SIST EN 81-44:2025

(Main)Safety rules for the construction and installation of lifts - Special lifts for the transport of persons and goods - Part 44: Lifting appliances in wind turbines

Safety rules for the construction and installation of lifts - Special lifts for the transport of persons and goods - Part 44: Lifting appliances in wind turbines

1.1 This document specifies the safety requirements for the construction and installation of power operated lifting appliances installed permanently for indoor or outdoor service in wind turbines and intended for access to workplaces on wind turbines, including rescue and evacuation procedures. A lifting appliance serves defined landing levels and can move persons to working positions where they are carrying out work (which could be from the carrier) and has a carrier which is:

a) designed for the transportation of persons and goods;

b) guided;

c) travelling vertically or along a path within 15° maximum from the vertical;

d) supported or sustained by rack and pinion or rope traction drive;

e) travelling with a speed not more than 0,7 m/s;

f) able to operate in a temperature range between - 25 °C to + 55 °C.

1.2 This document does not cover hazards related to:

a) noise;

b) the use of the lifting appliance for erection or dismantling of the wind turbine;

c) lightning protection;

d) use in potentially explosive atmospheres;

e) electromagnetic compatibility (emission, immunity);

f) transporting of goods outside the carrier;

g) the use of combustion engines;

h) hydraulic and pneumatic drive units;

i) the use of lifting appliances in floating wind turbines;

j) use during earthquakes.

1.3 This document is not applicable to lifting appliances manufactured before the date of its publication.

Sicherheitsregeln für die Konstruktion und Installation von Aufzügen - Besondere Aufzüge für den Transport von Personen und Gütern - Teil 44: Aufzüge in Windenergieanlagen

Règles de sécurité pour la construction et l'installation des élévateurs - Applications particulières pour les ascenseurs et les ascenseurs de charge - Partie 44 : Ascenseurs de chantier pour éolienne

1.1 This document specifies the safety requirements for the construction and installation of power operated lifting appliances installed permanently for indoor or outdoor service in wind turbines and intended for access to workplaces on wind turbines, including rescue and evacuation procedures. A lifting appliance serves defined landing levels and can move persons to working positions where they are carrying out work (which could be from the carrier) and has a carrier which is:

a) designed for the transportation of persons and goods;

b) guided;

c) travelling vertically or along a path within 15° maximum from the vertical;

d) supported or sustained by rack and pinion or rope traction drive;

e) travelling with a speed not more than 0,7 m/s;

f) able to operate in a temperature range between -25 °C to + 55 °C.

1.2 This document does not cover hazards related to:

a) noise;

b) the use of the lifting appliance for erection or dismantling of the wind turbine;

c) lightning protection;

d) use in potentially explosive atmospheres;

e) electromagnetic compatibility (emission, immunity);

f) transporting of goods outside the carrier;

g) the use of combustion engines;

h) hydraulic and pneumatic drive units;

i) the use of lifting appliances in floating wind turbines;

j) use during earthquakes.

1.3 This document is not applicable to lifting appliances manufactured before the date of its publication.

Varnostna pravila za konstruiranje in vgradnjo dvigal (liftov) - Posebna dvigala za prevoz oseb in blaga - 44. del: Dvigala v vetrnih turbinah

1.1 Ta dokument določa varnostne zahteve za konstruiranje in vgradnjo dvižnih naprav na električni pogon (v nadaljnjem besedilu »dvigala«), ki so trajno nameščene za notranjo ali zunanjo uporabo v vetrnih turbinah in so namenjene dostopu pristojnih oseb do delovnih mest na vetrnih turbinah. Dvigalo se uporablja za določene ravni podestov in lahko premakne osebe na delovna mesta, kjer opravljajo delo (npr. iz vozička), ter vključuje voziček, ki:

a) je zasnovan za prevoz oseb in blaga;

b) je voden;

c) potuje navpično ali pod kotom največ 15 stopinj od navpičnice;

d) je podprt ali ga držita tračnica in zobato kolesce ali vlečni pogon z vrvjo;

e) potuje s hitrostjo največ 0,7 m/s;

f) deluje v temperaturnem območju od –25 °C do +55 °C.

1.2 Ta dokument opredeljuje nevarnosti, navedene v točki 4, do katerih pride med različnimi fazami življenjske dobe take opreme, in opisuje metode za odpravo ali zmanjšanje teh nevarnosti, kadar se oprema uporablja v skladu s predvidenim namenom.

