prEN 19100-3

(Main)Eurocode 10 - Design of glass structures - Part 3: In-plane loaded glass components

Eurocode 10 - Design of glass structures - Part 3: In-plane loaded glass components

1.1 Scope of prEN 19100 3

(1) This document gives design rules for glass components and assemblies primarily subjected to in-plane loading. It also covers effects of loads acting both in-plane and parallel to the plane produced by the neutral axes of the component, including construction rules for joints connecting in-plane loaded glass components.

1.2 Assumptions

(1) The assumptions of EN 1990, prEN 19100-1 and prEN 19100-2 apply.

(2) This document is intended to be used in conjunction with, EN 1990, EN 1991 (all parts), EN 1993-1-1, EN 1995 1 1, EN 1998 (all parts), EN 1999 1 1, prEN 19100-1, prEN 19100-2 and EN 12488.

Eurocode 10 - Bemessung und Konstruktion von Bauteilen aus Glas - Teil 3: In Scheibenebene belastete Elemente

1.1 Anwendungsbereich von prEN 19100 3

(1) Dieses Dokument enthält Bemessungsregeln für Glaskomponenten und Baugruppen aus Glas, die in Scheibenebene belastet werden. Es umfasst außerdem Auswirkungen aus Lasten, die sowohl in Scheibenebene als auch parallel zur Ebene der neutralen Achse der Glaskomponente wirken einschließlich Konstruktionsregeln für Anschlüsse zur Verbindung von in Scheibenebene belasteten Glaskomponenten.

1.2 Voraussetzungen

(1) Es gelten die Voraussetzungen nach EN 1990, prEN 19100-1 und prEN 19100-2.

(2) Dieses Dokument ist für die Anwendung in Zusammenhang mit EN 1990, EN 1991 (alle Teile), EN 1993 1 1, EN 1995 1 1, EN 1998 (alle Teile), EN 1999 1 1, prEN 19100 1, prEN 19100 2 sowie mit EN 12488 vorgesehen.

Eurocode 10 - Calcul des structures en verre - Partie 3: Composants en verre chargés dans leur plan

Evrokod 10 - Projektiranje steklenih konstrukcij - 3. del: Stekleni elementi pod vplivom obtežb, ki delujejo v ravnini elementov

General Information

- Status

- Not Published

- Publication Date

- 01-Jul-2026

- Technical Committee

- CEN/TC 250 - Structural Eurocodes

- Drafting Committee

- CEN/TC 250/SC 11/WG 1 - Design of Glass Strcutures

- Current Stage

- 4599 - Dispatch of FV draft to CMC - Finalization for Vote

- Start Date

- 09-Dec-2025

- Due Date

- 20-Jun-2025

- Completion Date

- 09-Dec-2025

Relations

- Effective Date

- 19-Jan-2023

Overview

prEN 19100-3 (Eurocode 10 - Part 3) specifies design rules for in-plane loaded glass components and assemblies. It addresses glass elements primarily subjected to loads within their plane, and also covers effects of loads acting both in-plane and parallel to the plane produced by the neutral axes. The document includes construction rules for joints connecting in‑plane loaded glass elements and is intended to be used in conjunction with EN 1990 and the other Eurocodes and parts of EN 19100.

Key topics and requirements

- Scope and assumptions: Applies to mechanically supported glass components; assumptions of EN 1990, prEN 19100‑1 and prEN 19100‑2 apply. National choices (Nationally Determined Parameters) are allowed via National Annexes.

- Basis of design: Requirements follow Eurocode principles for safety and serviceability; use in combination with actions from EN 1991 and relevant material/product standards.

- Limit states and verifications:

- Fracture Limit State (FLS) and Post‑Fracture Limit State (PFLS) verification rules.

- Ultimate Limit State (ULS) and serviceability limit states are addressed.

- Consideration of dynamic effects in FLS.

- Structural analysis and modelling:

- Linear and non‑linear analyses including second‑order and third‑order (geometrically non‑linear) analyses.

- Effects of deformed geometry, membrane effect, and imperfections.

- Materials and durability: Material properties, long‑term and temperature effects; treatment of interlayers in laminated glass.

- Detailing and joints: Design and execution guidance for connections such as sleeve bearings, lapped splices with bolts in shear, and friction connections.

- Annexes (informative): procedures for calculating critical buckling loads and bending moments (Annex A), effective section properties for laminated glass (Annex B), and simplified K‑values for design (Annex C).

Practical applications and users

Who uses prEN 19100-3:

- Structural designers and façade engineers designing glass panels and in‑plane loaded glass elements.

- Manufacturers and fabricators specifying laminated glass, interlayers and joint details.

- Contractors and installers implementing compliant connections and detailing.

- Code authorities, certification bodies, software developers and educators working with Eurocode‑based glass design.

Typical applications:

- Frameless glass partitions and shear elements in façades.

- In‑plane loaded balustrades, spandrels and structural glass walls.

- Glass components integrated with steel, timber or aluminium members where in‑plane forces and joint detailing are critical.

