oSIST prEN 14067-5:2018

(Main)Railway applications - Aerodynamics - Part 5: Requirements and test procedures for aerodynamics in tunnels

Railway applications - Aerodynamics - Part 5: Requirements and test procedures for aerodynamics in tunnels

This document establishes requirements, test procedures, assessment methods and acceptance criteria for aerodynamics in tunnels and rolling stock in tunnels. Topics of aerodynamic pressures and loadings, aerodynamic resistance and micro-pressure waves are addressed.

Requirements for rolling stock with operating speeds equal to or above 200 km/h are provided for pressures generated in tunnel operation. Requirements for infrastructure with design speeds above 160 km/h or high blockage ratio or tunnels longer than 12 km are provided for pressures generated in tunnel operation. These requirements are not applicable to light rail and urban rail.

This document is applicable to all railway vehicles and infrastructure with track gauges from 1 435 mm to 1 668 mm inclusive.

Bahnanwendungen - Aerodynamik - Teil 5: Anforderungen und Prüfverfahren für Aerodynamik im Tunnel

Dieses Dokument legt Anforderungen, Prüfverfahren, Beurteilungsverfahren und Abnahmekriterien für die Aerodynamik in Tunneln und von Schienenfahrzeugen in Tunneln fest. Die Themen des aerodynamischen Drucks und der aerodynamischen Beanspruchung sowie des aerodynamischen Widerstands und der Mikrodruckfelder werden behandelt.

Anforderungen an Schienenfahrzeuge mit Betriebsgeschwindigkeiten von mindestens 200 km/h werden für im Tunnelbetrieb erzeuge Drücke angegeben. Anforderungen an die Infrastruktur bei Bemessungsgeschwindigkeiten von mehr als 160 km/h oder höhere Versperrungsmaße im Betrieb in Tunneln mit einer Länge von mehr als 12 km sind für die im Tunnelbetrieb erzeugten Drücke vorgesehen. Diese Anforderungen gelten nicht für Stadtbahnen und städtische Schienenbahnen.

Dieses Dokument gilt für alle Schienenfahrzeuge und Infrastruktur mit Spurweiten von 1 435 mm bis einschließlich 1 668 mm.

Applications ferroviaires - Aerodynamique - Partie 5 : Exigences et procédures d'essai pour l'aérodynamique en tunnel

Le présent document spécifie les exigences, les procédures d'essai, les méthodes d'évaluation et les critères d'acceptation relatifs à l'aérodynamique et au matériel roulant dans les tunnels. Il aborde les pressions et charges aérodynamiques, la résistance aérodynamique et les micro-ondes de pression.

Il spécifie les exigences applicables au matériel roulant circulant à une vitesse supérieure ou égale à 200 km/h en matière de pressions générées lors de la traversée d'un tunnel. Il donne les exigences applicables aux infrastructures dont la vitesse de conception est supérieure à 160 km/h ou ayant un fort rapport de blocage, ainsi qu'aux tunnels mesurant plus de 12 km de longueur en matière de pressions générées lors de la traversée d'un tunnel. Ces exigences ne s'appliquent pas aux systèmes ferroviaires légers ni aux systèmes ferroviaires urbains.

Le présent document s'applique à l'ensemble des véhicules ferroviaires et infrastructures dont l'écartement de voie est compris entre 1 435 mm et 1 668 mm, valeurs extrêmes incluses.

Železniške naprave - Aerodinamika - 5. del: Zahteve in preskusni postopki pri aerodinamiki v predorih

General Information

- Status

- Not Published

- Public Enquiry End Date

- 30-Nov-2018

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 98 - Abandoned project (Adopted Project)

- Start Date

- 03-Jan-2022

- Due Date

- 08-Jan-2022

- Completion Date

- 03-Jan-2022

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 04-Dec-2013

Overview

The CEN standard oSIST prEN 14067-5:2018 titled Railway applications - Aerodynamics - Part 5: Requirements and test procedures for aerodynamics in tunnels defines comprehensive requirements and testing methodologies for aerodynamic behavior within railway tunnels. This European standard addresses the effects of aerodynamic pressures, aerodynamic loadings, resistance, and micro-pressure waves generated by rolling stock traveling through tunnels.

Aimed at railway vehicles and infrastructure with track gauges between 1,435 mm and 1,668 mm, the standard specifically applies to rolling stock operating at speeds of 200 km/h or higher and infrastructure with design speeds over 160 km/h, particularly where tunnels have high blockage ratios or exceed 12 km in length. Importantly, it excludes light rail and urban rail systems.

Developed by the CEN Technical Committee 256, oSIST prEN 14067-5:2018 facilitates harmonized safety, comfort, and performance levels in high-speed rail tunnel environments by providing clear assessment criteria, test procedures, and acceptance thresholds.

