ISO 19014-3:2018

(Main)Earth-moving machinery - Functional safety - Part 3: Environmental performance and test requirements of electronic and electrical components used in safety-related parts of the control system

Earth-moving machinery - Functional safety - Part 3: Environmental performance and test requirements of electronic and electrical components used in safety-related parts of the control system

This document specifies the minimum requirements for environmental testing of electronic and electrical components identified as safety-related parts of the control system (SRP/CS) used on earth-moving machinery (EMM) as defined in ISO 6165 and their attachments.

Engins de terrassement — Sécurité fonctionnelle — Partie 3: Exigences pour la performance environnementale et l'essai des composants électroniques et électriques utilisés dans les parties relatives à la sécurité du système de commande

Le présent document spécifie les exigences minimales pour les essais d'environnement des composants électroniques et électriques identifiés comme des parties relatives à la sécurité du système de commande (SRP/CS) utilisés sur les engins de terrassement, comme défini dans l'ISO 6165 et leurs accessoires.

General Information

- Status

- Published

- Publication Date

- 10-Sep-2018

- Technical Committee

- ISO/TC 127/SC 2 - Safety, ergonomics and general requirements

- Drafting Committee

- ISO/TC 127/SC 2 - Safety, ergonomics and general requirements

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 06-Dec-2023

- Completion Date

- 13-Dec-2025

Relations

- Effective Date

- 06-Jun-2022

- Effective Date

- 26-May-2018

- Effective Date

- 26-May-2018

Overview

ISO 19014-3:2018 - "Earth-moving machinery - Functional safety - Part 3" defines the environmental performance and test requirements for electronic and electrical components that are identified as safety-related parts of the control system (SRP/CS) on earth-moving machinery (EMM) and their attachments. It sets minimum environmental testing expectations so SRP/CS components reliably perform their safety functions across the harsh conditions typical for construction and earth-moving equipment.

Keywords: ISO 19014-3:2018, earth-moving machinery, functional safety, environmental testing, SRP/CS, electronic components, electrical components.

Key Topics

- Scope and classifications

- Applies to SRP/CS used on EMM as defined in ISO 6165.

- Defines functional status classifications (Class A–D) to guide test severity and applicability.

- Environmental and electrical test categories

- Contaminants: dust and chemical resistance tests.

- Corrosion/water: salt spray and pressure-wash requirements.

- Mechanical stress: random vibration and operating shock.

- Thermal stress: temperature cycles and thermal shock.

- Moisture: humidity cycles.

- Electrical stress: overvoltage, undervoltage (reset behavior), reverse polarity.

- Electromagnetic compatibility (EMC): required testing per machine EMC standards.

- Test governance

- References established norms such as ISO 6165, ISO 13766-1/2 (EMC), ISO 16750 (electrical/chemical loads), ISO 20653 (IP codes), and relevant IEC environmental test procedures (e.g., IEC 60068 series).

- Includes a test checklist (informative) to help structure validation.

Applications / Who Should Use This Standard

- Machine manufacturers (OEMs) - to specify, design and validate SRP/CS hardware for compliance and durability.

- Component suppliers - to ensure parts meet environmental and electrical robustness expected in EMM safety systems.

- Test laboratories - to develop test plans and reports that align with ISO 19014-3 requirements.

- Safety engineers and system integrators - to select components and verify that SRP/CS meet required functional safety performance under environmental stress.

- Regulators and conformity assessors - to evaluate whether SRP/CS achieve sufficient resilience for deployment in earth-moving equipment.

Related Standards

- ISO 19014 series (Parts 1–5) - broader functional safety framework for EMM.

- ISO 6165 - EMM types and terminology.

- ISO 13766-1 / 13766-2 - EMC requirements for earth-moving and building construction machinery.

- ISO 16750 series - road-vehicle environmental testing guidance.

- ISO 20653; IEC 60068 series - protective and environmental testing procedures.

