SIST EN 17168:2021

(Main)Railway applications - Platform barrier systems

Railway applications - Platform barrier systems

This European Standard specifies requirements for the design, construction and operation of platform barrier systems positioned at the edge of a station platform immediately adjacent to rail or other guided vehicles in stations and boarding points for passenger services and includes:

- requirements for the fixed structure and fixed parts along the platform;

- physical requirements for the movable doors and gates normally used by passengers;

- requirements for emergency doors;

- requirements for driver access doors;

- requirements for platform extremity doors;

- requirements for management of safety risks that are particular to barrier systems.

This European Standard also gives requirements for the integration of barriers with the overall rail system including:

- synchronization of vehicle and platform barrier doors or gates;

- audible and visible alerts;

- integrity of control systems;

- testing of the barrier installation;

- operational performance;

- requirements relating to other interfacing sub-systems, notably signalling and vehicles.

For barrier systems set back from the platform edge, which are used to control access to trains or for crowd management, relevant sections of the document can be used as guidance.

This European Standard applies to all actors involved in the implementation and system integration of a platform barrier system, including infrastructure owners, designers, installers and operators.

This European Standard does not cover barrier systems using bars, ropes, etc. or which operate in a vertical direction.

This European Standard applies to light rail services, e.g. metro and tramway systems and heavy rail services as requested by a project specification. It applies to small systems, working in conjunction with a single vehicle, or with larger systems working with a complete train.

This European Standard applies to platform barrier systems used at sub-surface stations, enclosed surface stations (e.g. those enclosed for the purposes of providing an air-conditioned environment for waiting passengers), and those fully in the open-air.

This European Standard does not cover normative requirements relating to fire performance or fire requirements arising from use of platform barrier systems as fire barriers.

Bahnanwendungen - Bahnsteig-Barrieresysteme

Dieses Dokument legt Anforderungen an die Auslegung, den Aufbau und den Betrieb von Bahnsteig-Barriere-Systemen fest, die direkt an der Bahnsteigkante neben den Schienen- oder anderen spurgebundenen Fahrzeugen in Stationen und an Einstiegsstellen für Fahrgäste positioniert sind. Dieses Dokument beinhaltet:

- Anforderungen an die statische Struktur und die fixen Teile entlang des Bahnsteigs;

- physische Anforderungen an die beweglichen Türen und Schleusen, die üblicherweise von Fahrgästen benutzt werden;

- Anforderungen an Notausstiegstüren;

- Anforderungen an Zugangstüren für Fahrer;

- Anforderungen an Bahnsteig-Abschlusstüren; und

- Anforderungen an das Management von Sicherheitsrisiken, die insbesondere Barriere-Systeme betreffen.

Dieses Dokument umfasst auch Anforderungen an die Integration der Barrieren in das allgemeine Schienenverkehrssystem, einschließlich:

- Synchronisierung der Fahrzeug und Bahnsteig-Barriere-Türen/ Schleusen;

- hör- und sichtbare Warnsignale;

- Integrität der Steuerungssysteme;

- Prüfung der Barriere-Installation;

- Verhalten im Betrieb; und

- Anforderungen in Bezug auf andere verbundene Subsysteme, vor allem Signaltechnik und Fahrzeuge.

Für entfernt von der Bahnsteigkante platzierte Barriere-Systeme, die zur Regelung des Zugangs zu Fahrzeugen oder zur Lenkung von Menschenmengen verwendet werden, können die entsprechenden Abschnitte des Dokuments als Leitlinie genutzt werden.

Dieses Dokument ist anzuwenden für alle Personen, die an der Umsetzung und Systemintegration eines Bahnsteig-Barriere-Systems beteiligt sind, einschließlich Infrastruktureigentümer, Konstrukteure, Monteure und Betreiber.

Dieses Dokument ist nicht anzuwenden für Barriere-Systeme mit Stäben, Seilen usw. oder Systeme, die in vertikaler Richtung betrieben werden.

Dieses Dokument ist je nach Anforderung durch eine Projektspezifikation anzuwenden für Bahnsysteme, z. B. U-Bahn , Straßenbahn , und Vollbahnsysteme. Es ist anzuwenden für kleine Systeme, die in Verbindung mit einem einzelnen Fahrzeug betrieben werden, oder für größere Systeme mit kompletten Zügen.

Dieses Dokument ist anzuwenden für Bahnsteig-Barriere-Systeme die sich in unterirdischen Stationen, geschlossenen Stationen an der Oberfläche (z. B. Stationen, die zur Bereitstellung einer klimatisierten Umgebung für wartende Fahrgäste geschlossen sind) und in Stationen, die sich komplett unter freiem Himmel befinden.

Dieses Dokument deckt keine normativen Anforderungen in Bezug auf Brandschutzeigenschaften oder Anforderungen an das Brandverhalten ab, die sich aus der Nutzung der Bahnsteig-Barriere-Systeme als Brandschutz-Barrieren ergeben.

Applications ferroviaires - Systèmes façades de quai

Le présent document spécifie les exigences pour la conception, la construction et l'exploitation des systèmes façades de quai implantés en bord de quai et à proximité immédiate des véhicules ferroviaires ou autres véhicules de transports guidés dans les stations et aux points d'embarquement des services voyageurs. Le présent document spécifie en particulier :

̶ les exigences relatives à la structure et aux parties fixes le long du quai ;

̶ les exigences physiques relatives aux portes palières utilisées normalement par les voyageurs ;

̶ les exigences relatives aux portes de secours ;

̶ les exigences relatives aux portes d'accès conducteur ;

̶ les exigences relatives aux portes d'extrémité de quai ;

̶ les exigences relatives à la prévention des risques de sécurité spécifiques aux systèmes façades de quai.