1.3 Ta dokument ne določa zahtev za:

a) obratovanje v težkih pogojih (npr. skrajne podnebne razmere, močna magnetna polja);

b) hrup;

c) uporabo dvigala za gradbena ali razstavljalna dela v zvezi z vetrno turbino;

d) zaščito pred udarom strele;

e) obratovanje, pri katerem veljajo posebna pravila (npr. potencialno eksplozivne atmosfere);

OPOMBA: Za vrsto strojev ali opreme, ki jo zajema ta evropski standard, je mogoče uporabiti Direktivo 2014/34/EU v zvezi z opremo in zaščitnimi sistemi, namenjenimi za uporabo v potencialno eksplozivnih atmosferah. Ta standard ne podaja načinov za dokazovanje skladnosti z bistvenimi zdravstvenimi in varnostnimi zahtevami Direktive 2014/34/EU.

f) elektromagnetno združljivost (emisije, odpornost);

g) ravnanje s tovori, ki lahko povzročijo nevarne razmere;

h) uporabo motorjev z notranjim zgorevanjem;

i) hidravlične in pnevmatske pogonske enote;

j) nevarnosti, ki se pojavljajo med proizvodnjo;

k) uporabo dvigal v plavajočih vetrnih turbinah;

l) uporabo pri potresih.

1.4 Ta dokument se ne uporablja za:

a) gradbena dvigala v skladu s standardi EN 12158-1:2000, EN 12158-2:2000 in EN 12159:2000;

b) upravljalna mesta za dviganje oz. spuščanje v skladu s standardom EN 14502-2:2005+A1:2008;

c) dvigala v skladu s standardom EN 81-20:2019;

d) delovne ploščadi v skladu s standardi EN 280:2013+A1:2015, EN 1808:2015 in EN 1495:1997+A2:2009;

e) dvigala na žerjavih v skladu s standardom EN 81-43:2009.

Ta dokument se ne uporablja za dvigala, ki so bila izdelana pred datumom njegove objave.

General Information

- Status

- Published

- Public Enquiry End Date

- 30-Mar-2021

- Publication Date

- 04-Feb-2025

- Technical Committee

- DTN - Lift and transport appliances

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 07-Aug-2024

- Due Date

- 12-Oct-2024

- Completion Date

- 05-Feb-2025

Overview

SIST EN 81-44:2025 (identical to EN 81-44:2024) specifies safety rules for the construction and permanent installation of power‑operated lifting appliances in wind turbines. It covers lifts intended to provide access to workplaces in wind turbine towers and nacelles, including provisions for rescue and evacuation. The standard applies to guided carriers transporting people and goods that travel vertically (or within 15° of vertical), are supported by rack-and‑pinion or rope traction drives, run at speeds ≤ 0.7 m/s, and are designed to operate between -25 °C and +55 °C. It is not applicable to lifting appliances manufactured before the date of publication.

Key technical topics and requirements

- Scope & exclusions: Clarifies hazards not covered (e.g., noise, lightning protection, explosive atmospheres, floating turbines, hydraulic drives, earthquakes).

- Loads and calculations: Design loads, load combinations, static and fatigue strength, suspension and rope calculations, and calculation methods.

- Liftway protection & access: Requirements for liftway enclosures, landing access and base enclosures suitable for tower environments.

- Guiding systems & carriers: Specifications for rigid guides, mast or rope guiding, carrier floors, walls, roofs, doors, trapdoors and inspection openings.

- Drive units: Requirements for traction hoist and rack‑and‑pinion drives, including redundant drive configurations.

- Control & safety devices: Travel limit switches, slack‑rope detection, overload and obstruction detection, emergency stops, interlocks and overspeed/fall‑arrest devices.

- Electrical installations: Protection from faults and external influences, wiring, safety contacts and lighting.

- Verification & testing: Detailed verification tests before first use (normative annexes cover drive, overspeed/fall arrest, landing gate tests).

- Information for use: User manuals, maintenance instructions, marking, and in‑carrier/bottom‑landing information.

- Informative guidance: Evacuation/rescue guidance, list of significant hazards and calculation guidance (informative annexes).

Practical applications

- Designing and certifying tower elevators and service lifts for onshore wind turbines.

- Specifying drive systems (rack & pinion or rope traction) and safety devices for turbine access.

- Preparing installation, commissioning and verification test plans for turbine lifts.

- Creating maintenance, rescue and evacuation procedures for wind farm operators.

- Demonstrating conformity with relevant EU requirements (see Annex ZA on Directive 2006/42/EC).

Who should use this standard

- Lift manufacturers and suppliers for wind turbines

- Wind turbine OEMs and integrators

- Installation and commissioning teams

- Safety engineers and certification bodies

- Maintenance managers and site operators

Related keywords: EN 81-44, lifts in wind turbines, wind turbine elevator safety, rack and pinion lifts, traction hoist drives, overspeed safety devices, liftway protection, lift verification tests.

Frequently Asked Questions

SIST EN 81-44:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Safety rules for the construction and installation of lifts - Special lifts for the transport of persons and goods - Part 44: Lifting appliances in wind turbines". This standard covers: 1.1 This document specifies the safety requirements for the construction and installation of power operated lifting appliances installed permanently for indoor or outdoor service in wind turbines and intended for access to workplaces on wind turbines, including rescue and evacuation procedures. A lifting appliance serves defined landing levels and can move persons to working positions where they are carrying out work (which could be from the carrier) and has a carrier which is: a) designed for the transportation of persons and goods; b) guided; c) travelling vertically or along a path within 15° maximum from the vertical; d) supported or sustained by rack and pinion or rope traction drive; e) travelling with a speed not more than 0,7 m/s; f) able to operate in a temperature range between - 25 °C to + 55 °C. 1.2 This document does not cover hazards related to: a) noise; b) the use of the lifting appliance for erection or dismantling of the wind turbine; c) lightning protection; d) use in potentially explosive atmospheres; e) electromagnetic compatibility (emission, immunity); f) transporting of goods outside the carrier; g) the use of combustion engines; h) hydraulic and pneumatic drive units; i) the use of lifting appliances in floating wind turbines; j) use during earthquakes. 1.3 This document is not applicable to lifting appliances manufactured before the date of its publication.