Related standards

- EN 1990 (Basis of structural design)

- EN 1991 (Actions on structures)

- EN 1993‑1‑1, EN 1995‑1‑1, EN 1998 (all parts), EN 1999‑1‑1

- prEN 19100‑1, prEN 19100‑2 (other parts of Eurocode 10)

- EN 12488

- Supersedes CEN/TS 19100‑3:2021

Keywords: Eurocode 10, prEN 19100-3, in-plane loaded glass components, design of glass structures, fracture limit state, laminated glass, joints and connections, Eurocodes.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

prEN 19100-3 is a draft published by the European Committee for Standardization (CEN). Its full title is "Eurocode 10 - Design of glass structures - Part 3: In-plane loaded glass components". This standard covers: 1.1 Scope of prEN 19100 3 (1) This document gives design rules for glass components and assemblies primarily subjected to in-plane loading. It also covers effects of loads acting both in-plane and parallel to the plane produced by the neutral axes of the component, including construction rules for joints connecting in-plane loaded glass components. 1.2 Assumptions (1) The assumptions of EN 1990, prEN 19100-1 and prEN 19100-2 apply. (2) This document is intended to be used in conjunction with, EN 1990, EN 1991 (all parts), EN 1993-1-1, EN 1995 1 1, EN 1998 (all parts), EN 1999 1 1, prEN 19100-1, prEN 19100-2 and EN 12488.

1.1 Scope of prEN 19100 3 (1) This document gives design rules for glass components and assemblies primarily subjected to in-plane loading. It also covers effects of loads acting both in-plane and parallel to the plane produced by the neutral axes of the component, including construction rules for joints connecting in-plane loaded glass components. 1.2 Assumptions (1) The assumptions of EN 1990, prEN 19100-1 and prEN 19100-2 apply. (2) This document is intended to be used in conjunction with, EN 1990, EN 1991 (all parts), EN 1993-1-1, EN 1995 1 1, EN 1998 (all parts), EN 1999 1 1, prEN 19100-1, prEN 19100-2 and EN 12488.

prEN 19100-3 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building; 91.080.99 - Other structures. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 19100-3 has the following relationships with other standards: It is inter standard links to CEN/TS 19100-3:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 19100-3 is associated with the following European legislation: Standardization Mandates: M/515. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 19100-3 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2024

Evrokod 10 - Projektiranje steklenih konstrukcij - 3. del: Stekleni elementi pod

vplivom obtežb, ki delujejo v ravnini elementov

Eurocode 10 - Design of glass structures - Part 3: In-plane loaded glass components

Eurocode 10 - Bemessung und Konstruktion von Bauteilen aus Glas - Teil 3: In

Scheibenebene belastete Elemente

Eurocode 10 - Calcul des structures en verre - Partie 3: Composants en verre chargés

dans leur plan

Ta slovenski standard je istoveten z: prEN 19100-3

ICS:

81.040.20 Steklo v gradbeništvu Glass in building

91.080.99 Druge konstrukcije Other structures

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

September 2024

ICS 81.040.20; 91.080.99 Will supersede CEN/TS 19100-3:2021

English Version

Eurocode 10 - Design of glass structures - Part 3: In-plane

loaded glass components

Eurocode 10 - Calcul des structures en verre - Partie 3: Eurocode 10 - Bemessung und Konstruktion von

Composants en verre chargés dans leur plan Bauteilen aus Glas - Teil 3: In Scheibenebene belastete

Elemente

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 250.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 19100-3:2024 E

worldwide for CEN national Members.

