ISO 28219:2017

(Main)Packaging — Labelling and direct product marking with linear bar code and two-dimensional symbols

Packaging — Labelling and direct product marking with linear bar code and two-dimensional symbols

ISO 28219:2017 - defines minimum requirements for identifying items, - provides guidelines for item marking with machine-readable symbols, - covers both labels and direct marking of items, - includes testing procedures for label adhesive characteristics and mark durability, - provides guidance for the formatting on the label of data presented in linear bar code, two-dimensional symbol or human-readable form, - is intended for applications which include, but are not limited to, support of systems that automate the control of items during the processes of: - production, - inventory, - distribution, - field service, - point of sale, - point of care, - repair, and - is intended to include, but it is not limited to, multiple industries including: - automotive, - aerospace, - chemical, - consumer items, - electronics, - health care, - marine, - rail, - telecommunications. The location and application method of the marking are not defined (these will be reviewed and agreed upon by suppliers and manufacturers and their trading partners before implementing ISO 28219:2017). ISO 28219:2017 does not supersede or replace any applicable safety or regulatory marking or labelling requirements. ISO 28219:2017 is meant to satisfy the minimum item marking requirements of numerous applications and industry groups and as such its applicability is to a wide range of industries, each of which may have specific implementation guidelines for it. ISO 28219:2017 is to be applied in addition to any other mandated labelling direct-marking requirements. The labelling and direct marking requirement of ISO 28219:2017 and other standards can be combined into one label or marking area or appear as separate labels or marking areas. ISO 28219:2017 uses the terms "part marking" and "item marking" interchangeably. Unless otherwise stated, ISO 28219:2017 will use the term "item marking" to describe both the labelling and direct part marking (DPM) of an item, where DPM includes, but is not limited to, altering (e.g. dot peen, laser etch, chemical etch), as well as additive type processes (e.g. ink jet, vacuum deposition). The purpose of ISO 28219:2017 is to establish the machine-readable (linear, two-dimensional, and composite symbols) and human-readable content for direct marking and labelling of items, parts, and components. ISO 28219:2017 provides a means for items, parts and components to be marked, and read in either fixtured or hand-held scanning environments at any manufacturer's facility and then read by customers purchasing items for subsequent manufacturing operations or for final end use. Intended applications include, but are not limited to, supply chain applications, e.g. inventory, distribution, manufacturing, quality control, acquisition, transportation, supply, repair, and disposal. The figures are illustrative and not necessarily to scale or to the quality requirements specified in ISO 28219:2017.

Emballage — Étiquetage et marquage direct sur le produit avec un code à barres et des symboles bidimensionnels

