EN 13067:2003

(Main)Plastics welding personnel - Qualification testing of welders - Thermoplastics welded assemblies

Plastics welding personnel - Qualification testing of welders - Thermoplastics welded assemblies

This standard specifies the method of testing the knowledge and skill of a welder who is required to carry out welds on thermoplastics in new constructions and repair work. The skill examination of a welder is an essential condition for the assurance of the quality of the welding work. The application of this standard guarantees that the examination is carried out according to a uniform test procedure. Testing of a welder duly passed in accordance with this standard ensures that the welder concerned has demonstrated the minimum skill and knowledge demanded by techniques required.

Kunststoffschweißpersonal - Anerkennungsprüfung von Schweißern - Thermoplastische Schweißverbindungen

Diese Norm legt Verfahren für die Prüfung der Kenntnisse und Fertigkeiten eines Schweißers fest, der Schweißarbeiten an Thermoplasten bei Neuanfertigungen und Reparaturarbeiten durchzuführen hat.

Die Prüfung der Fertigkeiten eines Schweißers ist eine notwendige Bedingung für die Sicherung der Qualität bei Schweißarbeiten. Die Anwendung dieser Norm stellt sicher, dass die Prüfung nach einheitlichen Prüfverfahren durchgeführt wird.

Diese Norm findet Anwendung, wenn der Auftraggeber oder die für das Anwendungsgebiet verantwortliche Behörde dies fordert. Gas- und Wasserversorgungsunternehmen, die alternative Anerkennungsprogramme haben, sind von dieser Norm ausgeschlossen.

Diese Norm gilt für folgende Schweißverfahren:

Warmgasschweißen: Runddüse, Schnellschweißdüse, Keil;

Extrusionsschweißen;

Heizelementschweißen: Stumpfstoß, Sattel, Muffe, Keil;

Heizwendelschweißen: Muffe, Sattel.

Diese Norm gilt für das Schweißen folgender Produkte:

Tafel;

Rohr;

Formstücke;

Dichtungsbahnen.

Diese Norm gilt für das Schweißen der folgenden Werkstoffgruppen:

für Tafeln, Rohre und Formstücke:

Gruppe 1: PVC (einschließlich aller Typen von PVC-U und ABS und PC)

Gruppe 2: PP (einschließlich aller Typen von PP)

Gruppe 3: PE (einschließlich aller Typen von PE, PB)

Gruppe 4: PVDF

Gruppe 5: ECTFE oder PFA oder FEP

für Dichtungsbahnen:

Gruppe 6: PVC-P

Gruppe 7: PE (einschließlich aller Typen von PE)

Gruppe 8: ECB

Personnel en soudage des plastiques - Epreuve de qualification des soudeurs - Assemblages soudés thermoplastiques

La présente norme européenne spécifie la méthode à utiliser pour évaluer les connaissances et l'habileté d'un soudeur qui doit réaliser des soudures sur des matières thermoplastiques pour des constructions neuves et des travaux de réparation. L'examen de l'habileté d'un soudeur est une condition essentielle de l'assurance de la qualité du soudage. L'application de la présente norme garantit que l'examen se déroule selon une procédure d'épreuve uniforme.

Osebje za varjenje plastike - Preskušanje usposobljenosti varilcev – Varjenje plastomerov

General Information

- Status

- Withdrawn

- Publication Date

- 15-Apr-2003

- Withdrawal Date

- 06-Nov-2012

- Technical Committee

- CEN/TC 249 - Plastics

- Drafting Committee

- CEN/TC 249/SC 5/WG 4 - Plastics welding personnel

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 07-Nov-2012

- Completion Date

- 07-Nov-2012

Relations

- Effective Date

- 14-Nov-2012

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN 13067:2003 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics welding personnel - Qualification testing of welders - Thermoplastics welded assemblies". This standard covers: This standard specifies the method of testing the knowledge and skill of a welder who is required to carry out welds on thermoplastics in new constructions and repair work. The skill examination of a welder is an essential condition for the assurance of the quality of the welding work. The application of this standard guarantees that the examination is carried out according to a uniform test procedure. Testing of a welder duly passed in accordance with this standard ensures that the welder concerned has demonstrated the minimum skill and knowledge demanded by techniques required.

