EN 1870-13:2007+A1:2009

(Main + Amendment)Safety of woodworking machines - Circular sawing machines - Part 13: Horizontal beam panel sawing machines

Safety of woodworking machines - Circular sawing machines - Part 13: Horizontal beam panel sawing machines

This document deals with the significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to horizontal beam panel sawing machines where the saw unit is mounted below the workpiece support and which are manually or mechanically loaded and / or unloaded, fitted with:

- a side pressure device and / or

- the facility for scoring and / or

- the facility for post-formed / soft-formed edge pre-cutting and / or

- a panel turning device and / or

- a pushing out device and / or

- pneumatic clamping of the saw blade and / or

- a powered panel loading device and / or

- a grooving device and / or

- additional cutting line(s) inside the machine for longitudinal and / or head cut (before transversal cutting line) and / or

- workpiece vacuum clamping as part of a panel turning device or of a panel loading device,

hereinafter referred to as "machines" when they are used as intended and under the conditions foreseen by the manufacturer.

The machines are designed for cutting panels consisting of:

a) wood based materials such as chipboard, fibreboard, plywood and also these materials where they are covered with plastic/light alloy laminates which can be cut easily;

b) solid wood;

c) hardened rubber and hardened plastic material;

d) non ferrous materials e.g. light alloy;

e) gypsum boards, gypsum bounded fibreboards;

f) composite boards made from the materials listed above.

This document does not deal with specific hazards related to:

1) specific features which differ from the list above;

2) the machining of panels with grooving tools;

3) mechanical unloading of panels;

4) the combination of a single machine being used with any other machine (as part of a line).

This document is not applicable to horizontal beam panel sawing machines which are manufactured before the date of its publication as EN.

Sicherheit von Holzbearbeitungsmaschinen - Kreissägemaschinen - Teil 13: Horizontale Plattenkreissägemaschinen mit Druckbalken

Dieses Dokument behandelt !alle signifikanten Gefährdungen", Gefährdungssituationen und Gefährdungsereignisse,

wie sie in Abschnitt 4 aufgelistet sind, und die zutreffen auf horizontale Plattenkreissägemaschinen

mit Druckbalken, bei denen das Sägeaggregat unterhalb der Werkstückauflage angeordnet ist und

mit Beschickung von Hand oder automatisch und/oder Handentnahme, die ausgerüstet sind mit:

einer Seitenandruckeinrichtung (Seitenausrichter) und/oder

einer Einrichtung zum Ritzsägen und/oder

einer Einrichtung zum Postforming/Softforming-Schneiden und/oder

einer Plattendreheinrichtung und/oder

einem Plattenausstoßer und/oder

einer pneumatischen Sägeblattspannung und/oder

einer kraftbetätigten Plattenaufgabeeinrichtung und/oder

einer Nuteinrichtung und/oder

einer zusätzlichen Schnittlinie/zusätzlichen Schnittlinien innerhalb der Maschine für Längs- und/oder

Kopfschnitt (vor der Schnittlinie zum Querschneiden angeordnet) und/oder

einer Vakuum-Werkstückspannung als Teil einer Plattendreheinrichtung oder einer Plattenaufgabeeinrichtung

im Folgenden als „Maschinen“ bezeichnet, wenn sie bestimmungsgemäß und entsprechend den vorhersehbaren

Bedingungen des Herstellers verwendet werden.

Die Maschinen sind bestimmt zum Schneiden von Platten, bestehend aus:

a) Holzwerkstoffen wie Spanplatten, Faserplatten und Sperrholz sowie diesen Werkstoffen, wenn sie mit

Laminat aus Kunststoff oder Leichtmetall-Legierung beschichtet sind, die leicht zu zerspanen sind;

b) Massivholz;

c) Hartgummi und Hartkunststoff;

d) Nichteisenmetallen, z. B. Leichtmetall-Legierung;

e) Gipsplatten, mit Gips gebundene Faserplatten;

f) Verbundplatten, die aus den oben genannten Materialien bestehen.

