SIST EN 14427:2022

(Main)LPG equipment and accessories - Transportable refillable composite cylinders for LPG - Design and construction

LPG equipment and accessories - Transportable refillable composite cylinders for LPG - Design and construction

This document:

— specifies minimum requirements for materials, design, construction, prototype testing and routine manufacturing inspections of fully wrapped composite cylinders with a water capacity from 0,5 litre up to and including 150 litres for liquefied petroleum gases (LPG) exposed to ambient temperatures, with a test pressure of at least 30 bar;

— is only applicable to cylinders which are fitted with a pressure relief valve (see 4.1.3);

— is applicable to cylinders with a liner of metallic material (welded or seamless) or non-metallic material (or a mixture thereof), reinforced by fibres of glass, carbon or aramid (or a mixture thereof);

— is also applicable to composite cylinders without liners.

Cylinders manufactured to this document are suitable for temperatures down to −40 °C.

This document does not address the design, fitting and performance of removable protective sleeves. Where these are fitted, the choice of material and sleeve performance are expected to be considered separately.

Flüssiggas-Geräte und Ausrüstungsteile - Ortsbewegliche wiederbefüllbare vollumwickelte Flaschen aus Verbundwerkstoff für Flüssiggas (LPG) - Auslegung und Bau

Dieses Dokument

— legt Mindestanforderungen an Werkstoffe, Auslegung, Bau, Baumusterprüfungen und Prüfungen bei der Herstellung von vollumwickelten Flaschen aus Verbundwerkstoff mit einem Fassungsraum von 0,5 l bis einschließlich 150 l für Flüssiggas (LPG) mit einem Prüfdruck von mindestens 30 bar fest, die Umgebungstemperaturen ausgesetzt sind;

— gilt nur für Flaschen, die mit einem Sicherheitsventil ausgestattet sind (siehe 4.1.3);

— gilt für Flaschen mit einem Liner aus metallischem Werkstoff (geschweißt oder nahtlos) oder aus nichtmetallischem Werkstoff (oder einer Kombination aus beidem), der durch Fasern aus Glas, Kohlenstoff oder Aramid (oder einer Kombination daraus) verstärkt ist;

— gilt auch für Flaschen aus Verbundwerkstoff ohne Liner.

Nach diesem Dokument hergestellte Flaschen sind für Temperaturen von bis zu −40 °C geeignet.

Dieses Dokument behandelt nicht die Auslegung, das Anbringen und die Leistung von abnehmbaren Schutzhüllen. Wenn diese angebracht werden, sind die Werkstoffauswahl und die Leistung der Hülle getrennt zu betrachten.

Équipements pour gaz de pétrole liquéfiés et leurs accessoires - Bouteilles entièrement bobinées en matériau composite, transportables et rechargeables pour gaz de pétrole liquéfié (GPL) - Conception et fabrication

Le présent document :

— spécifie les exigences minimales relatives aux matériaux, à la conception, à la fabrication, aux essais de qualification de modèle et aux contrôles courants de production des bouteilles composites entièrement bobinées pour gaz de pétrole liquéfié (GPL), d'une capacité en eau comprise entre 0,5 l et 150 l inclus, exposées aux températures ambiantes, pour une pression d'essai d'au moins 30 bar ;

— s'applique uniquement aux bouteilles qui sont dotées d'une soupape de sécurité (voir 4.1.3) ;

— s'applique aux bouteilles munies d'un liner métallique (avec ou sans soudure) ou non métallique (ou constitué d'un mélange de ces matériaux), renforcé par des fibres de verre, de carbone ou d'aramide (ou un mélange de ces matériaux) ;

— s'applique également aux bouteilles composites sans liner.

Les bouteilles fabriquées selon le présent document sont adaptées à des températures pouvant descendre jusqu'à –40 °C.

Le présent document ne traite pas de la conception, du montage et des performances des enveloppes de protection amovibles. Lorsque celles-ci sont montées, il est attendu que le choix du matériau et les performances des enveloppes soient considérés séparément.

Oprema in pribor za utekočinjeni naftni plin (UNP) - Premične, ponovno polnljive jeklenke iz kompozitnih materialov za UNP - Konstruiranje in izdelava

Ta evropski standard:

– določa minimalne zahteve za materiale, konstruiranje, izdelavo, preskušanje prototipov in rutinske proizvodne inšpekcijske preglede popolnoma obvitih jeklenk iz kompozitnih materialov s prostornino vode od 0,5 l do vključno 150 l za utekočinjeni naftni plin (UNP), izpostavljene temperaturam okolja, s preskusnim tlakom vsaj 30 barov;

– se uporablja le za jeklenke, ki so opremljene z varnostnim ventilom (glej točko 4.1.3);

– se uporablja za jeklenke z oblogo iz kovinskega materiala (varjenega ali nevarjenega) ali nekovinskega materiala (ali njegove mešanice), okrepljene s steklenimi vlakni, ogljikovimi ali aramidnimi (ali njuno mešanico);

– se uporablja tudi za jeklenke iz kompozitnih materialov brez oblog.

Jeklenke, proizvedene v skladu s tem evropskim standardom, so primerne za temperature do –40 °C.

Ta evropski standard ne obravnava konstruiranja, nameščanja in lastnosti odstranljivih zaščitnih ovitkov. Kadar so zaščitni ovitki nameščeni, naj bi se izbira materiala in lastnosti ovitkov obravnavale ločeno.

