automatic control according to 2) with the following supplement: The supply water temperature set-point is corrected by the output of a room temperature feedback controller, to adapt the set-point to non-predictable day-to-day variation of the heat gain. Since TABS react slowly, only day-to-day room temperature correction is applied, an instant correction cannot be achieved with TABS. The room temperature that is fed back is the temperature of a reference room or another temperature representative for the zone. c) Advanced central automatic control with intermittent operation and room temperature feedback control 1.3 Control of distribution network hot water temperature (supply or return)

Similar function can be applied to the control of direct electric heating networks

0 No automatic control

1 Outside temperature compensated control: Action lower the mean flow temperature

2 Demand based control: E.g. based on indoor temperature; Actions leads generally to a decrease of the flow rate 1.4 Control of distribution pumps in networks

The controlled pumps can be installed at different levels in the network

0 No automatic control

1 On off control: To reduce the auxiliary energy demand of the pumps

2 Multi-Stage control: To reduce the auxiliary energy demand of the pumps

3 Variable speed pump control: With constant or variable ∆p and with demand evaluation to reduce the auxiliary energy demand of the pumps

One controller can control different rooms/zones having same occupancy patterns

0 No automatic control

1 Automatic control with fixed time program: To reduce the indoor temperature and the operation time

2 Automatic control with optimum start/stop: To reduce the indoor temperature and the operation time

3 Automatic control with demand evaluation: To reduce the indoor temperature and the operation time 1.6; Different generator control for combustion and district heating

The goal consists generally in minimising the generator operation temperature

0 Constant temperature control

1 Variable temperature control depending on outdoor temperature

2 Variable temperature control depending on the load: E.g. depending on supply water temperature 1.7 Generator control for heat pumps

The goal consists generally in minimising the generator operation temperature

0 Constant temperature control

1 Variable temperature control depending on outdoor temperature

2 Variable temperature control depending on the load: E.g. depending on supply water temperature 1.8 Sequencing of different generators

0 Priorities only based on running time

1 Priorities only based on loads

2 Priorities based on loads and demand of the generator capacities

3 Priorities based on generator efficiency: The generator operational control is set individually to available generators so that they operate with an overall high degree of efficiency (e.g. solar, geothermic heat, cogeneration plant, fossil fuels)

Term: Function Charging time release: Storage charging time release by time switch program Multi-sensor storage management: Demand-oriented storage management using two or more temperature sensors Heat generation: Boilers (fired with different types of fuels), heat pump, solar power, district heating, CHP. Demand-oriented supply: Information exchange to supply according storage temperature demand Return temperature control: Charging pump control for return temperature reduction Solar storage charge: Control of charging pump on / off to maximum DHW storage temperature during supply of free solar energy. Solar collector supplies the first priority energy. Supplementary storage charge: Release of supplementary control from heat generation with storage charging time release by time switch program to nominal DHW storage temperature or when going below the reduced DHW storage temperature. Heat generation supplies the second priority energy. 2.1 Control of DHW storage temperature with integrated electric heating or electric heat pump

0 Automatic control on / off

1 Automatic control on / off and charging time release

2 Automatic control on / off and charging time release and multi-sensor storage management 2.2 Control of DHW storage temperature using heat generation

0 Automatic control on / off

1 Automatic control on / off and charging time release

2 Automatic control on / off, charging time release and demand-oriented supply or multi-sensor storage management

3 Automatic control on / off, charging time release, demand-oriented supply or return temperature control and multi-sensor storage management 2.3 Control of DHW storage temperature, varying seasonally: with heat generation or integrated electric heating

0 Manual selected control with charging pump on / off or electric heating

1 Automatic selected control with charging pump on / off or electric heating and charging time release

2 Automatic selected control with charging pump on / off or electric heating, charging time release and demand-oriented supply or multi-sensor storage management

3 Automatic selected control with heat generation, demand-oriented supply and return temperature control or electric heating, charging time release and multi-sensor storage management 2.4 Control of DHW storage temperature with solar collector and heat generation

0 Manual selected control of solar energy or heat generation

1 Automatic control of solar storage charge (Prio. 1) and supplementary storage charge

2 Automatic control of solar storage charge (Prio. 1) and supplementary storage charge and demand-oriented supply or multi-sensor storage management

3 Automatic control of solar storage charge (Prio. 1) and supplementary storage charge, demand-oriented supply, return temperature control and multi-sensor storage management

2.5 Control of DHW circulation pump

Continuous operation, time switch program controlled or demand-oriented on / off

0 Without time switch program

1 With time switch program

2 Demand-oriented control: Demand dependent on water usage (e.g. open/close tap)

The control system is installed at the emitter or room level, for case 1 one system can control several rooms

0 No automatic control: Providing the room temperature

1 Central automatic control: There is only central automatic control acting either on the distribution or on the generation. This can be achieved for example by an outside temperature controller conforming to EN 12098-1 or EN 12098-3

2 Individual room control: By thermostatic valves or electronic controller

3 Individual room control with communication and demand control: Communication between controllers and to BACS; Demand control performed by occupancy 3.2 Emission control for TABS for cooling

0 No automatic control: Of the room temperature

1 Central automatic control: The central automatic control for a TABS zone (which comprises all rooms which get the same supply water temperature) typically is a supply water temperature control loop whose set-point is dependant on the filtered outside temperature, e.g. the average of the previous 24 hours.