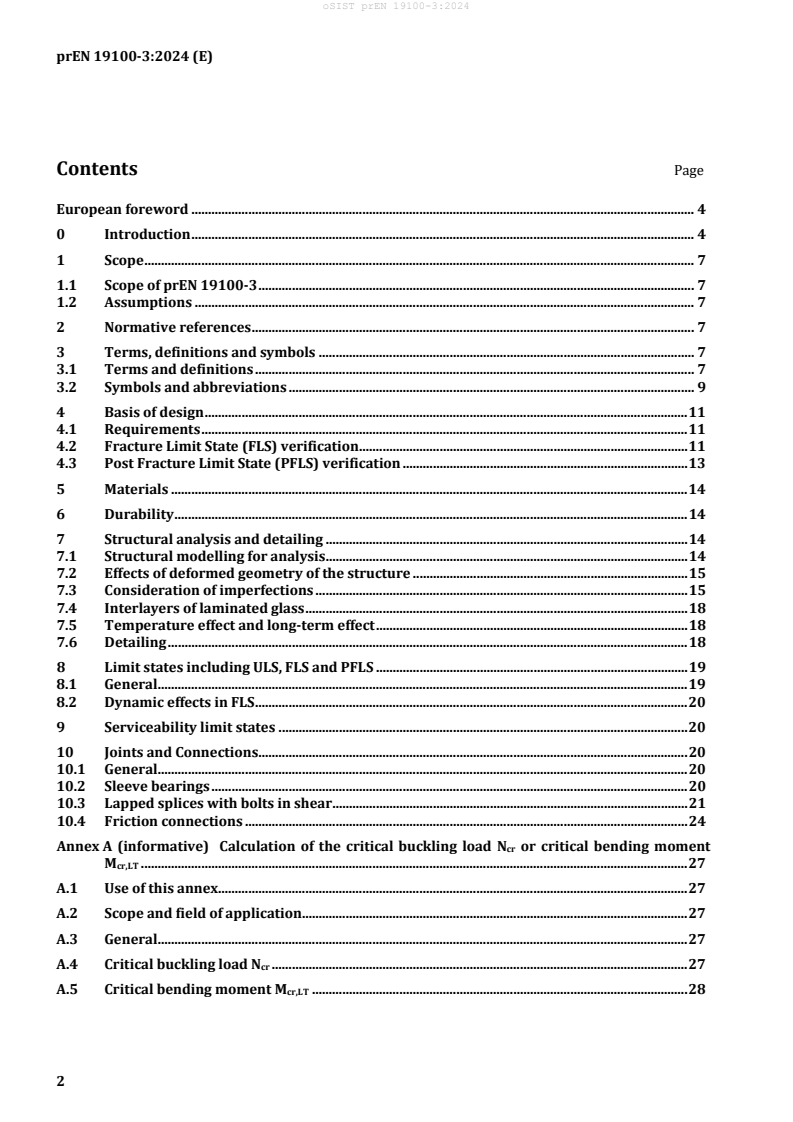

Contents Page

European foreword . 4

0 Introduction . 4

1 Scope . 7

1.1 Scope of prEN 19100-3 . 7

1.2 Assumptions . 7

2 Normative references . 7

3 Terms, definitions and symbols . 7

3.1 Terms and definitions . 7

3.2 Symbols and abbreviations . 9

4 Basis of design . 11

4.1 Requirements . 11

4.2 Fracture Limit State (FLS) verification . 11

4.3 Post Fracture Limit State (PFLS) verification . 13

5 Materials . 14

6 Durability . 14

7 Structural analysis and detailing . 14

7.1 Structural modelling for analysis. 14

7.2 Effects of deformed geometry of the structure . 15

7.3 Consideration of imperfections . 15

7.4 Interlayers of laminated glass . 18

7.5 Temperature effect and long-term effect . 18

7.6 Detailing . 18

8 Limit states including ULS, FLS and PFLS . 19

8.1 General . 19

8.2 Dynamic effects in FLS . 20

9 Serviceability limit states . 20

10 Joints and Connections . 20

10.1 General . 20

10.2 Sleeve bearings . 20

10.3 Lapped splices with bolts in shear . 21

10.4 Friction connections . 24

Annex A (informative) Calculation of the critical buckling load N or critical bending moment

cr

M . 27

cr,LT

A.1 Use of this annex. 27

A.2 Scope and field of application. 27

A.3 General . 27

A.4 Critical buckling load N . 27

cr

A.5 Critical bending moment M . 28

cr,LT

Annex B (informative) Calculation of I and I of laminated glass . 30

z,eff T,eff

B.1 Use of this annex. 30

B.2 Scope and field of application. 30

B.3 General . 30

Annex C (informative) Calculation of K - values for simplified calculation . 32

m

C.1 Use of this annex. 32

C.2 Scope and field of application. 32

C.3 General . 32

Bibliography. 34

European foreword

This document (prEN 19100-3:2024) has been prepared by Technical Committee CEN/TC 250 “Structural

Eurocodes”, the secretariat of which is held by BSI. CEN/TC 250 is responsible for all Structural Eurocodes and

has been assigned responsibility for structural and geotechnical design matters by CEN.

This document is currently submitted to the CEN Enquiry.

This document will supersede CEN/TS 19100-3:2021.

In comparison with the previous edition, the following changes have been made:

— modified title and scope;

— updated references.

The first generation of EN Eurocodes was published between 2002 and 2007. This document forms part of the

second generation of the Eurocodes, which have been prepared under Mandate M/515 issued to CEN by the

European Commission and the European Free Trade Association.

The Eurocodes have been drafted to be used in conjunction with relevant execution, material, product and test

standards, and to identify requirements for execution, materials, products and testing that are relied upon by

the Eurocodes.

The Eurocodes recognize the responsibility of each Member State and have safeguarded their right to

determine values related to regulatory safety matters at national level through the use of National Annexes.

0 Introduction

0.1 Introduction to the Eurocodes

The Structural Eurocodes comprise the following standards generally consisting of a number of parts:

EN 1990 Eurocode — Basis of structural and geotechnical design

EN 1991 Eurocode 1 — Actions on structures

EN 1992 Eurocode 2 — Design of concrete structures

EN 1993 Eurocode 3 — Design of steel structures

EN 1994 Eurocode 4 — Design of composite steel and concrete structures

EN 1995 Eurocode 5 — Design of timber structures

EN 1996 Eurocode 6 — Design of masonry structures

EN 1997 Eurocode 7 — Geotechnical design

EN 1998 Eurocode 8 — Design of structures for earthquake resistance

EN 1999 Eurocode 9 — Design of aluminium structures

EN 19100 Eurocode 10 — Design of glass structures

The Eurocodes are intended for use by designers, clients, manufacturers, constructors, relevant authorities (in

exercising their duties in accordance with national or international regulations), educators, software

developers, and committees drafting standards for related product, testing and execution standards.

