oSIST prEN IEC 60974-1:2025

(Main)Arc welding equipment - Part 1: Welding power sources

Arc welding equipment - Part 1: Welding power sources

Lichtbogenschweißeinrichtungen - Teil 1: Schweißstromquellen

Matériel de soudage à l'arc - Partie 1: Sources de courant de soudage

Oprema za obločno varjenje - 1. del: Viri varilnega toka

General Information

- Status

- Not Published

- Public Enquiry End Date

- 11-Sep-2025

- Technical Committee

- I09 - Imaginarni 09

- Current Stage

- 4020 - Public enquire (PE) (Adopted Project)

- Start Date

- 24-Jun-2025

- Due Date

- 11-Nov-2025

- Completion Date

- 08-Sep-2025

Relations

- Effective Date

- 29-Apr-2025

- Effective Date

- 22-Oct-2024

- Effective Date

- 22-Oct-2024

- Revises

SIST EN IEC 60974-1:2023 - Arc welding equipment - Part 1: Welding power sources (IEC 60974-1:2021) - Effective Date

- 31-Oct-2023

Overview

The oSIST prEN IEC 60974-1:2025 standard, titled Arc welding equipment - Part 1: Welding power sources, is a fundamental document published by the CLC that sets comprehensive requirements for welding power sources used in arc welding. This standard addresses crucial safety, performance, and testing criteria to ensure reliable and safe operation of welding equipment. It applies to manufacturers, testing institutions, and users involved in the arc welding industry who seek harmonized technical guidance for welding power sources.

Key Topics

This standard covers a wide range of technical and safety aspects of welding power sources, including:

Electrical Safety

Detailed provisions for protection against electric shock, covering both normal operation (direct contact) and fault conditions (indirect contact). It defines insulation requirements and safety tests to protect operators from electrical hazards.Thermal Requirements

Guidelines for temperature rise limits, heating tests, and thermal protection mechanisms to prevent overheating during operation. It also includes specifications for thermal protection device construction and operation.Mechanical Provisions

Standards for the physical construction of the power source such as enclosures, handling, drop withstand capacity, and tilting stability ensuring durability and operator safety in various working environments.Performance Testing

Comprehensive test methods including type tests, routine tests, and abnormal operation tests such as stalled fan, short circuit, and overload tests to verify equipment reliability under operating stresses.Supply Network Connection

Requirements for power supply connections, terminal markings, and protective circuits ensuring compatibility and safety when interfacing with electrical networks.Control Circuits and Hazard Reduction

Specifications for control circuit isolation, voltage levels, and integration of hazard reducing devices that minimize risks during arc welding operations.Markings and Instructions

Mandatory labeling, rating plates, and user instructions to guide safe handling, maintenance, and operation of welding power sources.Specialized Areas

Additional annexes cover topics such as battery-powered welding power sources, idle state power measurement, unbalanced loads in AC tungsten inert-gas welding, and isolation resistance tests to cover evolving welding technologies.

Applications

The oSIST prEN IEC 60974-1:2025 standard is essential for:

Manufacturers designing and producing welding power sources to meet international safety and performance benchmarks.

Quality Assurance Teams performing conformity assessments, type testing, and routine testing to ensure compliance with strict operational standards.

Safety Engineers identifying and mitigating electrical and thermal risks associated with welding equipment.

Training Providers developing instructional content based on standardized safety and operational guidelines.

Welding Operators and Technicians through enhanced equipment reliability, clear instructions, and hazard information leading to safer working conditions.

This standard supports industries such as construction, manufacturing, automotive, shipbuilding, and maintenance where arc welding is a critical process.

Related Standards

For a comprehensive arc welding equipment safety and performance framework, oSIST prEN IEC 60974-1:2025 should be used in conjunction with related standards, including:

IEC 60974 series covering other parts of arc welding equipment such as torch, cables, and ancillary accessories.

ISO 17637 and ISO 9606 series focusing on welding inspection and welder qualification.

EN 60204-1 - Safety of machinery - Electrical equipment of machines.

IEC 60335 series for electrical appliance safety applicable to welding machines.

Utilizing these interconnected standards ensures full compliance and operational excellence across all welding processes.

Keywords: arc welding equipment, welding power sources, IEC 60974-1, electrical safety, thermal protection, welding standard, welding equipment testing, welding power supply, battery-powered welding, welding safety requirements.