Key Topics

Aerodynamic Pressure Limitations

The standard sets precise limits on pressure variations inside tunnels to protect passengers' comfort, infrastructure integrity, and worker safety. It defines criteria targeting both the maximum pressure variation and the pressure gradients responsible for micro-pressure wave generation.Micro-Pressure Wave Management

Requirements focus on controlling the pressure gradients at tunnel entry points to minimize micro-pressure waves-commonly known as "tunnel sonic booms"-which can lead to noise pollution and structural stresses.Aerodynamic Load and Resistance

Criteria include resistance to aerodynamic loading from tunnel-induced airflows and transiting trains, addressing exceptional loads, fatigue loads, and ensuring rolling stock structural robustness.Infrastructure Considerations

Guidelines extend to infrastructure design aspects such as tunnel shape, length, ventilation, induced airflow, and pressure comfort in underground stations, ensuring a holistic approach to aerodynamic safety and comfort.Test Procedures and Assessment Methods

The standard specifies multiple methods for evaluating aerodynamic effects including full-scale measurements inside tunnels, measurements on train exteriors, numerical simulations, reduced-scale model tests, and predictive formulae. These provide flexible and rigorous approaches to conformity assessment.Conformity Assessment

Both full and simplified assessment pathways are outlined for verifying compliance with pressure variation limits and aerodynamic loading requirements, facilitating practical implementation.

Applications

High-Speed Railway Design

Ensures that design of rolling stock and tunnels for speeds above 160-200 km/h meet aerodynamic safety and comfort standards.Tunnel Construction and Upgrades

Provides criteria for tunnel dimensions and ventilation systems to manage aerodynamic pressures and mitigate micro-pressure wave generation effectively.Rolling Stock Development

Guides manufacturers in aerodynamic design for trains operating in tunnel environments to reduce pressure loadings and improve energy efficiency.Safety and Comfort Assurance

Protects passenger health by limiting rapid pressure changes and auditory discomfort caused by pressure waves in tunnels.Regulatory Compliance

Supports compliance with European and international railway safety and operational regulations concerning aerodynamics in tunnels.

Related Standards

EN 14067-1 to 4: Cover general aerodynamics of railway vehicles and applications outside tunnels, including aerodynamic noise and drag reduction strategies.

EN 14067-6: Addresses aerodynamic requirements for rail-bound vehicles under different operational conditions, complementing tunnel-specific guidelines.

Tunnel Construction Standards (ICS 93.060): Provide structural and safety requirements for tunnel engineering, often used in conjunction with aerodynamic standards for comprehensive tunnel design.

Railway Rolling Stock Standards (ICS 45.060.01): Define technical requirements for rolling stock safety, performance, and interoperability relating to various operational environments.

By implementing oSIST prEN 14067-5:2018, railway operators, engineers, and manufacturers can enhance tunnel aerodynamics performance, ensure passenger comfort, improve operational safety, and mitigate environmental impact effectively within high-speed rail networks.

Frequently Asked Questions

oSIST prEN 14067-5:2018 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - Aerodynamics - Part 5: Requirements and test procedures for aerodynamics in tunnels". This standard covers: This document establishes requirements, test procedures, assessment methods and acceptance criteria for aerodynamics in tunnels and rolling stock in tunnels. Topics of aerodynamic pressures and loadings, aerodynamic resistance and micro-pressure waves are addressed. Requirements for rolling stock with operating speeds equal to or above 200 km/h are provided for pressures generated in tunnel operation. Requirements for infrastructure with design speeds above 160 km/h or high blockage ratio or tunnels longer than 12 km are provided for pressures generated in tunnel operation. These requirements are not applicable to light rail and urban rail. This document is applicable to all railway vehicles and infrastructure with track gauges from 1 435 mm to 1 668 mm inclusive.

This document establishes requirements, test procedures, assessment methods and acceptance criteria for aerodynamics in tunnels and rolling stock in tunnels. Topics of aerodynamic pressures and loadings, aerodynamic resistance and micro-pressure waves are addressed. Requirements for rolling stock with operating speeds equal to or above 200 km/h are provided for pressures generated in tunnel operation. Requirements for infrastructure with design speeds above 160 km/h or high blockage ratio or tunnels longer than 12 km are provided for pressures generated in tunnel operation. These requirements are not applicable to light rail and urban rail. This document is applicable to all railway vehicles and infrastructure with track gauges from 1 435 mm to 1 668 mm inclusive.

