EN 13683:2003+A1:2009

(Main + Amendment)Garden equipment - Integrally powered shredders/chippers - Safety

Garden equipment - Integrally powered shredders/chippers - Safety

This European Standard specifies safety requirements and their verification for the design and construction of hand fed, shredders/chippers with integral power source and with or without vacuum assisted collection which are designed primarily to reduce organic material to smaller pieces. It is only applicable to shredders/chippers that are designed for use outdoors in a stationary position by an operator standing on the ground. It applies to shredders/chippers with feed intake openings in the form of a single opening or an opening divided into a number of segments. The feed intake openings or segments each being of any shape that will fit into a square of 250 mm - 250 mm measured at the relevant safety distance to the cutting means.

NOTE Feed safety openings are limited to 250 mm - 250 mm but the total feed intake opening can be any size.

This standard describes methods of elimination or reduction of hazards arising from the use of shredders/chippers. In addition it specifies the type of information to be provided by the manufacturer on safe working practices.

This standard does not cover requirements for:

- units driven by an external power source;

- mobile use of units which can be used in both stationary and mobile modes;

- units with powered discharge intended to broadcast material or load vehicles;

- units with mechanically powered feed intake or attachments;

- units with cutting means of either one or more non-metallic filaments, or one or more non-metallic cutting elements pivotally mounted on a generally circular central drive unit, where these cutting elements rely on centrifugal force to achieve cutting, and have a kinetic energy for each single cutting means of less than 10 J;

- electrical aspects of electrically driven shredders.

Environmental hazards and EMC have not been considered in this standard.

This standard deals with all significant hazards, hazardous situations and events relevant to shredders/chippers, when they are used as intended

Gartengeräte - Motorgetriebene Schredder/Zerkleinerer - Sicherheit

Diese Europäische Norm legt sicherheitstechnische Anforderrungen und Prüfungen für die Gestaltung und

Konstruktion von Schredder/Zerkleinerer mit integriertem Antrieb und mit oder ohne vakuumunterstütztem

Sammelbehälter fest, die in erster Linie zur Reduzierung organischen Materials in kleinere Teile und in fester

Arbeitsposition, wobei der Benutzer auf dem Boden steht, bestimmt sind. Sie gilt für Schredder/Zerkleinerer

mit Einwurföffnungen in Form einer einzelnen Öffnung oder einer in Segmenten unterteilten Öffnung. Die

Einwurföffnungen bzw. Segmente müssen jeweils so geformt sein, dass sie eine Fläche von

250 mm × 250 mm, gemessen vom relevanten Sicherheitsabstand zum Schneidwerkzeug, aufweisen.

ANMERKUNG Die Einwurfsicherheitsöffnungen sind auf 250 mm × 250 mm begrenzt, die Größe der gesamten

Einwurföffnung ist unbeschränkt.

Diese Norm beschreibt Verfahren zur Eliminierung oder Reduzierung von Gefährdungen, die sich aus dem

Gebrauch von Schreddern/Zerkleinerern ergeben. Außerdem legt sie die Art von Informationen fest, die der

Hersteller für den sicheren Gebrauch bereitstellen muss.

Diese Norm enthält keine Anforderungen für:

von einer externen Energiequelle angetriebene Einheiten;

den mobilen Einsatz von Einheiten, die sowohl mobil als auch stationär verwendet werden können;

Einheiten mit motorgetriebenem Auswurf zum Ausstreuen von Material oder zum Beladen von Fahrzeugen;

Einheiten mit mechanisch angetriebenem Einzug oder Anbauten;

Einheiten mit ein oder mehreren nicht metallischen Fäden, oder mit ein oder mehreren nicht metallischen

Schneidelementen, schwenkbar montiert auf eine im Allgemeinen kreisförmige zentrale Antriebseinheit,

wo diese Schneidelemente durch zentrifugale Kraft schneiden und die kinetische Energie für jedes

einzelne Schneidwerkzeug unter 10 J beträgt;

elektrische Aspekte von elektrisch getriebenen Zerkleinerern;

die Gefährdung der Umwelt und EMV wird in dieser Norm nicht in Betracht gezogen.