Frequently Asked Questions

oSIST prEN IEC 60974-1:2025 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Arc welding equipment - Part 1: Welding power sources". This standard covers: Arc welding equipment - Part 1: Welding power sources

Arc welding equipment - Part 1: Welding power sources

oSIST prEN IEC 60974-1:2025 is classified under the following ICS (International Classification for Standards) categories: 25.160.30 - Welding equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN IEC 60974-1:2025 has the following relationships with other standards: It is inter standard links to SIST EN IEC 60974-1:2023/A13:2025, SIST EN IEC 60974-1:2023/A12:2023, SIST EN IEC 60974-1:2023/A11:2023, SIST EN IEC 60974-1:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN IEC 60974-1:2025 is associated with the following European legislation: EU Directives/Regulations: 2014/35/EU, 2019/1784; Standardization Mandates: M/511, M/559. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

oSIST prEN IEC 60974-1:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2025

Oprema za obločno varjenje - 1. del: Viri varilnega toka

Arc welding equipment - Part 1: Welding power sources

Lichtbogenschweißeinrichtungen - Teil 1: Schweißstromquellen

Matériel de soudage à l'arc - Partie 1: Sources de courant de soudage

Ta slovenski standard je istoveten z: prEN IEC 60974-1:2025

ICS:

25.160.30 Varilna oprema Welding equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

26/776/CDV

COMMITTEE DRAFT FOR VOTE (CDV)

PROJECT NUMBER:

IEC 60974-1 ED7

DATE OF CIRCULATION: CLOSING DATE FOR VOTING:

2025-06-20 2025-09-12

SUPERSEDES DOCUMENTS:

26/765/CD, 26/773/CC

IEC TC 26 : ELECTRIC WELDING

SECRETARIAT: SECRETARY:

Austria Mr Josef Feichtinger

OF INTEREST TO THE FOLLOWING COMMITTEES: HORIZONTAL FUNCTION(S):

ASPECTS CONCERNED:

Safety

SUBMITTED FOR CENELEC PARALLEL VOTING NOT SUBMITTED FOR CENELEC PARALLEL VOTING

Attention IEC-CENELEC parallel voting

The attention of IEC National Committees, members of

CENELEC, is drawn to the fact that this Committee Draft

for Vote (CDV) is submitted for parallel voting.

The CENELEC members are invited to vote through the

CENELEC online voting system.

This document is still under study and subject to change. It should not be used for reference purposes.

Recipients of this document are invited to submit, with their comments, notification of any relevant patent rights of which they

are aware and to provide supporting documentation.

Recipients of this document are invited to submit, with their comments, notification of any relevant “In Some Countries”

clauses to be included should this proposal proceed. Recipients are reminded that the CDV stage is the final stage for

submitting ISC clauses. (SEE AC/22/2007 OR NEW GUIDANCE DOC).

TITLE:

Arc welding equipment - Part 1: Welding power sources

PROPOSED STABILITY DATE: 2028

NOTE FROM TC/SC OFFICERS:

electronic file, to make a copy and to print out the content for the sole purpose of preparing National Committee positions.

You may not copy or "mirror" the file or printed version of the document, or any part of it, for any other purpose without

permission in writing from IEC.