oSIST prEN 14067-5:2018 is classified under the following ICS (International Classification for Standards) categories: 45.060.01 - Railway rolling stock in general; 93.060 - Tunnel construction. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN 14067-5:2018 has the following relationships with other standards: It is inter standard links to SIST EN 14067-5:2007+A1:2010, SIST EN 14067-5:2007+A1:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN 14067-5:2018 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC; Standardization Mandates: M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

oSIST prEN 14067-5:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2018

Železniške naprave - Aerodinamika - 5. del: Zahteve in preskusni postopki pri

aerodinamiki v predorih

Railway applications - Aerodynamics - Part 5: Requirements and test procedures for

aerodynamics in tunnels

Bahnanwendungen - Aerodynamik - Teil 5: Anforderungen und Prüfverfahren für

Aerodynamik im Tunnel

Applications ferroviaires - Aerodynamique - Partie 5 : Exigences et procédures d'essai

pour l'aérodynamique en tunnel

Ta slovenski standard je istoveten z: prEN 14067-5

ICS:

45.060.01 Železniška vozila na splošno Railway rolling stock in

general

93.060 Gradnja predorov Tunnel construction

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

September 2018

ICS 45.060.01; 93.060 Will supersede EN 14067-5:2006+A1:2010

English Version

Railway applications - Aerodynamics - Part 5:

Requirements and test procedures for aerodynamics in

tunnels

Applications ferroviaires - Aerodynamique - Partie 5 : Bahnanwendungen - Aerodynamik - Teil 5:

Exigences et procédures d'essai pour l'aérodynamique Anforderungen und Prüfverfahren für Aerodynamik im

en tunnel Tunnel

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 256.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2018 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 14067-5:2018 E

worldwide for CEN national Members.

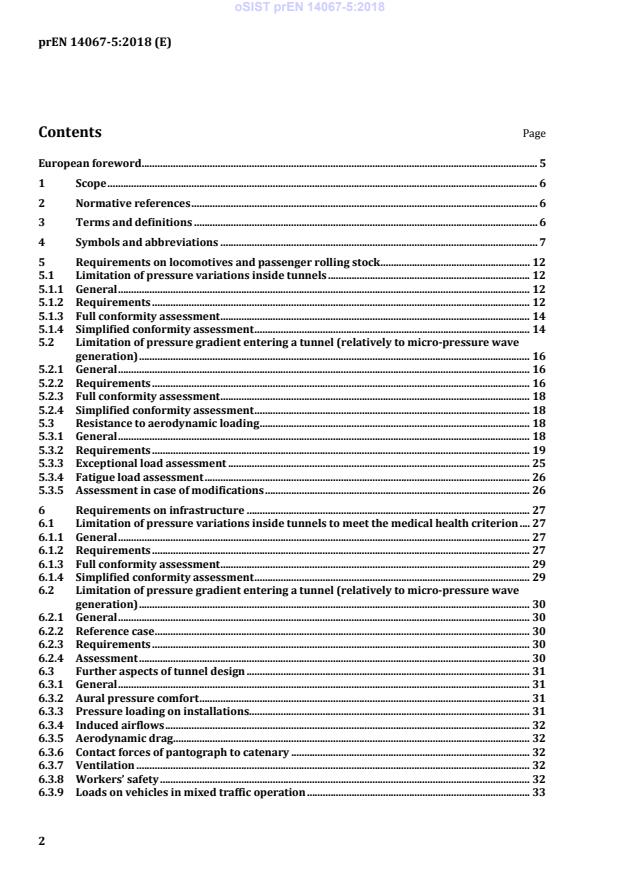

Contents Page

European foreword . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Symbols and abbreviations . 7