Sécurité des machines pour le travail du bois - Machines à scie circulaire - Partie 13: Scies à panneaux horizontales à presseur

Varnost lesnoobdelovalnih strojev - Krožne žage - 13. del: Horizontalni krožni žagalni stroji za razrez plošč

General Information

- Status

- Withdrawn

- Publication Date

- 29-Sep-2009

- Withdrawal Date

- 27-Mar-2012

- Technical Committee

- CEN/TC 142 - Woodworking machines - Safety

- Drafting Committee

- CEN/TC 142/WG 4 - Circular sawing machines

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 28-Mar-2012

- Completion Date

- 28-Mar-2012

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 18-Jan-2012

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jul-2009

- Effective Date

- 17-Jul-2010

Get Certified

Connect with accredited certification bodies for this standard

Gozdarski inštitut Slovenije

Slovenian Forestry Institute. Forest management certification support, timber testing.

Sponsored listings

Frequently Asked Questions

EN 1870-13:2007+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of woodworking machines - Circular sawing machines - Part 13: Horizontal beam panel sawing machines". This standard covers: This document deals with the significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to horizontal beam panel sawing machines where the saw unit is mounted below the workpiece support and which are manually or mechanically loaded and / or unloaded, fitted with: - a side pressure device and / or - the facility for scoring and / or - the facility for post-formed / soft-formed edge pre-cutting and / or - a panel turning device and / or - a pushing out device and / or - pneumatic clamping of the saw blade and / or - a powered panel loading device and / or - a grooving device and / or - additional cutting line(s) inside the machine for longitudinal and / or head cut (before transversal cutting line) and / or - workpiece vacuum clamping as part of a panel turning device or of a panel loading device, hereinafter referred to as "machines" when they are used as intended and under the conditions foreseen by the manufacturer. The machines are designed for cutting panels consisting of: a) wood based materials such as chipboard, fibreboard, plywood and also these materials where they are covered with plastic/light alloy laminates which can be cut easily; b) solid wood; c) hardened rubber and hardened plastic material; d) non ferrous materials e.g. light alloy; e) gypsum boards, gypsum bounded fibreboards; f) composite boards made from the materials listed above. This document does not deal with specific hazards related to: 1) specific features which differ from the list above; 2) the machining of panels with grooving tools; 3) mechanical unloading of panels; 4) the combination of a single machine being used with any other machine (as part of a line). This document is not applicable to horizontal beam panel sawing machines which are manufactured before the date of its publication as EN.

This document deals with the significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to horizontal beam panel sawing machines where the saw unit is mounted below the workpiece support and which are manually or mechanically loaded and / or unloaded, fitted with: - a side pressure device and / or - the facility for scoring and / or - the facility for post-formed / soft-formed edge pre-cutting and / or - a panel turning device and / or - a pushing out device and / or - pneumatic clamping of the saw blade and / or - a powered panel loading device and / or - a grooving device and / or - additional cutting line(s) inside the machine for longitudinal and / or head cut (before transversal cutting line) and / or - workpiece vacuum clamping as part of a panel turning device or of a panel loading device, hereinafter referred to as "machines" when they are used as intended and under the conditions foreseen by the manufacturer. The machines are designed for cutting panels consisting of: a) wood based materials such as chipboard, fibreboard, plywood and also these materials where they are covered with plastic/light alloy laminates which can be cut easily; b) solid wood; c) hardened rubber and hardened plastic material; d) non ferrous materials e.g. light alloy; e) gypsum boards, gypsum bounded fibreboards; f) composite boards made from the materials listed above. This document does not deal with specific hazards related to: 1) specific features which differ from the list above; 2) the machining of panels with grooving tools; 3) mechanical unloading of panels; 4) the combination of a single machine being used with any other machine (as part of a line). This document is not applicable to horizontal beam panel sawing machines which are manufactured before the date of its publication as EN.