General Information

- Status

- Published

- Public Enquiry End Date

- 01-Dec-2020

- Publication Date

- 18-Aug-2022

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 03-Aug-2022

- Due Date

- 08-Oct-2022

- Completion Date

- 19-Aug-2022

Relations

- Effective Date

- 01-Sep-2022

Overview

EN 14427:2022 (CEN) specifies minimum requirements for the design, construction, materials, prototype testing and routine manufacturing inspections of transportable, refillable composite cylinders for LPG. It applies to fully wrapped composite cylinders with a water capacity from 0.5 litre up to and including 150 litres, with a test pressure of at least 30 bar, and is only applicable to cylinders fitted with a pressure relief valve. The 2022 edition supersedes EN 14427:2014 and introduces cylinder types, formal rejection criteria and updated testing/inspection rules. Cylinders manufactured to this standard are suitable for service temperatures down to −40 °C.

Key topics and technical requirements

- Cylinder types and design - introduction of defined cylinder types and required design drawings and documentation.

- Materials and construction - applicability to cylinders with metallic (welded or seamless) or non‑metallic liners and to liner‑less composite cylinders; reinforcement by glass, carbon or aramid fibres (or mixes).

- Composite overwrap and winding - material selection, winding procedures and manufacturing controls for fully wrapped composite cylinders.

- Mandatory fitting - requirement for a pressure relief valve (see scope).

- Prototype, design-variant and production testing - detailed test programme covering:

- composite material and liner material tests

- liner burst tests (metallic liners)

- proof pressure and cylinder burst tests

- pressure cycle, artificial ageing and elevated temperature exposure

- impact, drop, spike puncture and fire resistance tests

- permeability testing for specific cylinder types (Type 4 and 5)

- neck strength, neck ring and torque tests

- Manufacturing inspections and rejection criteria - establishment of routine inspection regimes and objective rejection criteria for finished cylinders.

- Marking, documentation and conformity - requirements for traceability and marking consistent with related LPG standards.

Applications and who uses EN 14427:2022

- Cylinder designers and manufacturers of refillable composite LPG cylinders seeking compliance with European safety and design expectations.

- Testing laboratories and certification bodies conducting prototype and production testing per EN 14427.

- Regulators and transport authorities referencing standards in RID/ADR technical annexes.

- OEMs, filling stations and LPG distributors ensuring cylinder compatibility, safety and traceability.

- Safety engineers and QA teams responsible for material selection, production inspection and lifetime performance.

Related standards

EN 14427 references pertinent standards for welded steel/aluminium cylinders (e.g., EN 1442, EN 13110), plastics and test methods (EN ISO 527, EN ISO 75), and marking (EN 14894). Users should consult these normative references and RID/ADR transport regulations where applicable.

Keywords: EN 14427:2022, LPG composite cylinders, transportable refillable composite cylinders, design and construction, CEN, LPG cylinder testing, composite overwrap, pressure relief valve.

Frequently Asked Questions

SIST EN 14427:2022 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "LPG equipment and accessories - Transportable refillable composite cylinders for LPG - Design and construction". This standard covers: This document: — specifies minimum requirements for materials, design, construction, prototype testing and routine manufacturing inspections of fully wrapped composite cylinders with a water capacity from 0,5 litre up to and including 150 litres for liquefied petroleum gases (LPG) exposed to ambient temperatures, with a test pressure of at least 30 bar; — is only applicable to cylinders which are fitted with a pressure relief valve (see 4.1.3); — is applicable to cylinders with a liner of metallic material (welded or seamless) or non-metallic material (or a mixture thereof), reinforced by fibres of glass, carbon or aramid (or a mixture thereof); — is also applicable to composite cylinders without liners. Cylinders manufactured to this document are suitable for temperatures down to −40 °C. This document does not address the design, fitting and performance of removable protective sleeves. Where these are fitted, the choice of material and sleeve performance are expected to be considered separately.

This document: — specifies minimum requirements for materials, design, construction, prototype testing and routine manufacturing inspections of fully wrapped composite cylinders with a water capacity from 0,5 litre up to and including 150 litres for liquefied petroleum gases (LPG) exposed to ambient temperatures, with a test pressure of at least 30 bar; — is only applicable to cylinders which are fitted with a pressure relief valve (see 4.1.3); — is applicable to cylinders with a liner of metallic material (welded or seamless) or non-metallic material (or a mixture thereof), reinforced by fibres of glass, carbon or aramid (or a mixture thereof); — is also applicable to composite cylinders without liners. Cylinders manufactured to this document are suitable for temperatures down to −40 °C. This document does not address the design, fitting and performance of removable protective sleeves. Where these are fitted, the choice of material and sleeve performance are expected to be considered separately.

