ISO 3087:2020

(Main)Iron ores — Determination of the moisture content of a lot

Iron ores — Determination of the moisture content of a lot

This document specifies a method for the determination of the moisture content of a lot of iron ore. This method is applicable to all iron ores, whether natural or processed.

Minerais de fer — Détermination de l'humidité d'un lot

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 3087

Fifth edition

2020-07

Iron ores — Determination of the

moisture content of a lot

Minerais de fer — Détermination de l'humidité d'un lot

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

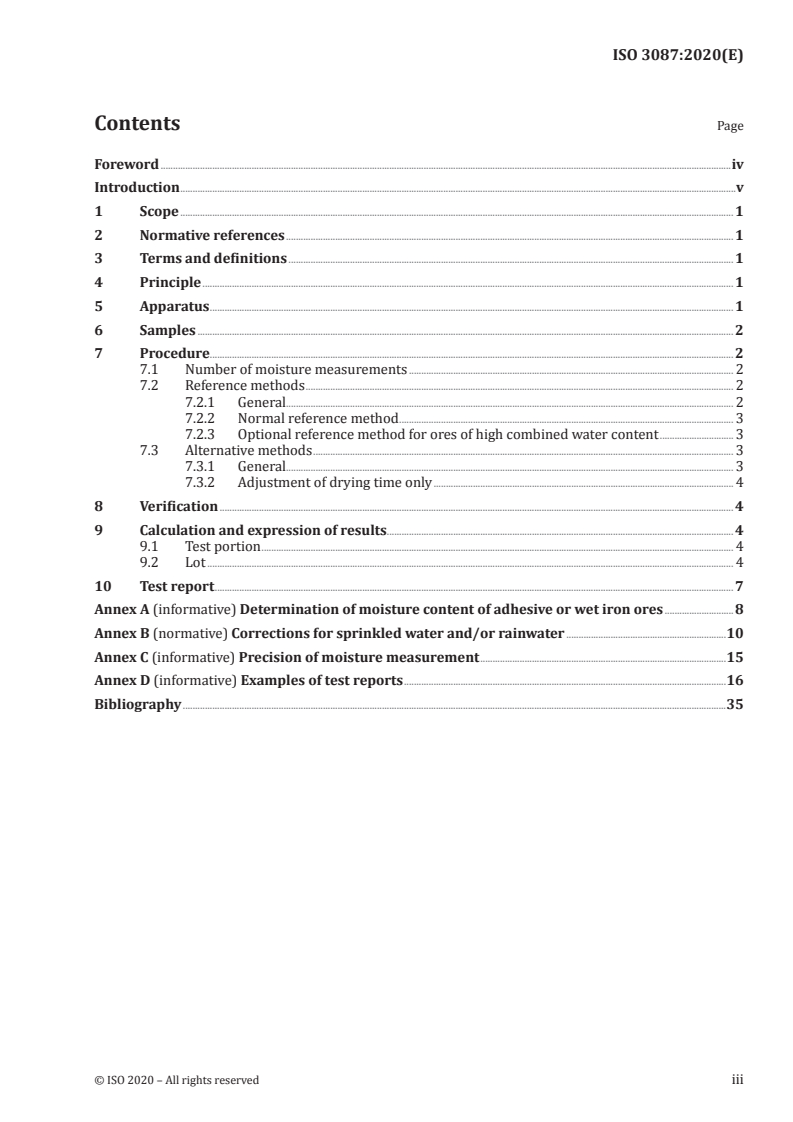

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 1

5 Apparatus . 1

6 Samples . 2

7 Procedure. 2

7.1 Number of moisture measurements . 2

7.2 Reference methods . 2

7.2.1 General. 2

7.2.2 Normal reference method . 3

7.2.3 Optional reference method for ores of high combined water content . 3

7.3 Alternative methods . 3

7.3.1 General. 3

7.3.2 Adjustment of drying time only . 4

8 Verification . 4

9 Calculation and expression of results . 4

9.1 Test portion . 4

9.2 Lot . 4

10 Test report . 7

Annex A (informative) Determination of moisture content of adhesive or wet iron ores .8

Annex B (normative) Corrections for sprinkled water and/or rainwater .10

Annex C (informative) Precision of moisture measurement .15

Annex D (informative) Examples of test reports .16

Bibliography .35

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 102, Iron ore and direct reduced iron,

Subcommittee SC 1, Sampling.