This standard specifies the method of testing the knowledge and skill of a welder who is required to carry out welds on thermoplastics in new constructions and repair work. The skill examination of a welder is an essential condition for the assurance of the quality of the welding work. The application of this standard guarantees that the examination is carried out according to a uniform test procedure. Testing of a welder duly passed in accordance with this standard ensures that the welder concerned has demonstrated the minimum skill and knowledge demanded by techniques required.

EN 13067:2003 is classified under the following ICS (International Classification for Standards) categories: 25.160.10 - Welding processes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13067:2003 has the following relationships with other standards: It is inter standard links to EN 13067:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13067:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Osebje za varjenje plastike - Preskušanje usposobljenosti varilcev – Varjenje plastomerovKunststoffschweißpersonal - Anerkennungsprüfung von Schweißern - Thermoplastische SchweißverbindungenPersonnel en soudage des plastiques - Epreuve de qualification des soudeurs - Assemblages soudés thermoplastiquesPlastics welding personnel - Qualification testing of welders - Thermoplastics welded assemblies25.160.01Varjenje, trdo in mehko spajkanje na splošnoWelding, brazing and soldering in general03.100.30Vodenje ljudiManagement of human resourcesICS:Ta slovenski standard je istoveten z:EN 13067:2003SIST EN 13067:2003en01-julij-2003SIST EN 13067:2003SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13067April 2003ICS 25.160.10English versionPlastics welding personnel - Qualification testing of welders -Thermoplastics welded assembliesPersonnel en soudage des plastiques - Epreuve dequalification des soudeurs - Assemblages soudésthermoplastiquesKunststoffschweißpersonal - Anerkennungsprüfung vonSchweißern - Thermoplastische SchweißverbindungenThis European Standard was approved by CEN on 9 September 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13067:2003 ESIST EN 13067:2003

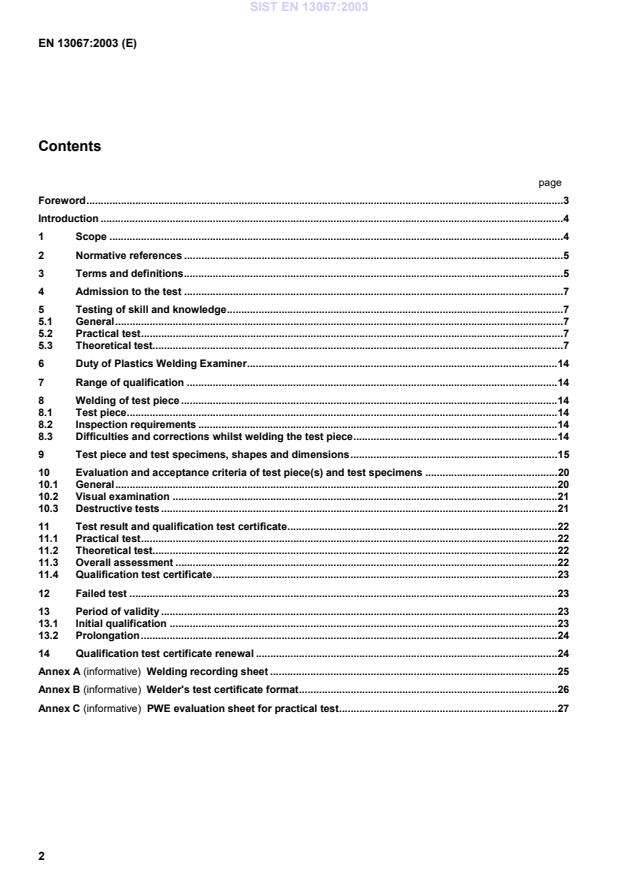

Welding recording sheet.25Annex B (informative)

Welder's test certificate format.26Annex C (informative)