Practical value: ISO 19014-3:2018 helps reduce safety failures caused by environmental and electrical stresses, supports robust SRP/CS design, and harmonizes test methods across suppliers, OEMs, and test labs in the earth-moving machinery sector.

ISO 19014-3:2018 - Earth-moving machinery -- Functional safety

REDLINE ISO 19014-3:2018 - Earth-moving machinery — Functional safety — Part 3: Environmental performance and test requirements of electronic and electrical components used in safety-related parts of the control system Released:9/11/2018

ISO 19014-3:2018 - Engins de terrassement -- Sécurité fonctionnelle

Frequently Asked Questions

ISO 19014-3:2018 is a standard published by the International Organization for Standardization (ISO). Its full title is "Earth-moving machinery - Functional safety - Part 3: Environmental performance and test requirements of electronic and electrical components used in safety-related parts of the control system". This standard covers: This document specifies the minimum requirements for environmental testing of electronic and electrical components identified as safety-related parts of the control system (SRP/CS) used on earth-moving machinery (EMM) as defined in ISO 6165 and their attachments.

This document specifies the minimum requirements for environmental testing of electronic and electrical components identified as safety-related parts of the control system (SRP/CS) used on earth-moving machinery (EMM) as defined in ISO 6165 and their attachments.

ISO 19014-3:2018 is classified under the following ICS (International Classification for Standards) categories: 53.100 - Earth-moving machinery. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 19014-3:2018 has the following relationships with other standards: It is inter standard links to ISO/ASTM 51401:2013, ISO/TS 15998-2:2012, ISO 15998:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 19014-3:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 19014-3

First edition

2018-09

Earth-moving machinery —

Functional safety —

Part 3:

Environmental performance and

test requirements of electronic and

electrical components used in safety-

related parts of the control system

Engins de terrassement — Sécurité fonctionnelle —

Partie 3: Exigences pour la performance environnementale et l'essai

des composants électroniques et électriques utilisés dans les parties

relatives à la sécurité du système de commande

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

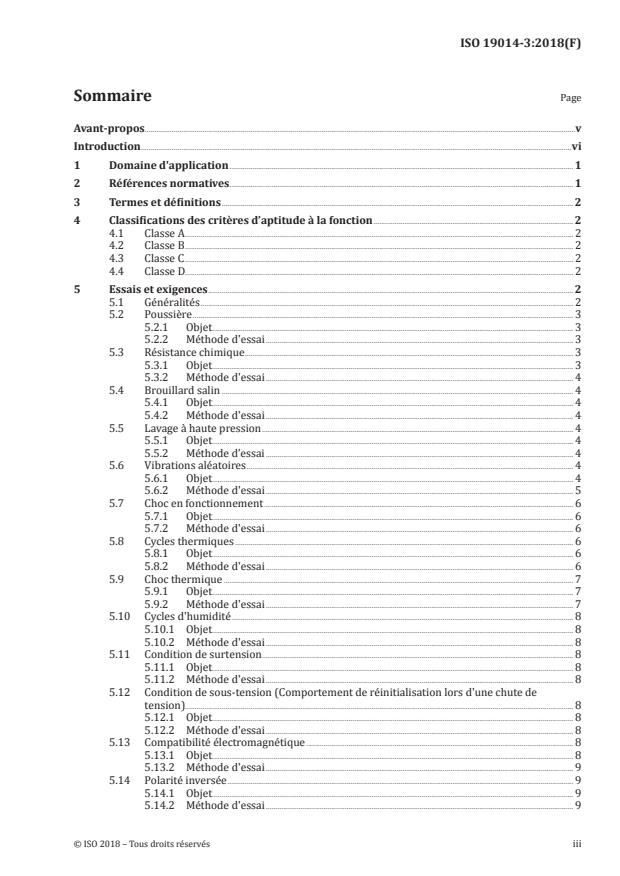

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Functional status classifications . 2