5 Requirements on locomotives and passenger rolling stock . 12

5.1 Limitation of pressure variations inside tunnels . 12

5.1.1 General . 12

5.1.2 Requirements . 12

5.1.3 Full conformity assessment . 14

5.1.4 Simplified conformity assessment . 14

5.2 Limitation of pressure gradient entering a tunnel (relatively to micro-pressure wave

generation) . 16

5.2.1 General . 16

5.2.2 Requirements . 16

5.2.3 Full conformity assessment . 18

5.2.4 Simplified conformity assessment . 18

5.3 Resistance to aerodynamic loading . 18

5.3.1 General . 18

5.3.2 Requirements . 19

5.3.3 Exceptional load assessment . 25

5.3.4 Fatigue load assessment . 26

5.3.5 Assessment in case of modifications . 26

6 Requirements on infrastructure . 27

6.1 Limitation of pressure variations inside tunnels to meet the medical health criterion . 27

6.1.1 General . 27

6.1.2 Requirements . 27

6.1.3 Full conformity assessment . 29

6.1.4 Simplified conformity assessment . 29

6.2 Limitation of pressure gradient entering a tunnel (relatively to micro-pressure wave

generation) . 30

6.2.1 General . 30

6.2.2 Reference case . 30

6.2.3 Requirements . 30

6.2.4 Assessment . 30

6.3 Further aspects of tunnel design . 31

6.3.1 General . 31

6.3.2 Aural pressure comfort . 31

6.3.3 Pressure loading on installations. 31

6.3.4 Induced airflows . 32

6.3.5 Aerodynamic drag . 32

6.3.6 Contact forces of pantograph to catenary . 32

6.3.7 Ventilation . 32

6.3.8 Workers’ safety . 32

6.3.9 Loads on vehicles in mixed traffic operation . 33

6.4 Additional aspects for underground stations . 33

6.4.1 Pressure changes . 33

6.4.2 Induced airflows . 33

6.4.3 Specific case for loads on platform barrier systems due to trains passing . 34

7 Methods and test procedures . 34

7.1 General . 34

7.2 Methods to determine pressure variations in tunnels . 36

7.2.1 General . 36

7.2.2 Full scale measurements at fixed locations in a tunnel . 37

7.2.3 Instrumentation . 38

7.2.4 Full scale measurements on the exterior of the train . 40

7.2.5 Predictive formulae . 41

7.2.6 Assessment by numerical simulation . 42

7.2.7 Reduced scale measurements at fixed locations in a tunnel . 42

7.3 Assessment of maximum pressure changes (vehicle reference case) . 43

7.3.1 General . 43

7.3.2 Transformation of measurement values by a factor (approach 1) . 43

7.3.3 Transformation of measurement values based on A.3.3 (approach 2) . 44

7.3.4 Transformation by simulation (approach 3) . 45

7.3.5 Assessment of pressure time history . 46

7.3.6 Assessment quantities and comparison . 50

7.4 Assessment of maximum pressure changes (infrastructure reference case) . 51

7.5 Assessment of the pressure gradient of a train entering a tunnel (vehicle reference

case, relative to micro-pressure wave generation). 52

7.5.1 General . 52

7.5.2 Assessment by simulations . 52

7.5.3 Assessment by moving model rig tests . 53

7.6 Assessment of the micro-pressure wave (infrastructure reference case). 53

7.6.1 General . 53

7.6.2 Assessment by numerical simulations . 54

7.6.3 Assessment by reduced scale moving model rig tests . 55

7.7 Assessment of aerodynamic load . 57

7.7.1 Assessment of load due to strong wind . 57

7.7.2 Assessment of open air passings . 57

7.7.3 Assessment of exceptional transient loads in tunnels . 59

7.7.4 Assessment of fatigue loads . 61

7.7.5 Determination of the damage-equivalent load amplitude for scenario . 63

7.7.6 Documentation . 64

7.7.7 Simplified load cases . 65

7.8 Assessment of the pressure sealing . 66

7.8.1 General . 66

7.8.2 Dynamic pressure tightness . 67

7.8.3 Equivalent leakage area . 67

7.8.4 Test methods . 68

7.8.5 Dynamic tests . 70

Annex A (informative) Predictive formulae . 72

A.1 General . 72

A.2 SNCF approach . 72

A.2.1 Entry of the nose of the train . 72

A.2.2 Entry of the body of the train . 72

A.2.3 Entry of the rear of the train . 73

A.3 TU Vienna approach . 73

A.3.1 General . 73

A.3.2 Symbols . 73

A.3.3 Calculation of Δp . 74

N

A.3.4 Calculation of Δp . 75

fr

A.3.5 Calculation of Δp . 76

T

A.3.6 Calculation of the nose passing pressure drop Δp . 78

HP

A.3.7 Calculation of the drag coefficient C . 78

x,tu

A.4 GB approach, ignoring changes in air density and the speed of sound . 80

A.4.1 General . 80

A.4.2 Calculation of ∆p . 80

N

A.4.3 Calculation of ∆p . 81

fr

A.4.4 Calculation of ∆p . 81

T

Annex B (informative) Pressure comfort criteria . 82

B.1 General . 82

B.2 Unsealed trains (generally τ < 0,5 s) . 82

dyn

B.3 Sealed trains (generally τ > 0,5 s). 82

dyn

Annex C (informative) Micro-pressure wave . 83

C.1 General . 83

C.2 Wave generation. 83

C.3 Wave propagation . 84

C.4 Wave radiation . 84

Annex D (informative) Pressure loading on unsealed crossing trains . 86

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of EU Directive 2008/57/EC aimed to be covered . 89

Bibliography . 92

European foreword

This document (prEN 14067-5:2018) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 14067-5:2006+A1:2010.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive 2008/57/EC.

For relationship with EU Directive 2008/57/EC, see informative Annex ZA, which is an integral part of

this document.