NOTE Some aspects of design are most appropriately specified by relevant authorities or, where not specified, can be

agreed on a project-specific basis between relevant parties such as designers and clients. The Eurocodes identify such

aspects making explicit reference to relevant authorities and relevant parties.

0.2 Introduction to EN 19100 (all parts)

EN 19100 (all parts) applies to the structural design of mechanically supported glass components and

assemblies of glass components. It complies with the principles and requirements for the safety and

serviceability of structures, the basis of their design and verification that are given in EN 1990, Basis of

structural and geotechnical design.

EN 19100 is subdivided into three parts:

EN 19100-1, Eurocode 10 — Design of glass structures — Part 1: General rules

EN 19100-2, Eurocode 10 — Design of glass structures — Part 2: Out-of-plane loaded glass components

EN 19100-3, Eurocode 10 — Design of glass structures — Part 3: In-plane loaded glass components

0.3 Introduction to EN 19100-3

EN 19100-3 applies to the structural design of in-plane loaded glass components in conjunction with

EN 19100-1 and EN 19100-2.

0.4 Verbal forms used in the Eurocodes

The verb “shall" expresses a requirement strictly to be followed and from which no deviation is permitted in

order to comply with the Eurocodes.

The verb “should” expresses a highly recommended choice or course of action. Subject to national regulation

and/or any relevant contractual provisions, alternative approaches could be used/adopted where technically

justified.

The verb “may" expresses a course of action permissible within the limits of the Eurocodes.

The verb “can" expresses possibility and capability; it is used for statements of fact and clarification of concepts.

0.5 National annex for EN 19100-3

National choice is allowed in this document where explicitly stated within notes. National choice includes the

selection of values for Nationally Determined Parameters (NDPs).

The national standard implementing EN 19100-1 can have a National Annex containing all national choices to

be used for the design of buildings and civil engineering works to be constructed in the relevant country.

When no national choice is given, the default choice given in this document is to be used.

When no national choice is made and no default is given in this document, the choice can be specified by a

relevant authority or, where not specified, agreed for a specific project by appropriate parties.

National choice is allowed in EN 19100-1 through notes to the following clauses:

4.2.1(2) 4.2.1(5) – 2 choices 4.3.1(2) 4.3.1(3)

4.3.1(7) 7.3.2(1) 8.2(3) 10.3.1(4) – 2 choices

10.3.3(1) 10.3.4.3(2) 10.4.1(1)

National choice is allowed in EN 19100-3 on the application of the following informative annexes:

Annex A Annex B Annex C

The National Annex can contain, directly or by reference, non-contradictory complementary information for

ease of implementation, provided it does not alter any provisions of the Eurocodes.

1 Scope

1.1 Scope of prEN 19100-3

(1) This document gives design rules for glass components and assemblies primarily subjected to in-plane

loading. It also covers effects of loads acting both in-plane and parallel to the plane produced by the neutral

axes of the component, including construction rules for joints connecting in-plane loaded glass components.

1.2 Assumptions

(1) The assumptions of EN 1990, prEN 19100-1 and prEN 19100-2 apply.

(2) This document is intended to be used in conjunction with, EN 1990, EN 1991 (all parts), EN 1993-1-1,

EN 1995-1-1, EN 1998 (all parts), EN 1999-1-1, prEN 19100-1, prEN 19100-2 and EN 12488.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references, the

latest edition of the referenced document (including any amendments) applies.

NOTE See the Bibliography for a list of other documents cited that are not normative references, including those

referenced as recommendations (i.e. through ‘should’ clauses) and permissions (i.e. through ‘may’ clauses).

EN 1990, Eurocode — Basis of structural and geotechnical design

prEN 19100-1:2024, Eurocode 10 — Design of glass structures — Part 1: Basis of design and materials

prEN 19100-2:2024, Eurocode 10 — Design of glass structures — Part 2: Design of out-of-plane loaded glass

components

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in prEN 19100-1 and prEN 19100-2 and the

following apply.

3.1.1

shear element made of glass

glass element sustaining on purpose loads or stresses in-plane (F , F ,p , p ,)

x z x z

Note 1 to entry: The element may be loaded also by loading transversal to the plane (qy).

3.1.2

buckling length

system length of an otherwise similar member with pinned ends, which has the same critical buckling load as

a given member or segment of member

[SOURCE: EN 1993-1-1:2022, 3.1.7]

3.1.3

second order analysis

geometrically non-linear analysis taking account of the out-of-plane deflections whilst calculating equilibrium

of stresses or sectional forces of a glass pane

3.1.4

third order analysis

geometrically non-linear analysis taking account of both the out-of-plane and in-plane deflections whilst

calculating equilibrium of stresses or sectional forces of a glass pane

3.1.5

membrane effect

influence on stresses and sectional forces due to consideration of in-plane deflections in static equilibrium

3.1.6

axes of a glass pane, component or member and their direction

x-x in the glass pane, component or member, preferably one of the gravity lines

y-y perpendicular to the glass pane, defined by the x- and the z-axes

z-z in the glass pane, component or member, perpendicular to x-x

Note 1 to entry: The directions of x-, y- and z-axes should accord to those of thumb (x), index finger (y) and middle finger

(z) of the right hand in the defined planes, see Figure 3.1.