EN 1870-13:2007+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 79.120.10 - Woodworking machines. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1870-13:2007+A1:2009 has the following relationships with other standards: It is inter standard links to EN 1870-13:2007+A2:2012, EN 1870-13:2007, EN 1870-13:2007/prA1, EN 1870-13:2007+A1:2009/FprA2. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1870-13:2007+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1870-13:2007+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sicherheit von Holzbearbeitungsmaschinen - Kreissägemaschinen - Teil 13: Horizontale Plattenkreissägemaschinen mit DruckbalkenSécurité des machines pour le travail du bois - Machines à scier circulaires - Partie 13: Scies à panneaux horizontales à presseurSafety of woodworking machines - Circular sawing machines - Part 13: Horizontal beam panel sawing machines79.120.10Lesnoobdelovalni strojiWoodworking machines25.080.60Strojne žageSawing machinesICS:Ta slovenski standard je istoveten z:EN 1870-13:2007+A1:2009SIST EN 1870-13:2008+A1:2009en01-december-2009SIST EN 1870-13:2008+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1870-13:2007+A1

September 2009 ICS 79.120.10 Supersedes EN 1870-13:2007English Version

Safety of woodworking machines - Circular sawing machines - Part 13: Horizontal beam panel sawing machines

Sécurité des machines pour le travail du bois - Machines à scier circulaires - Partie 13: Scies à panneaux horizontales à presseur

Sicherheit von Holzbearbeitungsmaschinen - Kreissägemaschinen - Teil 13: Horizontale Plattenkreissägemaschinen mit Druckbalken This European Standard was approved by CEN on 21 October 2007 and includes Amendment 1 approved by CEN on 13 August 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1870-13:2007+A1:2009: ESIST EN 1870-13:2008+A1:2009

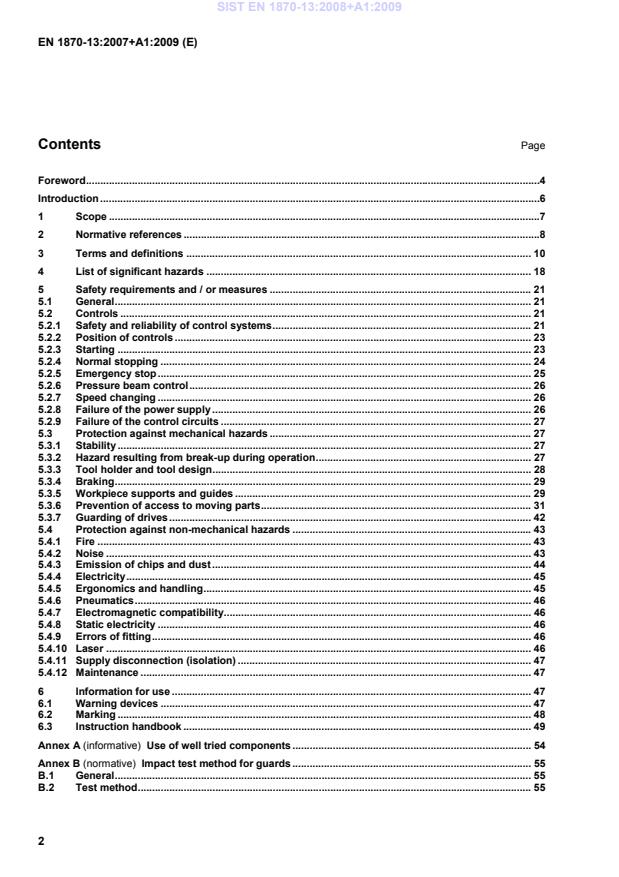

Use of well tried components . 54Annex B (normative)

Impact test method for guards . 55B.1 General . 55B.2 Test method . 55SIST EN 1870-13:2008+A1:2009