This fifth edition cancels and replaces the fourth edition (ISO 3087:2011), which has been technically

revised. The main changes compared with the previous edition are as follows:

— the existing two 105 °C moisture determination methods have been confirmed to serve as reference

methods;

— alternative moisture determination methods are now allowed if they can be shown to result in

equivalent moisture contents as the reference methods;

— the weighing device readability requirement has been changed from 0,05 % to 0,01 % equivalent of

test portion mass;

— Clause 9 has been revised;

— Annex D has been updated with new example reports.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

iv © ISO 2020 – All rights reserved

Introduction

Currently, large tonnages of iron ore are traded internationally and a small error in the measured

moisture content [mass fraction (%)] of a lot has a considerable effect on the commercial transaction.

The correct determination of moisture content of a lot is, therefore, a matter of importance for both the

purchaser and the vendor.

This document does not address the determination of the hygroscopic moisture content of a test sample

for chemical analysis. If the hygroscopic moisture content is required to be determined, reference

should be made to ISO 2596:2006.

INTERNATIONAL STANDARD ISO 3087:2020(E)

Iron ores — Determination of the moisture content of a lot

1 Scope

This document specifies a method for the determination of the moisture content of a lot of iron ore. This

method is applicable to all iron ores, whether natural or processed.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3082, Iron ores — Sampling and sample preparation procedures

ISO 3085, Iron ores — Experimental methods for checking the precision of sampling, sample preparation

and measurement

ISO 3086, Iron ores — Experimental methods for checking the bias of sampling

ISO 11323, Iron ore and direct reduced iron — Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 11323 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

4 Principle

Dry the test portion in air at 105 °C and measure the loss in mass. Express the moisture content as the

mass loss relative to the original mass of the sample as a mass fraction (%).

5 Apparatus

5.1 Drying pan, with a smooth surface, free from contamination and capable of accommodating the

specified quantity of a test portion in a layer of nominal thickness not greater than 31,5 mm.

5.2 Drying oven, equipped with a temperature indicator and control apparatus capable of regulating

the temperature at any point in the oven at 105 °C ± 5 °C and so designed as to maintain this temperature

with a current of air to ensure efficient drying but without any loss of sample, and fitted with a fan that

allows for both the circulation and change of air.

5.3 Weighing device, with readability equivalent to at least 0,01 % of the Table 1 minimum test

portion mass. The weighing device should be protected from the influence of heat.

The capacity of the weighing device shall be enough for the combined mass of the drying pan and the

initial mass of the test portion.

6 Samples

Test samples that have been taken and prepared in accordance with ISO 3082 shall be used. The

mass of a test portion, in relation to its nominal top size, is specified in Table 1, in accordance with

ISO 3082:2017, 10.6.

The nominal top size of the moisture test sample shall be 31,5 mm or less. Samples with a nominal

top size greater than 31,5 mm shall be crushed prior to extraction of test samples for moisture

determination. When it is difficult to conduct crushing and dividing owing to a sample being adhesive

or excessively wet, the sample may be partially dried in accordance with the procedure in Annex A.

For convenience, the test portion of mass 10 kg for ore of particle size less than 31,5 mm may be divided

into two portions, each of which is subjected to moisture measurement. In calculating the results, the

mean of the two values of initial mass and the mean of the two values of the drying loss in mass should

be used.

Table 1 — Minimum mass of test portion

Nominal top size of test Minimum mass of test

portion portion

mm kg

Over Up to and

including

22,4 31,5 10

10,0 22,4 5

― 10,0 1

7 Procedure

7.1 Number of moisture measurements

Carry out one moisture measurement per test portion on the number of test portions specified in

Table 2, in accordance with the conditions of preparation of the test sample.

In order to minimize losses of moisture to the atmosphere, it is necessary to perform all the initial

weighings of the test portions as quickly as possible after obtaining those test portions.

Table 2 — Number of test portions

Preparation of test sample Number of partial samples per lot Number of test portions to be tested

From gross sample — 4 per gross sample

2 4 per partial sample

From partial sample 3 to 7 2 minimum per partial sample

≥ 8 1 minimum per partial sample

From increment — 1 minimum per increment

7.2 Reference methods

7.2.1 General

The moisture determination shall be conducted in accordance with 7.2.2 or, optionally for ores with

8 % or more of combined water, in accordance with 7.2.3.

