SIST EN 14336:2025

(Main)Heating systems in buildings - Installation and commissioning of water based heating systems

Heating systems in buildings - Installation and commissioning of water based heating systems

This document specifies the requirements for the installation and commissioning of water-based heating, water-based cooling, and heating of domestic hot water (DHW) systems in buildings with a maximum operating temperature of 105 °C.

This document is applicable to the commissioning of systems as a whole, in cases of new systems, renovations and replacement of equipment.

This document does not apply to superheated water systems or steam systems and it does not apply to the specific commissioning requirements for individual components (e.g. how to set fuel/air ratio on a burner). Also, it does not apply to the installation or commissioning of attached systems (e.g. air conditioning, domestic hot water distribution, ventilation systems).

This document specifies only technical requirements but it does not specify any commercial or contractual arrangements between parties.

Heizungsanlagen in Gebäuden - Installation und Abnahme der Warmwasser - Heizungsanlagen

Dieses Dokument legt die Anforderungen an die Installation und Abnahme wassergeführter Heizungs- und wassergeführter Kühlanlagen sowie häuslicher Anlagen zur Erwärmung von Warmwasser (DHW) in Gebäuden mit einer maximalen Betriebstemperatur von 105 °C fest.

Dieses Dokument ist auf die Abnahme von Anlagen als Ganzes bei neuen Anlagen, Renovierungen und Austausch der Geräte anwendbar.

Dieses Dokument gilt nicht für Heißwasser- oder Heißdampfsysteme und es gilt nicht für die spezifischen Abnahmeanforderungen für einzelne Komponenten (z. B. Einstellen des Brennstoff-Luft-Verhältnisses an einem Brenner). Außerdem gilt es nicht für die Installation und die Abnahme von zugeschalteten Anlagen (z. B. Klimaanlagen, Hauswasseranlagen, Verteileranlagen, Lüftungsanlagen).

Dieses Dokument legt nur die technischen Voraussetzungen fest, aber nicht das vertragliche Verhältnis zwischen Auftraggeber und Auftragnehmer (Planer und Ausführenden).

Systèmes de chauffage dans les bâtiments - Installation et commissionnement des systèmes de chauffage à eau

Le présent document spécifie les exigences relatives à l’installation et au commissionnement des systèmes de chauffage à eau, des systèmes de refroidissement à eau, et des systèmes de production d’eau chaude sanitaire des bâtiments fonctionnant avec une température maximale de 105 °C.

Le présent document s'applique au commissionnement des systèmes dans son ensemble, en cas d'installation de nouveaux systèmes, de rénovations et de remplacement d'un équipement.

Ce document ne s'applique pas aux systèmes d'eau surchauffée ou aux systèmes de chauffage à la vapeur, ni aux exigences spécifiques de commissionnement des composants individuels (par exemple, comment régler le rapport combustible/air sur un brûleur). De plus, il ne s'applique pas en cas d'installation ou de commissionnement des systèmes connexes (par exemple, systèmes de conditionnement d’air, de production d’eau chaude sanitaire, de ventilation).

Le présent document spécifie uniquement les spécifications techniques, mais il ne spécifie pas les accords contractuels ou commerciaux entre les parties.

Ogrevalni sistemi v stavbah - Vgradnja in zagon toplovodnih sistemov

Ta dokument določa zahteve za vgradnjo in zagon sistemov za ogrevanje in hlajenje z vodo ter ogrevanje tople sanitarne vode (DHW) v stavbah z najvišjo obratovalno temperaturo 105 °C. Uporablja se za zagon sistemov kot celote, v primeru novih sistemov, prenov in zamenjave opreme. Ta dokument se ne uporablja za sisteme za pregreto vodo ali paro niti za posebne zahteve glede zagona posameznih komponent (npr. kako nastaviti razmerje gorivo/zrak na gorilniku). Prav tako se ne uporablja za vgradnjo ali zagon priključenih sistemov (npr. klimatske naprave, distribucija tople sanitarne vode, prezračevalni sistemi). Ta dokument določa le tehnične zahteve; ne določa nobenih komercialnih ali pogodbenih dogovorov med strankami.