Note 2 to entry: When bending about the y-axis occurs this axis is also called strong axis, and accordingly, when bending

about the x-axis or the z-axis these axes are called weak axes.

Figure 3.1 — Definition of axes of a glass pane, component or member and their direction

3.1.7

structural redundancy

ability of a structure to redistribute among its members/connections the loads which can no longer be carried

by some other damaged portions

3.1.8

sudden fracture

fracture event of unpredictable origin

3.1.9

protection measure

measure that is intended to prevent or reduce the risk of accidental damage of a glass member that may affect

its structural function

3.1.10

polymeric-modified mortar

mortar, used for filling gaps between glass and other parts for force and stress transmission

Note 1 to entry: For reasons of strength and ductility, to avoid stress peaks, polymeric materials are added to the mortar.

3.2 Symbols and abbreviations

3.2.1 Latin upper-case letters

A Glass cross section area of ply i

i

C , C Factors taking into account different bending moments

1 2

E Modulus of elasticity for glass

F Design loading on the structure

Ed

F Elastic critical buckling load for global instability mode based on initial elastic stiffnesses

cr

G Shear modulus of glass

G Shear modulus of interlayer

int

I Moment of inertia of ply i

i

I Effective torsional moment of inertia

T,eff

I Effective moment of inertia about the minor axis (z-axis)

z,eff

Km Equilibrium parameter

L Buckling length

B

L Buckling length (lateral torsional buckling)

LT

M The design value of the moment

Ed

M Critical buckling moment (lateral torsional buckling)

cr,LT

N Design value of normal forces in the relevant direction of the considered cross section or joint

Ed

N Elastic critical force for the relevant buckling mode

cr

P Arbitrary in-plane load

P Actions having been present in the plies whose fracture is investigated

fractured

P Actions having been and still being present in the unfractured part of the cross section

unfractured

Pu Ultimate arbitrary in-plane load

P Applied bolt pre-stress

P,b

P P Forces according to Table C.1

x,I ( x,m)

S Design bolt forces

b,Ed

S Friction shear resistance

Fr,b,Rd

V Design value of the shear force

Ed

3.2.2 Latin lower-case letters

b Width

b Effective width

m

d Hole diameter

e Basic imperfection

e Considering all imperfections of the component being length related

0,length

e Considering deviations coming from unplanned eccentric load introduction

0,installation

e Distance of the mid-plane of two conjunct glass panels

z

fg,d Design bending strength according to prEN 19100-1:2024, Annex A

h Glass ply thickness

h Component thickness for calculation of installation eccentricity

e

h Thickness of ply i

i

h Thickness of the interlayer

int

h Total thickness of the laminate

tot

k Factors considering constructive influences for the design of bolted shear connections, {j=1, …

j

10}

NOTE The factors k1 to k10 are not the same as the ki factor given in prEN 19100-1:2024, Annex A.

l Length of the shorter edge of the glass pane

l Component length

n Number of plies

p Hole distance

i

t Sleeve thickness

sleeve

v Initial lateral deflection of midplane

0,m

w Deflection in z-direction

w Width of the polymer or polymeric-modified mortar

mortar

z Distance of the i-th ply's center to center of adjacent interlayer

i

zp Distance between the member axis and the point where the load is applied

3.2.3 Greek upper-case letters

Δe Eccentricity shift due to fracture of a ply

shift

Δe Forced constraint deformation

exp

Θ Torsional deflection

0,m

3.2.4 Greek lower-case letters

α Factor by which the design loading would have to be increased to cause the critical elastic

cr

instability in terms of indifferent equilibrium

λ Slenderness for torsional buckling

T

µ Coefficient of friction

Fr

μ Design value of friction coefficient

Fr,d

σ Maximal principal stress

p,Ed

σ Maximum stress for lapped splices

φ,max,E

Φ Dynamic load amplification factor for those actions which originate from mass inertia

Φ Dynamic amplification factor

mg

4 Basis of design

4.1 Requirements

(1) For an in-plane loaded glass component, the Limit State Scenario (LSS) should be chosen according to

prEN 19100-1:2024, 4.2.4.

(2) The fracture of any glass plies shall neither compromise the stability or resistance of adjacent components

nor result into a progressive collapse.

(3) Verification in ULS, FLS and PFLS is deemed to verify that fracture of a glass ply prevents progressive

collapse.

(4) Special attention shall be paid to robustness of the structure, see prEN 19100-1 and EN 1990.

(5) When ensuring sufficient robustness, depending on the function, importance and installation position (e.g.

height over ground or floor resp., vertical or non-vertical), care shall be taken on the aspects as given in

prEN 19100-2:2024, 4.1(3). In addition to that, sufficient redundancy by providing a second load path

(background safety) on assembly level and/or structure´s level shall be ensured.

(6) In case of laminated glass, the shear interaction provisions as given in prEN 19100-1:2024, 7.2.2 should be

used. Guidance can be taken from prEN 19100-2:2024, Annex A or from EN 16612.

(7) In case of fracture of a ply or of a component the consequences for the safety and integrity of adjoining

structure, components and people shall be analysed and verified.