2 © ISO 2020 – All rights reserved

7.2.2 Normal reference method

Apply the following procedure.

a) Spread the test portion in a layer of nominal thickness not greater than 31,5 mm in the tared drying

pan (5.1) and determine the total mass immediately. Record the total mass, the mass of the drying

pan, the initial mass of the test portion (m ) and the numerical value of 0,05 % of m . To reduce

1 1

drying time, it is recommended that the layer-thickness of the sample be kept as low as possible. It

should be specified for particular ores by check experiments carried out beforehand.

b) Place the drying pan with the test portion in the drying oven (5.2) set at 105 °C, and maintain this

temperature for not less than 4 h. Remove the drying pan with the test portion from the drying

oven and weigh it immediately while still hot in order to minimize any reabsorption of moisture.

Otherwise, weigh the test portion after cooling in air in a container having a close-fitting airtight

lid. In each case, report the method of weighing.

c) Once more, place the drying pan with the test portion in the drying oven, heat for a further 1 h, and

then repeat the weighing.

d) Repeat the procedure described in item c) until the difference in mass between subsequent

measurements becomes 0,05 % or less of the initial mass of the test portion. Record the total mass

and the mass of the test portion after each additional hour of drying (m and onwards).

7.2.3 Optional reference method for ores of high combined water content

For ores containing 8 % or more combined water, the following procedure may be applied.

a) Spread the test portion in a layer of nominal thickness not greater than 31,5 mm in the tared drying

pan (5.1) and determine the total mass immediately. Record the total mass, the mass of the drying

pan and the initial mass of the test portion (m ).

b) Place the drying pan with the test portion in the drying oven (5.2) set at 105 °C and maintain this

temperature for not less than 24 h. Remove the drying pan with the test portion from the drying

oven and weigh it immediately while still hot in order to minimize any reabsorption of moisture.

Otherwise, weigh the test portion after cooling in air in a container having a close-fitting airtight

lid. Record the total mass and the mass of the test portion after drying (m₂). In each case, report the

method of weighing.

7.3 Alternative methods

7.3.1 General

Alternative methods refer to the potential use of different technology, such as ovens that do not rely on

convection drying alone, or to procedures that potentially differ in terms of oven temperature (up to

140 °C) and time from what is described in 7.2, but which do not deviate from the conditions stipulated

in Clause 6 and 7.1 (minimum mass of test portion and number of portions to be tested).

Such alternative methods or modifications for determining the moisture content are allowed where

check experiments carried out beforehand, which demonstrate satisfactorily to all parties concerned

that an equivalent moisture result is obtained when compared to the applicable reference method

specified in 7.2. This demonstration shall include ISO 3086 bias testing using a relevant bias of no more

than 0,05 % moisture and where the confidence interval includes the zero. Further, the precision of the

alternative method shall be demonstrated by ISO 3085 to be the same or better than achieved by the

applicable reference method.

If the sample is subsequently to be used for multiple use, the chemistry, LOI and size distribution of the

dried remains shall be checked by means of ISO 3086 to ensure they are not different to dried remains

from equivalent reference moisture testing methods. If any changes are identified, the alternative

method shall be discarded.

7.3.2 Adjustment of drying time only

In the case where an alternative method changes only the drying times specified in 7.2.2 in order to

eliminate repeat weighings for verification of constant mass, then it is only necessary to demonstrate

equivalence of precision and moisture result.

8 Verification

Regular checking of apparatus and procedures is essential to verify the test results. Checks shall be

carried out prior to the commencement of a routine test in accordance with this document and at

regular intervals thereafter. The frequency of checking is a matter for each laboratory to determine. A

detailed record of all verification activities shall be maintained for the following items:

— sprinkled water measurement:

— volumenometer;

— rainfall measurement:

— rain gauge;

— moisture test:

— oven temperature/temperature regulation;

— circulation and change of air in oven;

— weighing device.

9 Calculation and expression of results

9.1 Test portion

The result of the determination of the moisture content, w , expressed as a mass fraction (%), for each

i

test portion, is given by Formula (1) and reported to the second decimal place:

mm−

w = ×100 (1)

i

m

where

m is the initial mass, in grams, of the test portion;

m is the mass, in grams, of the test portion after drying.

An illustration of moisture determination of a random test portion is shown in an example test report

in Table D.1.

9.2 Lot

9.2.1 The moisture content of a lot is given by one of the Formulae (2) to (6), as the occasion may

demand, and reported to the first decimal place.

Sprinkled water and/or rainwater over iron ore during loading and/or unloading operation, i.e. moisture

added after/before the point where sampling has taken place, shall be corrected in accordance with the

procedure specified in Annex B.