General Information

- Status

- Published

- Public Enquiry End Date

- 19-Jun-2024

- Publication Date

- 10-Jun-2025

- Technical Committee

- OGS - Heating for buildings

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 11-Jun-2025

- Due Date

- 16-Aug-2025

- Completion Date

- 11-Jun-2025

Relations

- Effective Date

- 01-Jul-2025

Overview

SIST EN 14336:2025 - Heating systems in buildings - Installation and commissioning of water‑based heating systems - is the updated European standard that sets technical requirements for the installation and commissioning of water‑based heating, water‑based cooling and domestic hot water (DHW) heating systems in buildings. It applies to new installations, renovations and equipment replacement for systems with a maximum operating temperature of 105 °C. The standard does not cover superheated water or steam systems, nor specific component commissioning steps (e.g. burner fuel/air settings), and it excludes attached systems such as air conditioning, DHW distribution and ventilation.

Key technical topics and requirements

The standard organizes practical, technical activities for reliable commissioning and includes (but is not limited to):

- Installation preparation and site inspection

- Documentation, site preparation, incoming goods checks and storage/handling of materials.

- Pre‑functional checks

- General equipment and electrical checks before commissioning.

- Pressure testing and tightness

- Hydraulic, pneumatic and leak tests plus load testing procedures.

- System cleaning and flushing

- Simple and dynamic flushing, mechanical and chemical cleaning options and reporting.

- Filling, venting and frost precautions

- Procedures for safe system filling, air removal and protective measures.

- Balancing water flow rates

- Methods and procedures to achieve correct flow distribution through the system.

- Functional testing and sequence verification

- Device settings, control/monitoring verification and validation of sequences of operation.

- Handover and documentation

- Required operation, maintenance and handover documentation for building owners/operators.

The standard includes informative annexes with sample checklists, test reports and practical guidance for pumps, boilers, heat pumps, fan‑coil units, valves and more.

Practical applications and users

SIST EN 14336:2025 is intended for professionals responsible for the safe and efficient delivery of water‑based heating and cooling systems:

- HVAC installers and commissioning engineers

- Mechanical contractors and site supervisors

- System designers and consulting engineers

- Facility managers and building owners

- Inspectors and regulatory authorities

Use the standard to ensure consistent, verifiable commissioning and to produce the commissioning records required for handover, maintenance planning and energy performance verification.

Related standards and context

- Supersedes earlier editions of EN 14336 (previous national/adopted versions).

- Contains normative references to other European and national standards (see document for details).

Keywords: SIST EN 14336:2025, EN 14336, heating systems in buildings, installation and commissioning, water‑based heating, system commissioning, HVAC balancing, pressure test, system cleaning.

Frequently Asked Questions

SIST EN 14336:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Heating systems in buildings - Installation and commissioning of water based heating systems". This standard covers: This document specifies the requirements for the installation and commissioning of water-based heating, water-based cooling, and heating of domestic hot water (DHW) systems in buildings with a maximum operating temperature of 105 °C. This document is applicable to the commissioning of systems as a whole, in cases of new systems, renovations and replacement of equipment. This document does not apply to superheated water systems or steam systems and it does not apply to the specific commissioning requirements for individual components (e.g. how to set fuel/air ratio on a burner). Also, it does not apply to the installation or commissioning of attached systems (e.g. air conditioning, domestic hot water distribution, ventilation systems). This document specifies only technical requirements but it does not specify any commercial or contractual arrangements between parties.

This document specifies the requirements for the installation and commissioning of water-based heating, water-based cooling, and heating of domestic hot water (DHW) systems in buildings with a maximum operating temperature of 105 °C. This document is applicable to the commissioning of systems as a whole, in cases of new systems, renovations and replacement of equipment. This document does not apply to superheated water systems or steam systems and it does not apply to the specific commissioning requirements for individual components (e.g. how to set fuel/air ratio on a burner). Also, it does not apply to the installation or commissioning of attached systems (e.g. air conditioning, domestic hot water distribution, ventilation systems). This document specifies only technical requirements but it does not specify any commercial or contractual arrangements between parties.