EN 14067 Railway applications — Aerodynamics consists of the following parts:

— Part 1: Symbols and units;

— Part 3: Aerodynamics in tunnels;

— Part 4: Requirements and test procedures for aerodynamics on open track;

— Part 5: Requirements and test procedures for aerodynamics in tunnels;

— Part 6: Requirements and test procedures for cross wind assessment.

The results of the EU-funded research project “AeroTRAIN” (Grant Agreement No. 233985) have been

used.

The contents of the previous edition of EN 14067-5 have been integrated in this document; they have

been re-structured and extended to support the Technical Specifications for the Interoperability of the

Trans-European rail system. Requirements on conformity assessment for rolling stock were added.

1 Scope

This document establishes requirements, test procedures, assessment methods and acceptance criteria

for aerodynamics in tunnels and rolling stock in tunnels. Topics of aerodynamic pressures and loadings,

aerodynamic resistance and micro-pressure waves are addressed.

Requirements for rolling stock with operating speeds equal to or above 200 km/h are provided for

pressures generated in tunnel operation. Requirements for infrastructure with design speeds above

160 km/h or high blockage ratio or tunnels longer than 12 km are provided for pressures generated in

tunnel operation. These requirements are not applicable to light rail and urban rail.

This document is applicable to all railway vehicles and infrastructure with track gauges from 1 435 mm

to 1 668 mm inclusive.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12663-1, Railway applications — Structural requirements of railway vehicle bodies — Part 1:

Locomotives and passenger rolling stock (and alternative method for freight wagons)

EN 12663-2:2010, Railway applications — Structural requirements of railway vehicle bodies — Part 2:

Freight wagons

EN 14067-4:2013, Railway applications — Aerodynamics — Part 4: Requirements and test procedures for

aerodynamics on open track

EN 15273 (all parts), Railway applications — Gauges

ISO 8756, Air quality — Handling of temperature, pressure and humidity data

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

compression wave

approximate step change in pressure above ambient that travels at the speed of sound

3.2

expansion wave

approximate step change in pressure below ambient that travels at the speed of sound

3.3

Computational Fluid Dynamics

(CFD)

numerical methods of approximating and solving the formulae of fluid dynamics

3.4

exceptional loads

maximum loads occurring occasionally during normal operations due to both static and transient loads

3.5

fatigue loads

very large number of dynamic and aerodynamic loads of varying magnitude that the structures of rail

vehicle bodies or infrastructure components are subjected to during their operational life

3.6

static loads

loads that are constant or nearly constant with time

Note 1 to entry: These loads include the dynamic pressure due to the airflow acceleration around the front of

the train and pressure changes caused by strong side winds.

3.7

transient loads

loads that vary in time

Note 1 to entry: Transient loads can be divided into three kinds:

a) loads caused by trains running in the open air, due to the pressure field around the train;

b) loads caused by trains travelling alone or crossing with other trains in tunnels;

c) loads that arise due to the turbulent nature of the flow around trains.

Note 2 to entry: Loads a) and b) are relevant for all train structures, but loads c) may be only relevant for some

high speed train components and are not considered in this standard.

3.8

tunnel

excavation or a construction around the track provided to allow the railway to pass through, for

example, higher land, buildings or water

Note 1 to entry: A tunnel in the context of this standard has a length greater than 100 m.

3.9

tunnel length

length of a tunnel is defined as the length of the fully enclosed section, measured centrally at rail level

3.10

tunnel cross-sectional area (for blockage ratio)

free cross-sectional area of a tunnel not including ballast rail, sleepers, longitudinal piping, platform

3.11

vehicle cross-sectional area (for blockage ratio)

cross-sectional area of a vehicle in lengthwise direction

4 Symbols and abbreviations

For the purposes of this document, the following symbols apply.

Table 1 — Symbols

Symbol Significance Explanation or remark Unit

A , A area of integration see Figure 11 sPa

S T

A tunnel free cross-sectional area 2

tu m

B, B1, B2 train/tunnel blockage ratio

S

tr

B =

S

tu

b width of vehicle m

C train friction factor or coefficient

f,tr

C tunnel friction factor or coefficient

f,tu

C factor depending on the shape of the train nose and Formula (C.2)