4.1 Class A . 2

4.2 Class B . 2

4.3 Class C . 2

4.4 Class D . 2

5 Tests and requirements . 2

5.1 General . 2

5.2 Dust . 3

5.2.1 Purpose . 3

5.2.2 Test method . 3

5.3 Chemical resistance . 3

5.3.1 Purpose . 3

5.3.2 Test method . 3

5.4 Salt spray . 4

5.4.1 Purpose . 4

5.4.2 Test method . 4

5.5 Pressure wash . 4

5.5.1 Purpose . 4

5.5.2 Test method . 4

5.6 Random vibration . 4

5.6.1 Purpose . 4

5.6.2 Test method . 4

5.7 Operating shock . 5

5.7.1 Purpose . 5

5.7.2 Test method . 5

5.8 Temperature cycles . 6

5.8.1 Purpose . 6

5.8.2 Test method . 6

5.9 Thermal shock . 7

5.9.1 Purpose . 7

5.9.2 Test method . 7

5.10 Humidity cycles . 7

5.10.1 Purpose . 7

5.10.2 Test method . 8

5.11 Overvoltage condition. 8

5.11.1 Purpose . 8

5.11.2 Test method . 8

5.12 Undervoltage condition (reset behaviour at voltage drop) . 8

5.12.1 Purpose . 8

5.12.2 Test method . 8

5.13 Electromagnetic compatibility . 8

5.13.1 Purpose . 8

5.13.2 Test method . 8

5.14 Reverse polarity . 9

5.14.1 Purpose . 9

5.14.2 Test method . 9

Annex A (informative) Test checklist .10

Bibliography .11

iv © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso

.org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 127, Earth-moving machinery,

Subcommittee SC 2, Safety, ergonomics and general requirements.

This first edition of ISO 19014-3, together with ISO 19014-1, ISO 19014-2, ISO 19014-4 and ISO/

TS 19014-5, cancels and replaces ISO 15998, which has been technically revised.

The main changes compared to the previous document are as follows:

— details added to existing test requirements;

— additional electrical and environmental tests.

A list of all parts in the ISO 19014-series can be found on the ISO website. At the time of publication of

this document, Part 2, Design and evaluation of safety-related machine control systems, Part 4, Design and

evaluation of software and transmission for safety related parts of the control system, and Part 5, Tables of

performance levels, are under development.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

Introduction

This document addresses electronic and electrical systems used for functional safety in earth-moving

machinery.

The structure of safety standards in the field of machinery is as follows.

Type-A standards (basis standards) give basic concepts, principles for design and general aspects that

can be applied to machinery.

Type-B standards (generic safety standards) deal with one or more safety aspects, or one or more types

of safeguards that can be used across a wide range of machinery:

— type-B1 standards on particular safety aspects (e.g. safety distances, surface temperature, noise);

— type-B2 standards on safeguards (e.g. two-hands controls, interlocking devices, pressure sensitive

devices, guards).

Type-C standards (machinery safety standards) deal with detailed safety requirements for a particular

machine or group of machines.

This document, when taken together with the other parts of ISO 19014, is a type-C standard as stated

in ISO 12100.

This document is of relevance, in particular, for the following stakeholder groups representing the

market players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e. g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events

are covered are indicated in the Scope of this document.

When requirements of this type-C standard are different from those which are stated in type-A or

type-B standards, the requirements of this type-C standard take precedence over the requirements of

the other standards for machines that have been designed and built according to the requirements of

this type-C standard.

vi © ISO 2018 – All rights reserved

INTERNATIONAL STANDARD ISO 19014-3:2018(E)

Earth-moving machinery — Functional safety —

Part 3:

Environmental performance and test requirements of

electronic and electrical components used in safety-related

parts of the control system

1 Scope

This document specifies the minimum requirements for environmental testing of electronic and

electrical components identified as safety-related parts of the control system (SRP/CS) used on earth-

moving machinery (EMM) as defined in ISO 6165 and their attachments.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of th

...