SIST EN 14427:2022 is classified under the following ICS (International Classification for Standards) categories: 23.020.35 - Gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14427:2022 has the following relationships with other standards: It is inter standard links to SIST EN 14427:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14427:2022 is associated with the following European legislation: EU Directives/Regulations: 2008/68/EC, 94/55/EC, 96/49/EC; Standardization Mandates: M/086. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14427:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2022

Nadomešča:

SIST EN 14427:2014

Oprema in pribor za utekočinjeni naftni plin (UNP) - Premične, ponovno polnljive

jeklenke iz kompozitnih materialov za UNP - Konstruiranje in izdelava

LPG equipment and accessories - Transportable refillable composite cylinders for LPG -

Design and construction

Flüssiggas-Geräte und Ausrüstungsteile - Ortsbewegliche wiederbefüllbare

vollumwickelte Flaschen aus Verbundwerkstoff für Flüssiggas (LPG) - Auslegung und

Bau

Équipements pour gaz de pétrole liquéfiés et leurs accessoires - Bouteilles entièrement

bobinées en matériau composite, transportables et rechargeables pour gaz de pétrole

liquéfié (GPL) - Conception et fabrication

Ta slovenski standard je istoveten z: EN 14427:2022

ICS:

23.020.35 Plinske jeklenke Gas cylinders

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14427

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2022

EUROPÄISCHE NORM

ICS 23.020.35 Supersedes EN 14427:2014

English Version

LPG equipment and accessories - Transportable refillable

composite cylinders for LPG - Design and construction

Équipements pour gaz de pétrole liquéfiés et leurs Flüssiggas-Geräte und Ausrüstungsteile -

accessoires - Bouteilles entièrement bobinées en Ortsbewegliche wiederbefüllbare vollumwickelte

matériau composite, transportables et rechargeables Flaschen aus Verbundwerkstoff für Flüssiggas (LPG) -

pour gaz de pétrole liquéfié (GPL) - Conception et Auslegung und Bau

fabrication

This European Standard was approved by CEN on 13 March 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14427:2022 E

worldwide for CEN national Members.