Le présent document spécifie également les exigences pour l'intégration des façades à l'infrastructure ferroviaire globale, notamment ce qui concerne les aspects suivants :

̶ synchronisation des portes du train avec les portes palières ;

̶ avertissements sonores et visuels ;

̶ intégrité des systèmes de commande ;

̶ essais de type et de série du système façade de quai ;

̶ performance opérationnelle ;

̶ exigences relatives aux autres sous-systèmes en interface, plus particulièrement les systèmes de signalisation et les trains.

Pour les systèmes façades de quai implantés en retrait du nez de quai, dont la fonction est de contrôler l'accès aux trains ou de gérer le trafic lors des pics d'affluence, les parties applicables du présent document peuvent servir de recommandations.

Le présent document s'applique à l'ensemble des personnes participant à la réalisation et l'intégration système d'un système façade de quai (gestionnaires d'infrastructure, concepteurs, installateurs et exploitants).

Le présent document ne couvre pas les systèmes façades de quai faisant usage de barres, cordes, etc. ou qui fonctionnent dans la direction verticale.

Le présent document s'applique aux réseaux ferroviaires, comme les métros et les tramways, ainsi qu'aux réseaux ferroviaires lourds selon les spécifications particulières du projet. Elle s'applique aux petits systèmes qui fonctionnent conjointement avec un véhicule isolé ou aux systèmes plus grands qui fonctionnent conjointement avec un train complet.

Le présent document s'applique aux systèmes façades de quai implantés dans les stations souterraines, les stations en surface fermées (dans le but, par exemple, de fournir un environnement climatisé aux voyageurs attendant sur le quai), ainsi que les stations entièrement à l'extérieur.

Le présent document ne couvre pas les exigences normatives relatives à la tenue au feu, ni les exigences de résistance au feu liées à l'usage de systèmes façades de quai comme dispositif coupe-feu.

Železniške naprave - Ploščad pregradnih sistemov

General Information

- Status

- Published

- Public Enquiry End Date

- 29-Feb-2020

- Publication Date

- 16-Aug-2021

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 05-Aug-2021

- Due Date

- 10-Oct-2021

- Completion Date

- 17-Aug-2021

Overview

EN 17168:2021 - published by CEN - is the European standard for platform barrier systems used at the edge of station platforms in railway applications. It defines requirements for the design, construction, integration and operation of barriers (movable doors and gates) positioned immediately adjacent to rail or other guided vehicles. The standard covers metro, tram/light rail and, where project-specified, heavy rail systems, and applies across sub-surface, enclosed and open-air stations.

Key Topics

- Physical and structural requirements

- Fixed platform structure, glazing/panelling, environmental, acoustic and thermal considerations.

- Structural loading, design principles and guidance (referenced Eurocodes).

- Doors and gates

- Physical requirements for passenger-use movable doors/gates and special provisions for emergency doors, driver access doors and platform extremity doors.

- Protection against entrapment and interface alignment with vehicles.

- Control, electrical and safety systems

- Synchronization of train and platform barrier doors/gates, status indication, audible/visible alerts.

- Integrity and verification of control systems, earthing/bonding strategies and local control arrangements.

- Operational requirements

- Maintainability, accessibility for persons with reduced mobility, gauging and tripping-hazard mitigation.

- Performance criteria for mechanical gap fillers where used.

- Testing and verification

- Type, routine, functional and systems-integration testing; Annex A provides a testing plan.

- Scope limitations

- Excludes vertical barriers and simple barriers using bars or ropes.

- Does not set normative fire-performance requirements for barriers used as fire barriers.

Applications and Who Uses This Standard

EN 17168:2021 is intended for:

- Infrastructure owners and asset managers specifying platform retrofit or new-build requirements.

- Designers and system integrators engineering barrier structures, control and signalling interfaces.

- Manufacturers and installers of platform doors, gates, glazing and control equipment.

- Operators and maintainers responsible for operational performance, testing and safety risk management.

Practical uses include improving passenger safety (preventing track incursions), enabling automated train operation, facilitating station climate and noise control, and guiding integration with signalling and vehicle door systems.

Related Standards

EN 17168 references and aligns with other standards such as:

- Eurocodes (EN 1990, EN 1991, EN 1993, EN 1999) for structural design

- EN 1090 series for steel/aluminium execution

- EN 1125 for panic exit devices

- EN 13501 series for fire classification

- Rolling stock lighting standards (EN 13272 series)

Keywords: EN 17168:2021, platform barrier systems, railway applications, platform screen doors, metro safety, door synchronization, control system integrity, station platform design.