ISO/TC 127

Deleted: 06

Date: 2018‐09

ISO/TC 127/SC 2

Earth-moving machinery — Functional Safety — Part 3: Environmental

performance and test requirements of electronic and electrical components used

in safety-related parts of the control system

Deleted: Section Break (Next Page)

Copyright notice¶

This ISO document is a Draft

International Standard and is

copyright‐protected by ISO.

Except as permitted under the

applicable laws of the user's

country, neither this ISO draft nor

any extract from it may be

reproduced, stored in a retrieval

system or transmitted in any

form or by any means, electronic,

photocopying, recording or

otherwise, without prior written

permission being secured.¶

Requests for permission to

reproduce should be addressed

to either ISO at the address below

or ISO's member body in the

country of the requester.¶

ISO copyright office¶

Case postale 56 • CH‐1211 Geneva

20¶

Tel. + 41 22 749 01 11¶

Fax + 41 22 749 09 47¶

E‐mail copyright@iso.org¶

Web www.iso.org¶

Reproduction may be subject to

royalty payments or a licensing

agreement.¶

Violators may be prosecuted.¶

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national

standards bodies (ISO member bodies). The work of preparing International Standards is normally

carried out through ISO technical committees. Each member body interested in a subject for which

a technical committee has been established has the right to be represented on that committee.

International organizations, governmental and non‐governmental, in liaison with ISO, also take

part in the work. ISO collaborates closely with the International Electrotechnical Commission (IEC)

on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for

the different types of ISO documents should be noted. This document was drafted in accordance

with the editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject

of patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

Details of any patent rights identified during the development of the document will be in the

Introduction and/or on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does

not constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 127, Earth-moving machinery,

Subcommittee SC 2, Safety, ergonomics and general requirements.

This first edition of ISO 19014‐3, together with ISO 19014‐1, ISO 19014‐2, ISO 19014‐4 and

ISO/TS 19014‐5, cancels and replaces ISO 15998, which has been technically revised.

The main changes compared to the previous document are as follows:

— details added to existing test requirements;

— additional electrical and environmental tests.

A list of all parts in the ISO 19014‐series can be found on the ISO website. At the time of publication

of this document, Part 2, Design and evaluation of safety-related machine control systems, Part 4,

Design and evaluation of software and transmission for safety related parts of the control system, and

Part 5, Tables of performance levels, are under development.

Any feedback or questions on this document should be directed to the user’s national standards

body. A complete listing of these bodies can be found at www.iso.org/members.html.

2 ©ISO 2018– All rights reserved

Deleted: /FDIS

Introduction

This document addresses electronic and electrical systems used for functional safety in earth‐

moving machinery.

The structure of safety standards in the field of machinery is as follows.

Type‐A standards (basis standards) give basic concepts, principles for design and general aspects

that can be applied to machinery.

Type‐B standards (generic safety standards) deal with one or more safety aspects, or one or more

types of safeguards that can be used across a wide range of machinery:

— type‐B1 standards on particular safety aspects (e.g. safety distances, surface temperature,

noise);

— type‐B2 standards on safeguards (e.g. two‐hands controls, interlocking devices, pressure

sensitive devices, guards).

Type‐C standards (machinery safety standards) deal with detailed safety requirements for a

particular machine or group of machines.

This document, when taken together with the other parts of ISO 19014, is a type‐C standard as

stated in ISO 12100.

This document is of relevance, in particular, for the following stakeholder groups representing the

market players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance

etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by

the above‐mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e. g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above‐mentioned stakeholder groups have been given the possibility to participate at the

drafting process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous

events are covered are indicated in the Scope of this document.

When requirements of this type‐C standard are different from those which are stated in type‐A or

type‐B standards, the requirements of this type‐C standard take precedence over the requirements

of the other standards for machines that have been designed and built according to the

requirements of this type‐C standard.