Saw spindle dimensional tolerances . 58Annex D (normative)

Rigidity test for sectional safety curtain material . 59Annex E (normative)

Braking tests . 61E.1 Conditions for all tests . 61E.2 Tests . 61E.2.1 Un-braked run-down time . 61E.2.2 Braked run-down time . 61Annex F (normative)

Use of electronic components . 62F.1 General . 62F.2 SRECS design . 62F.2.1 Components, hardware . 62F.2.2 Safety related software . 63Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC . 65Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""" . 68Bibliography . 72 SIST EN 1870-13:2008+A1:2009

1 Scope This document deals with !all significant hazards", hazardous situations and events as listed in Clause 4 which are relevant to horizontal beam panel sawing machines where the saw unit is mounted below the workpiece support and which are manually or mechanically loaded and / or unloaded, fitted with: a side pressure device and / or the facility for scoring and / or the facility for post-formed / soft-formed edge pre-cutting and / or a panel turning device and / or a pushing out device and / or pneumatic clamping of the saw blade and / or a powered panel loading device and / or a grooving device and / or additional cutting line(s) inside the machine for longitudinal and / or head cut (before transversal cutting line) and / or workpiece vacuum clamping as part of a panel turning device or of a panel loading device, hereinafter referred to as "machines" when they are used as intended and under the conditions foreseen by the manufacturer. The machines are designed for cutting panels consisting of: a) wood based materials such as chipboard, fibreboard, plywood and also these materials where they are covered with plastic/light alloy laminates which can be cut easily; b) solid wood; c) hardened rubber and hardened plastic material; d) non ferrous materials e.g. light alloy; e) gypsum boards, gypsum bounded fibreboards; f) composite boards made from the materials listed above. This document does not deal with specific hazards related to: 1) specific features which differ from the list above; 2) the machining of panels with grooving tools; 3) mechanical unloading of panels; 4) the combination of a single machine being used with any other machine (as part of a line). SIST EN 1870-13:2008+A1:2009

Part 2: Immunity SIST EN 1870-13:2008+A1:2009

(ISO 11202:1995) EN ISO 11204:1995, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at a work station and at other specified positions — Method requiring environmental corrections (ISO 11204:1995) EN ISO 11688-1:1998, Acoustics — Recommended practice for the design of low-noise machinery and equipment — Part 1: Planning (ISO/TR 11688-1:1995) SIST EN 1870-13:2008+A1:2009

Figure 1 a) — Example of a horizontal beam panel saw with panel loading from the rear side by a powered loading device and with fixed distance guarding and light barrier SIST EN 1870-13:2008+A1:2009

Figure 1 b) — Example of a horizontal beam panel saw with panel loading from the front side and with fixed distance guarding SIST EN 1870-13:2008+A1:2009

Figure 1 c) — Example of a horizontal beam panel saw with panel loading from the front and with individual safeguarding of hazardous points Figure 1 — Examples of horizontal beam panel saws

Key 1 front cutting line 2 longitudinal cutting line 3 head cutting line Figure 2 — Horizontal beam panel saw cutting lines 3.2 integrated feed feed mechanism for the workpiece and the saw unit(s) incorporating the saw blade(s) which are integrated with the machine and where the workpiece and the saw unit(s) are held and controlled mechanically during the machining operation 3.3 manual loading where the operator puts the workpiece on the workpiece support from the front side of the machine i.e. there is no intermediate loading device to transfer the workpiece from the operator to the machine front cutting line 3.4 manual unloading where the operator removes the workpiece from the workpiece support i.e. there is no intermediate unloading device to transfer the workpiece from the cutting position to the operator within 1 500 mm 3.5 powered loading where the workpiece(s) is / are put on the workpiece support by e.g. a lifting unit or a loading device, normally a lifting platform SIST EN 1870-13:2008+A1:2009