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 28219

Second edition

2017-09

Packaging — Labelling and direct

product marking with linear bar code

and two-dimensional symbols

Emballage — Étiquetage et marquage direct sur le produit avec un

code à barres et des symboles bidimensionnels

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

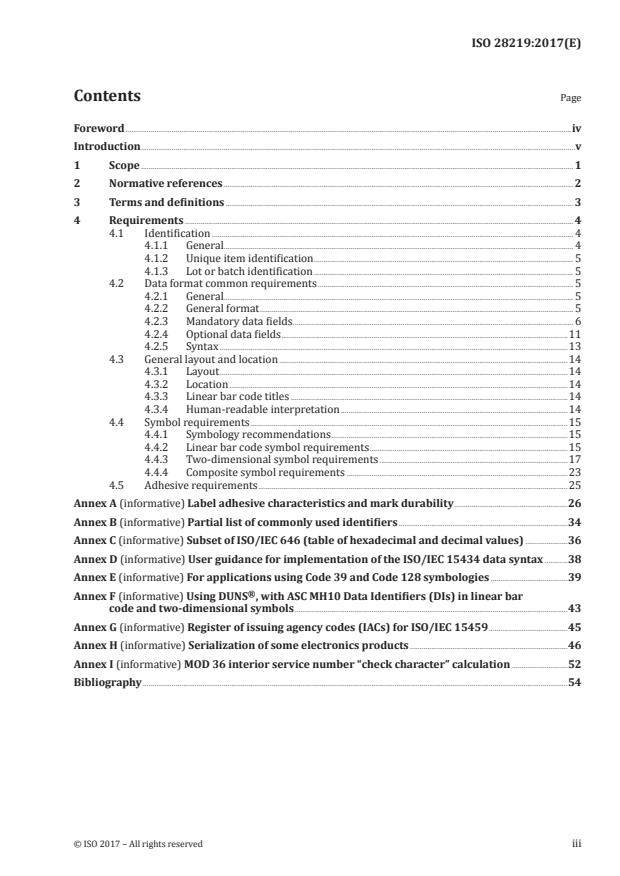

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 3

4 Requirements . 4

4.1 Identification . 4

4.1.1 General. 4

4.1.2 Unique item identification . 5

4.1.3 Lot or batch identification . 5

4.2 Data format common requirements . 5

4.2.1 General. 5

4.2.2 General format . 5

4.2.3 Mandatory data fields . 6

4.2.4 Optional data fields .11

4.2.5 Syntax .13

4.3 General layout and location .14

4.3.1 Layout .14

4.3.2 Location .14

4.3.3 Linear bar code titles .14

4.3.4 Human-readable interpretation .14

4.4 Symbol requirements .15

4.4.1 Symbology recommendations .15

4.4.2 Linear bar code symbol requirements .15

4.4.3 Two-dimensional symbol requirements .17

4.4.4 Composite symbol requirements .23

4.5 Adhesive requirements .25

Annex A (informative) Label adhesive characteristics and mark durability .26

Annex B (informative) Partial list of commonly used identifiers .34

Annex C (informative) Subset of ISO/IEC 646 (table of hexadecimal and decimal values) .36

Annex D (informative) User guidance for implementation of the ISO/IEC 15434 data syntax .38

Annex E (informative) For applications using Code 39 and Code 128 symbologies .39 ®

Annex F (informative) Using DUNS , with ASC MH10 Data Identifiers (DIs) in linear bar

code and two-dimensional symbols .43

Annex G (informative) Register of issuing agency codes (IACs) for ISO/IEC 15459 .45

Annex H (informative) Serialization of some electronics products .46

Annex I (informative) MOD 36 interior service number “check character” calculation .52

Bibliography .54

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 122, Packaging.

This second edition cancels and replaces the first edition (ISO 28219:2009), which has been technically

revised.

iv © ISO 2017 – All rights reserved

Introduction

Today, global industries widely use machine-readable markings on products for inventory control,

quality control, and product life cycle management. Common technologies, data structures,

conformance, and applications standards are necessary to enable all trading partners to use such

markings internally and throughout the supply chain.

A number of different product labelling and marking standards exist, each designed to meet the

requirements of the specific industry sector. For effective and economic use within and between

industry sectors, one common multi-industry standard is a necessity.

A standard linear bar code or two-dimensional symbol marked on a product or part will facilitate the

automation of inventory control, quality control, and product life cycle management. The linear bar code

or two-dimensional symbol information on the product can be used as a key to access the appropriate

database that contains detailed information about the product, including information transmitted via

EDI. In addition, a product mark can contain other information as agreed between the trading partners.

This document does not supersede or replace any applicable safety or regulatory marking or labelling

requirements. This document is meant to satisfy the minimum product package requirements of

numerous applications and industry groups. As such, its applicability is to a wide range of industries,

each of which can have specific implementation guidelines for this document. This document is intended

to be applied in addition to any other mandated labelling requirements.

This document supersedes and replaces ANS MH10.8.7.

This document supersedes and replaces CEA-802.

This document supersedes and replaces CEA-621-A.

INTERNATIONAL STANDARD ISO 28219:2017(E)

Packaging — Labelling and direct product marking with

linear bar code and two-dimensional symbols

1 Scope

This document

— defines minimum requirements for identifying items,

— provides guidelines for item marking with machine-readable symbols,

— covers both labels and direct marking of items,

— includes testing procedures for label adhesive characteristics and mark durability,

— provides guidance for the formatting on the label of data presented in linear bar code, two-

dimensional symbol or human-readable form,

— is intended for applications which include, but are not limited to, support of systems that automate

the control of items during the processes of:

— production,

— inventory,

— distribution,

— field service,

— point of sale,

— point of care,

— repair, and

— is intended to include, but it is not limited to, multiple industries including:

— automotive,

— aerospace,

— chemical,

— consumer items,

— electronics,

— health care,

— marine,

— rail,

— telecommunications.

The location and application method of the marking are not defined (these will be reviewed and agreed

upon by suppliers and manufacturers and their trading partners before implementing this document).

This document does not supersede or replace any applicable safety or regulatory marking or labelling

requirements. This document is meant to satisfy the minimum item marking requirements of numerous

applications and industry groups and as such its applicability is to a wide range of industries, each of

which may have specific implementation guidelines for it. This document is to be applied in addition to

any other mandated labelling direct-marking requirements.

The labelling and direct marking requirement of this document and other standards can be combined

into one label or marking area or appear as separate labels or marking areas.

This document uses the terms “part marking” and “item marking” interchangeably. Unless otherwise

stated, this document will use the term “item marking” to describe both the labelling and direct part

marking (DPM) of an item, where DPM includes, but is not limited to, altering (e.g. dot peen, laser etch,

chemical etch), as well as additive type processes (e.g. ink jet, vacuum deposition).

The purpose of this document is to establish the machine-readable (linear, two-dimensional, and

composite symbols) and human-readable content for direct marking and labelling of items, parts, and

components.

This document provides a means for items, parts and components to be marked, and read in either

fixtured or hand-held scanning environments at any manufacturer’s facility and then read by customers

purchasing items for subsequent manufacturing operations or for final end use. Intended applications

include, but are not limited to, supply chain applications, e.g. inventory, distribution, manufacturing,

quality control, acquisition, transportation, supply, repair, and disposal.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.