Deleted: © ISO 2018– All rights

reserved

Deleted: /FDIS

Earth-moving machinery — Safety — Part 3: Environmental performance and test requirements of

electronic and electrical components used in safety-related parts of the control system

1 Scope

This document specifies the minimum requirements for environmental testing of electronic and electrical

components identified as safety‐related parts of the control system (SRP/CS) used on earth‐moving

machinery (EMM) as defined in ISO 6165 and their attachments.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 6165, Earth-moving machinery — Basic types — Identification and terms and definitions

ISO 13766‐1, Earth-moving and building construction machinery — Electromagnetic compatibility (EMC) of

Deleted: machinery

machines with internal electrical power supply — Part 1: General EMC requirements under typical

Deleted: and road

electromagnetic environmental conditions

ISO 13766‐2, Earth-moving and building construction machinery — Electromagnetic compatibility (EMC) of

Deleted: machinery

machines with internal electrical power supply — Part 2: Additional EMC requirements for functional safety

Deleted: and road

ISO 16750‐2:2012, Road vehicles — Environmental conditions and testing for electrical and electronic

equipment — Part 2: Electrical loads

ISO 16750‐5, Road vehicles — Environmental conditions and testing for electrical and electronic

equipment — Part 5: Chemical loads

ISO 19014‐1, Earth-moving machinery — Safety — Part 1: Risk assessment methodology to determine

control system performance requirements

ISO 20653, Road vehicles — Degrees of protection (IP code) — Protection of electrical equipment against

foreign objects, water and access

IEC 60068‐2‐11, Basic environmental testing procedures — Part 2: Tests — Test Ka: Salt mist

IEC 60068‐2‐14, Environmental testing — Part 2: Tests — Test N: Change of temperature

IEC 60068‐2‐27, Environmental testing — Part 2-27: Tests — Test Ea and guidance: Shock

IEC 60068‐2‐38, Environmental testing — Part 2-38: Tests — Test Z/AD: Composite temperature/humidity

cyclic test

IEC 60068‐2‐52, Environmental testing — Part 2-52: Tests — Test Kb: Salt mist, cyclic (sodium chloride

solution)

IEC 60068‐2‐64:2008, Environmental testing — Part 2-64: Tests — Test Fh: Vibration, broadband random

and guidance

IEC 60529, Degrees of protection provided by enclosures (IP Code)

© ISO 2018– All rights reserved 1

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 6165, ISO 19014‐1 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

life cycle

time between commissioning and decommissioning of a component

4 Functional status classifications

4.1 Class A

All safety functions of the device under test (DUT) perform as designed during and after the test.

4.2 Class B

All safety functions of the DUT perform as designed during the test. The DUT may perform outside of the

designed tolerance during the test; however, all functions shall automatically return within the specified

tolerance after the test. Memory functions shall remain class A.

The functions of the DUT that are required to perform as designed during the test, and the functions that

may perform beyond the specified tolerance, shall be specified by the machine manufacturer.

4.3 Class C

For DUTs that are powered and monitored, one or more functions of a DUT do not perform as designed

during the test, but return automatically to normal operation after the test.

For DUTs that re not powered and monitored, the DUT performs as designed after the test.

4.4 Class D

One or more functions of a DUT do not perform as designed during the test and do not return to normal

operation after the test until the DUT is reset.

5 Tests and requirements

5.1 General

The test conditions specified in this document are the minimum requirements. The EMM manufacturer

Deleted: equipment

shall ensure electrical and electronic components are suitable for the environment in which they are used.

The EMM manufacturer shall determine the use environment as it applies to the test conditions in this

Deleted: equipment

document. The environmental requirements for each application depend on its mounting location (engine

compartment, operator station, chassis, etc.), which shall be taken into account when developing the test

specification.

Significant variation in environmental conditions due to diurnal and seasonal cycles can be expected and

shall be considered when testing according to this document.