Key 1 post-formed / soft-formed edge pre-cutting saw blade 2 feed direction of the saw unit 3 movement of post-formed / soft-formed edge pre-cutting saw blade 4

main saw blade

Figure 3 — Post-formed / soft-formed edge pre-cutting 3.12 post-formed / soft-formed edge pre-cutting saw blade saw blade used for post-formed edge pre-cutting. This may be the scoring saw blade or a separate saw blade specifically for this purpose 3.13 saw blade rest position position to which the saw blade(s) return(s) at the end of the cut outside the cutting area i.e. into a position below the workpiece support or together with the saw unit into a position outside the cutting area also with protruding saw blade(s) 3.14 saw unit rest position position to which the saw unit returns at the end of each cutting cycle 3.15 pressure beam rest position position to which the pressure beam returns after the saw blade(s) has/have reached its/their rest position 3.16 cutting cycle movements of the saw unit incorporating the saw blade during the machining operation comprising: movement of the saw blade from its rest position to the cutting position; movement of the saw unit from its cutting position through the cutting stroke; SIST EN 1870-13:2008+A1:2009

No Hazards, hazardous situations and hazardous events EN ISO 12100

Relevant clause of this document

Part 1:2003 Part 2:2003

1 Mechanical hazards related to: - machine parts or workpieces due to:

a) shape; 4.2 4.2.1, 4.2.2, 5

5.2.2, 5.3.3, 5.3.5, 5.3.6, 6.2, 6.3, Annex C

b) relative location; 5.2.2, 5.2.3, 5.2.6, 5.3.6, 6.2

c) mass and stability (potential energy of elements which may move under the effect of gravity); 5.2.6, 5.2.8

d) mass and velocity (kinetic energy of elements in controlled or uncontrolled motion); 5.2.3, 5.2.6, 5.3.5, 5.3.6

e) mechanical strength; 5.3.2, Annex B, Annex D

- accumulation of energy inside the machinery by:

f) gases under pressure; 4.2 4.10, 5.5.4 5.4.6 1.1 Crushing hazard 4.2.1

5.2.3, 5.2.4, 5.2.6, 5.3.4, 5.3.5, 5.3.6, 5.3.7, 5.4.11, 5.4.12 1.2 Shearing hazard 5.2.3, 5.2.4, 5.3.4, 5.3.5, 5.3.6, 5.3.7, 5.4.11, 5.4.12 1.3 Cutting or severing hazard 5.2.3, 5.2.4, 5.2.5, 5.2.6, 5.3.4, 5.3.6, 5.3.7, 5.4.11, 5.4.12 1.4 Entanglement hazard 5.2.4, 5.2.5, 5.3.6, 5.3.7, 5.4.11, 5.4.12 1.5 Drawing-in or trapping hazard 5.2.3, 5.2.4, 5.2.5, 5.3.4, 5.3.6, 5.3.7, 5.4, 11, 5.4.12 1.6 Impact hazard 5.2.3, 5.3.5, 5.4.11 1.9 High pressure fluid injection or ejection hazard

4.2.1 4.10

5.2.4, 5.3.5, 5.4.7, 5.4.11 SIST EN 1870-13:2008+A1:2009

5.4.4, 5.4.11 2.2 Contact of persons with parts which have become live under faulty conditions (indirect contact) 4.3 4.9

5.4.4, 5.4.11 2.4 Electrostatic phenomena 4.3 4.9

5.4.8 4 Hazards generated by noise, resulting in: 4.1 Hearing loss (deafness), other physiological disorders (loss of balance, loss of awareness) 4.5 4.2.2, 5

5.4.2 4.2 Interference with speech communication, acoustic signals 6.3 6 Hazards generated by radiation 6.5 Laser 4.7

5.4.10 7 Hazards generated by materials and substances (and their constituent elements) processed or used by the machinery 7.1 Hazards from contact with or inhalation of harmful fluids and dusts 4.8 4.3b, 4.4 5.4.3, 6.3 7.2 Fire