1.1 This document specifies the safety requirements for the construction and installation of power operated lifting appliances installed permanently for indoor or outdoor service in wind turbines and intended for access to workplaces on wind turbines, including rescue and evacuation procedures. A lifting appliance serves defined landing levels and can move persons to working positions where they are carrying out work (which could be from the carrier) and has a carrier which is: a) designed for the transportation of persons and goods; b) guided; c) travelling vertically or along a path within 15° maximum from the vertical; d) supported or sustained by rack and pinion or rope traction drive; e) travelling with a speed not more than 0,7 m/s; f) able to operate in a temperature range between - 25 °C to + 55 °C. 1.2 This document does not cover hazards related to: a) noise; b) the use of the lifting appliance for erection or dismantling of the wind turbine; c) lightning protection; d) use in potentially explosive atmospheres; e) electromagnetic compatibility (emission, immunity); f) transporting of goods outside the carrier; g) the use of combustion engines; h) hydraulic and pneumatic drive units; i) the use of lifting appliances in floating wind turbines; j) use during earthquakes. 1.3 This document is not applicable to lifting appliances manufactured before the date of its publication.

SIST EN 81-44:2025 is classified under the following ICS (International Classification for Standards) categories: 27.180 - Wind turbine energy systems; 91.140.90 - Lifts. Escalators. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 81-44:2025 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 81-44:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2025

Varnostna pravila za konstruiranje in vgradnjo dvigal (liftov) - Posebna dvigala za

prevoz oseb in blaga - 44. del: Dvigala v vetrnih turbinah

Safety rules for the construction and installation of lifts - Special lifts for the transport of

persons and goods - Part 44: Lifting appliances in wind turbines

Sicherheitsregeln für die Konstruktion und Installation von Aufzügen - Besondere

Aufzüge für den Transport von Personen und Gütern - Teil 44: Aufzüge in

Windenergieanlagen

Règles de sécurité pour la construction et l'installation des élévateurs - Applications

particulières pour les ascenseurs et les ascenseurs de charge - Partie 44 : Ascenseurs

de chantier pour éolienne

Ta slovenski standard je istoveten z: EN 81-44:2024

ICS:

27.180 Vetrne elektrarne Wind turbine energy systems

91.140.90 Dvigala. Tekoče stopnice Lifts. Escalators

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 81-44

EUROPEAN STANDARD

NORME EUROPÉENNE

July 2024

EUROPÄISCHE NORM

ICS 27.180; 91.140.90

English Version

Safety rules for the construction and installation of lifts -

Special lifts for the transport of persons and goods -

Part 44: Lifting appliances in wind turbines

Règles de sécurité pour la construction et l'installation Sicherheitsregeln für die Konstruktion und Installation

des élévateurs - Élévateurs particuliers destinés au von Aufzügen - Besondere Aufzüge für den Transport

transport des personnes et des matériaux - von Personen und Gütern - Teil 44: Aufzüge in

Partie 44 : Élévateurs pour éolienne Windenergieanlagen

This European Standard was approved by CEN on 30 June 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATIO N

EUROPÄISCHES KOMITEE FÜR NORMUN G

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 81-44:2024 E

worldwide for CEN national Members.