2 © ISO 2018– All rights reserved

Deleted: /FDIS

The EMM manufacturer shall test any components that are likely to be submerged in, or exposed to,

Deleted: equipment

chemical agents (mining liquids, salts, alkaline, fertilizer, etc.) and ensure the components are immune to

contamination or degradation.

Components that are immune to contaminants may be exempt from testing if the EMM manufacturer

provides documentary evidence to that effect. The EMM manufacturer shall determine suitability for

Deleted: equipment

chemical exposure according to ISO 16750‐5. Resistance to the specified chemical agents should be

considered as early as possible (e.g. during the material selection process.)

See Annex A for an example of a test checklist, which includes a column for the EMM manufacturer to

Deleted: equipment

document the rationale for excluding a test.

NOTE If explosion proofing is required, refer to IEC 60079. National or regional requirements can apply.

5.2 Dust

5.2.1 Purpose

Electronic components (controllers, joysticks, displays, switches, solenoids, etc.) adversely affected by

du

...

NORME ISO

INTERNATIONALE 19014-3

Première édition

2018-09

Engins de terrassement — Sécurité

fonctionnelle —

Partie 3:

Exigences pour la performance

environnementale et l'essai des

composants électroniques et

électriques utilisés dans les parties

relatives à la sécurité du système de

commande

Earth-moving machinery — Functional safety —

Part 3: Environmental performance and test requirements of

electronic and electrical components used in safety-related parts of

the control system

Numéro de référence

©

ISO 2018

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2018

Tous droits réservés. Sauf prescription différente ou nécessité dans le contexte de sa mise en œuvre, aucune partie de cette

publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique,

y compris la photocopie, ou la diffusion sur l’internet ou sur un intranet, sans autorisation écrite préalable. Une autorisation peut

être demandée à l’ISO à l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

ISO copyright office

Case postale 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Genève

Tél.: +41 22 749 01 11

Fax: +41 22 749 09 47

E-mail: copyright@iso.org

Web: www.iso.org

Publié en Suisse

ii © ISO 2018 – Tous droits réservés

Sommaire Page

Avant-propos .v

Introduction .vi

1 Domaine d'application . 1

2 Références normatives . 1

3 Termes et définitions . 2

4 Classifications des critères d’aptitude à la fonction . 2

4.1 Classe A . 2

4.2 Classe B . 2

4.3 Classe C . 2

4.4 Classe D. 2

5 Essais et exigences . 2

5.1 Généralités . 2

5.2 Poussière . 3

5.2.1 Objet. 3

5.2.2 Méthode d'essai . 3

5.3 Résistance chimique . 3

5.3.1 Objet. 3

5.3.2 Méthode d'essai . 4

5.4 Brouillard salin . 4

5.4.1 Objet. 4

5.4.2 Méthode d'essai . 4

5.5 Lavage à haute pression . 4

5.5.1 Objet. 4

5.5.2 Méthode d’essai . 4

5.6 Vibrations aléatoires . 4

5.6.1 Objet. 4

5.6.2 Méthode d'essai . 5

5.7 Choc en fonctionnement . 6

5.7.1 Objet. 6

5.7.2 Méthode d'essai . 6

5.8 Cycles thermiques . 6

5.8.1 Objet. 6

5.8.2 Méthode d'essai . 6

5.9 Choc thermique . 7

5.9.1 Objet. 7

5.9.2 Méthode d'essai . 7

5.10 Cycles d'humidité . 8

5.10.1 Objet. 8

5.10.2 Méthode d'essai . 8

5.11 Condition de surtension . 8

5.11.1 Objet. 8

5.11.2 Méthode d'essai . 8

5.12 Condition de sous-tension (Comportement de réinitialisation lors d'une chute de

tension). 8

5.12.1 Objet. 8

5.12.2 Méthode d'essai . 8

5.13 Compatibilité électromagnétique . 8

5.13.1 Objet. 8

5.13.2 Méthode d'essai . 9

5.14 Polarité inversée . 9

5.14.1 Objet. 9

5.14.2 Méthode d'essai . 9

Annexe A (informative) Liste de contrôle d’essai .10

Bibliographie .11

iv © ISO 2018 – Tous droits réservés

Avant-propos

L'ISO (Organisation internationale de normalisation) est une fédération mondiale d'organismes