2 IEC 60974-1 ED7 © IEC 2025

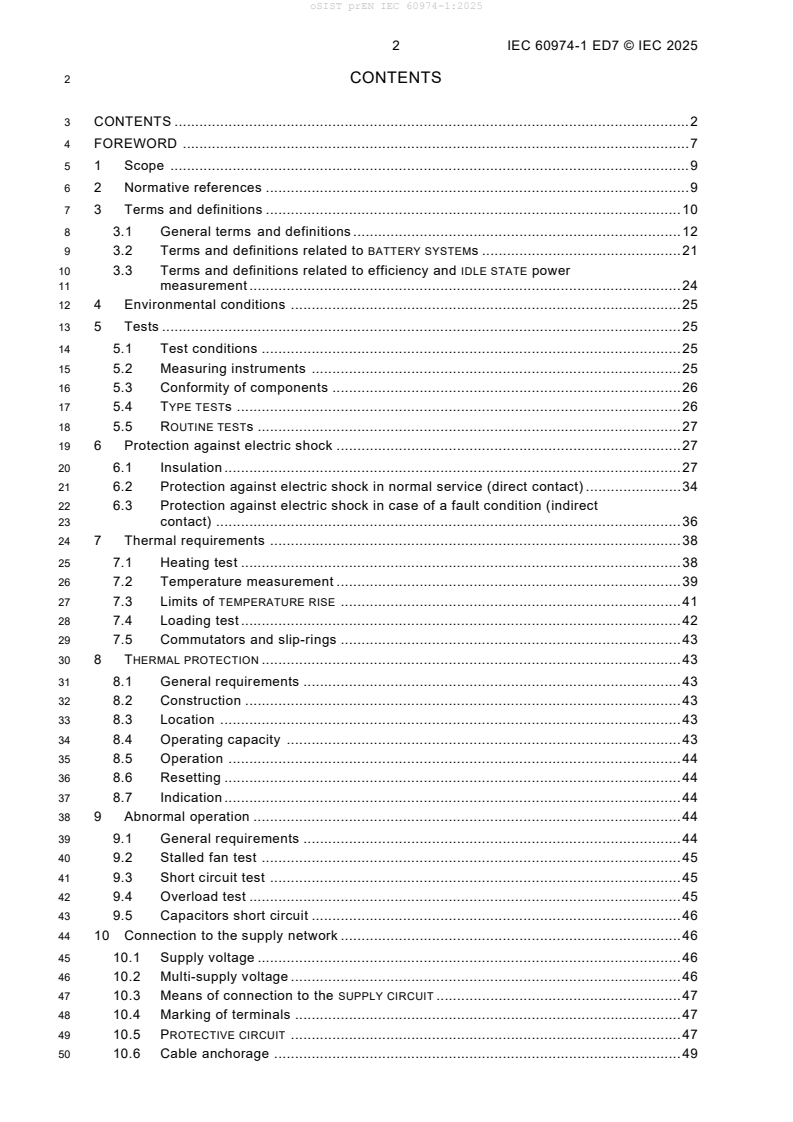

2 CONTENTS

3 CONTENTS . 2

4 FOREWORD . 7

5 1 Scope . 9

6 2 Normative references . 9

7 3 Terms and definitions . 10

8 3.1 General terms and definitions . 12

9 3.2 Terms and definitions related to BATTERY SYSTEMs . 21

10 3.3 Terms and definitions related to efficiency and IDLE STATE power

11 measurement . 24

12 4 Environmental conditions . 25

13 5 Tests . 25

14 5.1 Test conditions . 25

15 5.2 Measuring instruments . 25

16 5.3 Conformity of components . 26

17 5.4 TYPE TESTs . 26

18 5.5 ROUTINE TESTs . 27

19 6 Protection against electric shock . 27

20 6.1 Insulation . 27

21 6.2 Protection against electric shock in normal service (direct contact) . 34

22 6.3 Protection against electric shock in case of a fault condition (indirect

23 contact) . 36

24 7 Thermal requirements . 38

25 7.1 Heating test . 38

26 7.2 Temperature measurement . 39

27 7.3 Limits of TEMPERATURE RISE . 41

28 7.4 Loading test . 42

29 7.5 Commutators and slip-rings . 43

30 8 THERMAL PROTECTION . 43

31 8.1 General requirements . 43

32 8.2 Construction . 43

33 8.3 Location . 43

34 8.4 Operating capacity . 43

35 8.5 Operation . 44

36 8.6 Resetting . 44

37 8.7 Indication . 44

38 9 Abnormal operation . 44

39 9.1 General requirements . 44

40 9.2 Stalled fan test . 45

41 9.3 Short circuit test . 45

42 9.4 Overload test . 45

43 9.5 Capacitors short circuit . 46

44 10 Connection to the supply network . 46

45 10.1 Supply voltage . 46

46 10.2 Multi-supply voltage . 46

47 10.3 Means of connection to the SUPPLY CIRCUIT . 47

48 10.4 Marking of terminals . 47

49 10.5 PROTECTIVE CIRCUIT . 47

50 10.6 Cable anchorage . 49

IEC 60974-1 ED7 © IEC 2025 3

51 10.7 Inlet openings . 50

52 10.8 SUPPLY CIRCUIT on/off switching device . 50

53 10.9 Supply cables . 51

54 10.10 Supply coupling device (attachment plug) . 51

55 11 Output . 51

56 11.1 RATED NO-LOAD VOLTAGE . 51

57 11.2 TYPE TEST values of the CONVENTIONAL LOAD VOLTAGE . 54

58 11.3 Mechanical switching devices used to adjust output . 55

59 11.4 WELDING CIRCUIT connections . 55

60 11.5 Power supply to external devices connected to the WELDING CIRCUIT . 57

61 11.6 Auxiliary power supply . 57

62 11.7 Welding cables . 57

63 12 CONTROL CIRCUITs . 58

64 12.1 General requirement . 58

65 12.2 Isolation of CONTROL CIRCUITs . 58

66 12.3 WORKING VOLTAGEs of remote CONTROL CIRCUITs . 58

67 13 HAZARD REDUCING DEVICE . 58

68 13.1 General requirements . 58

69 13.2 Types of HAZARD REDUCING DEVICES . 59

70 13.3 Requirements for HAZARD REDUCING DEVICEs . 59

71 14 Mechanical provisions . 60

72 14.1 General requirements . 60

73 14.2 Enclosure . 60

74 14.3 Handling means . 60

75 14.4 Drop withstand . 61

76 14.5 Tilting stability . 62

77 15 RATING PLATE . 62

78 15.1 General requirements . 62

79 15.2 Description . 62

80 15.3 Contents . 63

81 15.4 Tolerances . 66

82 15.5 Direction of rotation . 66

83 16 Adjustment of the output . 66

84 16.1 Type of adjustment . 66

85 16.2 Marking of the adjusting device . 66

86 16.3 Indication of current or voltage control . 67

87 17 Instructions and markings . 67

88 17.1 Instructions . 67

89 17.2 Markings . 68

90 Annex A (normative) Nominal voltages of supply networks . 70

91 Annex B (informative) Example of a combined dielectric test . 73

92 Annex C (normative) Unbalanced load in case of AC tungsten inert-gas WELDING

93 . 74

POWER SOURCES

94 C.1 General . 74

95 C.2 Unbalanced load . 74

96 C.3 Example for an unbalanced load . 75