SIST EN 14336:2025 is classified under the following ICS (International Classification for Standards) categories: 91.140.10 - Central heating systems. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14336:2025 has the following relationships with other standards: It is inter standard links to SIST EN 14336:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14336:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2025

Nadomešča:

SIST EN 14336:2005

Ogrevalni sistemi v stavbah - Vgradnja in zagon toplovodnih sistemov

Heating systems in buildings - Installation and commissioning of water based heating

systems

Heizungsanlagen in Gebäuden - Installation und Abnahme der Warmwasser -

Heizungsanlagen

Systèmes de chauffage dans les bâtiments - Installation et commissionnement des

systèmes de chauffage à eau

Ta slovenski standard je istoveten z: EN 14336:2025

ICS:

91.140.10 Sistemi centralnega Central heating systems

ogrevanja

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14336

EUROPEAN STANDARD

NORME EUROPÉENNE

June 2025

EUROPÄISCHE NORM

ICS 91.140.10 Supersedes EN 14336:2004

English Version

Heating systems in buildings - Installation and

commissioning of water based heating and cooling

systems

Systèmes de chauffage dans les bâtiments - Installation Heizungsanlagen in Gebäuden - Installation und

et commissionnement des systèmes de chauffage à eau Abnahme der Warmwasser-Heizungsanlagen

This European Standard was approved by CEN on 21 April 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14336:2025 E

worldwide for CEN national Members.