nationaux de normalisation (comités membres de l'ISO). L'élaboration des Normes internationales est

en général confiée aux comités techniques de l'ISO. Chaque comité membre intéressé par une étude

a le droit de faire partie du comité technique créé à cet effet. Les organisations internationales,

gouvernementales et non gouvernementales, en liaison avec l'ISO participent également aux travaux.

L'ISO collabore étroitement avec la Commission électrotechnique internationale (IEC) en ce qui

concerne la normalisation électrotechnique.

Les procédures utilisées pour élaborer le présent document et celles destinées à sa mise à jour sont

décrites dans les Directives ISO/IEC, Partie 1. Il convient, en particulier de prendre note des différents

critères d'approbation requis pour les différents types de documents ISO. Le présent document a été

rédigé conformément aux règles de rédaction données dans les Directives ISO/IEC, Partie 2 (voir www

.iso .org/directives).

L'attention est attirée sur le fait que certains des éléments du présent document peuvent faire l'objet de

droits de propriété intellectuelle ou de droits analogues. L'ISO ne saurait être tenue pour responsable

de ne pas avoir identifié de tels droits de propriété et averti de leur existence. Les détails concernant

les références aux droits de propriété intellectuelle ou autres droits analogues identifiés lors de

l'élaboration du document sont indiqués dans l'Introduction et/ou dans la liste des déclarations de

brevets reçues par l'ISO (voir www .iso .org/brevets).

Les appellations commerciales éventuellement mentionnées dans le présent document sont données

pour information, par souci de commodité, à l’intention des utilisateurs et ne sauraient constituer un

engagement.

Pour une explication de la nature volontaire des normes, la signification des termes et expressions

spécifiques de l'ISO liés à l'évaluation de la conformité, ou pour toute information au sujet de l'adhésion

de l'ISO aux principes de l’Organisation mondiale du commerce (OMC) concernant les obstacles

techniques au commerce (OTC), voir le lien suivant: www .iso .org/iso/fr/avant -propos.

Le présent document a été élaboré par le comité technique ISO/TC 127, Engins de terrassement, SC 2,

Sécurité, ergonomie et exigences de sécurité.

Cette première édition de l’ISO 19014-3, avec l’ISO 19014-1, l’ISO 19014-2 et l’ISO 19014-4, et l'ISO/

TS 19014-5 annule et remplace l’ISO 15998, qui a fait l’objet d’une révision technique.

Les principales modifications par rapport à l’édition précédente sont les suivantes:

— détails ajoutés aux exigences d'essai existantes;

— essais électriques et environnementaux supplémentaires .

Une liste de toutes les parties de la série ISO 19014 se trouve sur le site web de l’ISO. Au moment de

la publication du présent document, la Partie 2, Conception et évaluation des systèmes électroniques

de commande de la machine relatifs à la sécurité, Partie 4, Conception et évaluation du logiciel et de la

transmission des données pour les parties relatives à la sécurité du système de commande et la Partie 5,

Analyse du risque et tableaux des niveaux de performance des engins (PL) sont en préparation.

Il convient que l’utilisateur adresse tout retour d’information ou toute question concernant le présent

document à l’organisme national de normalisation de son pays. Une liste exhaustive desdits organismes

se trouve à l’adresse www .iso .org/fr/members .html.

Introduction

Le présent document traite des systèmes électriques et électroniques utilisés pour assurer la sécurité

fonctionnelle des engins de terrassement.

Dans le domaine de la sécurité des machines, les normes sont articulées de la façon suivante.