Frequently Asked Questions

SIST EN 17168:2021 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - Platform barrier systems". This standard covers: This European Standard specifies requirements for the design, construction and operation of platform barrier systems positioned at the edge of a station platform immediately adjacent to rail or other guided vehicles in stations and boarding points for passenger services and includes: - requirements for the fixed structure and fixed parts along the platform; - physical requirements for the movable doors and gates normally used by passengers; - requirements for emergency doors; - requirements for driver access doors; - requirements for platform extremity doors; - requirements for management of safety risks that are particular to barrier systems. This European Standard also gives requirements for the integration of barriers with the overall rail system including: - synchronization of vehicle and platform barrier doors or gates; - audible and visible alerts; - integrity of control systems; - testing of the barrier installation; - operational performance; - requirements relating to other interfacing sub-systems, notably signalling and vehicles. For barrier systems set back from the platform edge, which are used to control access to trains or for crowd management, relevant sections of the document can be used as guidance. This European Standard applies to all actors involved in the implementation and system integration of a platform barrier system, including infrastructure owners, designers, installers and operators. This European Standard does not cover barrier systems using bars, ropes, etc. or which operate in a vertical direction. This European Standard applies to light rail services, e.g. metro and tramway systems and heavy rail services as requested by a project specification. It applies to small systems, working in conjunction with a single vehicle, or with larger systems working with a complete train. This European Standard applies to platform barrier systems used at sub-surface stations, enclosed surface stations (e.g. those enclosed for the purposes of providing an air-conditioned environment for waiting passengers), and those fully in the open-air. This European Standard does not cover normative requirements relating to fire performance or fire requirements arising from use of platform barrier systems as fire barriers.

This European Standard specifies requirements for the design, construction and operation of platform barrier systems positioned at the edge of a station platform immediately adjacent to rail or other guided vehicles in stations and boarding points for passenger services and includes: - requirements for the fixed structure and fixed parts along the platform; - physical requirements for the movable doors and gates normally used by passengers; - requirements for emergency doors; - requirements for driver access doors; - requirements for platform extremity doors; - requirements for management of safety risks that are particular to barrier systems. This European Standard also gives requirements for the integration of barriers with the overall rail system including: - synchronization of vehicle and platform barrier doors or gates; - audible and visible alerts; - integrity of control systems; - testing of the barrier installation; - operational performance; - requirements relating to other interfacing sub-systems, notably signalling and vehicles. For barrier systems set back from the platform edge, which are used to control access to trains or for crowd management, relevant sections of the document can be used as guidance. This European Standard applies to all actors involved in the implementation and system integration of a platform barrier system, including infrastructure owners, designers, installers and operators. This European Standard does not cover barrier systems using bars, ropes, etc. or which operate in a vertical direction. This European Standard applies to light rail services, e.g. metro and tramway systems and heavy rail services as requested by a project specification. It applies to small systems, working in conjunction with a single vehicle, or with larger systems working with a complete train. This European Standard applies to platform barrier systems used at sub-surface stations, enclosed surface stations (e.g. those enclosed for the purposes of providing an air-conditioned environment for waiting passengers), and those fully in the open-air. This European Standard does not cover normative requirements relating to fire performance or fire requirements arising from use of platform barrier systems as fire barriers.

SIST EN 17168:2021 is classified under the following ICS (International Classification for Standards) categories: 45.020 - Railway engineering in general; 93.100 - Construction of railways. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17168:2021 is associated with the following European legislation: Standardization Mandates: M/486. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 17168:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2021

Železniške naprave - Ploščad pregradnih sistemov

Railway applications - Platform barrier systems

Bahnanwendungen - Bahnsteig-Barrieresysteme

Applications ferroviaires - Systèmes façades de quai

Ta slovenski standard je istoveten z: EN 17168:2021

ICS:

45.020 Železniška tehnika na Railway engineering in

splošno general

93.100 Gradnja železnic Construction of railways

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17168

EUROPEAN STANDARD

NORME EUROPÉENNE

July 2021

EUROPÄISCHE NORM

ICS 45.020; 45.120

English Version

Railway applications - Platform barrier systems

Applications ferroviaires - Systèmes façades de quai Bahnanwendungen - Bahnsteig-Barriere-Systeme

This European Standard was approved by CEN on 30 May 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17168:2021 E

worldwide for CEN national Members.