97 Annex D (informative) Extrapolation of temperature to time of shutdown . 77

98 Annex E (normative) Construction of SUPPLY CIRCUIT terminals . 78

99 E.1 Size of terminals . 78

100 E.2 Connections at the terminals . 78

4 IEC 60974-1 ED7 © IEC 2025

101 E.3 Construction of the terminals . 79

102 E.4 Fixing of the terminals . 79

103 Annex F (informative) Cross-reference to non-SI units . 80

104 Annex G (normative) Suitability of supply network for the measurement of the true

105 RMS value of the supply current . 81

106 Annex H (informative) Plotting of STATIC CHARACTERISTICS . 82

107 H.1 General . 82

108 H.2 Method . 82

109 H.3 Analysis of the results . 82

110 Annex I (normative) Test methods for a 10 Nm impact . 83

111 I.1 Pendulum impact hammer . 83

112 I.2 Free fall spherical steel weight . 83

113 Annex J (normative) Thickness of sheet metal for enclosures . 85

114 Annex K (informative) Examples of RATING PLATES . 87

115 Annex L (informative) Graphical symbols for arc welding equipment . 94

116 L.1 General . 94

117 L.2 Use of symbols . 94

118 L.3 Symbols . 94

119 L.4 Examples of combinations of symbols . 111

120 L.5 Examples of control panels . 113

121 Annex M (informative) Efficiency and IDLE STATE power measurement . 116

122 M.1 General conditions for measurement . 116

123 M.2 Measurements . 117

124 M.3 Test report . 120

125 M.4 Test report template . 121

126 Annex N (normative) TOUCH CURRENT measurement . 124

127 Annex O (normative) Battery-powered WELDING POWER SOURCES . 130

128 O.1 General . 130

129 O.4 Environmental conditions . 131

130 O.5 Tests . 131

131 O.6 Protection against electric shock . 132

132 O.7 Thermal requirements . 135

133 O.8 THERMAL PROTECTION . 137

134 O.9 Abnormal operation . 137

135 O.10 Connection to the supply network . 141

136 O.14 Mechanical provisions . 142

137 O.15 RATING PLATE . 144

138 O.17 Instructions and markings . 145

139 Annex P (normative) Isolation resistance measurements for BATTERY VOLTAGE CLASS B

140 electric circuits . 147

141 Bibliography . 149

143 Figure 1 – Flow chart for conformity methods of 5.3 . 26

144 Figure 2 – Example of insulation configuration for CLASS I EQUIPMENT . 28

145 Figure 3 – Measurement of WELDING CIRCUIT TOUCH CURRENT . 35

146 Figure 4 – Measurement of TOUCH CURRENT in normal condition . 36

147 Figure 5 – Measurement of RMS values . 53

148 Figure 6 – Measurement of peak values . 54

149 Figure 7 – Principle of the RATING PLATE . 63

IEC 60974-1 ED7 © IEC 2025 5

150 Figure B.1 – Combined high-voltage transformers . 73

151 Figure C.1 – Voltage and current during AC tungsten inert-gas welding . 74

152 Figure C.2 – Unbalanced voltage during AC tungsten inert-gas welding . 75

153 Figure C.3 – AC WELDING POWER SOURCE with unbalanced load . 75

154 Figure I.1 – Test set-up . 83

155 Figure K.1 – Single-phase transformer . 87

156 Figure K.2 – Three-phase rotating frequency converter . 88

157 Figure K.3 – Subdivided RATING PLATE: single-/three-phase transformer rectifier . 89

158 Figure K.4 – Engine-generator-rectifier . 90

159 Figure K.5 – Single-/three-phase inverter type . 91

160 Figure K.6 – Battery-powered WELDING POWER SOURCE with INTEGRAL BATTERY . 92

161 Figure K.7 – Battery-powered WELDING POWER SOURCE with detachable / separable

162 BATTERY . 93

163 Figure L.1 – Input voltage power switch . 114

164 Figure L.2 – Arc force control potentiometer . 114

165 Figure L.3 – Remote receptacle and selector switches . 114

166 Figure L.4 – Terminals with inductance selector for MIG/MAG welding. 114

167 Figure L.5 – Process switch (MMA, TIG, MIG) . 115