(8) To achieve robustness a sufficient number of glass plies should be provided.

NOTE Redundancy and robustness can be enhanced by a coarse crack pattern and/or further restricting boundary

conditions of the glass component.

(9) A concept for the repair or replacement of in-plane loaded glass components should be provided.

4.2 Fracture limit state (FLS) verification

4.2.1 General

(1) In the FLS sufficient safety during sudden fracture shall be verified (failsafe verification).

NOTE 1 For events of impact in the FLS, see 4.2.1(5).

NOTE 2 The sudden fracture can be of one or several glass plies or of one or several glass components.

NOTE 3 If fracture of glass components is taken into account, then normally the number of suddenly fractured glass

components is 1.

(2) In the FLS, an appropriate load combination should be used for the static loading that arises during the

sudden fracture and if necessary during the event of impact, see 4.2.1(5).

NOTE The load combination in the FLS is the accidental load combination according to EN 1990, unless the National

Annex gives a different specification. For load combination in case of dynamic effects in the FLS, see 8.2.

(3) Depending on the project specific situation also elevated temperatures e.g. due to solar absorption should

be taken into account for laminated glass components, see prEN 19100-1:2024, 4.3.1.

(4) In the FLS the glass component can be verified by experimental testing or alternatively, by a theoretical

assessment.

NOTE Verification can include reference to previously executed tests or calculations.

(5) Depending on the project, an additional energy intensive lateral impact verification perpendicular to the

surface at the most unfavourable location may be conducted. The type of impactor and energy should be as

specified by the relevant authority or, where not specified, agreed for a specific project by the relevant parties.

NOTE 1 The National Annex can also specify type of impactor and energy.

NOTE 2 Generally, further provisions for the verification in the FLS can be given in the National Annex.

4.2.2 Verification of the Fracture Limit State by testing

(1) For the verification of the FLS by experimental testing, prEN 19100-2:2024, 4.2.2 should be applied.

4.2.3 Verification of the Fracture Limit State by theoretical assessment

(1) Alternatively to 4.2.2, a theoretical assessment in the FLS may be performed. All static and dynamic effects

originating from impact and/or damage/fracture of parts of the glass component or of the whole shall

reasonably be taken into account for the short time of impact including:

— dynamic amplification;

— eccentricity shift due to fracture of a ply if laminated glass is used, see Figure 7.1;

— forced constraint deformation on the remaining cross-section after breakage of a ply if laminated glass is

used, see Figure 7.2;

— stiffness and resistance reduction of the cross-section.

NOTE Generally, a theoretical assessment in the FLS is performed by a transient numerical simulation.

(2) The applicability of the theoretical model shall be validated.

NOTE Normally, the applicability of a theoretical model is validated by experimental benchmark tests.

(3) To that end, the dynamic amplification effects by fracture

— of one or more plies of the laminate glass component (i.e. sudden fracture out of the static rest position due

to hard impact with low energy or spontaneous breakage), and

— if necessary, of one or more plies of the laminate with hard lateral impact with energy, and

— if necessary, of one or more glass components

should be taken into account.

NOTE For the amount of the dynamic amplification out of the static rest position, see 8.2.

(4) If a lateral mass impact has additionally to be taken into account (lateral impact with energy), a further

investigation should be carried out to determine the amount of impact energy and the resulting effective

dynamic amplification factor Φ due to mass inertia.

(5) Whether a lateral mass impact needs to be taken into account should be specified by the relevant authority

or, where not specified, agreed for a specific project by the relevant parties.

4.3 Post fracture limit state (PFLS) verification

4.3.1 General

(1) In the PFLS sufficient safety after fracture for a limited period of time shall be verified (verification of

residual resistance of the glass component or verification of an alternative load path). The fracture may be of

one or several glass plies or of one or several components.

NOTE 1 The mechanical behaviour, including the residual resistance, of the glass component in the post fracture limit

state (PFLS) is influenced by the type of glass component (e.g. mode of breakage, type of interlayer, number of plies), the

size of the glass component and its supporting system.

NOTE 2 If fracture of a component is taken into account then normally the number of fractured glass components is 1.

(2) In the PFLS an appropriate load combination should be used.

NOTE The load combination in the PFLS is the accidental load combination according to EN 1990 and prEN 19100-1

unless the National Annex gives different specification.

(3) Aspects that should be considered for the determination of the time period can originate from the following:

time to secure the environment, temporary support, time to replace, time to remove the load etc. The time

limited variable actions may be reduced according to EN 1991-1-6.

NOTE Post fracture time periods in the PFLS can be set by the National Annex.

(4) Depending on the project specific situation compared to the ambient temperature level, elevated

temperatures e.g. due to solar absorption should be taken into account for laminated glass components for

assessment in PFLS.

(5) In the PFLS the glass component can be verified by experimental testing or alternatively by a theoretical

assessment.

(6) The verification of the residual resistance of in plane loaded glass components for PFLS should be verified

by testing only. If an alternative load path is ensured, then the verification of the residual resistance for PFLS

may be neglected.

NOTE Verification can include reference to previously executed tests.