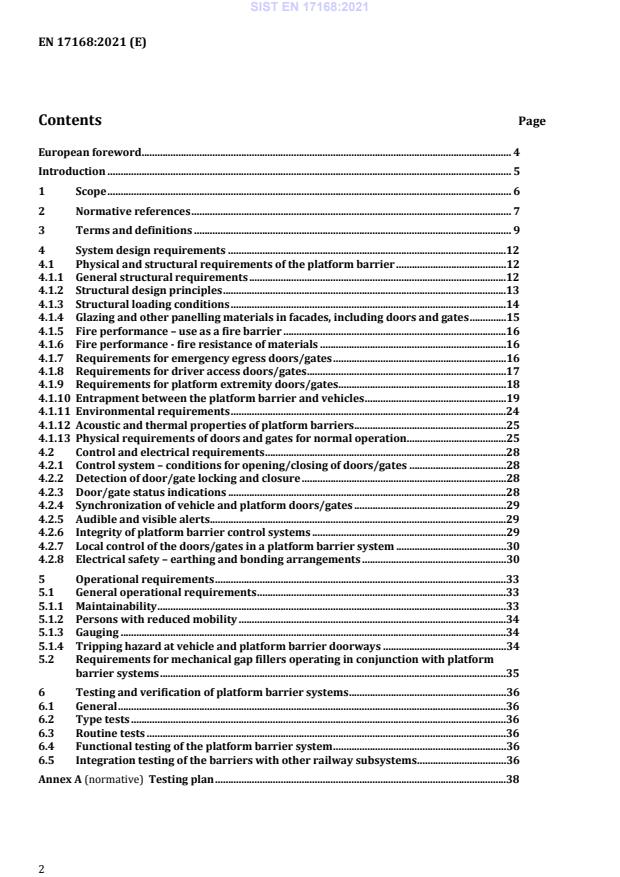

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 7

3 Terms and definitions . 9

4 System design requirements .12

4.1 Physical and structural requirements of the platform barrier .12

4.1.1 General structural requirements .12

4.1.2 Structural design principles .13

4.1.3 Structural loading conditions .14

4.1.4 Glazing and other panelling materials in facades, including doors and gates .15

4.1.5 Fire performance – use as a fire barrier .16

4.1.6 Fire performance - fire resistance of materials .16

4.1.7 Requirements for emergency egress doors/gates .16

4.1.8 Requirements for driver access doors/gates .17

4.1.9 Requirements for platform extremity doors/gates .18

4.1.10 Entrapment between the platform barrier and vehicles .19

4.1.11 Environmental requirements .24

4.1.12 Acoustic and thermal properties of platform barriers .25

4.1.13 Physical requirements of doors and gates for normal operation.25

4.2 Control and electrical requirements .28

4.2.1 Control system – conditions for opening/closing of doors/gates .28

4.2.2 Detection of door/gate locking and closure .28

4.2.3 Door/gate status indications .28

4.2.4 Synchronization of vehicle and platform doors/gates .29

4.2.5 Audible and visible alerts.29

4.2.6 Integrity of platform barrier control systems .29

4.2.7 Local control of the doors/gates in a platform barrier system .30

4.2.8 Electrical safety – earthing and bonding arrangements .30

5 Operational requirements .33

5.1 General operational requirements .33

5.1.1 Maintainability .33

5.1.2 Persons with reduced mobility .34

5.1.3 Gauging .34

5.1.4 Tripping hazard at vehicle and platform barrier doorways .34

5.2 Requirements for mechanical gap fillers operating in conjunction with platform

barrier systems .35

6 Testing and verification of platform barrier systems .36

6.1 General .36

6.2 Type tests .36

6.3 Routine tests .36

6.4 Functional testing of the platform barrier system .36

6.5 Integration testing of the barriers with other railway subsystems .36

Annex A (normative) Testing plan .38

Annex B (informative) Guidance on structural design . 40

Annex C (informative) Principles for earthing and bonding strategies . 46

C.1 Factors for consideration . 46

C.2 Principle A — The platform barrier system is bonded to station earth . 46

C.3 Principle B — The platform barrier system is insulated from station earth and also

from the traction current return rail (i.e. floating) . 47

C.4 Principle C — The barrier system is bonded to the traction return rail and insulated

from station earth . 47

C.5 Principle D — The platform barrier is constructed of non-conductive materials . 50

Annex D (informative) System integration . 51

D.1 Purpose . 51

D.2 Responsibility . 51

D.3 Overall targets . 51

D.4 Specific considerations . 51

D.4.1 Integration with railway control systems and with train operation . 51

D.4.2 Control system – conditions for opening/closing of doors/gates . 51

D.4.3 Accuracy of stopping . 53

D.4.4 Alignment . 53

D.4.5 Visibility of platform-train interface . 53

D.4.6 Other physical considerations . 54

Annex E (informative) Guidance on aerodynamic loading from trains . 55

E.1 Introduction . 55

E.2 Technical basis and method . 55

E.3 Calculation of equivalent pressures . 56

Bibliography . 58

European foreword

This document (EN 17168:2021) has been prepared by Technical Committee CEN/TC 256 “Railway

Applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by January 2022, and conflicting national standards shall

be withdrawn at the latest by January 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

Platform barrier systems provide a movable barrier between trains and other guided transit vehicles,

and passengers waiting at stations and boarding points.

Platform barrier systems are used increasingly on metro and other rail networks to ensure the safety of

passengers on the station platform who are waiting to board vehicles. Such systems are also used on

“people-mover” guided systems for short-distance transits, for example at airports. Their use is

recommended by EN 62267 for any fully automated transit system.

In particular platform barrier systems can be used to control the risk of:

— incursion by passengers or other persons on the railway track (deliberate or accidental); and

— contact between passengers and moving vehicles.

These risks can be especially significant where there is the possibility of overcrowding on station

platforms at busy locations. Barriers may increase the safely useable space in the station for passengers

waiting and circulating on the platforms.

Platform barrier systems integrate the operation of the platform barrier doors and gates with opening

and closing of train doors and also assist in the management of station operations, to safely permit higher

speeds for trains entering and exiting the stations.

Barrier installations can also be part of a continuous partition between the running tracks and the station

areas for the purposes of:

— fire safety (including smoke management);

— tunnel and station ventilation (including reduction of the piston effect);

— trackside noise reduction; and

— passenger comfort at climate-controlled stations.

Additionally, the terminology used in connection with platform barrier systems, in particular to improve

the specification and understanding of safety requirements, should be standardized.

1 Scope

This document specifies requirements for the design, construction and operation of platform barrier

systems positioned at the edge of a station platform immediately adjacent to the rail or other guided

vehicles in stations and boarding points for passenger services. This document includes:

— requirements for the fixed structure and fixed parts along the platform;

— physical requirements for the movable doors and gates normally used by passengers;

— requirements for emergency doors;

— requirements for driver access doors;

— requirements for platform extremity doors; and

— requirements for the management of safety risks that are particular to barrier systems.

This document also gives requirements for the integration of barriers within the overall rail system,

including:

— synchronization of vehicle and platform barrier doors/gates;

— audible and visible alerts;

— integrity of control systems;

— testing of the barrier installation;

— operational performance; and

— requirements relating to other interfacing sub-systems, notably signalling and vehicles.

For barrier systems set back from the platform edge, which are used to control access to trains or for

crowd management, relevant sections of the document can be used as guidance.

This document applies to all persons involved in the implementation and system integration of a platform

barrier system, including infrastructure owners, designers, installers and operators.