4 © ISO 2020 – All rights reserved

9.2.2 When moisture determination is conducted on the gross sample from the lot, the moisture of the

lot is determined as follows.

When the range of the four test results does not exceed 1,3r, as given in Table 3, the arithmetic mean w

of the four results shall be the moisture content, expressed as a mass fraction (%), of the lot as given by

Formula (2):

w ++w w +w

12 34

w= (2)

where w , w , w and w are the results of the determinations of the moisture contents, expressed as a

1 2 3 4

mass fraction (%), on each of the four test portions.

When the range of the four test results exceeds 1,3r, as given in Table 3, the median shall be taken as

the moisture content of the lot. The median of four test results is defined as the mean of the two non-

extreme test results.

Table 3 — Repeatability limit of moisture determination on the gross sample

Average of moisture content Repeatability limit Repeatability limit

a

w r 1,3r

mass fraction (%) mass fraction (%) mass fraction (%)

w≤3 0,20 0,26

36<≤w 0,25 0,33

0,31 0,40

6

a

The theoretical background of the repeatability limit is shown in Annex C.

An illustration of moisture determination of a gross sampled lot with four test portions, where the

range of the four moistures do not exceed 1,3r, is shown in an example test report in Table D.2.

An illustration of moisture determination of a gross sampled lot with four test portions, where the

range of the four moistures exceed 1,3r, is shown in an example test report in Table D.3.

9.2.3 When mass-basis sampling has been performed and moisture determination is conducted on

each partial sample, the weighted mean, w , of the results from all the partial samples, considering the

number of increments for each partial sample, shall be the moisture content, expressed as a mass fraction

(%), of the lot, as given by Formula (3):

k

Nw

∑

ii

i=1

w= (3)

k

N

∑

i

i=1

where

k is the number of partial samples;

N is the number of increments in the ith partial sample;

i

w

is the result of the determination of the moisture content, expressed as a mass fraction (%), of

i

the ith partial sample, in accordance with Table 2, using either four or two as the number of test

portions.

When partial samples are used and four test portions are conducted in any partial sample, the criteria

established in 9.2.2 may be applied.

Illustrations of moisture determination of mass-basis sampled lots with two, four and eight partial

samples are shown in the example test reports given in Annex D in Tables D.4, D.6 and D.8, respectively.

If it is impracticable to sample the lot as a whole, or desirable to sample a lot in separate parts of unequal

mass as in the case of time-basis sampling, the moisture content of each part shall be determined

independently and the weighted mean, w , of the results, expressed as a mass fraction (%), of the lot

calculated from the individual results using Formula (4):

k

mw

∑

i i

i=1

w= (4)

k

m

∑ i

i=1

where

k is the number of partial samples;

m is the mass of the ith part;

i

is the result of the determination of the moisture content, expressed as a mass fraction (%), of

w

i

the ith part.

Illustrations of moisture determination of time-basis sampled lots with two, four and eight partial

samples are shown in the example test reports given in Annex D, in Tables D.5, D.7 and D.9, respectively.

9.2.4 When moisture determination is conducted on each increment during mass basis sampling, the

arithmetic mean, w , of the results for all increments obtained in accordance with 9.1 shall be the

moisture content, expressed as a mass fraction (%), of the lot as given by Formula (5):

n

w

∑

i

i=1

w= (5)

n

where

n is the number of increments;

w is the result of the determination of the moisture content, expressed as a mass fraction (%), of

i

the ith increment.

An illustration of moisture determination of a mass-basis sampled lot where moisture is individually

determined for each of 30 increments, is shown in an example test report in Table D.10.

When moisture determination is conducted on each increment during time basis sampling, the weighted

mean, w , of the results for all increments obtained in accordance with 9.1 shall be the moisture content,

expressed as a mass fraction (%), of the lot as given by Formula (6):

k

mw

ii

∑

i=1

w= (6)

k

m

∑ i

i=1

where

6 © ISO 2020 – All rights reserved

k is the number of increments;

m is the mass of the ith part that the increment represents;

i

w is the increment moisture content, expressed as a mass fraction (%).

i

An illustration of moisture determination of a time-basis sampled lot, where moisture is individually

determined for each of 25 increments, is shown in an example test report in Table D.11.

10 Test report

The test report shall contain the following information:

a) a reference to this document, i.e. ISO 3087:2020;

b) the details necessary for the identification of the sample;

c) the results of the test;

d) the reference number of the result;

e) the details of the procedure (including apparatus, temperature and time used in the test);

f) any characteristics noticed during the determination, and any operation not specified in this

document;

g) the date of the test.