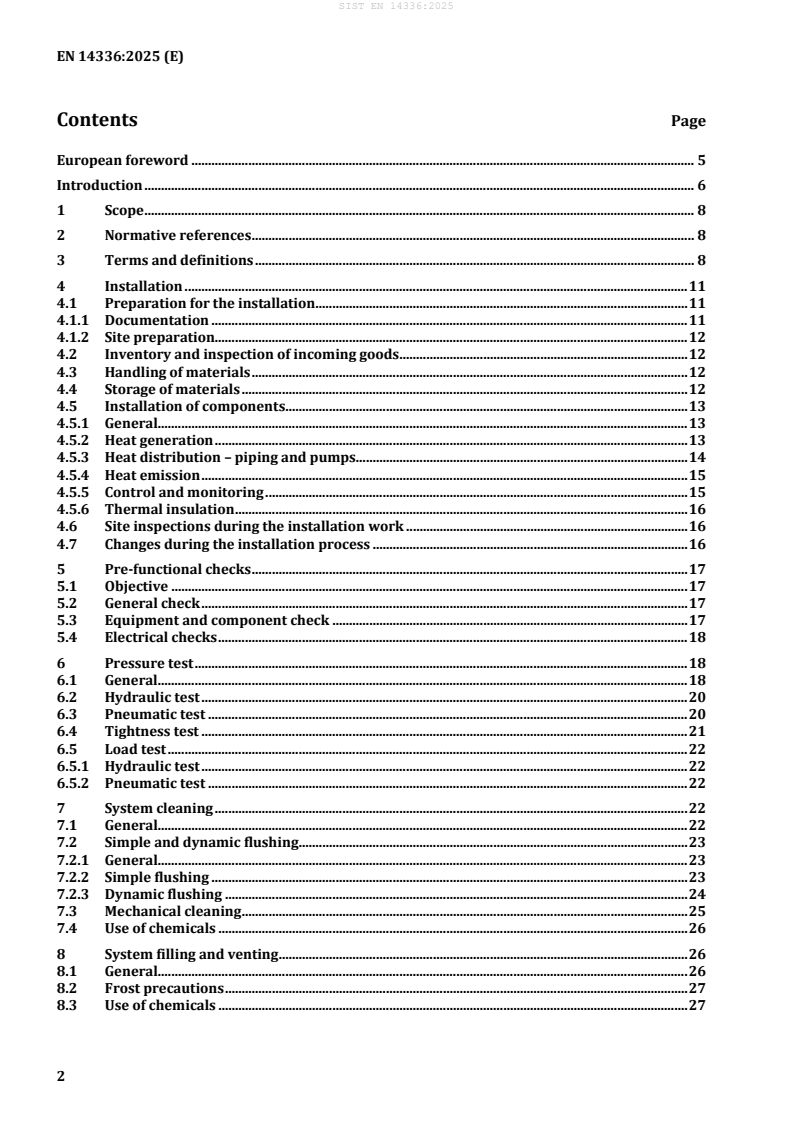

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 8

4 Installation . 11

4.1 Preparation for the installation . 11

4.1.1 Documentation . 11

4.1.2 Site preparation. 12

4.2 Inventory and inspection of incoming goods . 12

4.3 Handling of materials . 12

4.4 Storage of materials . 12

4.5 Installation of components . 13

4.5.1 General. 13

4.5.2 Heat generation . 13

4.5.3 Heat distribution – piping and pumps . 14

4.5.4 Heat emission . 15

4.5.5 Control and monitoring . 15

4.5.6 Thermal insulation . 16

4.6 Site inspections during the installation work . 16

4.7 Changes during the installation process . 16

5 Pre-functional checks . 17

5.1 Objective . 17

5.2 General check . 17

5.3 Equipment and component check . 17

5.4 Electrical checks . 18

6 Pressure test . 18

6.1 General. 18

6.2 Hydraulic test . 20

6.3 Pneumatic test . 20

6.4 Tightness test . 21

6.5 Load test . 22

6.5.1 Hydraulic test . 22

6.5.2 Pneumatic test . 22

7 System cleaning . 22

7.1 General. 22

7.2 Simple and dynamic flushing . 23

7.2.1 General. 23

7.2.2 Simple flushing . 23

7.2.3 Dynamic flushing . 24

7.3 Mechanical cleaning . 25

7.4 Use of chemicals . 26

8 System filling and venting . 26

8.1 General. 26

8.2 Frost precautions . 27

8.3 Use of chemicals . 27

8.4 Filling report . 27

9 Balancing water flow rates . 28

10 Functional testing . 29

10.1 General . 29

10.2 Testing and settings of individual devices . 29

10.3 Testing the sequences of operation . 29

11 Handover . 30

11.1 Objective . 30

11.2 Documents for operation, maintenance and use . 30

11.3 Instructions on operation and use . 30

11.4 Hand over documentation . 30

Annex A (informative) List of test and control activities . 32

A.1 General . 32

A.2 Contents of the list . 32

A.3 Sample list of test and control activities . 34

Annex B (informative) Installation site inspection . 35

B.1 General . 35

B.2 Installation site inspection report . 35

B.3 Sample site inspection report . 36

Annex C (informative) PRE-COMMISSIONING CHECKS . 37

C.1 General . 37

C.2 Equipment and major components check-lists . 37

C.2.1 Pump . 37

C.2.2 Boiler . 38

C.2.3 Heat pump . 40

C.2.4 Fan-coil unit . 41

C.2.5 Control valves . 42

C.3 Electrical checks . 43

Annex D (informative) Pressure testing . 46

D.1 General . 46

D.2 Sample pressure test report . 46

Annex E (informative) System cleaning . 49

E.1 General . 49

E.2 Procedures . 49

E.2.1 Flushing . 49

E.2.2 Chemical cleaning . 51

E.2.3 Sample cleaning report . 52

Annex F (informative) Filling and venting . 54

F.1 General information . 54

F.2 Sample filling report . 54

Annex G (informative) Balancing of water flow rates . 56

G.1 General. 56

G.2 Simple setting . 56

G.2.1 Concept . 56

G.2.2 Sample specification and report . 57

G.3 Balancing with manual balancing valves and flow measurement . 58

G.3.1 General. 58

G.3.2 The iterative method . 59

G.3.3 The proportional method . 59

G.3.4 The compensated method . 59

G.3.5 Computer aided balancing method . 60

G.4 Balancing with flow measurement and self-acting balancing valves . 60

G.4.1 Differential pressure controller . 60

G.4.2 Flow limiter . 60

G.5 Balancing by temperature measurements . 60

G.5.1 General. 60

G.5.2 Concept . 61

G.5.3 Method . 61

G.6 Flow accuracy . 61

G.7 Balancing report. 62

Annex H (informative) Functional testing . 64

H.1 General information . 64

H.2 Functional testing of individual appliances and controls . 64

H.3 Global check . 65

Annex I (informative) Sample hand-over checklist . 67

Bibliography . 68

European foreword

This document (EN 14336:2025) has been prepared by Technical Committee CEN/TC 228 “Heating

systems and water-based cooling systems in buildings”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by December 2025, and conflicting national standards shall

be withdrawn at the latest by December 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14336:2004.