n

the shape of the tunnel portal

C load collective for trains encountering on the open

oa,cros

track

C collective for solo passages in the tunnel

tu,solo

CFL Courant-Friedrich-Levy number

c speed of sound m/s

D hydraulic diameter m

h

F maximum measured force see Figure D.4 N

max

g acceleration due to gravity 2

m/s

h height m

h frequenciey corresponding to a class of amplitudes

l

in a rainflow matrix

h distance from top of rail to the underside of the m

carbody

h height of tunnel centre above ground m

c

Δh difference between maximum and minimum m

altitudes in the tunnel

H, H , H relative humidity of air %

1 2

k Wöhler curve exponent

k vehicle structural rigidity factor

k factor

j

k train roughness parameter m

s

L nose length of train m

n

L critical tunnel length m

tu,crit

L length of the vehicle m

veh

L length of the route section km

section,i

L length of train m

tr

L length of tunnel m

tu

L minimum length in a tunnel measured from entry m

tu,min

portal

L virtual length of the tunnel m

virttun

L Mileage per year km/year

year

N sections of open track 1/year

oa

N reference cycle

c

N Number of trains passing a stationary point in one 1/h

trainsperhour

direction per hour

N Number of tunnels, in which trains encounter

tu,cros

N Number of tunnels, in which solo passages occur

tu,solo

n frequency for trains crossing on the open track

oa,cros,i

n frequency for trains crossing in a double track

tu,cros,j

tunnel

n frequency of single train passages without train

tu,solo,i

encounter in a double track tunnel

Pe perimeter of train m

tr

Pe perimeter of tunnel m

tu

p pressure Pa

p damage-equivalent amplitude Pa

eq

p classified amplitude Pa

l

p pressure load Pa

L

p atmospheric pressure Pa

atm

p pressure difference between external and internal Pa

d

pressure

p external pressure outside of a vehicle Pa

e

p internal pressure in a vehicle Pa

i

p reference static pressure Pa

o

p offset pressure Pa

offset

p(t) pressure signal in tunnel from simulation software Pa

sim

p(t) pressure signal in tunnel from track test Pa

test

r radius distance between tunnel m

exit portal centre (on the

ground) and the point of

interest (reception

point), see Annex C

r corner radius of the micro-pressure wave m

b

reference vehicle

R tunnel radius m

S equivalent leakage area 2

eq m

S Train cross-sectional area see 3.10 2

tr m

S Tunnel cross-sectional area see 3.9 2

tu m

t, t , t , t , t time s

A B S T

t difference in entry time s

e

t Train service life year

life

T absolute temperature K

T tunnel factor

f

U local dominant speed (train speed or pressure see 7.6.2 m/s

wave speed)