Examples of test reports are shown in Annex D.

Annex A

(informative)

Determination of moisture content of adhesive or wet iron ores

A.1 General

When it is difficult to conduct sieving, crushing, and dividing, owing to a sample being adhesive or

excessively wet, the sample may be partially dried until preparation can be conducted without difficulty.

In this case, the moisture content of the lot shall be obtained by using the partial drying method in

accordance with the procedure specified in this annex. In handling the test sample and weighing

the initial mass and partially dried mass of the test sample, attention shall be paid to ensuring the

measurement precision of the partially dried moisture content.

A.2 Procedure

A.2.1 Determine the initial mass of the test sample.

A.2.2 Spread the test sample in a uniform thickness and dry it in air or in a drying apparatus at a

temperature no higher than 105 °C. The choice of temperature and time for this partial drying stage shall

not exceed a point where an ore is likely to reabsorb moisture during subsequent processing.

A.2.3 After partial drying, again determine the mass of the test sample.

A.2.4 Calculate the partially dried moisture content, w , expressed as a mass fraction (%), of the test

p

sample using Formula (A.1):

′ ′

mm−

w = ×100 (A.1)

p

′

m

where

m′ is the initial mass, in grams, of the test sample;

′

m is the mass, in grams, of the test sample after partial drying.

A.2.5 Prepare the test portions for moisture measurement from the partially dried sample in

accordance with the procedure in ISO 3082.

A.2.6 Determine the drying loss of the test portion in accordance with 7.2 and calculate the additional

moisture content, expressed as a mass fraction (%), in accordance with 9.1.

8 © ISO 2020 – All rights reserved

A.2.7 Calculate the total (as received) moisture content, w , expressed as a mass fraction (%), of the

pd

test sample using Formula (A.2):

100−w

p

w =+w ×w (A.2)

pd p d

where w is the additional moisture content obtained in accordance with 9.1 after partial drying,

d

expressed as a mass fraction (%).

A.2.8 Determine the moisture content, as a mass fraction (%), of the lot in accordance with 9.2.

A.2.9 If the mass of the moisture sample is not large, the entire quantity of the sample may be dried in

order to conduct the moisture determination in accordance with the method specified in the body of this

document.

Annex B

(normative)

Corrections for sprinkled water and/or rainwater

B.1 General

B.1.1 In many countries, strict environmental regulations must be observed in the iron ore and steel

industry. When water is sprinkled over iron ore during loading and/or unloading operations to prevent

dust evolution, the moisture content of a lot shall be corrected, in accordance with the procedure

specified in this annex, for the mass of water sprinkled.

This annex also describes a method for correcting the moisture content of a lot containing rainwater.

B.1.2 Water is sprinkled for the following reasons:

a) environmental regulations at loading and/or unloading ports;

b) difficulty of handling iron ores due to ore characteristics, weather conditions, handling

equipment, etc.

B.1.3 Correction for rainwater shall be made whenever rainfall occurs during the loading or unloading

operations, and the moisture content of the lot is known to have been affected.

B.2 Corrections for sprinkled water

B.2.1 General

In the case of unloading a lot, sprinkled water refers to water sprinkled (or sprayed) in the vessel holds

and/or on any sections extending to a point where samples are taken. In the case of loading of a lot,

sprinkled water refers to water sprinkled in the holds and/or on the loading conveyors located after the

point where moisture samples are taken.

Two methods of correction for sprinkled water are mentioned in this subclause. One refers to water

added before the sampling point during unloading operations, the other to water added after the

sampling point during loading operations.

B.2.2 Measurement of sprinkled water

The measurement of sprinkled water shall be made with a volumenometer having an accuracy of ±5 %.

The volume obtained shall be converted to a mass, m , in tonnes, by multiplying it by the density of the

sprinkled water.

NOTE Fresh water is assumed to have a density of 1 t/m .

B.2.3 Mass of lot

The mass of the lot, m , in tonnes, as received or as despatched without sprinkled water or rainwater, or

the mass of the lot, m , in tonnes as received or as despatched containing sprinkled water or rainwater,

10 © ISO 2020 – All rights reserved

should be determined by draught survey or by other internationally recognized means, such as

weightometer or weigh hopper.

