ISO 16742:2014

(Main)Iron ores — Sampling of slurries

Iron ores — Sampling of slurries

ISO 16742:2014 sets out the basic methods for sampling fine iron ore of nominal top size The procedures described in ISO 16742:2014 apply to sampling of iron ore that is transported in moving streams as a slurry. These streams can fall freely or be confined in pipes, launders, chutes, spirals, or similar channels.

Minerais de fer — Échantillonnage des schlamms

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 16742

First edition

2014-03-01

Corrected version

2015-09-15

Iron ores — Sampling of slurries

Minerais de fer — Échantillonnage des schlamms

Reference number

©

ISO 2014

© ISO 2014, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2014 – All rights reserved

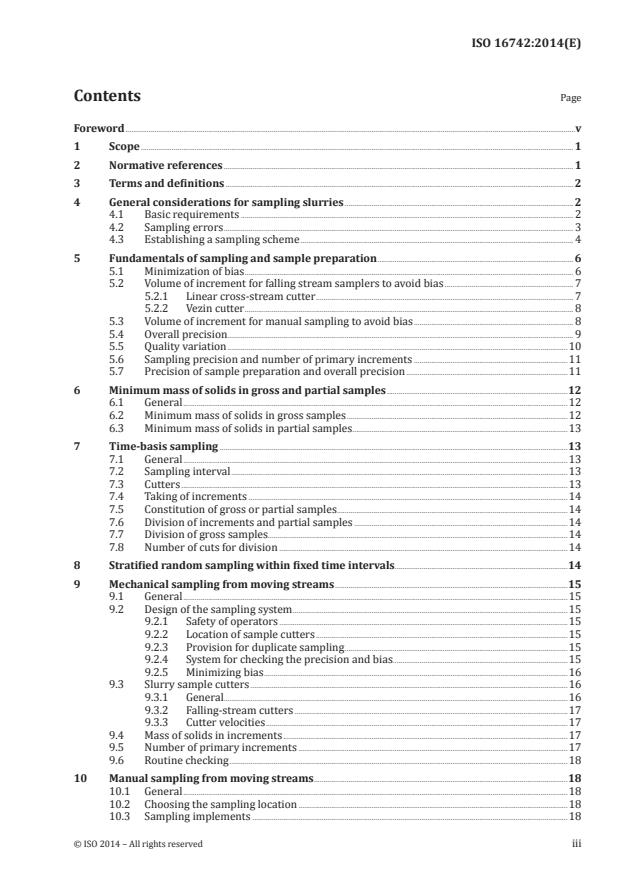

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 General considerations for sampling slurries . 2

4.1 Basic requirements . 2

4.2 Sampling errors . 3

4.3 Establishing a sampling scheme . 4

5 Fundamentals of sampling and sample preparation . 6

5.1 Minimization of bias . 6

5.2 Volume of increment for falling stream samplers to avoid bias . 7

5.2.1 Linear cross-stream cutter . 7

5.2.2 Vezin cutter . 8

5.3 Volume of increment for manual sampling to avoid bias . 8

5.4 Overall precision . 9

5.5 Quality variation .10

5.6 Sampling precision and number of primary increments .11

5.7 Precision of sample preparation and overall precision .11

6 Minimum mass of solids in gross and partial samples .12

6.1 General .12

6.2 Minimum mass of solids in gross samples .12

6.3 Minimum mass of solids in partial samples .13

7 Time-basis sampling .13

7.1 General .13

7.2 Sampling interval .13

7.3 Cutters .13

7.4 Taking of increments .14

7.5 Constitution of gross or partial samples .14

7.6 Division of increments and partial samples .14

7.7 Division of gross samples.14

7.8 Number of cuts for division .14

8 Stratified random sampling within fixed time intervals.14

9 Mechanical sampling from moving streams .15

9.1 General .15

9.2 Design of the sampling system .15

9.2.1 Safety of operators .15

9.2.2 Location of sample cutters .15

9.2.3 Provision for duplicate sampling .15

9.2.4 System for checking the precision and bias.15

9.2.5 Minimizing bias .16

9.3 Slurry sample cutters .16

9.3.1 General.16

9.3.2 Falling-stream cutters .17

9.3.3 Cutter velocities .17

9.4 Mass of solids in increments .17

9.5 Number of primary increments .17

9.6 Routine checking .18

10 Manual sampling from moving streams .18

10.1 General .18

10.2 Choosing the sampling location .18

10.3 Sampling implements .18

10.4 Volume of increments .18

10.5 Number of primary increments .19

10.6 Sampling procedures .19

11 Sampling of stationary slurries .19

12 Sample preparation procedures .20

12.1 General .20

12.2 Grinding mills .20

12.3 Sample division.20

12.4 Chemical analysis samples . .20

12.5 Physical test samples .20

13 Packing and marking of samples .20

Annex A (informative) Examples of correct slurry sampling devices .22

Annex B (informative) Examples of incorrect slurry sampling devices .25

Annex C (normative) Manual sampling implements .28

Bibliography .29

iv © ISO 2014 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does n

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.