Matériel de jardinage - Broyeurs/déchiqueteurs à moteur intégré - Sécurité

La présente Norme européenne spécifie les prescriptions de sécurité et leurs vérifications pour la conception et la construction des broyeurs/déchiqueteurs à chargement manuel avec une source de puissance incorporée, munis ou non d'un système de ramassage par aspiration, qui sont conçus principalement pour réduire les matières organiques en morceaux plus petits. Elle s’applique à des broyeurs/déchiqueteurs qui sont conçus pour une utilisation à l’extérieur en position fixe par un utilisateur se tenant debout sur le sol. Elle s'applique aux broyeurs/déchiqueteurs munis d'ouvertures de prise d’alimentation formées d'une seule ouverture ou d'une ouverture divisée en segments. Les ouvertures ou les segments de prise d’alimentation ont chacun une forme quelconque pouvant s'inscrire dans un carré de 250 mm x 250 mm mesuré à la distance de sécurité appropriée de l’organe de coupe.

NOTE Les ouvertures d’alimentation de sécurité sont limitées à 250 mm x 250 mm mais l’ouverture de prise d’alimentation totale peut être de n’importe quelle dimension.

La présente norme décrit les méthodes pour éliminer ou réduire les phénomènes dangereux inhérents à l'utilisation des broyeurs/déchiqueteurs. En outre, elle spécifie le type d'informations que le fabricant doit fournir sur les pratiques d’utilisation sûre.

La présente norme ne traite pas des prescriptions applicables à :

- des machines alimentées par une source de puissance externe ;

- une utilisation mobile d’unités qui peuvent être utilisées à la fois en mode fixe et mobile ;

- des machines munies d’une éjection à moteur destinée à répandre le matériau ou à charger des véhicules ;

- des machines munies d’une prise d’alimentation ou d’outils à alimentation mécanique ;

[....]

Oprema za nego vrta - Motorni drobilniki/sekalniki - Varnost

General Information

- Status

- Withdrawn

- Publication Date

- 21-Apr-2009

- Withdrawal Date

- 08-Mar-2011

- Technical Committee

- CEN/TC 144 - Tractors and machinery for agriculture and forestry

- Drafting Committee

- CEN/TC 144/WG 7 - Garden equipment

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 09-Mar-2011

- Completion Date

- 09-Mar-2011

- Directive

- 98/37/EC - Machinery

Relations

- Merged Into

EN 13683:2003+A2:2011 - Garden equipment - Integrally powered shredders/chippers - Safety - Effective Date

- 18-Jan-2023

- Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 25-Feb-2009

Get Certified

Connect with accredited certification bodies for this standard

Control Union Certifications

Global certification for agriculture and sustainability.

ECOCERT

Organic and sustainability certification.

Rainforest Alliance Certification

Sustainable agriculture and forestry certification.

Sponsored listings

Frequently Asked Questions

EN 13683:2003+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Garden equipment - Integrally powered shredders/chippers - Safety". This standard covers: This European Standard specifies safety requirements and their verification for the design and construction of hand fed, shredders/chippers with integral power source and with or without vacuum assisted collection which are designed primarily to reduce organic material to smaller pieces. It is only applicable to shredders/chippers that are designed for use outdoors in a stationary position by an operator standing on the ground. It applies to shredders/chippers with feed intake openings in the form of a single opening or an opening divided into a number of segments. The feed intake openings or segments each being of any shape that will fit into a square of 250 mm - 250 mm measured at the relevant safety distance to the cutting means. NOTE Feed safety openings are limited to 250 mm - 250 mm but the total feed intake opening can be any size. This standard describes methods of elimination or reduction of hazards arising from the use of shredders/chippers. In addition it specifies the type of information to be provided by the manufacturer on safe working practices. This standard does not cover requirements for: - units driven by an external power source; - mobile use of units which can be used in both stationary and mobile modes; - units with powered discharge intended to broadcast material or load vehicles; - units with mechanically powered feed intake or attachments; - units with cutting means of either one or more non-metallic filaments, or one or more non-metallic cutting elements pivotally mounted on a generally circular central drive unit, where these cutting elements rely on centrifugal force to achieve cutting, and have a kinetic energy for each single cutting means of less than 10 J; - electrical aspects of electrically driven shredders. Environmental hazards and EMC have not been considered in this standard. This standard deals with all significant hazards, hazardous situations and events relevant to shredders/chippers, when they are used as intended