NOTE In the examples given in B.2.4, B.2.5, B.3.6, B.3.7, B.4 and B.5, it is assumed that the mass of the lot has

been determined by draught survey. In these instances, the determination of mass is conducted either before any

sprinkled water or rainwater is added (unloading operations) or after all sprinkled water or rainwater has been

added (loading operations).

If a weightometer or weigh hopper is used, special care shall be taken to ensure that corrections take

into account the relative position of the weighing device and the sampling point. For example, during

unloading operations, if sampling is conducted immediately after the weighing device, no corrections

for sprinkled water or rainwater are necessary. However, corrections may be necessary if the sampling

point is remote from the weighing device.

B.2.4 Calculation of moisture content corrected for sprinkled water added during

unloading operations prior to taking moisture samples

The moisture content of the lot, w , expressed as a mass fraction (%), corrected for sprinkled water is

s

given by Formula (B.1) and reported to the first decimal place:

m

ww=−()100−w f (B.1)

s

m

where

w

is the mean value of the moisture content, expressed as a mass fraction (%), of a sample taken

containing sprinkled water, calculated to the second decimal place;

m is the mass, in tonnes, of sprinkled water;

m is the mass, in tonnes, of the lot as received without sprinkled water, as determined in B.2.3;

f is a predetermined factor to correct for water lost during sprinkling.

NOTE In determining a suitable f factor, the following factors are considered on a case-by-case basis:

— atmospheric conditions:

— humidity;

— air temperature;

— wind effects;

— rainfall;

— ore type/ore characteristics:

— sizing;

— mineralogy;

— porosity/texture;

— moisture content;

— sprinkler arrangement/geometry;

— chemical reagents/additives in water.

B.2.5 Calculation of moisture content corrected for sprinkled water added during

loading operations after taking moisture samples

The moisture content of the lot, w , expressed as a mass fraction (%), corrected for sprinkled water, is

s

given by Formula (B.2) and reported to the first decimal place:

m

ww=+()100−w f (B.2)

s

m

where

w

is the mean value of the moisture content, expressed as a mass fraction (%), of a sample taken

prior to sprinkled water, calculated to the second decimal place;

m is the mass, in tonnes, of sprinkled water;

m is the mass, in tonnes, of the lot containing sprinkled water, as determined in B.2.3;

f is a predetermined factor to correct for water lost during sprinkling.

B.3 Corrections for rainwater

B.3.1 General

The moisture content of the lot shall be determined from the as-tested moisture content by allowing

for the influx of rainwater into the vessel's hold(s), and/or onto the handling equipment during both

loading and unloading operations.

Two methods of correction for rainwater are mentioned in this subclause. One refers to rainwater influx

before the sampling point during unloading operations, the other to rainwater influx after the sampling

point during loading operations.

B.3.2 Effective area caught in the rain

The effective area exposed to the rain shall be calculated by summation of the areas specified below,

rounded to the nearest square metre.

a) Hatch(es): The open area, in square metres, of the hatch(es) through which the lot is exposed to the

rain shall be calculated on the basis of the drawings provided on board the carrying vessel.

b) Surge hopper(s): The open area, in square metres, of the hopper(s) used during handling the lot and

exposed to the rain shall be calculated on the basis of drawings of the hopper(s).

c) Belt conveyor(s): The open area, in square metres, of the belt conveyor(s) shall be calculated by

multiplying the effective belt width by the length exposed to the rain during transportation of the

lot between the vessel and the point where moisture samples are taken.

B.3.3 Duration of rainy periods

The duration of rainy periods shall be determined from the time of the opening of the hatches to

completion of sampling.

B.3.4 Amount of rainwater

The amount of rainwater shall be determined by means of an approved rain gauge placed close to the

loading or the unloading port. The amount of rainwater shall be measured to the nearest millimetre.

12 © ISO 2020 – All rights reserved

B.3.5 Mass of rainwater

The mass, m , in tonnes, of rainwater is given by Formula (B.3) and rounded off to the nearest unit:

R

ARρ

m = (B.3)

R

where

A is the effective area, in square metres, exposed to the rain, as calculated in B.3.2;

R is the quantity, in millimetres, of rainwater obtained in B.3.4;

ρ is the density, expressed in tonnes per cubic metre, of rainwater (usually ρ = 1 t/m ).