168 Figure L.6 – Selector switch on AC/DC equipment . 115

169 Figure L.7 – Panel indicator lights (overheat, fault, arc striking, output voltage) . 115

170 Figure L.8 – Setting pulsing parameters using digital display . 115

171 Figure M.1 – Measurement procedure . 120

172 Figure N.1 – Measuring network, TOUCH CURRENT weighted for perception or

173 startle-reaction . 124

174 Figure N.2 – Measuring network, TOUCH CURRENT weighted for letgo-immobilization . 125

175 Figure N.3 – Diagram for TOUCH CURRENT measurement on fault condition at operating

176 temperature for single-phase connection of appliances other than those of CLASS II . 127

177 Figure N.4 – Diagram for TOUCH CURRENT measurement on fault condition for three-

178 phase four-wire system connection of appliances other than those of CLASS II . 129

179 Figure O.1 – Marking of BATTERY VOLTAGE CLASS B electric components . 146

180 Figure P.1 – Example for the measurement of the isolation resistance . 147

182 Table 1 – Alphabetical list of terms . 11

183 Table 2 – Minimum CLEARANCES for overvoltage category III . 29

184 Table 3 – Minimum CREEPAGE DISTANCES . 31

185 Table 4 – Insulation resistance . 32

186 Table 5 – Minimum dielectric test voltages . 33

187 Table 6 – Minimum distance through insulation . 36

188 Table 7 – Temperature limits for windings, commutators and slip-rings . 41

189 Table 8 – Temperature limits for external surfaces . 42

190 Table 9 – Cross-section of the output short-circuit conductor . 45

191 Table 10 – Current and time requirements for PROTECTIVE CIRCUITS . 48

192 Table 11 – Minimum cross-sectional area of the external protective copper conductor . 48

193 Table 12 – Verification of continuity of the PROTECTIVE CIRCUIT . 49

194 Table 13 – Pull. 49

195 Table 14 – Summary of allowable RATED NO-LOAD VOLTAGES . 53

6 IEC 60974-1 ED7 © IEC 2025

196 Table 15 – HAZARD REDUCING DEVICE requirements . 58

197 Table A.1 – Nominal voltages for supply networks with protective overvoltage control . 70

198 Table A.2 – Single-phase three-wire or two-wire AC or DC systems . 71

199 Table A.3 – Three-phase four-wire or three-wire AC systems . 72

200 Table E.1 – Range of conductor dimensions to be accepted by the SUPPLY CIRCUIT

201 terminals . 78

202 Table F.1 – Cross-reference for mm to American wire gauge (AWG) . 80

203 Table I.1 – Angle of rotation θ to obtain 10 Nm impact . 83

204 Table I.2 – Mass of the free fall weight and height of the free fall . 84

205 Table J.1 – Minimum thickness of sheet metal for steel enclosures . 85

206 Table J.2 – Minimum thickness of sheet metal for enclosures of aluminium, brass or

207 copper . 86

208 Table L.1 – Letters used as symbols . 95

209 Table M.1 – Typical nominal electricity supply details for some regions . 116

210 Table M.2 – Load conditions for the ARC WELDING POWER SOURCE . 118

211 Table M.3 – Required reported data (measured and calculated). 121

IEC 60974-1 ED7 © IEC 2025 7

214 INTERNATIONAL ELECTROTECHNICAL COMMISSION

215 ____________

217 ARC WELDING EQUIPMENT –

219 Part 1: Welding power sources

221 FOREWORD

222 1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

223 all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

224 co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

225 in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

226 Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

227 preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

228 may participate in this preparatory work. International, governmental and non-governmental organizations liaising