U flow velocity in tunnel relative to train before train m/s

entry

v train speed m/s

tr

v train speed see 7.7.4.3 m/s

tr,1

v speed of the encountering train see 7.7.4.3 m/s

tr,2

v maximum line speed or design speed of a line km/h

max, line

v maximum train speed or design speed of a train Maximum train speed km/h

tr,max

referes to train operation

If limited by

infrastructure, maximum

train speed may be lower

than design speed

v train reference speed km/h

tr,ref

v train test speed m/s

tr,test

V internal volume of the vehicle 3

int m

X , X , X , X dummy variables

d h fr t

x distance between the entrance portal and the m

p

measuring position

x , x , x longitudinal positions on the train defined in 7.7.3.4 m

1 2 3

Y track distance centre to centre m

tr

ΔL additional length m

Δp, Δp(t) differential pressure at time t Pa

Δp natural pressure variation due to altitude Pa

alt

maximum difference between internal and external see Figure D.4

∆p

d,max

pressures

Δp pressure change due to friction effects caused by see Figure 6

fr

the entry of the main part of the train into the

tunnel

Δp pressure change due to friction effects caused by see 7.2.4 Pa

fr,o

the entry of the main part of the train into the

tunnel

Δp pressure signature caused by the passing of the see Figure 6 Pa

HP

train nose at the measurement position in the

tunnel

maximum peak-to-peak pressure change on Pa

∆p

max

outside of train

Δp pressure change caused by the entry of the nose of see Figure 6 Pa

N

the train into a tunnel

Δp pressure change caused by the entry of the nose of see 7.2.4 Pa

N,o

the train into a tunnel measured on a train on the

exterior of the train

Δp pressure change caused by the entry of the tail of see Figure 6 Pa

T

the train into a tunnel

Δp pressure change caused by the entry of the tail of see 7.2.4 Pa

T,o

the train into a tunnel measured on the exterior of

a train

pressure after train tail entrance see A.3.2 Pa

∆p

average nose entry pressure change Pa

∆p

N

average frictional pressure rise Pa

∆p

fr

average tail entry pressure change Pa

∆p

T

characteristic time interval for the pressure rise

∆t

time increment s

∆t

e

lower bound of entry time interval s

∆t

e,min

upper bound of entry time interval s

∆t

e,max

additional distance m

∆x

deviation between test and simulation

ε

∆p

loss coefficient for tunnel portal

ζ

E

loss coefficient of the train nose in the tunnel

ζ

h

loss coefficient of the train nose in the open air

ζ

h0

coefficient for additional loss of the train nose in

ζ

h1

the tunnel

loss coefficient of the train tail in the tunnel

ζ

t

loss coefficient of the train tail in the open air

ζ

t0

coefficient for additional loss of the train tail in the

ζ

t1

tunnel

loss coefficient for the train

ζ

train nose pressure loss coefficient

ζ

N

tunnel portal pressure loss coefficient

ζ

P

train tail pressure loss coefficient

ζ

T

θ

temperature ° C

ambient atmospheric air density 3

ρ kg/m

amb

air density 3

ρ,,ρ ρ kg/m

1 2

tau-model, representing train operation; values of s

τ

dyn

pressure tightness coefficient for moving rail

vehicles

values of pressure tightness coefficient for static

τ

stat

rail vehicles

Ω solid angle representing the configuration around

the tunnel exit portal

average of the value

, (overbar)

5 Requirements on locomotives and passenger rolling stock

5.1 Limitation of pressure variations inside tunnels

5.1.1 General

When a train enters and exits a tunnel, pressure variations are generated which propagate along the

tunnel at sonic speed and are reflected back at portals into the tunnel. These pressure variations may

cause aural discomfort or, in the worst case, aural damage, to train passengers and train staff and will

produce transient loads on the structure of trains and the infrastructure components.

To define a clear interface between the subsystems of rolling stock and infrastructure in the heavy rail

system, the train-induced aerodynamic pressure variations inside tunnels need to be known and

limited. In order to describe and to limit the train-induced aerodynamic pressure variations inside

tunnels, two reference cases for rolling stock assessment are defined.

5.1.2 Requirements

5.1.2.1 Reference case

For track gauges from 1 435 mm to 1 668 mm inclusive, the pressure variations generated by a train

entering a simple, non-inclined tube-like tunnel, (i.e. without any shafts, etc.), are defined by pressure

signatures for two given combinations of train speed and tunnel cross-section. The latter are referred to

as the reference cases.

The pressure signature consists of three characteristic pressure variations: Δp caused by the entry of

N

the nose of the train into the tunnel, Δp due to friction effects caused by the entry of the main part of

fr

the train into the tunnel, and Δp caused by the entry of the tail of the train into the tunnel

T

(see Figure 6).

NOTE Compliance with this requirement does not necessarily ensure free access to all lines.

The assessment shall be made for standard meteorological conditions: atmospheric

pressure p = 101 325 Pa, air density ρ = 1,225 kg/m , temperature θ = 15 °C with no initial air

atm amb

flow in the tunnel.

Table 2 — Maximum tunnel characteristic pressure changes Δp , Δp and Δp for the reference

fr N T

case

Reference case Criteria for the reference case

Maximum design

Reference speed, v A Δp Δp + Δp Δp + Δp + Δp

tr,ref tu N N fr N fr

speed/class

km/h 2 Pa Pa T

km/h

m

Pa

v < 200

No requirement

tr,max

200 ≤ v < 250

tr,max

200 53,6 ≤ 1 750 ≤ 3 000 ≤ 3 700

(Class 2)

250 ≤ v

tr,max

250 63,0 ≤ 1 600 ≤ 3 000 ≤ 4 100

(Class 1)

5.1.2.2 Fixed or pre-defined train compositions

A fixed or pre-defined train composition, running at the reference speed in the reference case tunnel

scenario without crossing other trains shall not cause the characteristic pressure variations at a fixed

point in the tunnel to exceed the values set out in Table 2.

NOTE Fixed and pre-defined train compositions are described in TSI LOC&PAS 2014, Section 2.2.1.

For train compositions that are non-symmetrical with respect to running direction, the requirement

applies for both running directions.

For fixed or pre-defined train compositions consisting of more than one train unit, the full assessment

shall be made for the maximum length of the train of coupled units, see 7.3.

Full scale tests provide input data for the assessment and may be carried out using shorter train

configurations, see 7.2.2.3.

5.1.2.3 Single rolling stock units fitted with a driver’s cab

A single unit fitted with a driver’s cab running as the leading vehicle at the reference speed in the

reference case tunnel scenario without crossing other trains shall not cause the characteristic pressure

variations Δp and Δp to exceed the values set out in Table 2. The pressure variation Δp shall be set

N T fr

to 1 250 Pa for trains with v < 250 km/h or, respectively to 1 400 Pa for trains with

tr,max

v ≥ 250 km/h.

tr,max

For single rolling stock units capable of bidirectional operation as a leading vehicle the requirement

applies for both running directions.