B.3.6 Calculation of moisture content corrected for rainwater ingress during unloading

operations prior to taking moisture samples

When a lot is partially or totally exposed to the rain during unloading operations prior to taking

moisture samples, the moisture content, w , expressed as a mass fraction (%), of the lot corrected for

R

rainwater is given by Formula (B.4) and reported to the first decimal place:

m

R

ww=−()100−w (B.4)

R

m

where

w

is the mean value of the moisture content, expressed as a mass fraction (%), of a sample taken

containing rainwater, calculated to the second decimal place;

m is the mass, in tonnes, of rainwater;

R

m is the mass, in tonnes, of the lot as received without rainwater, as determined in B.2.3.

B.3.7 Calculation of moisture content corrected for rainwater ingress during loading

operations after taking moisture samples

When a lot is partially or totally exposed to rain during loading operations after taking moisture

samples, the moisture content, w , expressed as a mass fraction (%), of the lot corrected for rainwater

R

is given by Formula (B.5) and reported to the first decimal place:

m

R

ww=+()100−w (B.5)

R

m

where

w

is the mean value of the moisture content, expressed as a mass fraction (%), of a sample taken

prior to rain, calculated to the second decimal place;

m is the mass, in tonnes, of rainwater;

R

m is the mass, in tonnes, of the lot containing rainwater, as determined in B.2.3.

B.4 Corrections for both sprinkled water and rainwater ingress during unloading

operations prior to taking moisture samples

The corrected moisture content, w , expressed as a mass fraction (%), of a lot which has been wetted

o

with both sprinkled water and rainwater prior to taking moisture samples, is given by Formula (B.6)

and reported to the first decimal place:

()mf+m

3 R

ww=−()100−w (B.6)

o

m

where f, m , m , m and w are as previously defined.

3 4 R

B.5 Corrections for both sprinkled water and rainwater ingress during loading

operations after taking moisture samples

The corrected moisture content, w , expressed as a mass fraction (%), of a lot which has been wetted

o

with both sprinkled water and rainwater after taking moisture samples is given by Formula (B.7) and

reported to the first decimal place:

()mf+m

3 R

ww=+()100−w (B.7)

o

m

where f, m , m , m and w are as previously defined.

3 5 R

14 © ISO 2020 – All rights reserved

Annex C

(informative)

Precision of moisture measurement

This document assumes that single test results have the precision shown as β in Table C.1.

PM

When two test portions have been prepared from a single test sample and subjected to moisture

measurement in the same laboratory, the test results will generally agree to within the repeatability

limit, which is given as r in Table 3 and which may be calculated as 2β .

PM

Table C.1 — Precision of moisture measurement

Precision

Average moisture content

w

β

PM

mass fraction (%)

mass fraction (%)

w≤3 ±0,14

36<≤w ±0,18

6

Annex D

(informative)

Examples of test reports

Eleven examples of test reports are shown in Tables D.1 to D.11.

Table D.1 is a test report for moisture measurement on a test portion whereas the rest all pertain to the

calculation of the moisture content of lots.

Table D.1 — Example of a test report for calculating moisture measurement of a test portion

Moisture determination of a single random test portion in accordance with ISO 3087:2020, 9.1,

Formula (1)

Date 5 May 2012

Type of iron ore DR high grade lump

Nominal top size of ore 22,4 mm

Test portion minimum mass per ISO 3087:2020, Table 1 5 kg

Identity of test portion D45E

Testing of a single portion from a test sample

Remarks whether as part of gross sample, partial sample or

increment

Laboratory reference number D45E-5-IV-12

Laboratory technician TE Sterman

Total mass before drying (g) (1) 6 015,4

Mass of drying pan (g) (2) 949,8

Initial mass of test portion (g) (3) = (1) – (2) 5 065,6

0,05 % of initial mass of test portion (g) (4) = (3) / 2 000 2,5

Total mass after 4 h drying (g) (5) 5 804,8

Total mass after further 1 h drying (g) (6) 5 795,2

Difference after 5 h drying (5) – (6) 9,6

Total mass after another 1 h drying (g) (7) 5 793,5

Difference after 6 h drying (6) – (7) 1,7

Final drying loss (g) (8) = (1) – (7) 221,9

Value of moisture measurement, w (%) (9) = 8 / 3 4,38 %

i

The difference after 5 h drying (5) – (6) was 9,6 g and exceeded (4). Consequently, another 1 h drying

was conducted.

The difference after 6 h drying (6) – (7) became less than (4), therefore drying of this test portion was

terminated after the second 1 h interval.