4.8 4.4

5.4.1 8 Hazards generated by neglecting ergonomic principles in machinery design: 8.1 Unhealthy postures or excessive effort 4.9 4.7, 4.8.2, 4.11.12, 5.5.5, 5.5.6 5.2.2, 5.4.5 8.2 Hand-arm or foot-leg anatomy 4.9 4.8.3 5.4.5 8.4 Local lighting

4.8.6 6.3 8.5 Mental overload and underload, stress 4.9 4.8.5 6.3 8.6 Human error, human behaviour 4.9 4.8, 4.11.8, 4.11.10, 5.5.2, 6 6.3 8.7

Design, location or identification of manual controls

4.8.7, 4.11.8

5.2.2 8.8 Design or location of visual display units

4.8.8, 6.2

5.2.2 9 Combination of hazards 4.11

5.2.3, 5.2.5, 5.2.6, 5.2.7, 5.2.9, 5.3.6, 5.4.11, 5.4.12 10 Unexpected start-up, unexpected overrun/overspeed (or any similar malfunction) from: 10.1 Failure / disorder of the control system

4.11, 5.5.4

5.2.1, 5.2.9, 5.4.11 10.2 Restoration of energy supply after an interruption

4.11.4

5.2.8, 5.4.6 10.3 External influences on electrical equipment

4.11.11

5.4.7, Annex F 10.4 Other external influences (gravity)

!4.12.1" 5.3.5 10.5 Errors in the software

4.11.7 Annex F 10.6 Errors made by the operator (due to mismatch of machinery with human characteristics and abilities, see 8.6) 4.9 4.8, 4.11.8, 4.11.10, 5.5.2, 6

!5.2.2, 5.4.5," 6.3 (to be continued)SIST EN 1870-13:2008+A1:2009

Table 1 — List of significant hazards (concluded)

No Hazards, hazardous situations and hazardous events EN ISO 12100

Relevant clause of this document

Part 1: 2003 Part 2: 2003

11 Impossibility of stopping the machine in the best possible conditions

4.11.1, 4.11.3, 5.5.2

5.2.4, 5.2.5, 5.4.11 12 Variations in the rotational speed of tools

4.2.2, 4.3 5.2.7 13 Failure of the power supply

4.11.1, 4.11.4

5.2.8 14 Failure of the control circuit

4.11, 5.5.4

5.2.9 15 Errors of fitting 4.9

4.7, 6.5

5.4.9 16 Break-up during operation 4.2.2 4.3

5.3.2 17 Falling or ejected objects or fluids 4.2.2 4.3, 4.10

5.2.6, 6.3 18 Loss of stability / overturning of machinery 4.2.2 5.2.6

5.3.1

5 Safety requirements and / or measures 5.1 General The machine shall comply with the safety requirements and / or protective measures of Clauses 5 and 6. NOTE 1 In addition, the machine should be designed according to the principles of EN ISO 12100-1:2003 and

EN ISO 12100-2:2003 for hazards relevant but not significant, which are not dealt with by this document (e.g. sharp edges of the machine frame). NOTE 2 For guidance in connection with risk reduction by design see Clause 4 of EN ISO 12100-2:2003 and for safeguarding measures see Clause 5 of EN ISO 12100-2:2003. 5.2 Controls 5.2.1 Safety and reliability of control systems 5.2.1.1 General For the purpose of this document safety related part of a control system means the system from the initial device, e.g. push button or position detector or sensor up to and including the power control element of the final machine actuator or element, e.g. motor or brake. Safety related parts of the control system of this machine comprise parts concerning the following functions and they shall fulfil the requirements of the categories given below according to !EN ISO 13849-1:2008": a) for starting and restarting and for prevention of unexpected start-up after failure of power supply: category 1 or 3 (see 5.2.3, 5.2.8); b) for normal stopping: category 1 or 3 (see 5.2.4); SIST EN 1870-13:2008+A1:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...