In comparison with the previous edition EN 14336:2004, the following technical modifications have been

made:

— new technologies are covered;

— inclusion of new test procedures;

— editorial organization to facilitate the use of this document within a comprehensive commissioning

process.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

The subjects covered by CEN/TC 228 are the following:

— design of water-based heating and cooling systems;

— installation of heating systems;

— commissioning of heating systems;

— instructions for operation, maintenance and use of heating systems;

— methods for calculation of the design heat loss and heat loads;

— methods for calculation of the energy performance of heating systems.

Heating systems also include the effect of attached systems such as hot water production systems.

All these standards are systems standards, i.e. they are based on requirements addressed to the system

as a whole and not dealing with requirements to the products within the system.

Where possible, reference is made to other European or International Standards, such as product

standards. However, use of products complying with relevant product standards is no guarantee of

compliance with the system requirements.

The requirements are mainly expressed as functional requirements, i.e. requirements dealing with the

function of the system and not specifying shape, material, dimensions or the like.

The guidelines describe ways to meet the requirements, but other ways to fulfil the functional

requirements might be used if fulfilment can be proved.

Heating systems differ among the member countries due to climate, traditions and national regulations.

In some cases, requirements are given as classes so national or individual needs may be accommodated.

In cases where the standards contradict with national regulations, the latter should be followed.

Figure 1 illustrates the basic sequence of the installation and commissioning process.

Figure 1 — Installation and commissioning process

1 Scope

This document specifies the requirements for the installation and commissioning of water-based heating,

water-based cooling, and heating of domestic hot water (DHW) systems in buildings with a maximum

operating temperature of 105 °C.

This document is applicable to the commissioning of systems as a whole, in cases of new systems,

renovations and replacement of equipment.

This document does not apply to superheated water systems or steam systems and it does not apply to

the specific commissioning requirements for individual components (e.g. how to set fuel/air ratio on a

burner). Also, it does not apply to the installation or commissioning of attached systems (e.g. air

conditioning, domestic hot water distribution, ventilation systems).

This document specifies only technical requirements but it does not specify any commercial or

contractual arrangements between parties.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12170, Heating systems in buildings — Procedure for the preparation of documents for operation,

maintenance and use — Heating systems requiring a trained operator

EN 12171, Heating systems in buildings — Procedure for the preparation of documents for operation,

maintenance and use — Heating systems not requiring a trained operator

EN 61082-1, Preparation of documents used in electrotechnology — Part 1: Rules (IEC 61082-1)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

installer

party performing the installation process

3.2

client

party for whom the installation process is performed

Note 1 to entry: In some contexts, the client may be represented by a professional during the installation and

commissioning process.

3.3

commissioning

advancement of an installation from the stage when the mechanical and electrical installation work is

complete to a confirmed operation-ready state according to specified requirements

Note 1 to entry: The word “commissioning” is used here to identify the activities of checking, testing and setting to

work the installed systems prior to hand-over. This is only a part of the comprehensive “commissioning process” as

defined in Ashrae 202 standard.

3.4

hydraulic balancing

process of adjusting flow rates throughout the system to obtain the required flow rates under design

conditions

3.5

contaminant

undesired substance or particle which is present inside a water-based system

Note 1 to entry: Example of contaminants are welding scale, slag, cuttings, metal oxide particles, cutting oil

residues, dirt.