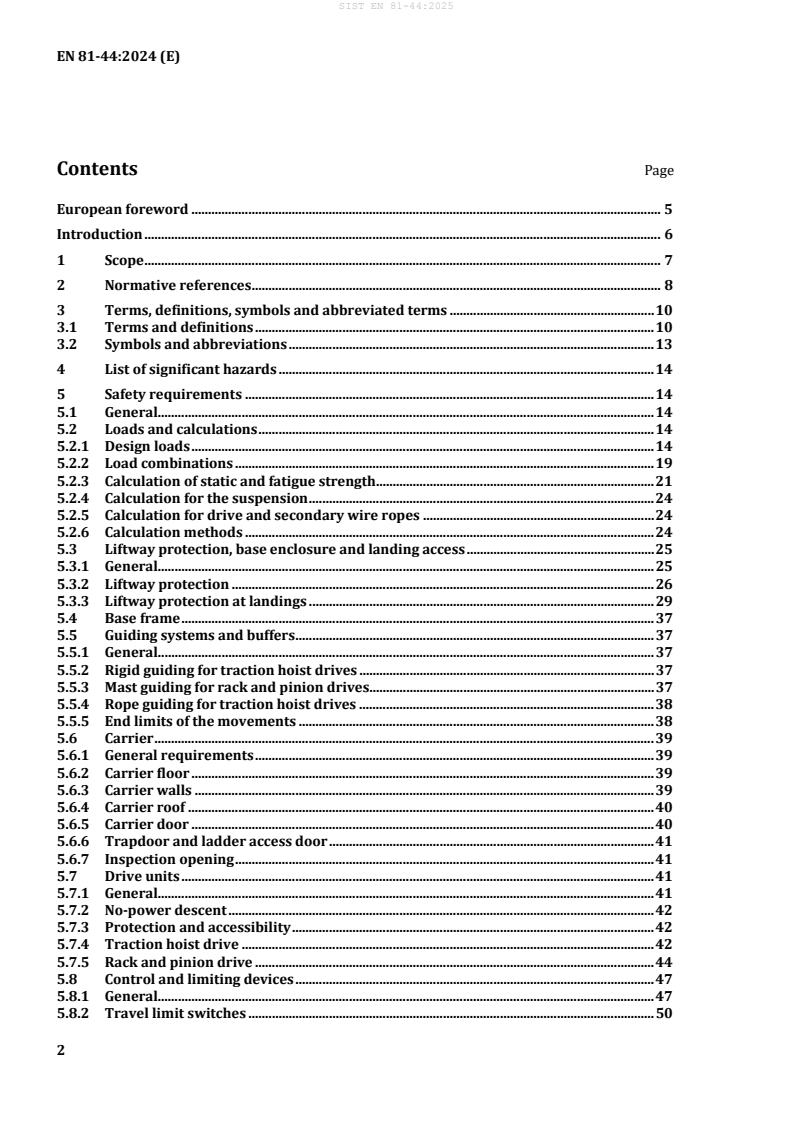

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 8

3 Terms, definitions, symbols and abbreviated terms . 10

3.1 Terms and definitions . 10

3.2 Symbols and abbreviations . 13

4 List of significant hazards . 14

5 Safety requirements . 14

5.1 General. 14

5.2 Loads and calculations . 14

5.2.1 Design loads . 14

5.2.2 Load combinations . 19

5.2.3 Calculation of static and fatigue strength . 21

5.2.4 Calculation for the suspension . 24

5.2.5 Calculation for drive and secondary wire ropes . 24

5.2.6 Calculation methods . 24

5.3 Liftway protection, base enclosure and landing access . 25

5.3.1 General. 25

5.3.2 Liftway protection . 26

5.3.3 Liftway protection at landings . 29

5.4 Base frame . 37

5.5 Guiding systems and buffers . 37

5.5.1 General. 37

5.5.2 Rigid guiding for traction hoist drives . 37

5.5.3 Mast guiding for rack and pinion drives . 37

5.5.4 Rope guiding for traction hoist drives . 38

5.5.5 End limits of the movements . 38

5.6 Carrier . 39

5.6.1 General requirements . 39

5.6.2 Carrier floor . 39

5.6.3 Carrier walls . 39

5.6.4 Carrier roof . 40

5.6.5 Carrier door . 40

5.6.6 Trapdoor and ladder access door . 41

5.6.7 Inspection opening . 41

5.7 Drive units . 41

5.7.1 General. 41

5.7.2 No-power descent . 42

5.7.3 Protection and accessibility . 42

5.7.4 Traction hoist drive . 42

5.7.5 Rack and pinion drive . 44

5.8 Control and limiting devices . 47

5.8.1 General. 47

5.8.2 Travel limit switches . 50

5.8.3 Slack rope device . 50

5.8.4 Overload detection device . 50

5.8.5 Obstruction detection device . 51

5.8.6 Emergency stopping devices . 52

5.8.7 Interlocking devices . 52

5.8.8 Drive unit fault detection device for rack and pinion system with two redundant drive

units . 55

5.8.9 Control modes . 55

5.9 Electric installations and appliances . 56

5.9.1 General . 56

5.9.2 Protection against electric faults . 56

5.9.3 Protection against the effects of external influences . 57

5.9.4 Electric wiring . 57

5.9.5 Contactors, relay-contactors . 57

5.9.6 Electric safety devices . 57

5.9.7 Safety contacts . 58

5.9.8 Lighting . 58

5.10 Safety devices against falling of the lifting appliance . 58

5.10.1 Overspeed safety device against falling of the lifting appliance (traction hoist drive)

................................................................................................................................................................... 58