229 with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

230 Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

231 2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

232 consensus of opinion on the relevant subjects since each technical committee has representation from all

233 interested IEC National Committees.

234 3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

235 Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

236 Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

237 misinterpretation by any end user.

238 4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

239 transparently to the maximum extent possible in their national and regional publications. Any divergence between

240 any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

241 5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

242 assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

243 services carried out by independent certification bodies.

244 6) All users should ensure that they have the latest edition of this publication.

245 7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

246 members of its technical committees and IEC National Committees for any personal injury, property damage or

247 other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

248 expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

249 Publications.

250 8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

251 indispensable for the correct application of this publication.

252 9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

253 rights. IEC shall not be held responsible for identifying any or all such patent rights.

254 IEC 60974-1 has been prepared by IEC technical committee 26: Electric welding. It is an

255 International Standard.

256 This seventh edition cancels and replaces the sixth edition published in 2021. This edition

257 constitutes a technical revision.

258 This edition includes the following significant technical changes with respect to the previous

259 edition:

260 a) New terms and definitions to clause 3.1 added;

261 b) Verbal form changes ‘may’ to ‘can’ of edition 6 introduced at FDIS reviewed and reverted

262 where necessary;

263 c) Deletion of Notes relating to (EU) 2019/1784 in clause 3.3.2, 15.3, 16.3.3 and M.1.1;

264 d) Type Tests requirements in clause 5.4 modified;

265 e) Note to CLEARANCE verification with AC or DC voltage in clause 6.1.2 added;

266 f) Editorial adjustment of Table 3 Minimum CREEPAGE DISTANCES to

267 IEC 60664-1:2020/AMD1:2025;

268 g) Capacitor short circuit test procedure in clause 9.5 refined;

269 h) Voltage reducing device test procedure in clause 13.2.1 reworded for clarification;

8 IEC 60974-1 ED7 © IEC 2025

270 i) Duty cycle requirements on RATING PLATE in clause 15.3 b) reworded for clarification;

271 j) Abnormal operation test requirements in O.9.1 aligned to 9.1;

272 k) New Annex P added.

273 The text of this International Standard is based on the following documents:

FDIS Report on voting

26/xxx/FDIS 26/xxx/RVD

275 Full information on the voting for its approval can be found in the report on voting indicated in

276 the above table.

277 The language used for the development of this International Standard is English.

278 This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

279 accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

280 at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

281 described in greater detail at www.iec.ch/standardsdev/publications.

282 In this document, the following print types are used:

283 – conformity statements: in italic type.

284 – terms used throughout this document which have been defined in Clause 3: SMALL ROMAN

285 CAPITALS.

286 A list of all parts of the IEC 60974 series can be found, under the general title Arc welding

287 equipment, on the IEC website.

288 The committee has decided that the contents of this document will remain unchanged until the

289 stability date indicated on the IEC website under webstore.iec.ch in the data related to the

290 specific document. At this date, the document will be

291 • reconfirmed,

292 • withdrawn,

293 • replaced by a revised edition, or

294 • amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

IEC 60974-1 ED7 © IEC 2025 9

298 ARC WELDING EQUIPMENT –

300 Part 1: Welding power sources

304 1 Scope

305 This part of IEC 60974 is applicable to power sources for arc welding and allied processes

306 designed for INDUSTRIAL AND PROFESSIONAL USE, and supplied by a voltage not exceeding

307 1 000 V, BATTERY supplied or driven by mechanical means.

308 This document specifies safety and performance requirements of WELDING POWER SOURCES and

309 PLASMA CUTTING SYSTEMS.

310 This document is not applicable to limited duty arc welding and cutting power sources which

311 are designed mainly for use by layperson and designed in accordance with IEC 60974-6.