2 Advanced central automatic control: This is an automatic control of the TABS zone that fulfils the following conditions: – If the TABS is used only for cooling: The central automatic control is designed and tuned to achieve an optimal self-regulating of the room temperature within the required comfort range (specified by the room temperature cooling set-point). "Optimal" means that the room temperatures of all rooms of the TABS zone remain during operation periods in the comfort range, to meet comfort requirements, but also is as high as possible to reduce the energy demand for cooling. – If the TABS is used for heating and cooling: The central automatic control is designed and tuned to achieve an optimal self-regulating of the room temperature within the required comfort range (specified by room temperature heating and cooling set-points). "Optimal" means that the room temperatures of all rooms of the TABS zone remain during operation periods in the comfort range, to meet comfort requirements, but also uses as far as possible the full range to reduce the energy demand for heating and cooling. – If the TABS is used for heating and cooling: the automatic switching between heating and cooling is not done only dependent on the outside temperature, but also taking at least indirectly the heat gains (internal and solar) into account.

3 Advanced central automatic control with intermittent operation and/or room temperature feedback control: a) Advanced central automatic control with intermittent operation. This is an advanced central automatic control according to 2 with the following supplement: The pump is switched off regularly to save electrical energy, either with a fast frequency - typically 6 hours on/off cycle time - or with a slow frequency, corresponding to 24 hours on/off cycle time. If the TABS is used for cooling, intermittent operation with 24 hours on/off cycle time can also be used to reject the heat to the outside air if the outside air is cold.

b) Advanced central automatic control with room temperature feedback control. This is an advanced central automatic control according to 2 with the following supplement: The supply water temperature set-point is corrected by the output of a room temperature feedback controller, to adapt the set-point to non-predictable day-to-day variation of the heat gain. Since TABS react slowly, only day-to-day room temperature correction is applied, an instant correction cannot be achieved with TABS. The room temperature that is fed back is the temperature of a reference room or another temperature representative for the zone. c) Advanced central automatic control with intermittent operation and room temperature feedback control 3.3 Control of distribution network cold water temperature (supply or return)

Similar function can be applied to the control of direct electric cooling (e.g. compact cooling units, split units) for individual rooms

0 Constant temperature control

1 Outside temperature compensated control: Action increase the mean flow temperature

2 Demand based control: E.g. Indoor temperature; Actions generally lead to an increase of the flow rate

The controlled pumps can be installed at different levels in the network

0 No automatic control

1 On off control: To reduce the auxiliary energy demand of the pumps

2 Multi-Stage control: To reduce the auxiliary energy demand of the pumps

3 Variable speed pump control: With variable ∆p and with demand evaluation to reduce the auxiliary energy demand of the pumps 3.5 Intermittent control of emission and/or distribution

One controller can control different rooms/zones having same occupancy patterns

0 No automatic control

1 Automatic control with fixed time program: To raise the indoor temperature and to lower the operation time

2 Automatic control with optimum start/stop: To raise the indoor temperature and to lower the operation time

3 Automatic control with demand evaluation: To raise the indoor temperature and to lower the operation time 3.6 Interlock between heating and cooling control of emission and/or distribution

To avoid at the same time heating and cooling in the same room depends on the system principle

0 No interlock: the two systems are controlled independently and can provide simultaneously heating and cooling

1 Partial interlock (dependant of the HVAC system): The control function is set up in order to minimize the possibility of simultaneous heating and cooling. This is generally done by defining a sliding set point for the supply temperature of the centrally controlled system

2 Total interlock: The control function enables to warranty that there will be no simultaneous heating and cooling. 3.7 Different generator control for cooling

The goal consists generally in minimising the generator operation temperature

0 Constant temperature control

1 Variable temperature control depending on outdoor temperature

2 Variable temperature control depending on the load: This includes control according to room temperature 3.8 Sequencing of different generators

0 Priorities only based on running time

1 Priorities only based on loads

2 Priorities based on loads and demand: Depending on the generator capacities

3 Priorities based on generator efficiency: The generator operational control is set individually to available generators so that they operate with an overall high degree of efficiency (e.g. outdoor air, river water, geothermic heat, refrigeration machines)

0 No automatic control: The system runs constantly ( e.g. manual controlled switch)

1 Time control: The system runs according to a given time schedule

2 Presence control: The system runs dependent on the presence (light switch, infrared sensors etc.)

3 Demand control: The system is controlled by sensors measuring the number of people or indoor air parameters or adapted criteria (e.g. CO2, mixed gas or VOC sensors). The used parameters shall be adapted to the kind of activity in the s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...