5.1.2.4 Other passenger rolling stock

Other passenger rolling stock running at the reference speed in the reference case tunnel scenario shall

not cause the characteristic pressure variations Δp to exceed the values set out in Table 2. The

fr

pressure variation Δp shall be set to 1 750 Pa and Δp shall be set to 700 Pa for trains with

N T

v < 250 km/h or, respectively to 1 600 Pa and 1 100 Pa for trains with v ≥ 250 km/h.

tr,max tr,max

For passenger rolling stock which is not covered in 5.1.2.2 or 5.1.2.3, conformity shall be assessed on

the basis of a train 400 m long train.

5.1.3 Full conformity assessment

A full conformity assessment of rolling stock shall be undertaken according to Table 3.

Table 3 — Methods applicable for the full conformity assessment of rolling stock

Maximum design speed Methods

km/h

v < 200 No assessment needed

tr,max

v ≥ 200 Documentation of compliance according to 5.1.4; or

tr,max

Full-scale tests according to 7.2.2 and Assessment according to 7.3

5.1.4 Simplified conformity assessment

A simplified conformity assessment may be carried out for rolling stock that is subject to minor design

differences by comparison with rolling stock for which a full conformity assessment already exists.

With respect to pressure variations in tunnels, the only relevant design differences are differences in

external geometry and differences in design speed and train length.

This simplified conformity assessment shall take one of the following forms in accordance with Table 4:

— a statement that the design differences have no impact on the pressure variations inside tunnels; or

— a comparative evaluation of the design differences relevant to the rolling stock for which a full

conformity assessment already exists.

Table 4 — Methods and requirements applicable for simplified conformity assessment of rolling

stock

Design differences Methods and requirements

Differences in external geometry limited to: Documentation of differences, statement of no

impact and reference to an existing compliant full

— reordering of examined coaches of the same

conformity assessment

type and/or cross-section;

— minor differences in external geometry:

— wipers, handles and antennae;

— long isolated protruding objects or gaps

that are not vertical or close to the front-

side radius or edge smaller than 5 cm in

the crosswise dimensions;

— small isolated protruding objects and

gaps smaller than 5 cm in each

This assessment will comply with the Railway Interoperability Directive.

Design differences Methods and requirements

dimension;

— pantographs, electrical wiring and pipes;

— other roof and underfloor equipment

changes smaller than 20 cm in each

physical dimension;

— addition of equipment fairings greater

than 10 m downstream from the tip of

the nose;

— fittings, seals, bonded joints, handle bars,

rear view installations, surface

roughness, doors, windows, changes in

glazing, signal lights, pipes, cabling and

plugs;

— other parts with changes in lateral

dimensions smaller than 5 cm.

— differences that are beneficial:

— increase of nose length;

— decrease of cross-sectional area;

— decrease of train length.

Other differences in external geometry (e.g. in Documentation of differences and reference to an

buffers, front couplers, snow ploughs, front or existing compliant full conformity assessment

side windows) keeping the basic nose shape AND

features, in particular the cross-sectional area

Assessment of the relative effect of differences by

and the nose length.

— reduced-scale moving model tests according

to 7.2.7 or

— three-dimensional CFD simulations

according to EN 14067-4:2013, 6.1.2.4

AND evidence and documentation that

i) The difference causes changes in

∆∆pp, + ∆p , and ∆∆pp++ ∆p ,

N N fr N fr T

each less than ± 5 %.

∆p − ∆p

ii,B ,A

< 0,05 for i = N, N +fr, N+fr +T

∆p

i ,A

NOTE Subscript B refers to the new train

geometry and subscript A refers to the existing

compliant train.

Design differences Methods and requirements

and

ii) The difference does not exceed 50 % of the

margin available on the compliance with

5.1.2.

∆p − ∆p <⋅0,5 ∆p − ∆p

ii,B ,A ( i,A )

i ,limit

Where

Δp , i = N, N+fr, N+fr+T, are given in

i,limit

Table 2.

— Documentation of differences AND

Increase of:

— design speed;

— transfer to the reference case by re-scaling

methods described in 7.3.2, 7.3.3 or 7.3.4;

— train length.

AND

— evidence and documentation that the train

still fulfils the requirements listed in 5.1.2.

5.2 Limitation of pressure gradient entering a tunnel (relatively to micro-pressure wave

generation)

5.2.1 General

When a high-speed train enters a tunnel a compression wave is generated by the piston effect. This

compression wave propagates through the tunnel at the speed of sound in front of the train towards the

opposite portal. At the opposite portal, the wave is partly reflected back into the tunnel and partly

emitted into the environment. The emitted part is called a micro-pressure wave. If the pressure

gradient of the compression wave inside the tunnel is sufficiently large, it can cause strong audible

effects on people and the environment. Further information is to be found in Annex C.

Therefore, a definition of a reference scenario consisting of a ref

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...