312 This document includes requirements for battery-powered WELDING POWER SOURCES and

313 BATTERY packs, which are given in Annex O.

314 This document is not applicable to testing of power sources during periodic maintenance or

315 after repair.

316 NOTE 1 Typical allied processes are electric arc cutting and arc spraying.

317 NOTE 2 AC systems having a nominal voltage between 100 V and 1 000 V are given in Table 1 of IEC 60038:2009.

318 NOTE 3 This document does not include electromagnetic compatibility (EMC) requirements.

319 2 Normative references

320 The following documents are referred to in the text in such a way that some or all of their content

321 constitutes requirements of this document. For dated references, only the edition cited applies.

322 For undated references, the latest edition of the referenced document (including any

323 amendments) applies.

324 IEC 60245-6, Rubber insulated cables – Rated voltages up to and including 450/750 V – Part 6:

325 Arc welding electrode cables

326 IEC 60445, Basic and safety principles for man-machine interface, marking and identification –

327 Identification of equipment terminals, conductor terminations and conductors

328 IEC 60529, Degrees of protection provided by enclosures (IP Code)

329 IEC 60664-1:2020, Insulation coordination for equipment within low-voltage systems – Part 1:

330 Principles, requirements and tests

331 IEC 60664-1:2020/AMD1:2025

332 IEC 60664-3, Insulation coordination for equipment within low-voltage systems – Part 3: Use of

333 coating, potting or moulding for protection against pollution

334 IEC 60695-11-10, Fire hazard testing – Part 11-10: Test flames – 50 W horizontal and vertical

335 flame test methods

336 IEC 60974-7, Arc welding equipment – Part 7: Torches

10 IEC 60974-1 ED7 © IEC 2025

337 IEC 60974-10, Arc welding equipment – Part 10: Electromagnetic compatibility (EMC)

338 requirements

339 IEC 61140, Protection against electric shock – Common aspects for installation and equipment

340 IEC 61558-2-4, Safety of transformers, reactors, power supply units and similar products for

341 supply voltages up to 1 100 V – Part 2-4: Particular requirements and tests for isolating

342 transformers and power supply units incorporating isolating transformers

343 IEC 61558-2-6, Safety of transformers, reactors, power supply units and similar products for

344 supply voltages up to 1 100 V – Part 2-6: Particular requirements and tests for safety isolating

345 transformers and power supply units incorporating safety isolating transformers

346 IEC 62133-1:2017, Secondary cells and batteries containing alkaline or other non-acid

347 electrolytes – Safety requirements for portable sealed secondary cells, and for batteries made

348 from them, for use in portable applications – Part 1: Nickel systems

349 IEC 62133-2:2017, Secondary cells and batteries containing alkaline or other non-acid

350 electrolytes – Safety requirements for portable sealed secondary lithium cells, and for batteries

351 made from them, for use in portable applications – Part 2: Lithium systems

352 IEC 62133-2:2017/AMD1:2021

353 IEC 62301:2011, Household electrical appliances – Measurement of standby power

354 ISO 7010:2019, Graphical symbols – Safety colours and safety signs – Registered safety signs

355 ISO 7010:2019/Amd 1:2020

356 ISO 7010:2019/Amd 2:2020

357 ISO 7010:2019/Amd 3:2021

358 ISO 7010:2019/Amd 4:2021

359 ISO 7010:2019/Amd 5:2022

360 ISO 7010:2019/Amd 6:2022

361 ISO 7010:2019/Amd 7:2023

362 ISO 7010:2019/Amd 8:2024

363 3 Terms and definitions

364 For the purposes of this document, the following terms and definitions apply.

365 ISO and IEC maintain terminological databases for use in standardization at the following

366 addresses:

367 • IEC Electropedia: available at http://www.electropedia.org/

368 • ISO Online browsing platform: available at http://www.iso.org/obp

369 Table 1 provides an alphabetical cross-reference listing of terms.

IEC 60974-1 ED7 © IEC 2025 11

370 Table 1 – Alphabetical list of terms

Term Term Term Term Term Term

number number number

AC, qualifier 3.1.68 expert 3.1.3 rated reduced no-load 3.1.27

voltage

active power 3.3.3 explosion 3.2.23 rated supply current 3.1.30

ancillary equipment 3.1.70 fixed installation 3.1.62 rated supply frequency 3.3.1