This document does not cover barrier systems using bars, ropes, etc. or which operate in a vertical

direction.

This document applies to rail services, e.g. metro, tram systems and heavy rail services as requested by a

project specification. It applies to small systems, working in conjunction with a single vehicle, or with

larger systems working with a complete train.

This document applies to platform barrier systems used at sub-surface stations, enclosed surface stations

(e.g. those enclosed for the purposes of providing an air-conditioned environment for waiting

passengers), and those fully in the open-air.

This document does not cover normative requirements relating to fire performance or fire requirements

arising from use of platform barrier systems as fire barriers.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1090-2, Execution of steel structures and aluminium structures — Part 2: Technical requirements for

steel structures

EN 1090-3, Execution of steel structures and aluminium structures — Part 3: Technical requirements for

aluminium structures

EN 1125, Building hardware — Panic exit devices operated by a horizontal bar, for use on escape routes —

Requirements and test methods

EN 1990:2002, Eurocode — Basis of structural design

EN 1991-1-1:2002, Eurocode 1: Actions on structures — Part 1-1: General actions — Densities, self-weight,

imposed loads for buildings

EN 1991-1-4, Eurocode 1: Actions on structures — Part 1-4: General actions — Wind actions

EN 1993-1-1, Eurocode 3: Design of steel structures — Part 1-1: General rules and rules for buildings

EN 1993-1-9, Eurocode 3: Design of steel structures — Part 1-9: Fatigue

EN 1998-1, Eurocode 8: Design of structures for earthquake resistance — Part 1: General rules, seismic

actions and rules for buildings

EN 1999-1-1, Eurocode 9: Design of aluminium structures — Part 1-1: General structural rules

EN 1999-1-3, Eurocode 9: Design of aluminium structures — Part 1-3: Structures susceptible to fatigue

EN ISO 12543-1, Glass in building — Laminated glass and laminated safety glass — Part 1: Definitions and

description of component parts (ISO 12543-1)

EN 12600, Glass in building — Pendulum test — Impact test method and classification for flat glass

EN 13272-1, Railway applications — Electrical lighting for rolling stock in public transport systems — Part

1: Heavy rail

EN 13272-2, Railway applications — Electrical lighting for rolling stock in public transport systems — Part

2: Urban rail

EN 13501-1, Fire classification of construction products and building elements — Part 1: Classification

using data from reaction to fire tests

EN 13501-2, Fire classification of construction products and building elements — Part 2: Classification

using data from fire resistance tests, excluding ventilation services

EN 13501-6, Fire classification of construction products and building elements — Part 6: Classification

using data from reaction to fire tests on power, control and communication cables

EN 14752:2019, Railway applications — Body side entrance systems for rolling stock

EN 16584-1, Railway applications — Design for PRM use — General requirements — Part 1: Contrast

EN 16584-3, Railway applications — Design for PRM use — General requirements — Part 3: Optical and

friction characteristics

EN 50121-4, Railway applications — Electromagnetic compatibility — Part 4: Emission and immunity of

the signalling and telecommunications apparatus

EN 50122-1:2011, Railway applications — Fixed installations — Electrical safety, earthing and the return

circuit — Part 1: Protective provisions against electric shock

EN 50122-2, Railway applications — Fixed installations — Electrical safety, earthing and the return circuit

- Part 2: Provisions against the effects of stray currents caused by d.c. traction systems

EN 50126 (all parts), Railway applications — The specification and demonstration of Reliability,

Availability, Maintainability and Safety (RAMS)

EN 50128, Railway applications — Communication, signalling and processing systems — Software for

railway control and protection systems

EN 50129, Railway applications — Communication, signalling and processing systems — Safety related

electronic systems for signalling

EN 50162, Protection against corrosion by stray current from direct current systems

HD 60364-4-41, Low-voltage electrical installations — Part 4-41: Protection for safety — Protection

against electric shock

HD 60364-5-54, Low-voltage electrical installations — Part 5-54: Selection and erection of electrical

equipment — Earthing arrangements and protective conductors

HD 60364-6, Low-voltage electrical installations — Part 6: Verification

EN 60529, Degrees of protection provided by enclosures (IP Code)

EN 61000-6-2, Electromagnetic compatibility (EMC) — Part 6-2: Generic standards — Immunity for

industrial environments

EN 61000-6-4, Electromagnetic compatibility (EMC) — Part 6-4: Generic standards — Emission standard

for industrial environments

EN 61140, Protection against electric shock — Common aspects for installation and equipment

EN 62061, Safety of machinery — Functional safety of safety-related electrical, electronic and

programmable electronic control systems

EN 62290-2:2014, Railway applications — Urban guided transport management and command/control

systems — Part 2: Functional requirements specification

EN 62305-1, Protection against lightning — Part 1: General principles

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• ISO Online browsing platform: available at https://www.iso.org/obp

• IEC Electropedia: available at https://www.electropedia.org/

3.1

correct alignment

correct position of the doors of the vehicle relative to the corresponding platform barrier doors/gates, to

permit safe and efficient transfer of passengers between vehicles and platform

3.2

doorway

section of a platform barrier through which passengers can board or alight from vehicles when platform

doors/gates are open

3.3

driver access door/gate

openable panel in a platform door or gate system designed to align with the driving cab door of a train

stopped at the station or boarding point

Note 1 to entry: Such panels (if provided) can open with a hinged or sliding action.