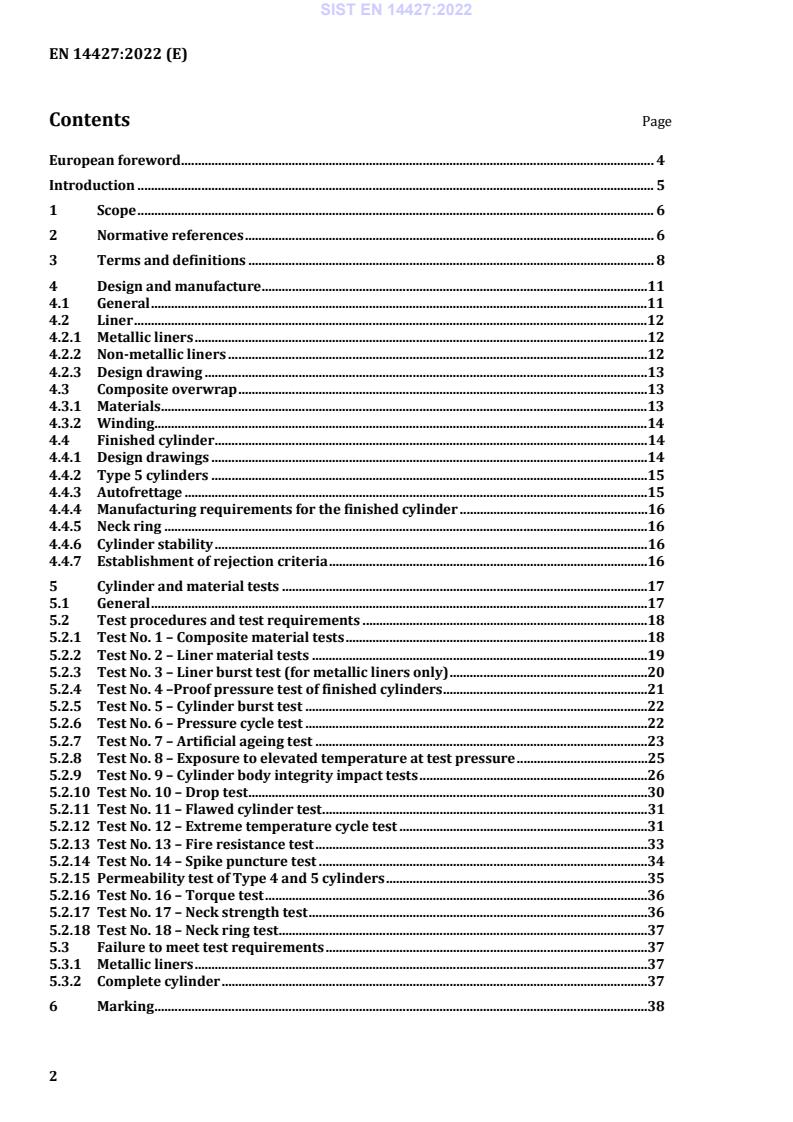

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 8

4 Design and manufacture .11

4.1 General .11

4.2 Liner .12

4.2.1 Metallic liners .12

4.2.2 Non-metallic liners .12

4.2.3 Design drawing .13

4.3 Composite overwrap .13

4.3.1 Materials .13

4.3.2 Winding.14

4.4 Finished cylinder .14

4.4.1 Design drawings .14

4.4.2 Type 5 cylinders .15

4.4.3 Autofrettage .15

4.4.4 Manufacturing requirements for the finished cylinder .16

4.4.5 Neck ring .16

4.4.6 Cylinder stability .16

4.4.7 Establishment of rejection criteria .16

5 Cylinder and material tests .17

5.1 General .17

5.2 Test procedures and test requirements .18

5.2.1 Test No. 1 – Composite material tests .18

5.2.2 Test No. 2 – Liner material tests .19

5.2.3 Test No. 3 – Liner burst test (for metallic liners only) .20

5.2.4 Test No. 4 –Proof pressure test of finished cylinders .21

5.2.5 Test No. 5 – Cylinder burst test .22

5.2.6 Test No. 6 – Pressure cycle test .22

5.2.7 Test No. 7 – Artificial ageing test .23

5.2.8 Test No. 8 – Exposure to elevated temperature at test pressure .25

5.2.9 Test No. 9 – Cylinder body integrity impact tests .26

5.2.10 Test No. 10 – Drop test .30

5.2.11 Test No. 11 – Flawed cylinder test .31

5.2.12 Test No. 12 – Extreme temperature cycle test .31

5.2.13 Test No. 13 – Fire resistance test .33

5.2.14 Test No. 14 – Spike puncture test .34

5.2.15 Permeability test of Type 4 and 5 cylinders .35

5.2.16 Test No. 16 – Torque test .36

5.2.17 Test No. 17 – Neck strength test .36

5.2.18 Test No. 18 – Neck ring test .37

5.3 Failure to meet test requirements .37

5.3.1 Metallic liners .37

5.3.2 Complete cylinder .37

6 Marking .38

Annex A (normative) Prototype testing, design variant testing and production testing . 39

A.1 General . 39

A.2 Prototype testing . 39

A.2.1 General . 39

A.2.2 Definition of new design . 40

A.2.3 Prototype testing requirements . 41

A.3 Design variant testing . 43

A.3.1 General . 43

A.3.2 Definition of a design variant . 43

A.3.3 Design variant test requirements . 46

A.4 Production testing . 49

A.4.1 General . 49

A.4.2 Production test requirements . 49

A.4.3 Liner batch tests and inspections . 49

A.4.4 Composite materials batch tests and inspections. 50

A.4.5 Tests and inspections of the finished cylinder . 50

Bibliography . 54

European foreword

This document (EN 14427:2022) has been prepared by Technical Committee CEN/TC 286 “Liquefied

petroleum gas equipment and accessories”, the secretariat of which is held by NSAI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2022, and conflicting national standards shall

be withdrawn at the latest by October 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14427:2014.

In comparison with the previous edition, the following technical modifications have been made:

— Introduction of cylinder types;

— Addition of criteria for design drawings;

— Establishment of rejection criteria;

— Addition of table – cylinder rejection criteria;

— Further update to 4.3.2.4, 5.2.6, 5.2.7, 5.2.9, 5.2.15, Annex A.

This document has been submitted for reference in:

— the RID [12]; and

— the technical annexes of the ADR [11].

NOTE These regulations take precedence over any clause of this standard. It is emphasized that RID/ADR are

being revised regularly at intervals of two years which can lead to temporary non-compliances with the clauses of

this document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document calls for the use of substances and procedures that can be injurious to health if adequate

precautions are not taken. It refers only to technical suitability and does not absolve the user from legal

obligations relating to health and safety at any stage.

It has been assumed in the drafting of this document that the execution of its provisions is entrusted to

appropriately qualified and experienced people.

Protection of the environment is a key political issue in Europe and elsewhere, for CEN/TC 286 this is

covered in CEN/TS 16765 [5] and this Technical Specification should be read in conjunction with this

document. This Technical Specification provides guidance on the environmental aspects to be considered

regarding equipment and accessories produced for the LPG industry and the following is addressed:

a) design;

b) manufacture;

c) packaging;

d) use and operation; and

e) disposal.

All pressures are gauge pressure unless otherwise stated.

NOTE This document requires measurement of material properties, dimensions and pressures. All such

measurements are subject to a degree of uncertainty due to tolerances in measuring equipment, etc. It may be

beneficial to refer to the leaflet “Measurement uncertainty leaflet SP INFO 2000 27” [13].

1 Scope

This document:

— specifies minimum requirements for materials, design, construction, prototype testing and routine

manufacturing inspections of fully wrapped composite cylinders with a water capacity from 0,5 litre

up to and including 150 litres for liquefied petroleum gases (LPG) exposed to ambient temperatures,

with a test pressure of at least 30 bar;

— is only applicable to cylinders which are fitted with a pressure relief valve (see 4.1.3);

— is applicable to cylinders with a liner of metallic material (welded or seamless) or non-metallic

material (or a mixture thereof), reinforced by fibres of glass, carbon or aramid (or a mixture thereof);

— is also applicable to composite cylinders without liners.

Cylinders manufactured to this document are suitable for temperatures down to −40 °C.

This document does not address the design, fitting and performance of removable protective sleeves.

Where these are fitted, the choice of material and sleeve performance are expected to be considered

separately.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1442, LPG equipment and accessories - Transportable refillable welded steel cylinders for LPG - Design

and construction

EN 1964-3, Transportable gas cylinders - Specification for the design and construction of refillable

transportable seamless steel gas cylinders of water capacities from 0,5 litre up to and including 150 litres -

Part 3: Cylinders made of seamless stainless steel with an Rm value of less than 1100 MPa

EN 12165, Copper and copper alloys - Wrought and unwrought forging stock

EN 12807, LPG equipment and accessories - Transportable refillable brazed steel cylinders for liquefied

petroleum gas (LPG) - Design and construction

EN 13110, LPG equipment and accessories - Transportable refillable welded aluminium cylinders for

liquefied petroleum gas (LPG) - Design and construction

EN 14140, LPG equipment and accessories - Transportable refillable welded steel cylinders for LPG -

Alternative design and construction

EN 14717, Welding and allied processes - Environmental check list

EN 14894, LPG equipment and accessories - Cylinder and drum marking

EN ISO 75-1, Plastics - Determination of temperature of deflection under load - Part 1: General test method