3.6

flushing

washing out of a piping system to remove contaminants

3.7

mechanical cleaning

process of pipe cleaning and removal of dirt and debris by forcing a device called a pig or scraper through

the pipeline

3.8

heat distribution system

configuration of interconnected components for the transport of heat from the heat generation system to

the heat emission system or any attached system

3.9

heat emission system

configuration of interconnected components for the dispersal of heat to a heated space

3.10

heat generation system

configuration of interconnected components/appliances for the supply of heat to the heat distribution

system

3.11

cooling generation system

configuration of interconnected components/appliances for the extraction of heat from the cooling

distribution system

3.12

maintenance

combination of all technical, administrative and managing actions necessary to retain an item in, or

restore it to, a state in which it can perform an intended function

[SOURCE: EN 12170 and EN 12171]

3.13

maximum operating pressure

maximum pressure at which the system, or parts of the system, is designed to operate

3.14

maximum operating temperature

maximum temperature at which the system, or parts of the system, is designed to operate

3.15

P&ID

piping and instrumentation diagram

3.16

OM&U

operation, maintenance and use

[SOURCE: EN 12170 and EN 12171]

3.17

operation

those actions necessary to make available the services, which the system has been designed to provide

[SOURCE: EN 12170 and EN 12171]

3.18

setting to work

process of setting a static system into operation

3.19

use

action of receiving the services, which the system has been designed to provide

[SOURCE: EN 12170 and EN 12171]

3.20

shop drawing

drawing or diagram prepared to be used during on-site installation activities

3.21

pressure test

combination of tightness and load test

3.22

tightness test

test performed to ensure that there are no leaks in a hydraulic system

Note 1 to entry: Tightness test is normally performed at lower pressure than load test.

3.23

load test

test performed to ensure that the system can withstand the designed fluid pressure and that is has the

required strength reliability under operating conditions

4 Installation

4.1 Preparation for the installation

4.1.1 Documentation

The installation activities can begin only after the design has been approved for execution and the

following documentation and/or information has been prepared and handed over for installation:

a) equipment and component specifications;

b) design specification including:

— functional diagrams;

— installation layout;

— installation details;

— materials to be used or not used (avoided);

— design flow rates and all other information needed for testing and balancing (hydraulic

balancing);

— specification of filling water;

NOTE Additional information can be found in EN 12828, EN 17671 and applicable regulations.

Some documents may be available later in the installation process.

c) a coordinated time schedule of the work, specifying priorities and relationship between installation

items, where appropriate (e.g. any timing to be respected between installation works);

d) a list of critical materials / equipment to be checked and / or approved upon delivery (see 4.2 –

incoming goods);

e) an agreed procedure or instructions to handle changes;

f) a list of test and control activities to be performed during the installation and commissioning process,

which include:

— anticipated tests to be performed during the installation process (e.g. any pressure testing of

concealed pipes before covering them);

— required pre-commissioning checks;

— required documented actions, installation site inspections, verifications and testing, such as

pressure test, cleaning, filling, balancing, etc.

Concerning item f), the client and the installer(s) shall agree the required reports to be provided during

the installation process.

Additional information and an example of a list according to item f) are given in informative Annex A.

The completed test reports and forms for the listed test and control activities shall be annexed to the

OM&U instructions.

4.1.2 Site preparation

It shall be ensured that:

— the site is available and accessible for installation;

— handling facilities are provided;

— storage facilities are provided;

— appropriate services/utilities (e.g. water, electricity, gas) are available;

— contractual obligations about site organization are met.

4.2 Inventory and inspection of incoming goods

Delivered materials shall be checked to ensure, that:

— quantities and descriptions correspond to the design specification;

— equipment and components are undamaged.

All accompanying documentation shall be archived and kept available for the installation activities and

for inclusion in the OM&U instructions.

The inspection of incoming materials that have been identified as critical to achieve the design objectives

shall be documented.

4.3 Handling of materials

Any manufacturer’s instructions on how to handle materials shall be followed.

Suitable handling equipment shall be used where necessary.

Penetration/accumulation of dirt and damage of exposed parts shall be avoided.

Attention shall be given to safety requirements.

4.4 Storage of materials

Storage of components shall be carried out according to the manufacturers’ specifications with particular

attention to safety requirements and climatic conditions.