5.10.2 Fall arrest device against falling of the lifting appliance (traction hoist drive) . 59

5.10.3 Safety device against falling of the carrier (rack and pinion drive) . 60

6 Verification . 61

6.1 General . 61

6.2 Verification tests on each lifting appliance before first use . 70

7 Information for use . 71

7.1 General . 71

7.2 User’s manual . 71

7.3 Information for installation and dismantling . 72

7.4 Information for maintenance . 72

7.5 User Information available in the carrier . 73

7.6 User Information available at the bottom landing . 73

7.7 Marking . 73

7.7.1 General . 73

7.7.2 Markings on the carrier . 73

7.7.3 Markings at landings . 74

7.7.4 Mast or guide section identification label for rack and pinion drive . 74

7.7.5 Ladder guiding identification label . 74

7.7.6 Overspeed safety device and fall arrest device label . 74

7.7.7 Drive unit label . 74

7.7.8 Marking for wire ropes for traction hoist drive . 75

7.7.9 Control elements . 75

Annex A (normative) Lifting appliance verification tests . 76

A.1 Test conditions and documentation . 76

A.2 Lifting appliance verification test in as installed configuration . 77

A.3 Carrier verification test . 87

Annex B (normative) Drive unit verification tests . 89

B.1 General . 89

B.2 Traction hoist drive . 89

B.3 Rack and pinion drive (One drive system) . 91

B.4 Rack and pinion system with two redundant drive units . 94

Annex C (normative) Overspeed safety device and fall arrest device verification tests . 97

C.1 General. 97

C.2 Overspeed safety devices and fall arrest devices for traction hoist drives . 97

C.3 Overspeed safety device for rack and pinion drive . 102

Annex D (normative) Other verification tests . 104

D.1 General. 104

D.2 Landing gate and enclosure verification tests . 104

Annex E (informative) Evacuation and rescue . 105

E.1 Introduction . 105

E.2 Evacuation scenario . 105

Annex F (informative) List of significant hazards . 106

Annex G (informative) Guidance on calculation methods . 108

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered . 109

Bibliography . 112

European foreword

This document (EN 81-44:2024) has been prepared by Technical Committee CEN/TC 10 “Lifts, escalators

and moving walks”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by January 2025, and conflicting national standards shall

be withdrawn at the latest by January 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document is part of the EN 81 series of standards. The structure of the EN 81 series is described in

CEN/TR 81-10:2008.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document is a type-C standard as stated in EN ISO 12100:2010.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the Scope of this document.

When requirements of this type-C standard are different from those which are stated in type-A or type-B

standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

1 Scope

1.1 This document specifies the safety requirements for the construction and installation of power

operated lifting appliances installed permanently for indoor or outdoor service in wind turbines and

intended for access to workplaces on wind turbines, including rescue and evacuation procedures. A lifting

appliance serves defined landing levels and can move persons to working positions where they are

carrying out work (which could be from the carrier) and has a carrier which is:

a) designed for the transportation of persons and goods;

b) guided;

c) travelling vertically or along a path within 15° maximum from the vertical;

d) supported or sustained by rack and pinion or rope traction drive;

e) travelling with a speed not more than 0,7 m/s;

f) able to operate in a temperature range between –25 °C to + 55 °C.

1.2 This document does not cover hazards related to:

a) noise;

b) the use of the lifting appliance for erection or dismantling of the wind turbine;

c) lightning protection;

d) use in potentially explosive atmospheres;

e) electromagnetic compatibility (emission, immunity);

f) transporting of goods outside the carrier;

g) the use of combustion engines;

h) hydraulic and pneumatic drive units;

i) the use of lifting appliances in floating wind turbines;

j) use during earthquakes.

1.3 This document is not applicable to lifting appliances manufactured before the date of its

publication.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 81-20:2020, Safety rules for the construction and installation of lifts — Lifts for the transport of persons

and goods — Part 20: Passenger and goods passenger lifts

EN 81-43:2009, Safety rules for the construction and installation of lifts — Special lifts for the transport of

persons and goods — Part 43: Lifts for cranes

EN 81-50:2020, Safety rules for the construction and installation of lifts — Examinations and tests — Part

50: Design rules, calculations, examinations and tests of lift components

EN 795:2012, Personal fall protection equipment — Anchor devices

EN 894-1:1997+A1:2008, Safety of machinery — Ergonomics requirements for the design of displays and

control actuators — Part 1: General principles for human interactions with displays and control actuators

EN 1808:2015, Safety requirements for suspended access equipment — Design calculations, stability

criteria, construction — Examinations and tests

EN 1991-1-3:2003 , Eurocode 1 — Actions on structures — Part 1-3: General actions — Snow loads

EN 10264-1:2012, Steel wire and wire products — Steel wire for ropes — Part 1: General requirements

EN 10264-2:2021, Steel wire and wire products — Steel wire for ropes — Part 2: Cold drawn non alloy steel

wire for ropes for general applications

EN 10264-3:2023, Steel wire and wire products — Steel wire for ropes — Part 3: Round and shaped non

alloyed steel wire for high duty applications

EN 10264-4:2012, Steel wire and wire products — Steel wire for ropes — Part 4: Stainless steel wire

EN 12385-1:2002+A1:2008, Steel wire ropes — Safety — Part 1: General requirements

EN 12385-2:2002+A1:2008, Steel wire ropes — Safety — Part 2: Definitions, designation and classification

EN 12385-3:2020, Steel wire ropes — Safety — Part 3: Information for use and maintenance

EN 12385-4:2002+A1:2008, Steel wire ropes — Safety — Part 4: Stranded ropes for general lifting

applications

EN 13001-2:2021, Crane safety — General design — Part 2: Load actions

EN 13411-1:2002+A1:2008, Terminations for steel wire ropes — Safety — Part 1: Thimbles for steel wire

rope slings

EN 13411-2:2001+A1:2008, Terminations for steel wire ropes — Safety — Part 2: Splicing of eyes for wire

rope slings

As impacted by EN 1991-1-3:2003/A1:2015 and EN 1991-1-3:2003/AC:2009.