(ISO 75-1)

EN ISO 75-3, Plastics - Determination of temperature of deflection under load - Part 3: High-strength

thermosetting laminates (ISO 75-3)

EN ISO 527-1, Plastics - Determination of tensile properties - Part 1: General principles (ISO 527-1)

EN ISO 527-2, Plastics - Determination of tensile properties - Part 2: Test conditions for moulding and

extrusion plastics (ISO 527-2)

EN ISO 1133-1, Plastics - Determination of the melt mass-flow rate (MFR) and melt volume-flow rate (MVR)

of thermoplastics - Part 1: Standard method (ISO 1133-1)

EN ISO 1133-2, Plastics - Determination of the melt mass-flow rate (MFR) and melt volume-flow rate (MVR)

of thermoplastics - Part 2: Method for materials sensitive to time-temperature history and/or moisture (ISO

1133-2)

EN ISO 1183-1, Plastics - Methods for determining the density of non-cellular plastics - Part 1: Immersion

method, liquid pycnometer method and titration method (ISO 1183-1)

EN ISO 1183-2, Plastics - Methods for determining the density of non-cellular plastics - Part 2: Density

gradient column method (ISO 1183-2)

EN ISO 1183-3, Plastics - Methods for determining the density of non-cellular plastics - Part 3: Gas

pyknometer method (ISO 1183-3)

EN ISO 2555, Plastics - Resins in the liquid state or as emulsions or dispersions - Determination of apparent

viscosity using a single cylinder type rotational viscometer method (ISO 2555)

EN ISO 2884-1, Paints and varnishes - Determination of viscosity using rotary viscometers - Part 1: Cone-

and-plate viscometer operated at a high rate of shear (ISO 2884-1)

EN ISO 3146, Plastics - Determination of melting behaviour (melting temperature or melting range) of semi-

crystalline polymers by capillary tube and polarizing-microscope methods (ISO 3146)

EN ISO 7866, Gas cylinders - Refillable seamless aluminium alloy gas cylinders - Design, construction and

testing (ISO 7866)

EN ISO 9227:2017, Corrosion tests in artificial atmospheres - Salt spray tests (ISO 9227:2017)

EN ISO 9809-1, Gas cylinders - Design, construction and testing of refillable seamless steel gas cylinders and

tubes - Part 1: Quenched and tempered steel cylinders and tubes with tensile strength less than 1 100 MPa

(ISO 9809-1)

EN ISO 9809-2, Gas cylinders - Design, construction and testing of refillable seamless steel gas cylinders and

tubes - Part 2: Quenched and tempered steel cylinders and tubes with tensile strength greater than or equal

to 1 100 MPa (ISO 9809-2)

EN ISO 9809-3, Gas cylinders - Design, construction and testing of refillable seamless steel gas cylinders and

tubes - Part 3: Normalized steel cylinders and tubes (ISO 9809-3)

EN ISO 14245, Gas cylinders - Specifications and testing of LPG cylinder valves - Self-closing (ISO 14245)

EN ISO 15995, Gas cylinders - Specifications and testing of LPG cylinder valves - Manually operated (ISO

15995)

EN ISO 15512, Plastics - Determination of water content (ISO 15512)

EN ISO 16474-3:2021, Paints and varnishes - Methods of exposure to laboratory light sources - Part 3:

Fluorescent UV lamps (ISO 16474-3:2021)

ISO 3341, Textile glass — Yarns — Determination of breaking force and breaking elongation

ISO 8521, Glass-reinforced thermosetting plastic (GRP) pipes — Test methods for the determination of the

initial circumferential tensile wall strength

ISO 11357-3, Plastics — Differential scanning calorimetry (DSC) — Part 3: Determination of temperature

and enthalpy of melting and crystallization

ASTM D 2196, Test methods for rheological properties of non-newtonian materials by rotational

(Brookfield type) viscometer

ASTM D 2290A, Standard Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic

Pipe

ASTM D 2291, Standard practice for fabrication of ring test specimens for glass-resin composites

ASTM D 2343, Standard test method for tensile properties of glass fibre strands, yarns and rovings used in

reinforced plastics

ASTM D 2344, Standard test method for short-beam strength of polymer matrix composite materials and

their laminates

ASTM D 3418, Standard test method for transition temperatures and enthalpies of fusion and

crystallization of polymers by differential scanning calorimetry

ASTM D 4018, Standard test methods for tensile properties of continuous filament carbon and graphite fibre

tows

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply. ISO and IEC maintain

terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

liquefied petroleum gas

LPG

low pressure liquefied gas composed of one or more light hydrocarbons which are assigned to UN 1011,

UN 1075, UN 1965, UN 1969 or UN 1978 only and which consists mainly of propane, propene, butane,

butane isomers, butene with traces of other hydrocarbon gases

3.2

ambient test temperature

temperature of surroundings varying between 10 °C and 35 °C (for test purposes only)

3.3

autofrettage

pressure application procedure which strains the metal liner past its yield point sufficiently to cause

permanent plastic deformation, and results in the liner having compressive stresses and the fibres having

tensile stresses when at zero internal gauge pressure

3.4

batch

quantity of fibres, pre-impregnated fibres or components of the matrix system homogeneous

quantity of material, identified and certified as such by the supplier

3.5

batch

quantity of liners of the same nominal diameter, thickness, length and design, made

successively from the same material cast and subjected to the same heat treatment for the same length

of time

3.6

batch

quantity of liners of the same nominal diameter, thickness, length and design, made

successively from the same batch of materials and subjected to the same manufacturing process

3.7

batch

quantity of finished cylinders, plus cylinders for destructive testing, of

the same nominal diameter, thickness, length and design

Note 1 to entry: The batch may contain different batches of liners, providing the batches are nominally the same

and have had the same treatment, fibres and matrix materials.

