ISO 21630:2007

(Main)Pumps — Testing — Submersible mixers for wastewater and similar applications

Pumps — Testing — Submersible mixers for wastewater and similar applications

ISO 21630:2007 prescribes acceptance test methods for submersible mixers used for mixing in wastewater and other applications where at least one system component is a liquid. "Submersible mixer" is taken to mean a fully submersible aggregate consisting of a drive unit and an axial flow type impeller, and optional parts, such as shrouds, supporting the basic functions. "Liquid" is taken to mean a body without capacity to accommodate shear stresses when at rest. This includes suspensions and dispersions (liquid/solid, gas/liquid and gas/liquid/solid), and non-Newtonian liquids, provided that a possible small yield stress does not prevent the liquid from flowing when agitated.

Pompes — Essais — Mélangeurs immergés pour eaux usées et applications similaires

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 21630

First edition

2007-08-15

Pumps — Testing — Submersible mixers

for wastewater and similar applications

Pompes — Essais — Mélangeurs immergés pour eaux usées et

applications similaires

Reference number

©

ISO 2007

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2007 – All rights reserved

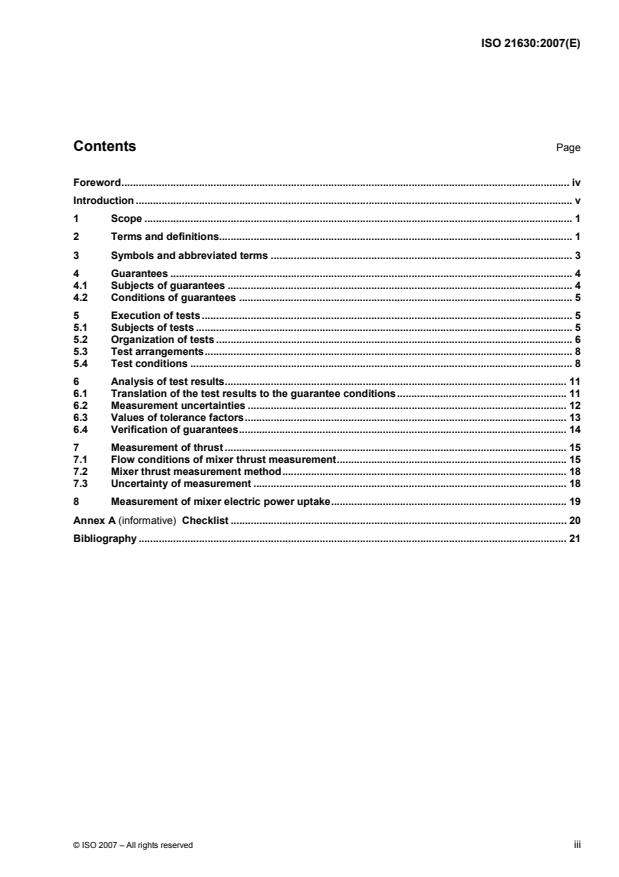

Contents Page

Foreword. iv

Introduction . v

1 Scope. 1

2 Terms and definitions. 1

3 Symbols and abbreviated terms . 3

4 Guarantees. 4

4.1 Subjects of guarantees . 4

4.2 Conditions of guarantees . 5

5 Execution of tests. 5

5.1 Subjects of tests . 5

5.2 Organization of tests . 6

5.3 Test arrangements. 8

5.4 Test conditions . 8

6 Analysis of test results. 11

6.1 Translation of the test results to the guarantee conditions. 11

6.2 Measurement uncertainties. 12

6.3 Values of tolerance factors. 13

6.4 Verification of guarantees. 14

7 Measurement of thrust . 15

7.1 Flow conditions of mixer thrust measurement. 15

7.2 Mixer thrust measurement method. 18

7.3 Uncertainty of measurement . 18

8 Measurement of mixer electric power uptake. 19

Annex A (informative) Checklist . 20

Bibliography . 21

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 21630 was prepared by Technical Committee ISO/TC 115, Pumps, Subcommittee SC 2, Methods of

measurement and testing.

iv © ISO 2007 – All rights reserved

Introduction

This International Standard prescribes acceptance test methods for submersible mixers for wastewater and

other applications. It is intended for performance measurements relevant to submersible mixers bearing in

mind the similarities to, and crucial differences from, submersible pumps. Hence head (pressure) and flow rate

measurements are not included. The basic output performance parameter is the thrust. As continuous

operation is commonplace, electric power consumption is important for the Life Cycle Cost, and is put forward

as an important parameter. It is acknowledged that the present International Standard draws heavily on

ISO 9906:1999 in the generalities.

The major objectives of this International Standard are to

⎯ increase uniformity/compatibility in equipment performance characterization, enabling a comparison of

mixers,

⎯ simplify communication between customer and supplier and protect customers,

⎯ reduce the need for documentation,

⎯ increase quality and efficiency in both machinery and process.

INTERNATIONAL STANDARD ISO 21630:2007(E)

Pumps — Testing — Submersible mixers for wastewater and

similar applications

1 Scope

This International Standard prescribes acceptance test methods for submersible mixers (hereafter “SM” or

“mixer”) used for mixing in wastewater and other applications where at least one system component is a liquid.