16 © ISO 2020 – All rights reserved

Table D.2 — Example test report showing recording and calculation for determining moisture content of a lot from a gross sample

(test portions’ average moisture used)

Moisture determination of a lot through a gross sample in accordance with ISO 3087:2020, 9.2.2

Date 15 December 2015

Type of iron ore Medium grade coarse fines

Nominal top size of ore 17,5 mm

Test portion minimum mass per ISO 3087:2020, Table 1 5 kg

Identity and quantity of lot Lot 2016-426, 229 727 t

Duration of loading 25,6 h

Remarks Four test portions per gross sample as per ISO 3087:2020, Table 2.

Moisture of lot calculated as per ISO 3087:2020, Formula (2)

Laboratory reference number MGCF-15-XII-15

Laboratory technician E Spinctor

Test portion # GS-TP1 GS-TP2 GS-TP3 GS-TP4

Total mass before drying (g) (1) 6 004,1 6 014,9 5 969,8 5 988,1

Mass of drying pan (g) (2) 957,2 950,1 946,6 948,3

Initial mass of test portion (g) (3) = (1) – (2) 5 046,9 5 064,8 5 023,2 5 039,8

0,05 % of initial mass of test portion (g) (4) = (3) / 2 000 2,52 2,53 2,51 2,52

Total mass after 4 h drying (g) (5) 5 800,3 5 805,2 5 768,8 5 790,9

Total mass after further 1 h drying (g) (6) 5 793,1 5 795,2 5 757,3 5 779,1

Difference after 5 h drying (g) (5) – (6) 7,2 10,0 11,5 11,8

Total mass after another 1 h drying (g) (7) 5 792,1 5 793,5 5 755,7 5 776,8

Difference after 6 h drying (g) (6) – (7) 1,0 1,7 1,6 2,3

Final drying loss (g) (8) = (1) – (7) 212,0 221,4 214,1 211,3

Test portion moisture content, w (9) = 8 / 3 4,20 % 4,37 % 4,26 % 4,19 %

i

Test portion moisture content range 0,18 %

Repeatability × 1,3 (see Table 3) 0,33 %

Moisture content of lot (Average of w ) 4,3 %

i

If sample containers and storage conditions prevent moisture change of moisture partial samples, moisture gross samples may be prepared for whole lots (see

ISO 3082:2017).

18 © ISO 2020 – All rights reserved

Table D.3 — Example test report showing recording and calculation for determining moisture content of a lot from a gross sample

(test portions’ median moisture used)

Moisture determination of a lot through a gross sample in accordance with ISO 3087:2020, 9.2.2

Date 29 March 2018

Type of iron ore High grade fines

Nominal top size of ore 6,3 mm

Test portion minimum mass per ISO 3087:2020, Table 1 1 kg

Identity and quantity of lot 201803-21, 122 574 t

Duration of loading 9,5 h

Remarks Four test portions per gross sample as per ISO 3087:2020, Table 2

Moisture of lot calculated as per ISO 3087:2020, 9.2.2

Laboratory reference number LGF339

Laboratory technician AS Sayer

Test portion # GS-TP1 GS-TP2 GS-TP3 GS-TP4

Total mass before drying (g) (1) 1 500,7 1 502,8 1 494,1 1 497,2

Mass of drying pan (g) (2) 475,3 475,1 475,7 475,2

Initial mass of test portion (g) (3) = (1) – (2) 1 025,4 1 027,7 1 018,4 1 022,0

0,05 % of initial mass of test portion (g) (4) = (3) / 2 000 0,51 0,51 0,51 0,51

Total mass after 4 h drying (g) (5) 1 476,7 1 477,1 1 474,6 1 472,2

Total mass after further 1 h drying (g) (6) 1 473,3 1 473,9 1 470,1 1 471,2

Difference after 5 h drying (g) (5) – (6) 3,4 3,2 4,5 1,0

Total mass after another 1 h drying (g) (7) 1 472,8 1 473,7 1 469,6 1 470,7

Difference after 6 h drying (g) (6) – (7) 0,5 0,2 0,5 0,5

Final drying loss (g) (8) = (1) – (7) 27,9 29,1 24,5 26,5

Test portion moisture content, w (9) = 8 / 3 2,72 % 2,83 % 2,41 % 2,59 %

i

Test portion moisture content range 0,43 %

Repeatability × 1,3 (see Table 3) 0,26 %

Moisture content of lot (Median of w ) 2,7 %

i

If sample containers and storage conditions prevent moisture change of moisture partial samples, moisture gross samples may be prepared for whole lots (see

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.