apparent power 3.3.4 flat characteristic 3.1.9 rated supply voltage 3.1.29

basic insulation 3.1.50 fully charged cell 3.2.10 rated switched no-load 3.1.28

voltage

basic protection 3.2.18 fully discharged cell 3.2.11 rated value 3.1.21

battery 3.2.1 functional insulation 3.1.65 rating plate 3.1.22

battery system 3.2.5 general purpose 3.2.12 reinforced insulation 3.1.53

batteries

battery voltage class A 3.2.19 hazard reducing device 3.1.47 remote control 3.1.60

battery voltage class B 3.2.20 idle state 3.1.66 routine test 3.1.6

C rate 3.2.6 industrial and 3.1.2 safety extra-low voltage 3.1.56

professional use

cell 3.2.7 instructed person 3.1.4 separable battery pack 3.2.4

charger 3.2.8 integral battery 3.2.2 single-fault condition 3.1.61

charging system 3.2.9 load voltage 3.1.14 specified operating 3.2.14

region

charring 3.2.21 material group 3.1.42 specified operating 3.2.14.1

region for charging

class I equipment 3.1.48 maximum charging 3.2.13 static characteristic 3.1.10

current

class II equipment 3.1.49 maximum effective 3.1.33 supplementary 3.1.51

supply current insulation

class of insulation 3.1.64 micro-environment 3.1.41 supply circuit 3.1.57

clearance 3.1.38 no-load voltage 3.1.15 temperature rise 3.1.43

consecutive operating

3.2.22 non-operating state 3.1.67 thermal equilibrium 3.1.44

cycle

control circuit 3.1.12 plasma cutting power 3.1.55 thermal protection 3.1.45

source

conventional load 3.1.18 plasma cutting system 3.1.54 total harmonic distortion 3.3.6

conventional load 3.1.20 pollution degree 3.1.40 touch current 3.1.59

voltage

conventional value 3.1.16 power factor 3.3.5 type test 3.1.5

conventional welding 3.1.17 protective circuit 3.1.63 upper limit charging 3.2.15

condition voltage

conventional welding 3.1.19 rated idle speed 3.1.36 venting 3.2.16

current

creepage distance 3.1.39 rated load speed 3.1.34 visual inspection 3.1.7

DC, qualifier 3.1.69 rated maximum supply 3.1.32 welding circuit 3.1.11

current

detachable battery pack 3.2.3 rated maximum welding 3.1.24 welding current 3.1.13

current

double insulation 3.1.52 rated minimum welding 3.1.25 welding power source 3.1.1

current

drooping characteristic 3.1.8 rated no-load speed 3.1.35 welding power source 3.3.2

efficiency

duty cycle 3.1.37 rated no-load supply 3.1.31 working voltage 3.1.58

current

electronic component 3.2.17 rated no-load voltage 3.1.26

12 IEC 60974-1 ED7 © IEC 2025

Term Term Term Term Term Term

number number number

environment with 3.1.46 rated output 3.1.23

increased risk of electric

shock

372 3.1 General terms and definitions

373 3.1.1

374 welding power source

375 arc welding power source

376 equipment for supplying current and voltage and having the required characteristics suitable for

377 arc welding and allied processes

378 Note 1 to entry: A WELDING POWER SOURCE can also supply services to other equipment and auxiliaries for example

379 auxiliary power, cooling liquid, consumable arc welding electrode and gas to shield the arc and the welding area.

380 [SOURCE: IEC 60050-851:20xx, 851-13-01]

381 3.1.2

382 industrial and professional use

383 use intended only for EXPERTS or INSTRUCTED PERSONS

384 [SOURCE: IEC 60050-851:2008, 851-11-12]

385 3.1.3

386 expert

387 person who can judge the work assigned and recognize possible hazards on the basis of

388 professional training, knowledge, experience and knowledge of the relevant equipment

389 Note 1 to entry: Several years of practice in the relevant technical field can be taken into consideration in

390 assessment of professional training.

391 [SOURCE: IEC 60050-851:20xx, 851-11-10]

392 3.1.4

393 instructed person

394 person informed about the tasks assigned and about the possible hazards involved in neglectful

395 behaviour

396 Note 1 to entry: If necessary, the person has undergone some training.

397 [SOURCE: IEC 60050-851:2008, 851-11-13]

398 3.1.5

399 type test

400 test of one or more devices made to a given design to check if these devices comply with the

401 requirements of the standard concerned

402 [SOURCE: IEC 60050-851:2008, 851-12-05]

403 3.1.6

404 routine test

405 test made on each individual device during or after manufacture to check if it complies with the

406 requirements of the standard concerned or the criteria speci

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...