3.8

batch

quantity of finished cylinders, plus cylinders for destructive testing,

of the same nominal diameter, thickness, length and design

3.9

burst pressure

highest pressure reached in a cylinder or liner during the relevant burst test

3.10

composite overwrap

fibres, or fibres embedded in a matrix taken together as a combined unit

3.11

elastomeric material

material which at ambient temperature can be stretched repeatedly to at least twice its original length

and will return with force to approximately its original length immediately upon release of the stress

3.12

exterior coating

layer of clear or pigmented material applied to the cylinder as protection

3.13

fibre

strand

load-carrying part of the composite overwrap

EXAMPLE glass, aramid or carbon

3.14

fully wrapped composite cylinder

cylinder reinforced by wrapping to take both circumferential and longitudinal stress

Note 1 to entry: These are referred within this document as types 3, 4 and 5 (refer to 3.23, 3.24 and 3.25).

3.15

liner

metallic or non-metallic vessel that retains the LPG in the cylinder, but may also contribute to the

mechanical behaviour of the cylinder

Note 1 to entry: This is a load sharing liner.

3.16

neck ring

collar or ring with or without external threads, securely attached to the cylinder neck by means other

than welding, brazing or soldering

3.17

non-load sharing liner

liner made of material(s) with a stiffness (e-modulus) that is less than 1/10 of the fibre stiffness and is

intended only to prevent diffusion of LPG

3.18

non-metallic liner

liner made from thermoplastic, thermosetting, or elastomer material or a combination thereof

3.19

matrix

material which is used to bind and hold the fibres in place

3.20

thermoplastic

plastics capable of being repeatedly softened by increase of temperature and hardened by decrease of

temperature

3.21

thermoset

plastics which when cured by the application of heat or chemical means changes into a substantially

infusible and insoluble product

3.22

removable protective sleeve

external sleeve intended to provide protection to the cylinder during operation which is not an integral

part of the design, not permanently fixed to the cylinder but which can be removed during service without

destroying the sleeve without the use of special tools

3.23

permanent protective attachment

integral part of the cylinder design affixed to composite cylinders (type 2 to 5) covering part of or the

entire surface of the cylinder, providing functions during handling, transport, and use

3.24

Type 3 cylinder

fully wrapped cylinder with a load-sharing metal liner and composite reinforcement on both cylindrical

and dome ends

3.25

Type 4 cylinder

fully wrapped cylinder with a non-load sharing liner and composite reinforcement on both cylindrical

and dome ends

3.26

Type 5 cylinder

fully wrapped cylinder without a liner and with composite reinforcement on both the cylindrical portion

and the dome ends

3.27

major interruption

where a process is halted for more than 6 hours, due to an unscheduled event

EXAMPLE break down of production equipment needing replacement

4 Design and manufacture

4.1 General

4.1.1 Fully wrapped composite LPG cylinders may be manufactured with a metallic or non-metallic

liner or without a liner. The composite overwrap shall not be manufactured from two or more parts

joined together regardless of the joining methods (e.g. using adhesive).

The thicknesses of the cylinder, including any liner, shall be determined by satisfactory completion of the

performance tests described in Clause 5. No design calculations are required.

The cylinder may also include an external coating and/or additional parts such as valve shrouds/handles,

bases and permanent protective attachments. Where these are an integral part of the design, they shall

be permanently fixed to the cylinder such that they cannot be removed during service without destroying

them, or by use of special tools.

The design of the cylinder shall take the following into account:

— minimizing the use of materials;

— the fittings required for the cylinder;

— minimizing the environmental impact of in service maintenance and end of life disposal;

— efficient transport of finished product.

For the welding associated with metallic liners, the environmental impact of welding and allied processes

shall be assessed in accordance with EN 14717.

The manufacturer should endeavour to minimize wastage of material by selecting appropriately sized

materials related to the finished parts required for manufacture. Unavoidable waste/scrap material

should be recycled where possible.

Noise levels and harmful emissions from the production process should be evaluated and measures put

into place to minimize the impact upon the external environment.

4.1.2 The location of all openings for service connections shall be restricted to one end of the cylinder.

Where it is necessary, for production reasons, to have an opening in both ends, the non-service opening

shall be permanently sealed before completion of the cylinder. The sealing arrangement shall be:

— permanent;

— inaccessible to users of the cylinder in service; and

— designed so that any leakage of product past the seal can only be released local to the service valve(s)

so that it will be detectable during post-fill leak checks.

4.1.3 Due to their limited volumetric expansion, cylinders designed to this document are intended to

be used only when fitted with a pressure relief valve, see EN 13953 [3].

4.2 Liner

4.2.1 Metallic liners

4.2.1.1 Metallic liners shall be manufactured in accordance with the relevant clauses of the following

European Standards:

a) seamless steel liners: EN ISO 9809-1, EN ISO 9809-2 or EN ISO 9809-3, as

appropriate;

b) seamless stainless steel liners: EN 1964-3;

c) seamless aluminium alloy liners: EN ISO 7866;

d) welded steel liners: EN 1442 or EN 14140;

e) brazed steel liners: EN 12807;

f) welded aluminium liners: EN 13110;

g) Brass boss inserts EN 12165 or equivalent (composition).