— normes de type A (normes fondamentales de sécurité), contenant des notions fondamentales, des

principes de conception et des aspects généraux relatifs aux machines;

— normes de type B (normes génériques de sécurité), traitant d'un aspect de la sécurité ou d'un moyen

de protection valable pour une large gamme de machines:

— normes de type B1, traitant d'aspects particuliers de la sécurité (par exemple, distances de

sécurité, température superficielle, bruit);

— normes de type B2, traitant de moyens de protection (par exemple, commandes bimanuelles,

dispositifs de verrouillage, dispositifs sensibles à la pression, protecteurs);

— normes de type C (normes de sécurité par catégorie de machines), traitant des exigences de sécurité

détaillées s'appliquant à une machine particulière ou à un groupe de machines particulier.

Le présent document est une norme de type C tel que mentionné dans l’ISO 12100.

Le présent document concerne, en particulier, les groupes de parties prenantes suivants représentant

les acteurs du marché en ce qui concerne la sécurité des machines:

— fabricants de machines (petites, moyennes et grandes entreprises);

— organismes de santé et de sécurité (autorités réglementaires, organismes de prévention des risques

professionnels, surveillance du marché, etc.)

D’autres partenaires peuvent être concernés par le niveau de sécurité des machines atteint à l’aide du

document par les groupes de parties prenantes mentionnés ci-dessus:

— utilisateurs de machines/employeurs (petites, moyennes et grandes entreprises);

— utilisateurs de machines/salariés (par exemple syndicats de salariés, organisations représentant

des personnes ayant des besoins particuliers);

— prestataires de services, par exemple sociétés de maintenance (petites, moyennes et grandes

entreprises);

— consommateurs (dans le cas de machines destinées à être utilisées par des consommateurs).

Les groupes de parties prenantes mentionnés ci-dessus ont eu la possibilité de participer à l’élaboration

du présent document.

Les machines concernées et l’étendue des phénomènes dangereux, situations dangereuses ou

événements dangereux couverts sont indiquées dans le Domaine d’application du présent document.

Lorsque des exigences de la présente norme de type C sont différentes de celles énoncées dans les

normes de type A ou les normes de type B, les exigences de la présente norme de type C ont priorité

sur celles des autres normes pour les machines ayant été conçues et fabriquées conformément aux

exigences de la présente norme de type C.

vi © ISO 2018 – Tous droits réservés

NORME INTERNATIONALE ISO 19014-3:2018(F)

Engins de terrassement — Sécurité fonctionnelle —

Partie 3:

Exigences pour la performance environnementale et l'essai

des composants électroniques et électriques utilisés dans

les parties relatives à la sécurité du système de commande

1 Domaine d'application

Le présent document spécifie les exigences minimales pour les essais d'environnement des composants

électroniques et électriques identifiés comme des parties relatives à la sécurité du système de

commande (SRP/CS) utilisés sur les engins de terrassement, comme défini dans l'ISO 6165 et leurs

accessoires.

2 Références normatives

Les documents suivants cités dans le texte constituent, pour tout ou partie de leur contenu, des

exigences du présent document. Pour les références datées, seule l'édition citée s'applique. Pour les

références non datées, la dernière édition du document de référence s'applique (y compris les éventuels

amendements).

ISO 6165, Engins de terrassement — Principaux types — Identification et termes et définitions

ISO 13766-1, Engins de terrassement et machines pour la construction des bâtiments — Compatibilité

électromagnétique (CEM) des machines équipées de réseaux électriques de distribution interne — Partie 1:

Exigences CEM générales dans des conditions électromagnétiques environnementales typiques

ISO 13766-2, Engins de terrassement et machines pour la construction des bâtiments — Compatibilité

électromagnétique (CEM) des machines équipées de réseaux électriques de distribution interne — Partie 2:

Exigences CEM supplémentaires pour les fonctions de sécurité

ISO 16750-2:2012, Véhicules routiers — Spécifications d'environnement et essais de l'équipement électrique

et électronique — Partie 2: Contraintes électriques

IS

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...