3.4

emergency egress device

operating element for manual opening from the trackside, in case of emergency, of any type of platform

door or gate

3.5

emergency egress door/gate

panel in a platform door or gate system which can be opened in an emergency, or if the vehicle(s) are not

in correct alignment with the platform doors/gates

Note 1 to entry: Emergency egress doors/gates can be of any design - hinged/sliding/push-out, etc.

3.6

entrapment

trapping of a person between the vehicle bodyside and the platform barrier after the vehicle and platform

doors/gates have been closed

3.7

façade

complete framework and panels (fixed and moving) of the platform barrier

3.8

finished floor level

level of the platform floor when all surface finishes (e.g. tiles, screed, threshold) have been applied

3.9

glazing

glass or equivalent transparent material fixed in frames as part of a platform barrier system

3.10

leading edge

vertical edge of a door or gate, leading during closing movement

3.11

local control panel

centralized control panel adjacent to or in the vicinity of the platform barrier which enables opening and

closing of a complete set of doors/gates in a barrier system by operations staff

3.12

mechanical gap filler

movable device mounted at the platform edge, at a platform door or gate, fully automatic and

actuated/controlled in conjunction with the barrier system opening/closing sequences

Note 1 to entry: The purpose of a mechanical gap filler is to reduce the horizontal stepping distance to a vehicle

to acceptable limits, or to facilitate access to a vehicle by persons with reduced mobility. Its structural integrity does

not rely on support from the vehicle.

3.13

operations staff

persons including train crew and station personnel authorized to perform tasks concerning train

operation or direct service to passengers

3.14

passive gap filler

strips, of frangible or partly flexible material at a doorway threshold such that the clearance between a

moving vehicle and the threshold can be safely reduced below that normally specified for gauge clearance

between infrastructure and vehicles

3.15

person with reduced mobility (PRM)

person whose mobility when using transport is reduced due to any physical disability (sensory or

locomotory, permanent or temporary), intellectual disability or impairment, or any other cause of

disability, or as a result of age, and whose situation needs appropriate attention and adaptation to his or

her particular needs of the service made available to all passengers

[SOURCE: EU Directive 2007/1371/EC]

Note 1 to entry: this population covers as well persons of small stature, elderly ones, pregnant women, persons

carrying heavy luggage or accompanied by children (including children in strollers).

3.16

platform

section of pathway, alongside tracks at a railway, metro or other guided transit system station at which

passengers can board or alight from vehicles

3.17

platform barrier system (PBS)

system providing a protective barrier between vehicle and platform, having power operated movable

panels with associated drive and control equipment, such panels moving horizontally and parallel with

edge of the platform, allowing passenger transfer through the barrier when a train is positioned at the

platform

3.18

platform door

movable panel or panels and forming part of a platform door system through which passengers normally

access and egress vehicles

3.19

platform door system

platform barrier system in which the movable panels are carried on a portal structure having headers or

lintels above the moving panels, carrying all or part of their weight

Note 1 to entry: Such a system can form part of a structure completely enclosing the platform area and

separating it entirely from the track on which vehicles move.

3.20

platform extremity door/gate

panel at the extremity of a platform door or gate system (usually, but not necessarily, at right angles to

the main structure) to allow access by authorized persons to the track, or to a tunnel walkway beyond

the station, or as emergency egress for persons evacuating from the track area

Note 1 to entry: Such panels can open with a hinged or sliding action.

Note 2 to entry: Platform extremity door/gates may not form part of the platform barrier system.

3.21

platform gate

movable panel or panels forming part of a platform gate system through which passengers normally

access and egress vehicles

3.22

platform gate system

platform barrier system in which the movable panels are supported from the bottom, or by cantilever

arrangement at an intermediate height on the barrier

3.23

routine test

conformity test made on each individual item of equipment during or after manufacture

3.24

station

unit comprising buildings and structures containing technical equipment, loading or unloading areas or

platforms, and any associated areas for reception and shelter

3.25

synchronization of doors

co-ordinated movement of vehicle doors with platform doors/gates

3.26

system integration

process of assuring that the design, installation and operation of the barrier system is consistent with the

overall safety and operational targets of the complete rail system, of which the barrier system is part

Note 1 to entry: The activity of system integration is elaborated on in Annex D (informative).

3.27

train

single self-propelled rail vehicle or a self-propelled group of physically coupled rail vehicles

[SOURCE: EN 17343:2020]

3.28

type test

conformity test made of one or more system and its components representative of the production to

prove that the design meets the standard and the relevant specifications

3.29

user population

range of persons (including operations staff) expected to use a platform barrier system, defined in terms

of their physical characteristics

4 System design requirements

4.1 Physical and structural requirements of the platform barrier

4.1.1 General structural requirements

4.1.1.1 Platform barrier systems form a safety barrier separating customers/passengers from

moving trains until it is safe to grant access. As such they shall be designed to resist crowd loading.

Platform barriers are also subject to aerodynamic loads induced by trains passing the structure. Platform

barrier systems installed in open sections shall also resist wind loading. In addition, platform barrier

systems can be subject to pressures generated by tunnel ventilation systems and can be required to resist

earthquakes. These separate actions shall be combined in accordance with Structural Eurocodes

referenced in this standard.

4.1.1.2 Tunnel ventilation systems can be associated with platform barrier systems that completely

enclose the platform area, separating it from the track on which vehicles move. Detailed

modelling/simulation shall be undertaken during system integration and shall consider all operating and

degraded modes of operation of the ventilation system to determine their effect on the platform barrier

system and how they combine with the aerodynamic actions from trains. In particular, pressures

generated by operation of ventilation systems for smoke extraction or fire management shall not inhibit

operation of emergency doors in accordance with 4.1.7. The ventilation and aerodynamic loading values

from the modelling/simulation shall form an input to the specification for the platform barrier system.