EN 13411-3:2022, Terminations for steel wire ropes — Safety — Part 3: Ferrules and ferrule-securing

EN 13411-4:2021, Terminations for steel wire ropes — Safety — Part 4: Metal and resin socketing

EN 13411-5:2003+A1:2008, Terminations for steel wire ropes — Safety — Part 5: U-bolt wire rope grips

EN 13411-6:2004+A1:2008, Terminations for steel wire ropes — Safety — Part 6: Asymmetric wedge

socket

EN 13411-7:2021, Terminations for steel wire ropes — Safety — Part 7: Symmetric wedge socket

EN 60204-1:2018, Safety of machinery — Electrical equipment of machines — Part 1: General

requirements (IEC 60204-1:2016)

EN 60529:1991 , Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN IEC 60947-4-1:2019 , Low-voltage switchgear and controlgear — Part 4-1: Contactors and motor-

starters — Electromechanical contactors and motor-starters (IEC 60947-4-1:2018)

EN 60947-5-1:2017 , Low-voltage switchgear and controlgear — Part 5-1: Control circuit devices and

switching elements — Electromechanical control circuit devices (IEC 60947-5-1:2016)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13849-1:2023, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design (ISO 13849-1:2023)

EN ISO 13850:2015, Safety of machinery — Emergency stop function — Principles for design

(ISO 13850:2015)

EN ISO 13851:2019, Safety of machinery — Two-hand control devices — Principles for design and selection

(ISO 13851:2019)

EN ISO 13854:2019, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body

(ISO 13854:2017)

EN ISO 13857:2019, Safety of machinery — Safety distances to prevent hazard zones being reached by

upper and lower limbs (ISO 13857:2019)

EN ISO 14119:2013, Safety of machinery — Interlocking devices associated with guards — Principles for

design and selection (ISO 14119:2013)

EN ISO 14122-3:2016, Safety of machinery — Permanent means of access to machinery — Part 3: Stairs,

stepladders and guard-rails (ISO 14122-3:2016)

EN ISO 14122-4:2016, Safety of machinery — Permanent means of access to machinery — Part 4: Fixed

ladders (ISO 14122-4:2016)

As impacted by EN 60529:1991/AC:2016-12, EN 60529:1991/A1:2000, EN 60529:1991/A2:2013 and

EN 60529:1991/A2:2013/AC:2019-02.

As impacted by EN IEC 60947-4-1:2019/AC:2021-04 and EN IEC 60947-4-1:2019/AC:2020-05.

As impacted by EN 60947-5-1:2017/AC:2020-05.

ISO 6336-1:2019, Calculation of load capacity of spur and helical gears — Part 1: Basic principles,

introduction and general influence factors

ISO 6336-2:2019, Calculation of load capacity of spur and helical gears — Part 2: Calculation of surface

durability (pitting)

ISO 6336-3:2019, Calculation of load capacity of spur and helical gears — Part 3: Calculation of tooth

bending strength

ISO 6336-5:2016, Calculation of load capacity of spur and helical gears — Part 5: Strength and quality of

materials

3 Terms, definitions, symbols and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010, EN 81-43:2009

and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1.1

lifting appliance

machine with a carrier which is guided and intended for transport between different levels

3.1.2

base frame

lowest framework of the rack and pinion lifting appliance upon which all other components are mounted

[SOURCE: EN 81-43:2009, definition 3.7, modified – term “rack and pinion” added, term “lift” replaced

with “lifting appliance”]

3.1.3

carrier

load carrying unit including floor, walls, doors and roof

[SOURCE: EN 81-43:2009, 3.13, definition modified]

3.1.4

interlocking device

interlock

mechanical, electrical or other type of device, the purpose of which is to prevent the operation of

hazardous machine functions under specified conditions (generally as long as a guard is not closed)

[SOURCE: EN ISO 12100:2010, 3.28.1]

3.1.5

guard locking device

device intended to lock a guard in the closed position and linked to the control system

Note 1 to entry: Interlocking device [3.1.4] with additional function of keeping the guard locked when the

hazardous machine functions are in operation.