PWE evaluation sheet for practical test.27SIST EN 13067:2003

P = pipeen = nominal wall thicknessdn = nominal pipe outsidediameterWeldingprocessWeldformPositionExaminationand testingType of testTest pieceaccordingto FigureRange of qualificationSDR = dn / en(See NOTE 1)DimensionsType of jointPosition1 PVC1.1Sen = 5Hot gasround nozzleVFlatV/B f + r1All enV , V , X, ^All1.2Sen = 5Hot gashigh speednozzleVFlatV/B f + r1All enV , V , X, ^All1.3Sen = 5Heated tool][MachineV/B1en ³ 3][Machine2 PP2.1Sen = 10Hot gashigh speednozzleXFlatV/B f + r1All enV, V , X, ^All2.2Sen = 10ExtrusioncontinuousVFlatV/B f + r1en ³ 3V , X, ^All2.3Sen = 10Heated tool][MachineV/B1en ³ 3][Machine2.4Pdn = 110SDR = 17,6Heated tool][MachineV/B r2en ³ 3dn £ 315][Machine2.5Pdn ³ 400SDR £ 17,6Heated tool][MachineV/B s2dn > 315][Machine2.6Pdn = 63SDR = 11Heated toolSocketMachineV/Pc4All dnSocketMachine2.7Pdn = 63SDR = 11ElectrofusionSocketMachineV/Pc4All dnSocketMachine(continued)SIST EN 13067:2003

P = pipeen = nominal wall thicknessdn = nominal pipe outsidediameterSDR = dn / enWeldingprocessWeldformPositionExaminationand testingType of test(See NOTE 1)Test pieceaccording toFigureDimensionsType of jointPosition3 PE3.1Sen = 10Hot gashigh speednozzleXFlatV/B f + r1All enX, V, V , ^All3.2Sen = 10ExtrusioncontinuousVFlatV/B f + r1en ³ 3V , X, ^All3.3Sen = 10Heated tool][MachineV/B1en ³ 3][Machine3.4Pdn = 110or dn = 180SDR = 11 orSDR = 17,6Heated tool][MachineV/T2dn £ 315][Machine3.5Pdn ³ 400SDR £ 17,6Heated tool][MachineV/T2dn > 315][Machine3.6Pdn = 90SDR = 11ElectrofusionSocketMachineV/Pd4dn £ 225All socketMachine3.7Pdn = 315SDR = 17,6ElectrofusionSocketMachineV/Pd4dn > 180All socketMachine3.8Pdn = 32on dn = 90SDR = 11ElectrofusionSaddleMachineV/Pd5All dnAll saddleMachine3.9Pdn = 63SDR = 11Heated toolSocketMachineV/Pc4All dnAll socketMachine3.10Pdn = 32on dn = 90SDR = 11Heated toolSaddleMachineV/Pc5All dnAll saddleMachine(continued)SIST EN 13067:2003

P = pipeen = nominal wall thicknessdn = nominal pipe outsidediameterWeldingprocessWeldformPositionExaminationand testingType of test(SeeTest pieceaccording toFigureRange of qualificationSDR = dn / enNOTE 1)DimensionsType of jointPosition4 PVDF4.1Sen = 4Hot gas highspeed nozzleVFlatV/B f + r1en ³ 2V , V, X ^All4.2Sen = 4Heated tool][MachineV/B1en ³ 2][Machine4.3Pdn = 110en = 5,3Heated tool][MachineV/B r2All dnen ³ 1,9][Machine4.4Pdn = 63en = 3Heated toolSocketMachineV/Pc4All dnSocketMachine5ECTFEor FEP5.1Sen = 2,3Hot gas highspeed nozzleVFlatV/T3en ³ 1,6V , V, X ^Allor PFA5.2Pdn = 110en = 3Heated tool][MachineV/T2All dnall en][MachineNOTE 1("/" = and)B = Bend test (f : face ; r : root ; s : side (for thick materials))Pc = Peel test (crush test)Pd = Peel test (decohesion test)V = Visual examinationT = Tensile testSIST EN 13067:2003

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...