4.1.1.3 Structural design shall take into account the requirements arising from the physical interface

with trains intended to operate in conjunction with the barrier system, in particular regarding

entrapment (4.1.10) and gauging (5.1.3).

4.1.1.4 General construction of platform barriers shall be in accordance with the Structural Eurocode

series. EN 1991-1-1 covers general actions and imposed loads. Imposed loads are defined by categories

of use in EN 1991-1-1:2002, Clause 6. This series of standards explicitly includes barriers on railway

platforms, in particular Category C5 which gives requirements for “Areas susceptible to large crowds, e.g.

in building for public events like concert hall, sports halls including stands, terraces and access areas and

railway platforms.”

4.1.1.5 The Structural Eurocode series of standards mandate the use of Ultimate and Serviceability

Limit States to ensure the safety of a structure in extreme conditions (e.g. storm-force winds for open-air

systems) and combinations of loads; however, normal operation of the platform doors/gates might not

be practicable under all such limit states. At least one Operational Limit State should be specified to reflect

normal operation of the barrier system. Further guidance is given in Annex B.

4.1.1.6 Deflection of the platform barrier system towards the track under any loading conditions

envisaged in this standard shall not exceed the limits defined by the gauging strategy for the platform

barrier system as described in 5.1.3. Plastic deformation may be permitted under Ultimate Limit State as

defined by the Eurocodes referenced in Annex B, subject to compliance with the gauging strategy.

4.1.1.7 Infill panels (i.e. glazing, or sheets of other materials, which separate the platform area from

the running tracks and are secured to the main structural framework of the barrier system) shall sustain

the applied loads.

It is recommended that, in addition, deflection of an infill panel that is structurally safe should not alarm

station users through large visible deformations relative to the frame in which the panel is mounted,

when subject to normal service conditions. Therefore, for serviceability considerations, the limiting

condition for deflection should be that the total horizontal displacement of the infill panel relative to the

frame at any point from its original unloaded position does not exceed the deflection limits determined

from the relevant structural design code (where applicable) for the material used, or 25 mm, whichever

is the smaller.

4.1.1.8 The calculations used in structural design shall be validated by load testing of a

representative structure.

NOTE This standard covers the requirements for the platform barrier system. It does not specify

requirements for the platforms, or other foundations and structures to which the platform barrier system

is secured. Design and construction of platforms, foundations or other structures are covered by other

appropriate structural Eurocode documents. However, the load cases considered in such designs are

consistent with those adopted for the design of the platform barrier system.

4.1.2 Structural design principles

4.1.2.1 Designs shall be in accordance with the requirements of EN 1990.

4.1.2.2 Where steel is used, structural design shall be in accordance with EN 1993-1-1.

4.1.2.3 Where aluminium is used, structural design shall be in accordance with EN 1999-1-1.

4.1.2.4 In the event that structural materials other than steel or aluminium are used, performance of

the design shall be demonstrated to be equivalent with the performance requirements of Eurocodes

category C5 as defined in 4.1.1.4.

4.1.2.5 Where required by the relevant National Annex to EN 1998-1 regarding design of structures

for earthquake resistance, the provisions of EN 1998-1 shall be applied in addition to the provisions of

the other relevant Eurocodes.

4.1.2.6 Where glass is used the thickness of the glazing material may be calculated using validated

mathematical analysis. Alternatively, thickness may be determined using empirical national codes.

Use of empirical codes can result in conservative design and increased weight. Calculated methods are

recommended where possible.

4.1.3 Structural loading conditions

4.1.3.1 Crowd loading

4.1.3.1.1 Design for horizontal crowd loading shall be in accordance with EN 1991-1-1:2002, 6.4. The

characteristic value for the line load q as defined in the standard shall be selected from the range for

k

Category C5 from Table 6.12.

4.1.3.1.2 The design value for crowd loading shall correspond to the minimum value defined in

EN 1991-1-1:2002 category C5 from Table 6.12. A higher value shall only be considered when a site-

specific risk assessment confirms a greater value is required. The structural design should not be

specified beyond what is essential in foreseeable conditions. “Over-design” may result in increased

volume and mass of moving and other parts with disadvantages for gauging and for safe and efficient

motion of doors and gates.

4.1.3.2 Aerodynamic loading from trains

4.1.3.2.1 Aerodynamic loads arising from the movement of trains alongside platform barrier systems

that completely enclose the platform area shall be considered in the structural design of the barrier. In

such a case the platform area is completely separated from the track on which vehicles move (e.g. where

separation is designed to support operation of a tunnel ventilation system, or climate control of the

station). Such systems shall be fully analysed in accordance with the requirements of 4.1.1.2.

4.1.3.2.2 Aerodynamic loads arising from the movement of trains alongside platform barrier systems

that do not fully enclose the platform area shall be considered in the structural design of the barrier. In

such cases design loads may be calculated in accordance with the methodology in Annex E or be based

on empirical measurement of comparable train and barrier combinations.

4.1.3.2.3 When assessing the mechanical and fatigue strength requirements of the barrier structure,

the aerodynamic actions can be assumed to be of an equivalent amplitude at the front and back of the

train and, in the case of coupled train units, also at the inter-unit coupler. This amplitude shall be taken

to be the largest of the actions generated during the complete time of passing of the train.

4.1.3.2.4 Since aerodynamic loading occurs every time the train passes or moves alongside a barrier,

the loads calculated in accordance with 4.1.3.2.1 or 4.1.3.2.2 shall be considered as fatigue loads.