4.2.1.2 The relevant clauses are those covering: materials, thermal treatments, neck design,

construction and workmanship, mechanical tests.

NOTE This excludes the design requirements, since the design is determined by the manufacturer in

accordance with this document for the design of the composite cylinder.

4.2.2 Non-metallic liners

4.2.2.1 A non-metallic liner shall be designed as non-load sharing. The liner material shall be

compatible with LPG. Guidance to material compatibility is given in EN ISO 11114-2 [6].

4.2.2.2 Where a metal end boss or end boss insert is used in a non-metallic liner, it shall be considered

part of the liner material and shall fulfil the material requirements specified in the relevant standard

listed in 4.2.1.1.

4.2.3 Design drawing

4.2.3.1 A fully dimensioned drawing of the liner shall be produced which shall include the

specification of the material and material properties.

4.2.3.2 The following properties shall be specified for metallic liners:

— minimum yield stress;

— minimum tensile strength;

— minimum elongation; and

— minimum burst pressure.

4.2.3.3 The following properties shall be specified for non-metallic liners:

— density;

— for thermoplastics, the melting point, as determined by EN ISO 3146 or ISO 11357-3;

— for thermoset materials, the temperature of deflection under load, as determined by EN ISO 75-1 and

EN ISO 75-3;

— for thermoset materials, the glass transition temperature as determined by differential scanning

calorimetry;

— composition;

— compatibility with LPG, guidance is provided in EN ISO 11114-2 [6]; and

— end boss material specification.

The end boss material specifications includes:

— minimum tensile strength at yield;

— minimum elongation of the boss material at yield.

4.3 Composite overwrap

4.3.1 Materials

Material requirements for the fibre and the matrix, where applicable, shall be as specified by the

manufacturer.

If glass fibre is used as the structural reinforcement of the cylinder, then only boron free glass fibre shall

be used.

4.3.2 Winding

4.3.2.1 Procedures shall be defined for the winding and curing process to ensure good repeatability

and traceability.

4.3.2.2 For all cylinders, the following parameters shall be defined and monitored:

a) the batch numbers of the fibres used;

b) the number of strands used;

c) the winding tension per strand as determined by the cylinder manufacturer;

d) the winding speed(s);

e) the winding angle and/or pitch for each layer; and

f) the number and order of layers.

The parameters in c) and d) are only applicable when relevant to the manufacturing process.

4.3.2.3 Where a matrix system is used, the following additional parameters shall be defined and

monitored:

a) percentages of the components of the matrix system and their batch numbers;

b) resin bath temperature range, (where applicable);

c) the procedure used to obtain correct impregnation (e.g. wet winding or pre-impregnation);

d) the polymerisation cycle; and

e) the polymerisation process (e.g. thermal cycling, ultrasonic, ultraviolet, or radiation).

4.3.2.4 For thermal polymerisation, the temperature and the length of the polymerisation cycle of

the resin system shall be such that they do not adversely affect the mechanical characteristics of the liner.

In addition, tolerances for holding time and temperature at each stage shall be defined. For non-metallic

liners it shall be shown that the material does not experience any significant alterations such as phase

changes or transitions over the temperature range and duration of the polymerization cycle. This can be

shown using e.g. Differential Scanning Calorimetry, Dynamic Mechanical Thermal Analysis,

Thermogravimetric analysis or similar test methods.

4.4 Finished cylinder

4.4.1 Design drawings

4.4.1.1 A fully dimensioned drawing of all parts that constitute the finished cylinder shall be

produced. The design drawing shall also include tolerances on all dimensions, including out-of-roundness

and straightness.

4.4.1.2 The drawing shall include the specification of the material(s), the material properties and the

reinforcement pattern. The specifications and the reinforcement patterns may be given in a technical

specification referenced on the drawing.

4.4.1.3 The details of any exterior coating and additional, permanently fixed parts, which are an

integral part of the design, shall be specified.

4.4.1.4 The manufacturer shall specify the minimum burst pressure for the design which shall be at

least 67,5 bar (the test pressure shall be at least 30 bar) i.e. a burst ratio of 2,25.

4.4.1.5 The drawing shall specify any special characteristics or special limitations (e.g. maximum

fitting torque restrictions).

4.4.1.6 For designs requiring the fitting of a PRV to pass any or all tests, the drawing shall specify the

requirements for fitting a specific type of relief device including performance criteria used in the fire

resistance test, see 5.2.13. (E.g. start to discharge pressure, flow rates and melting temperature range).

4.4.2 Type 5 cylinders

4.4.2.1 The composition of the composite materials and their properties shall be specified, as follows:

a) tensile strength;

b) tensile modulus;

c) elongation;

d) heat distortion temperature;

e) viscosity.

4.4.2.2 The composite materials shall be compatible with LPG. Guidance to material compatibility is

given in EN ISO 11114-2 [6].

4.4.2.3 Where a metal end boss is used in a Type 5 cylinder the drawing of the cylinder shall include

the specification of the material and material properties of the boss in accordance with 4.2.3.

4.4.3 Autofrettage

4.4.3.1 Internal pressurization to autofrettage pressure of cylinders with metallic liners can be part

of the manufacturing process; if so, this operation shall be executed after polymerisation of the composite

for thermosetting resins or after the consolidation process for thermoplastics.