“Submersible mixer” is taken to mean a fully submersible aggregate consisting of a drive unit and an axial flow

type impeller, and optional parts, such as shrouds, supporting the basic functions.

“Liquid” is taken to mean a body without capacity to accommodate shear stresses when at rest. This includes

suspensions and dispersions (liquid/solid, gas/liquid and gas/liquid/solid), and non-Newtonian liquids, provided

that a possible small yield stress does not prevent the liquid from flowing when agitated.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

thrust-to-power ratio

ratio of mixer thrust force to mixer power consumption

R = F / P

FP 1

NOTE 1 The ratio of minimum required mixing system power dissipation to mixer power consumption is an (end-user

oriented) system efficiency. To understand the importance of the thrust-to-power ratio, consider the case of an SM

generating a longitudinal flow velocity u in a recirculation channel such as a wastewater oxidation ditch. This is in fact a

common application of the SM, and the following argument is in principle possible to generalize to other applications.

The momentum loss of the flow over one circulation equals the rate of momentum provided by the SM at quasi-steady

state. This is given by the mixer thrust F. The power dissipated as a result of this momentum loss is P = F u, and this is the

minimum required mixing system power to maintain the velocity u. Hence, the system efficiency is P / P = F u / P .

1 1

It is possible to isolate the mixer properties from the system requirement in this expression, and this leads to the thrust-to-

power ratio, R , as the most relevant efficiency-related parameter of the SM. It should be noted that it is dimensional, and

FP

hence it depends on the impeller diameter and speed, not only on the impeller geometry. Other considerations than

energetic efficiency of generation of longitudinal flow provide for the multitude of impeller diameters and speeds available

in practice.

NOTE 2 An impeller efficiency, defined as the ratio of power of axial motion of the impeller discharge to the electric

power uptake of the mixer, can be defined. The definition draws on the assumption that the approaching velocity, u, is

small enough to have negligible influence on the mixer impeller characteristics. The hydraulic discharge power P = p Q

h

can be expressed in thrust using the relations

p = F / A and F = 2 ρ Q / A

which are approximately valid for the mixer test established herein. The conventional area of the vena contracta A / 2 is

used, as this discharge section best fulfils the flat velocity profile requirement. With A = π D / 4, one obtains

1/2 3/2 1/2

P = (F / A) (A F / 2 ρ) = F / [D (π ρ / 2) ]

h

Hence the impeller efficiency can be written

3/2 1/2

η = F / [(π ρ / 2) D P ]

It can be noted that, often correct to within 1 %, the efficiency is conventionally given as (assuming SI units [F] = Newton,

[P ] = Watt, [D] = meter, and clean cold water as defined in 5.4.5.2)

3/2

η = F / (40 D P )

Although the derivation given here is not based on completely correct assumptions, the approximate expression for the

efficiency may be derived in more rigorous ways.

The value of the impeller efficiency alone is not deemed to be of primary interest because of the dependency of mixer-

system efficiency on the impeller diameter and speed.

2.2

advance ratio

ratio of propeller traversing speed or mean liquid ambient speed to (essentially) tip speed

J = u / nD

2.3

impeller Reynolds number

ratio between inertial and viscous forces prevailing at impeller

1/2

Re = (F / ρ ) / ν

NOTE F is the thrust for the same mixer running at the same speed in clean cold water as defined in 5.4.5.2. Also

note that this is not the same as the blade Reynolds number, nor is it identical, but akin to the impeller Reynolds number

used for dry-installed agitators in the process industries.

2 © ISO 2007 – All rights reserved

3 Symbols and abbreviated terms

Table 1 summarizes the symbols in alphabetical order and SI units used.

Table 1 — Alphabetical list of letters used as symbols

Symbol Quantity Unit

A Area swept by impeller m

D Diameter of impeller m

e Uncertainty, relative (pure number), %

−1

f Frequency s , Hz

F Thrust N

J Propeller advance ratio (pure number)

L Length of lever m

−1

n Speed of rotation s , Hz

p Pressure Pa

P Power W

Q Flow rate m /s

R Thrust-to-power ratio N/W

FP

Re Impeller Reynolds number (pure number)

t Tolerance (pure number), %

T Time s

u Mean velocity in the axial or m/s

longitudinal direction

U Voltage V

x Generic measured entity

Time average of x

η Efficiency (pure number), %

ν Kinematic viscosity m /s

ρ Density kg/m

σ Standard deviation

Table 2 summarizes the subscripts used for the symbols.

Table 2 — Alphabetical list of letters and figures other than above used as subscript

Subscript Meaning

1 electric (power)

G guaranteed

L/L length ratio

h hydraulic (power)

LC load cell related

m measured

M mixer related

FP see R

FP

sp specified

Tr translated

TS time series

4 Guarantees

4.1 Subjects of guarantees

4.1.1 General

Terms used herein such as “guarantee” or “acceptance” should be understood in a technical but not in a legal

sense. The term “guarantee” therefore specifies values for checking purposes determined in the contract, but

does not say anything about the rights or duties arising if these values are not reached or fulfilled. The term

“acceptance” does not have any legal meaning here, either. Therefore, an acceptance test carried out

successfully alone does not represent an “acceptance” in the legal sense.

A procedure for verifying the guarantees is given in 6.4.

4.1.2 Thrust guarantee

One guarantee point shall be defined by a guarantee thrust

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.