[SOURCE: EN ISO 14119:2013, 3.4]

3.1.6

landing

level in the wind turbine intended for loading and unloading the carrier (3.1.3)

[SOURCE: EN 81-43:2009, 3.21, modified]

3.1.7

landing zone

zone, extending above and below the landing level, in which the carrier floor has to be to enable the

corresponding landing door to be unlocked

3.1.8

overspeed safety device

mechanical device for stopping and maintaining stationary the carrier in the event of over-speed

3.1.9

fall arrest device

mechanical device for stopping and maintaining stationary the carrier in the event of drive wire rope

failure

3.1.10

evacuation

specific actions required to safely release persons entrapped in the carrier without external help

3.1.11

rescue

specific actions required to safely release persons entrapped in the carrier

3.1.12

rigid guiding

guiding means where the carrier is guided by rigid rail or profile (e.g. mast guiding or ladder guiding)

3.1.13

mast guiding

structure that supports and guides the carrier

3.1.14

ladder guiding

ladder that guides the carrier and that can be used for climbing

3.1.15

obstruction detection device

protective equipment detecting obstacles during the travel of the carrier (i.e. persons or objects)

3.1.16

working load limit

WLL

maximum load that a drive unit, fall arrest device and/or an overspeed safety device is authorized to

sustain as designated by the manufacturer

3.1.17

rated load

m

H

load of persons and/or equipment that a lifting appliance has been designated to carry by the

manufacturer in normal use

3.1.18

traction hoist drive

assembly through which a wire rope is conveyed as a result of friction between the wire rope and the

traction assembly with no tail load

3.1.19

rope guiding

guiding by means of tensioned steel wire ropes that prevent the carrier from swinging and rotating while

being stationary and during travel

3.1.20

drive wire rope

active wire rope carrying the suspended load

3.1.21

secondary wire rope

wire rope not normally carrying the suspended load but rigged to work in conjunction with a fall arrest

device

3.1.22

buffer

resilient stop at the end of travel comprising a means of braking using fluids or springs (or other similar

means, e.g. rubber)

3.1.23

vision panel

transparent or perforated panel intended to provide a line of sight inside or outside the carrier

3.1.24

pit

recessed area, which is part of the liftway and has closed sides and is only accessible from above through

the liftway

3.2 Symbols and abbreviations

Symbols, Description

abbreviations

A Area of the lifting appliance on which the wind acts

ref

C Exposure coefficient related to snow loads

e

D Pulley pitch diameter

F Minimum breaking load of wire rope

min

F Wind load

w

H Pitch ratio

S Maximum tensile load in the rope

S Snow load on the carrier

c

S Characteristic value of snow load on the ground

k

Sd Shock load coefficient

St Test load

Tm Dynamic tensile force

WLL Working load limit

Z Drive rope factor

p

c Aerodynamic coefficient

a

d Rope diameter

f Limit design stress

Rd

f Limit design normal stress

Rdσ

f Limit design shear stress

Rdτ

f Ultimate strength

u

f Yield strength (= f in Eurocode 9)

y o

m Mass of unloaded carrier

c

m Mass of tools and equipment

e

m Rated load

H

m Mass of material in the lifting appliance

m

m Assumed mass of a person

p

m Mass of the power and control cables

pc

m Partial mass of the power cable based on traveling height depending on the

pce

overload system

m Mass of the drive ropes (for traction hoist drive)

R

Symbols, Description

abbreviations

m Partial mass of the drive wire rope based on traveling height depending on

Re

the overload system

m Mass of the tension weights (for traction hoist drive)

w

n Number of persons in the lifting appliance

n Number of load carrying ropes

r

q Wind pressure

v Reference storm wind speed

ref

γ Material safety factor for parts with continuous stress

f

γ Resistance coefficient

m

γ Partial safety factor for load

p

µ Impact factor

μ (0°) Snow load shape coefficient

σ Allowable stress

a

σ Calculated stress

c

σ Design normal stress

Sd

φ Dynamic factor due to buffer loads

τ Design shear stress

Sd

4 List of significant hazards

Significant hazards are listed in Annex F, Table F.1.

5 Safety requirements

5.1 General

Machinery shall comply with the safety requirements and/or protective/risk reduction measures of this

clause. In addition, the machine shall be designed according to the principles of EN ISO 12100:2010 for

relevant but not significant hazards which are not dealt with by this document.

5.2 Loads and calculations

5.2.1 Design loads

5.2.1.1 General

All suspended loads shall be taken into account (i.e. including power cables, cable trolley, ropes and

tension weights) which are subject to the component of part reviewed.

5.2.1.2 Dead weights

The following masses are part of the total dead weight and shall be taken into account in calculations

related to the lifting appliance and the lifting appliance components:

— m is mass of the unloaded carrier;

c

— masses of all additional equipment which moves together with the lifting appliance in the load

combination concerned and partial masses based on travelling height depending on the overload

system design which moves together with the lifting appliance such as:

— m is total mass of the drive wire ropes (only traction hoist drive);

R

— m is total mass of the power and control cables;

pc

— m is total mass of the tension weights (only traction hoist drive);

w

— m is partial mass of drive wire rope (only traction hoist drive) from the carrier to the

Re

suspension beam or maximum distance between landings if the lifting appliance control is

designed to stop the lifting appliance at landings during movement in case of overload;

— m is partial mass of power cables from the carrier to the top landing (trailing cable

pce

configuration) or from the carrier to the cable suspension point (travelling cable configuration).

Alternatively, the maximum distance between landings shall be used if the lifting appliance

control is designed to stop the lifting appliance at landings during movement in case of overload.