(7) In PFLS, the load carrying capacity of the global system shall be verified taking into account the fracture of

glass components. The number of fractured glass components in the global structure should be assessed based

on the specific design situation, see 4.3.1(1), unless it is as agreed for a specific project by the relevant parties.

NOTE Generally, further provisions for the verification in the PFLS can be given in the National Annex.

4.3.2 Verification of the Post Fracture Limit State by testing

(1) If the PFLS is verified by experimental testing, this may be performed either on the original (as built)

structure in situ or on appropriate mock-up or on an appropriate equivalent laboratory specimen.

(2) If testing is not performed by using the original component on the original structure in situ, it shall be

ensured, that the used equivalent mock up or equivalent laboratory specimen including all relevant details

correspond to the original structure including supports, load introduction, load scenario, etc.

(3) The tests shall be planned and evaluated such that clear conclusions with regard to safety and reliability

can be drawn. Special attention should be paid to the required number of tests.

NOTE The lower the number of tests the higher the margin between mean value of the test results and the design

resistance.

(4) The test results shall be evaluated by a transparent and reproducible procedure assessing safety and

reliability according to the requirements of EN 1990.

4.3.3 Verification of the Post Fracture Limit State by theoretical assessment

(1) Alternatively to 4.3.2 a theoretical assessment of the PFLS may be performed. Here all relevant actions, time

and ambient effects after the fracture event for the specified residual time period shall be taken into account

including:

— eccentricity shift due to fracture of a ply if laminated glass is used, see Figure 7.1;

— forced constraint deformation on the remaining cross-section after breakage of a ply if laminated glass is

used, see Figure 7.2;

— stiffness and resistance reduction of the cross-section.

(2) If the post fracture resistance of an in plane loaded glass component is assessed without testing, at least one

glass ply of the glass component should be assumed to remain unfractured, see also 4.3.1(6). This assumption

should be justified.

(3) The theoretical assessment should be performed on the reduced cross-section taking into account all

unfractured glass plies. A favourable effect of the fractured glass plies should be neglected. If the effect is

unfavourable, it should be considered.

NOTE The mechanical behaviour of glass in the PFLS is governed by the size of glass component and the supporting

system, size and shape of the shards, polymer type and thickness of the interlayer, the bond between interlayer and glass,

the delamination depth of the interlayer in contact of the single shards.

5 Materials

(1) For the material properties, prEN 19100-1:2024, Clause 5 shall be applied.

6 Durability

(1) The rules for durability in EN 1990 and prEN 19100-1:2024, Clause 6 shall be applied.

(2) The durability and reliability of the interlayer in terms of shear modulus and bonding strength is deemed

to be satisfied if the relevant characteristic mechanical parameter of the interlayer is evaluated according to

prEN 19100-1:2024, 5.2.

NOTE For design working life, see prEN 19100-1.

7 Structural analysis and detailing

7.1 Structural modelling for analysis

(1) The rules for structural analysis in prEN 19100-1:2024, Clause 7 shall be applied.

(2) The analysis should be performed using the nominal glass thicknesses.

(3) Single glass components should normally be supported in a statically determinate manner. In case of

statically non determinate supporting of components, realistic boundary conditions for the structural model

should be considered, e.g. coming from tolerances of the supporting structure. This should also include the

fabrication and erection stage.

(4) Favourable effects due to a slip restraint in laminated glass, see Figure 7.1 or rotational restraints of the

edges of the glass components should be neglected, unless beneficial effect can be quantified by experimental

evidence. This holds, although from the constructive point of view the edges should generally be enclosed.

(5) Glass components subjected to in plane compression stresses should be verified using geometrical non-

linear theory, when relevant.

NOTE For relevance, see 7.2.

7.2 Effects of deformed geometry of the structure

(1) The effects of the deformed geometry (second-order effects) should be considered if they increase the action

effects significantly or modify significantly the structural behaviour.

(2) First order analysis may be used for the structure, if the increase of the relevant internal forces or moments

or any other change of structural behaviour caused by deformations can be neglected. This condition may be

assumed to be fulfilled, if the following criterion is satisfied:

F

cr

α >10 (7.1)

cr

F

Ed

where

α is the factor by which the design loading would have to be increased to cause elastic instability in

cr

a global mode;

F is the design loading on the structure;

Ed

F is the elastic critical buckling load for global instability mode based on initial elastic stiffnesses.

cr

(3) The second order analysis may be performed by analytical or numerical means.

(4) In cases where membrane effects are safety relevant, a third order analysis should be carried out. In other

cases it may be carried out.

NOTE In cases of plate behaviour, a nonlinear geometric analysis that only considers second-order effects can

possibly be insufficient, as membrane effects can affect stability.

7.3 Consideration of imperfections

7.3.1 General

(1) For in-plane loaded glass components, in the structural analysis, the effects of imperfections shall be taken

into account.

NOTE The buckling resistance of glass components is influenced by geometrical and material imperfections.

(2) Geometrical and material imperfections may be combined into an equivalent geometrical imperfection

value.

(3) The equivalent geometrical imperfection may be considered in SLS. It should be considered in ULS, FLS and

PFLS.

NOTE In SLS and ULS, the equivalent geometrical imperfection to be taken into account is the basic imperfection

according to 7.3.2.