Protection of stored materials shall consider at least:

— sunlight (high temperatures and UV light);

— high temperatures;

— humidity, rain and other atmospheric agents;

— low temperatures and icing;

— animals (e.g. insects, rodents);

— penetration/accumulation of dirt and damage of exposed parts;

— hygiene;

— mechanical stresses due to inappropriate storage.

Special provisions shall be given if the installation process shall be residue free (see 4.5.1 and 7.1).

EXAMPLE Keeping caps on pipes and any other mean of avoiding component contamination.

4.5 Installation of components

4.5.1 General

Manufacturers’ instructions for the installation of components shall be available and followed.

The components shall be installed in accordance with the design specifications.

Proper accessories and tools for positioning, assembling and installation shall be available.

Before installation, every component shall be internally clean, visually checked and suitable for use.

The components shall be installed in a way that allows further (subsequent) installation work and

operations such as insulation. All serviceable components shall be installed in such a way that they can

be serviced, repaired or replaced.

EXAMPLE manoeuvring space and access to replace fan-coil filters

Components shall be placed, fixed and supported in such a way that they are steady and no harmful

deformations occur and so that thermal expansion is possible. Supports and bracings shall consider

seismic actions, if required by local regulation.

Clean working procedures (such as avoiding producing and/or leaving swarf and debris in the

components and pipes) shall be adopted if it is planned to avoid cleaning at the end of the mechanical

installation. The installation of filters is recommended in this case (residual risk, check regularly).

The installer shall notify the client of any obvious evidence of possible design mistakes or installation

difficulties and agree a solution.

NOTE The task of the installer is to carry out a plausibility check of the documentation but not to check

calculations or to revise the design documentation.

4.5.2 Heat generation

4.5.2.1 General

The structure upon which the heat supply (generator) is supported and its immediate surroundings shall

be in accordance with the design specifications.

Clearances between the heat generator and adjacent materials, e.g. for safety, cleaning and maintenance,

shall be at least in accordance with the heat generator manufacturer’s instructions.

Points of attention shall be:

a) protection of combustible material and fire protection;

b) any installation room of the heat generator shall be built and equipped according to the applicable

legal and safety regulations;

c) heat generator mounting, positioning and connection, in order to limit noise transmission from the

appliance;

d) avoiding stress transmission (connection of piping).

4.5.2.2 Combustion generator

Point of attention shall be:

a) combustion air supply and flue gas evacuation;

b) airing and ventilation openings;

c) fuel supply.

4.5.2.3 Heat pumps

Point of attention shall be:

a) noise and distance to the property limit for heat pumps with outdoor unit;

b) air ducts for indoor mounted, air source heat pumps.

4.5.2.4 Solar collectors

Point of attention shall be:

a) access to the roof;

b) shadings;

c) hangers and supports on the roof shall not compromise the roof waterproofing;

d) insulation material for collector pipes shall withstand high temperatures within steam range and be

weatherproof where necessary;

e) using suitable materials for glycol mixture;

f) weight of the system (for natural circulation with store on the roof).

4.5.2.5 Heat exchangers

Point of attention shall be:

a) right connection and flow direction;

b) room for disassembling and cleaning (shell and tube);

c) avoiding mechanical stresses from connections.

4.5.3 Heat distribution – piping and pumps

Measures shall be taken to prevent moisture, fire, smoke, noise and infestants where pipes pass through

a structure.

When pipes cross the building envelope or a separation between ventilation zones, air tightness shall be

maintained.

When crossing fire rated structures, applicable regulations and technical standards shall be followed.

The components shall be installed in a way that allows insulation according to the design.

In cases where joints and components are inaccessible, they shall be maintenance free and have an

appropriate life expectancy.

Point of attention shall be:

EXAMPLE provisions to allow thermal expansion of pipes (supports with fixed points and moving points)

a) provisions to avoid transmission of stresses to equipment (flexible joints);

b) provisions to fill, flush and drain the systems, vents and drains along pipes, including slope;

c) orientation of devices according to manufacturer instructions (e.g. control valves, pumps, meters);

d) positioning of sensors;

e) straight pipe runs before and after sensitive devices, e.g. heat meter, flow rate sensors;

f) provisions to measure pressure and/or temperature and/or flow rates during commissioning;

g) positioning of cold water pipes with respect to potentially hot lines.