4.4.3.2 During the autofrettage operation, the following parameters shall be recorded:

a) autofrettage pressure;

b) duration of application of this pressure;

c) expansion at autofrettage pressure;

d) permanent expansion after autofrettage.

4.4.3.3 Where autofrettage is performed, a check shall be made that the procedure has been

effectively performed on all cylinders.

4.4.4 Manufacturing requirements for the finished cylinder

The internal and external surfaces of the finished cylinder shall be free of defects which could adversely

affect the safe working of the cylinder. In addition, there shall be no visible foreign matter present inside

the cylinder (e.g. resin, swarf or other debris).

4.4.5 Neck ring

Where a neck ring is provided, it shall be of a material compatible with that of the cylinder. It shall be

securely attached by a method appropriate to the cylinder or boss material so as to withstand the test

specified in Test No. 18 (see 5.2.18).

4.4.6 Cylinder stability

For cylinders designed to stand on their base, the variation from vertical shall be less than 1 % of their

height. The outer diameter of the surface in contact with the ground shall be greater than 75 % of the

nominal outside diameter.

For cylinders with a height to diameter ratio of 3 or less, the variation from vertical does not have to be

verified.

Due consideration should be given to the safe handling (by mechanical or manual means) in relation to

the size and mass of the cylinder (e.g. handles or lifting points).

4.4.7 Establishment of rejection criteria

4.4.7.1 General

The manufacturer of the cylinder shall establish rejection criteria for defects and damage on the

composite overwrap.

The following types of damage shall be tested:

— abrasion damage;

— impact;

— structural;

— cuts or gouges, bulges;

— chemical;

— heat / fire.

The criteria shall be updated accordingly to reflect the return of experience, for example, discovery of a

new type of damage.

The established criteria shall be made available to the cylinder owner. These criteria should be used as

the basis for checking at the time of filling and periodic control, e.g. EN 1439 [2] and EN 16728 [4].

4.4.7.2 Procedure

For each design of cylinder, the rejection criteria shall be as follows;

a) For each defect, four cylinders with the same defect shall be tested. The size of each defect shall be

recorded, the variation in size between the largest and smallest defect shall not exceed 10 %.

b) Each of the four test cylinders can combine more than one type of defect provided that all four

cylinders have the same defect types.

c) Two cylinders shall be submitted to the cylinder burst test as described in 5.2.5 and two cylinders

shall be submitted to the pressure cycle test as described in 5.2.6.

d) If all the cylinders pass the tests, the type of defect is acceptable. The rejection limit shall then be

defined by the size of the largest defect.

5 Cylinder and material tests

5.1 General

This clause describes the tests to be conducted on fully wrapped composite cylinders, cylinder liners and

the materials used in manufacture of cylinders, as required by Annex A, for:

— prototype testing of new cylinder designs (see A.2);

— design variant testing (see A.3); and

— production testing (see A.4).

NOTE In RID/ADR, “production tests” are referred to as “initial inspection and tests”.

The tests listed are mandatory or optional, as identified in the schedule of testing and inspections in

Annex A.

Cylinders subjected to the tests shall include all permanently fixed parts, unless otherwise specified.

No tests shall be performed with a removable protective sleeve fitted to the cylinder, except where

specified (see Test 10, 5.2.10.1).

Attention is drawn to the risks associated with testing pressurized cylinders. Appropriate safety

precautions should be taken in order to reduce the risks to testing personnel e.g. during positioning and

handling of cylinders they can be depressurised between individual tests.

Consideration should be given to minimizing the environmental impact of the tests specified by including

the possible recovery of test fluids, recycling of mechanical test specimens, safe disposal of chemicals and

destroyed cylinders, etc.

5.2 Test procedures and test requirements

5.2.1 Test No. 1 – Composite material tests

5.2.1.1 Tests on all cylinders

5.2.1.1.1 Procedure

Tests on the composite materials to establish their mechanical properties shall be carried out as follows

for:

a) Tensile properties of fibres in accordance with the following standards:

For glass, aramid:

— ΙSO 8521 or ASTM D 2290A and ASTM D 2291;

— ISO 3341 or ASTM D 2343.

For carbon:

— ASTM D 3418;

— ASTM D 4018.

b) Shear properties for thermosetting plastics in accordance with the following standard:

— ASTM D 2344.

c) Matrix properties in accordance with the following standards:

— glass transition temperature: ASTM D 3418 or ISO 11357-3 by Differential Scanning

Calorimetry;

— heat distortion temperature: EN ISO 75-3;

— viscosity: ASTM D 2196.

NOTE For tests specified above at a, b, and c, alternative standards are acceptable providing that they give

equivalent results.

d) Test temperature:

Material tests specified in a) and b) above shall be carried out at ambient test temperature and at –

+ 0

20 °C (with a tolerance of °C).

− 5

At each temperature, three specimens shall be tested.

As an alternative, the cylinder impact tests (Test No. 9, see 5.2.9) with the cylinders at –20 °C (with a

+ 0

tolerance of °C) can be carried out.

− 5

Where possible, after completing of the tests all material should be processed for recycling.

5.2.1.1.2 Criteria

The mechanical properties shall meet the minimum requirements for the design as specified by the

manufacturer.

The average of the test results at –20 °C shall not be less than 95 % of the lower tolerance level of the

material specification.

5.2.1.2 Additional tests on Type 5 cylinders

5.2.1.2.1 Procedure

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...