4.1.3.2.5 Wind loading shall be considered in accordance with EN 1991-1-4 (including associated

National Annexes).

4.1.3.3 Fatigue

4.1.3.3.1 Structural fatigue performance shall satisfy the required safety and performance for the

design life of the installation. In particular, design against structural fatigue failure for steel and

aluminium elements shall be assessed in accordance with the following standards (including their

associated National Annexes):

— EN 1993-1-9, Eurocode 3 — Design of steel structures - Part 1-9: Fatigue (for steel); and

— EN 1999-1-3, Eurocode 9 —Design of aluminium structures – Part 1-3: Structures susceptible to fatigue

(for aluminium).

4.1.3.3.2 The fatigue effects of aerodynamic loading from passing trains shall be considered for all

platform barrier systems. The fatigue spectrum should not be specified beyond what is essential in

foreseeable conditions. “Over-design” can result in increased volume and mass of moving and other parts

with disadvantages for gauging and for safe and efficient motion of doors and gates.

4.1.3.3.3 If relevant, the fatigue effects of wind loading shall be considered for platform barrier systems

installed in open-air sections, taking account of established meteorological conditions as determined in

compliance with 4.1.11.1.

4.1.3.3.4 Crowd loading shall not be considered to be cyclical for the purposes of assessing the fatigue

life of the platform barrier system.

4.1.4 Glazing and other panelling materials in facades, including doors and gates

4.1.4.1 General principle

There is no normative requirement to make doors and gates, or the fixed part of the façades, fully or

partly transparent, but where glazing materials are used, the requirements of 4.1.4.2 shall be applied.

Where partial transparency is achieved through use of mesh or perforated material the requirements of

4.1.4.3 shall be applied.

4.1.4.2 Requirements for glazing materials

4.1.4.2.1 Where glass is used as a panelling material, it shall be of a type that does not fracture in a way

that creates hazard to passengers.

4.1.4.2.2 The glazing shall not readily fail in a way that creates an aperture in the barrier that

passengers can reach through and be exposed to hazards from moving trains.

4.1.4.2.3 Where laminated glass is used it shall be in accordance with EN ISO 12543-1.

4.1.4.2.4 Glazing used shall achieve level 1-B-1 in accordance with the quantification tests given in

EN 12600. The test described in EN 12600 is primarily designed for laminated glass, however, where

other types of glass are used they shall achieve an equivalent level of safety in respect of the requirements

in 4.1.4.2.1 and 4.1.4.2.2.

4.1.4.2.5 Alternative glazing materials shall as a minimum fulfil the same requirements as glass in

respect of impact resistance, and shall meet the general requirements for penetration, deflection under

load, and fire and smoke performance defined in the relevant sections in this standard, in particular 4.1.1

and 4.1.6.

4.1.4.2.6 Where glazing is fully transparent and extends to the full height of the doorway, strips or

patterns of non-transparent material or finish shall be added to the glazing to reduce the possibility of

accidental contact by passengers.

4.1.4.3 Mesh, perforated and other materials

4.1.4.3.1 Where panels made from mesh or perforated material are used the edges of the meshes or

perforations shall not have sharp edges or projections likely to cause injury.

4.1.4.3.2 It shall not be possible for any person from the user population to pass any part of their body

through the mesh or perforation of a panel such that they might be injured by opening or closing of a

door/gate, or by the movement of a train. This shall be achieved by ensuring that the degree of protection

corresponds to level IP3x of EN 60529.

4.1.4.3.3 Mesh or perforated panels shall meet the general requirements relating to fire and smoke

performance, deflection under load and impact resistance defined in the relevant sections in this

standard, in particular 4.1.1 and 4.1.6.

4.1.4.3.4 Mesh or perforated materials shall not be used for moving panels because of the increased

risk of finger trapping or of clothing etc. being drawn into door/or gate systems.

4.1.4.3.5 Any other materials used as panelling in any part of the façade shall meet the general

requirements relating to fire and smoke performance and deflection under load, defined in the relevant

sections in this standard in particular 4.1.1 and 4.1.6. The materials shall also meet the intent of

requirements of 4.1.4.2.1 and 4.1.4.2.2 regarding fracture and response to impact.

4.1.5 Fire performance – use as a fire barrier

Full height platform barriers at sub-surface or enclosed stations may be used as a direct fire barrier, to

minimize the spread of flame and/or smoke in the event of a fire on either side of the barrier, or simply

to segregate ventilation in the station and track areas. If a platform barrier system is intended to be used

as a fire barrier, requirements of this standard are still applicable, but in that case such a barrier shall

also conform to additional and relevant fire standards for buildings or national rules outside the scope of

this standard.

4.1.6 Fire performance - fire resistance of materials

4.1.6.1 Materials used shall have fire resistance properties in accordance with national rules and

European and national building codes. Components shall be defined and selected in accordance with the

requirements of EN 13501-1, EN 13501-2 and EN 13501-6. It is the responsibility of the entity in charge

of system integration to ensure that the fire performance of materials used, and fire scenarios considered

in the design, are appropriate to the context and location in which the barrier system is installed.

NOTE There might be specific national and European rules for materials used in underground and tunnel

environments (including, where the station falls within its scope, the Safety in Rail Tunnels Technical Specification

for Interoperability).

4.1.6.2 The material used in the interlayer of laminated glass shall not be considered as contributing

to a fire load unless specifically required by local regulations, provided that the laminated glass is fully

com

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...