(4) In FLS and PFLS, for laminated glass, to consider effects due to load introduction shift after fracture of a ply,

the basic imperfection according to 7.3.2 should be modified according to 7.3.3.

=

(5) In FLS and PFLS, for laminated glass, to consider effects due to expansion of a fractured ply of thermally

toughened glass the basic imperfection according to 7.3.2 should be modified according to 7.3.4.

(6) In case of in-plane loaded glass components combined with additional transverse loading, the transversal

deflection due to the additional transversal loading including the non-linear amplification of the deflection

should be taken into account in addition to the equivalent geometrical imperfection.

7.3.2 Basic imperfection

(1) The general format of the basic imperfection e should be as indicated in Formula (7.2):

e e + e (7.2)

0 0,,length 0 installation

NOTE 1 The basic imperfection e0 consists of a part e0,length considering all imperfections of the component being length

related, and a part e0,installation considering deviations coming from unplanned eccentric load introduction.

NOTE 2 The imperfections to be taken into account for different buckling phenomena are given in Table 7.1 (NDP),

unless the National Annex gives different values.

Table 7.1 (NDP) — Imperfection parts for buckling cases

Both for mono and laminated glass panes

Type l

a b,c,d

e e

0,length 0,installation

Distance of inflexion

Flexural buckling points in the relevant

l /333 h /2

0 e

and plate buckling critical mode in direction

of the applied load

Distance of inflexion

Lateral torsional points at the edge in

l0/450 he/2

buckling compression in the

relevant critical mode

Shear buckling Longest diagonal l /1000 h /5

0 e

a

e0,length should be applied at the location where the curvature of the relevant critical mode gets its maximum.

b

e may be applied at the location where the installation eccentricity occurs. Alternatively, for

0,installation

simplification reasons, it may be applied at the same location as the one of e0,length.

c

For perpendicular to the glass plane, straight edges over the thickness of the laminate, the value for he is:

= h . For stepped edges or other edge geometries, the value of h can be determined individually.

he tot e

d

If e is recorded on site it may be reduced to the measured value, but not smaller than 3 mm. This requires

0,installation

care in execution and control.

NOTE 3 The values given in Table 7.1 are intended for use in “normal cases”. There can be specific cases where other

imperfections or other reference lengths apply.

NOTE 4 Normally the relevant critical mode is the lowest eigenmode. For example, for a simply supported beam in

compression this is the half sinusoidal-shape (see Annex A).

NOTE 5 For eo,length, see also EN 12150-1:2015+A1:2019, Table 4 or EN 1863-1. In addition to the geometrical

imperfections, eo,length is deemed to also cover the structural imperfections, see prEN 19100-1:2024, 4.4.4(3).

=

7.3.3 Effects on imperfection due to load introduction shift after fracture of a ply

(1) When laminated glass is used, in FLS and/or PFLS, during or after fracture of a ply, the eccentricity due to

transversal movement of the effective neutral axis of the remaining cross section should be added to the basic

imperfection according to 7.3.2 if it has an unfavourable effect. It may be considered if it has a favourable effect.

NOTE 1 Depending on the position of the fractured ply, Δe can be positive or negative.

shift

NOTE 2 Whether an eccentricity shift is favourable or unfavourable also depends on whether the load is shifted

transversely to its direction or not (at the point of load introduction).

NOTE 3 An example for a favourable eccentricity shift Δeshift is given in Figure 7.1.

Figure 7.1 — Example for a favourable eccentricity shift Δe due to fracture of a ply in case of a load

shift

remaining at the point of load application

7.3.4 Effects on imperfection due expansion of a fractured ply of thermally toughened glass

(1) If laminated glass is used, in FLS and/or PFLS, fracture of a ply of thermally toughened glass can cause a

longitudinal expansion and curvature, see Figure 7.2, which can increase the basic imperfection according to

7.3.2 by an additional Δe and induce constraint sectional forces in the remaining intact cross-section. On the

exp

safe side, for the value of Δe the deformation may be applied, which corresponds to the one of the unloaded

exp

component with fracture of the same ply.

(2) If Δe has an unfavourable effect it should be considered. If it has a favourable effect it may be considered.

exp

(3) When verifying the remaining intact cross-section in the FLS or PFLS the effects of occurring curvature or

moment should be taken into account whereas those of the occurring longitudinal elongation or normal force

can be neglected.

NOTE 1 The geometrical effects (curvature and longitudinal elongation) are due to the moment and the normal force

appearing in the remaining intact cross-section, see Figure 7.2.

Key

broken glass

unfractured glass

Figure 7.2 — Forced constraint deformation Δe and induced sectional forces on the remaining

exp

cross-section during or after fracture of a ply of thermally toughened glass in a laminated glass

component

NOTE 2 [13] indicates that for a laminate with n plies of equal thickness hi = h and PVB-interlayer with hint = 1,52mm

l 1

Δeexp can be calculated by ∆=e ⋅ . Hereby, in case of a two-sided supported glass pane, l is the distance

exp

33,3 hn− 1

between the supports. In case of four-sided supported glass pane l is the length of the shorter edge of the glass pane.

(4) The valu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...