Depending on the overload system design (according to 5.8.4) and the different load combinations (see

5.2.2), the dead weights are calculated from following mass combinations:

1) Load combinations: A, B, C1, C3, C4, C5 and C6

The following masses shall be considered for overload system Type 1: m , m , m , m .

c pc Re pce

The following masses shall be considered for overload system Type 2 and Type 3: m , m , m .

c pc pce

2) Load combination: C2

The following masses shall be considered for overload system Type 1: m , m , m m , m , m .

c pc Re, pce R w

The following masses shall be considered for overload system Type 2 and Type 3: m , m , m , m , m .

c pc pce R w

5.2.1.3 Rated loads in the lifting appliance

The rated load m of the lifting appliance and the maximum number of persons (n) permitted in the lifting

H

appliance are to be stated by the lifting appliance manufacturer.

When calculating the lifting appliance and every related part, the following rated loads shall be taken into

account as a minimum:

for one person m = m + m + m (Minimum for 1 person: m = 120 kg) (1)

H p e m H

for two persons m = (2 × m ) + (2 × m ) + m (Minimum for 2 persons: m = 240 kg) (2)

H p e m H

for three or more persons m = (n × m ) + (1,5 × m ) + m (3)

H p e m

where

m is rated load;

H

m is 80 kg (mass of person);

p

m is 40 kg (mass of tools and equipment);

e

is the mass of other possible material in the lifting appliance (can be 0 kg);

m

m

n is number of persons.

The rated load is evenly distributed over the floor area of the carrier. Where the uniform distribution of

the rated load over the full area of the carrier floor is less than 4,0 kN/m then, for calculation purposes

of the floor, a minimum of 4,0 kN/m shall be placed over the whole area of the carrier floor.

5.2.1.4 Effect of friction forces

The friction forces acting on the carrier generated by guiding means and transmission chain shall be taken

into account, see Table 2.

5.2.1.5 Loads exerted by persons

5.2.1.5.1 General

When calculating the lifting appliance and every related part, the following loads, exerted by persons,

shall be taken into account.

Walls shall be capable of withstanding a load of 300 N applied normally at the least favourable point

without permanent deformation. The load shall be applied by pulling or pushing over a flat area of

100 mm × 100 mm. For elastic deformation, see 5.6.3.

Carrier doors and vision panels and their guides shall be capable of withstanding a load of 300 N applied

normally at any position without permanent deformation. The load shall be applied by pulling or pushing

over a flat area of 5 cm .

5.2.1.5.2 Individual loads (not to be combined with other loads)

The carrier floor surface shall be designed to withstand without permanent deformation a local static

load of 1,5 kN applied on the least favourable square area of 0,2 m × 0,2 m.

If the carrier roof is accessible, it shall be designed to withstand

— an evenly distributed load of at least 3,0 kN placed on the least favourable square area of 1,0 m . If

the roof area is smaller than 1,0 m , 3,0 kN shall be applied to the full roof area;

— a local static load of 1,2 kN applied on the least favourable square area of 0,2 m × 0,2 m without

permanent deformation.

The full height landing gates shall be designed to withstand, without permanent deformation and without

elastic deformation greater than 15 mm, a local static load of 300 N at the least favourable point on either

face, using a rigid square or round flat face of 5 cm .

The reduced height landing gates shall be designed to withstand, without permanent deformation, a local

static load of 1 kN vertically applied at the least favourable point along the top of the gate.

The same values for the resistance coefficient for materials as in the load combination A from Table 3

shall be used for the above-mentioned load cases in this clause.

The reduced height landing gates shall be designed to withstand horizontal loads according to

EN ISO 14122-3:2016, 8.1 and 8.2, with a minimum horizontal load of 300 N.

5.2.1.5.3 Loads caused by falling person

When calculating the structure where the anchor device is attached, a load of a falling person of 6 kN shall

be taken into account (for safety factors see Table 2).

When more than 1 anchor device is attached to the carrier, it is assumed that loads can’t occur in more

than one anchor device at the same time, so the structure shall be calculated for each anchor device

separately, not for all the anchor devices at the same time.

5.2.1.6 Wind loads for outside operating lifting appliances

5.2.1.6.1 Formulas for calculation of the wind loads

Wind loads shall be calculated according to EN 13001-2:2021.

F = q × c × A (4)

w ref

a

where

F is the wind load acting perpendicularly to the longitudinal axis of the member under

w

consideration;

q is the wind pressure: q(3) in service, q(z) out of service;

c is the aerodynamic coefficient of the member under consideration.

a

The coefficient c shall be used in combination with the characteristic area A . Values of c shall be those

a ref a

from EN 13001-2:2021, Annex A. For the carrier, it shall be assumed that the carrier walls are solid and

an aerodynamic coefficient c of 1,2 shall be applied. The factor 1,2 covers both the shape factor and the

a

shielding factor.

Wind loads are assumed to act horizontally at the centre of the area of the component parts of the lifting

appliance in any direction. The least favourable direction shall be taken into account.

The wind loads acting on a lifting appliance shall be considered to be acting on the suspension points

and/or on relevant tower interface components.

5.2.1.6.2 Lifting appliances in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...