NOTE Legionella growth is increased significantly at temperatures above 25 °C.

The pressure test (and any other relevant test concerning them) shall be carried out prior to the covering

of permanent joints and components.

4.5.4 Heat emission

Heat emitters shall be installed so as to allow venting.

Positioning shall consider maintenance (e.g. filter replacement for fan-coils).

Points of attention shall be:

a) hydraulic isolation (providing a means to shut off e.g. for maintenance purpose);

b) draining provisions, both of technical water and condensate (for cooling emitters);

c) flushing provisions;

d) dielectric isolation to prevent corrosion;

e) positioning of surface mounted emitters in respect of attaining the rated heat output (e.g. under

niches or obstructions);

f) positioning of humidity sensors for embedded cooling emitters.

For embedded heating and cooling surfaces, the installation shall comply with EN 1264-4 „Water based

surface embedded heating and cooling systems — Part 4: Installation”.

4.5.5 Control and monitoring

Controls and water sampling points shall be accessible for their use, setting and servicing.

Meters and sensors shall be accessible for reading and servicing.

The following factors shall be considered when installing water temperature sensors, which may be

either surface type sensors or insertion type sensors:

— stratification effects when mixing hot and cold water;

— time lag issues with automatic control;

— location on the upper side of pipes and surface contact for the surface type sensor;

— location in elbows or on the upper side of pipes and positioning in the water stream of the sensitive

part for the insertion type sensor;

— insulation from the environment.

For wireless connections, emitters, receivers and boosters (repeaters) shall be positioned according to

the design specification and manufacturer instruction to ensure the link.

4.5.6 Thermal insulation

Supports, suspensions, girders and fixpoints passing through the thermal insulation shall be installed so

as to limit heat losses.

Cooling circuits shall be fully insulated to avoid condensation.

The insulation material of cooling circuits shall be closed cells type.

4.6 Site inspections during the installation work

Site inspections can be arranged by installer and client.

Site inspections during the installation work are intended to verify that:

— the installation is proceeding according to design specifications and time schedule;

— the installation is proceeding according to the requirements set out in 4.2 to 4.5.

Any defects found during the on-site inspection shall be reported to the installer for rectification.

Further information on site inspections and a sample inspection report with provisions for follow-up of

rectification are given in Annex B.

4.7 Changes during the installation process

Any deviation from the design specification, including layout, shall be notified to the client, evaluated by

the installer and by the responsible of the design and authorized by the client.

Consequences regarding:

— energy performance;

— functionality and service level;

— maintenance;

— interference with other installation and commissioning work;

— repetition of any previous testing;

— compliance with regulatory requirement

shall be considered when evaluating a change.

5 Pre-functional checks

5.1 Objective

The purpose of the pre-commissioning checks is to guarantee that the mechanical and electrical

installation of the system is correct and completed and it is therefore possible and safe to proceed with

cleaning, pressure testing, filling, balancing and setting to operation.

The pre-commissioning checks include:

— a general check of the entire system;

— individual checks for equipment and major components;

— electrical checks.

Pre-functional test may be documented. Examples of suitable forms are given in Annex C.

5.2 General check

It shall be verified that the installation is in accordance with the design specification. The reference shall

be:

— functional diagrams (P&ID check);

— layout drawings.

5.3 Equipment and component check

Each equipment or major component shall be verified in order to ensure that:

— it has not been damaged during installation (especially surface mounted heating and cooling

emitters);

— it is adequately supported and levelled;

— the installation complies with design specifications and manufacturer instructions such as:

— functional diagrams, e.g. isolation valves are installed, check valves in the right direction;

— layout specifications, e.g. position, elevation, orientation, free straight runs after and before,

levelling, free space for maintenance;

— electrical actuators are paired with the correct service areas and temperature sensors and

controls;

— any wireless connection is stable;

— painting (protective coating) is finished;

— insulation is complete and thickness is correct, except where insulation shall be completed after

pressure testing;

— labels are in place;

— equipment and component documentation has been collected and archived;

— power and o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...