This European Standard specifies safety requirements and their verification for the design and construction of hand fed, shredders/chippers with integral power source and with or without vacuum assisted collection which are designed primarily to reduce organic material to smaller pieces. It is only applicable to shredders/chippers that are designed for use outdoors in a stationary position by an operator standing on the ground. It applies to shredders/chippers with feed intake openings in the form of a single opening or an opening divided into a number of segments. The feed intake openings or segments each being of any shape that will fit into a square of 250 mm - 250 mm measured at the relevant safety distance to the cutting means. NOTE Feed safety openings are limited to 250 mm - 250 mm but the total feed intake opening can be any size. This standard describes methods of elimination or reduction of hazards arising from the use of shredders/chippers. In addition it specifies the type of information to be provided by the manufacturer on safe working practices. This standard does not cover requirements for: - units driven by an external power source; - mobile use of units which can be used in both stationary and mobile modes; - units with powered discharge intended to broadcast material or load vehicles; - units with mechanically powered feed intake or attachments; - units with cutting means of either one or more non-metallic filaments, or one or more non-metallic cutting elements pivotally mounted on a generally circular central drive unit, where these cutting elements rely on centrifugal force to achieve cutting, and have a kinetic energy for each single cutting means of less than 10 J; - electrical aspects of electrically driven shredders. Environmental hazards and EMC have not been considered in this standard. This standard deals with all significant hazards, hazardous situations and events relevant to shredders/chippers, when they are used as intended

EN 13683:2003+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 65.060.70 - Horticultural equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13683:2003+A1:2009 has the following relationships with other standards: It is inter standard links to EN 13683:2003+A2:2011, EN 13683:2003, EN ISO 12460-4:2016, EN ISO 12460-3:2023, EN ISO 12460-3:2020, EN ISO 12460-5:2015, EN ISO 12460-3:2015, EN 13683:2003/FprA2. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13683:2003+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13683:2003+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Oprema za nego vrta - Motorni drobilniki/sekalniki - VarnostGartengeräte - Motorgetriebene Schredder/Zerkleinerer - SicherheitMatériel de jardinage - Broyeurs/déchiqueteurs à moteur integré - SécuritéGarden equipment - Integrally powered shredders/chippers - Safety65.060.70Vrtnarska opremaHorticultural equipmentICS:Ta slovenski standard je istoveten z:EN 13683:2003+A1:2009SIST EN 13683:2004+A1:2009en01-junij-2009SIST EN 13683:2004+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13683:2003+A1

April 2009 ICS 65.060.70 Supersedes EN 13683:2003 English Version

Garden equipment - Integrally powered shredders/chippers - Safety

Matériel de jardinage - Broyeurs/déchiqueteurs à moteur integré - Sécurité

Gartengeräte - Motorgetriebene Schredder/Zerkleinerer - Sicherheit This European Standard was approved by CEN on 8 September 2003 and includes Amendment 1 approved by CEN on 14 March 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13683:2003+A1:2009: ESIST EN 13683:2004+A1:2009

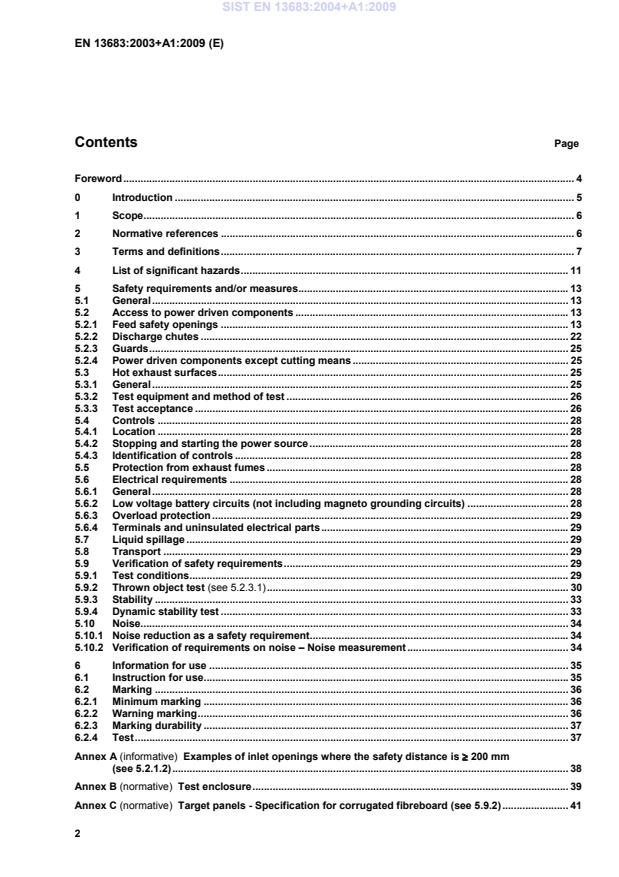

Examples of inlet openings where the safety distance is ≥≥≥≥ 200 mm

(see 5.2.1.2) . 38Annex B (normative)

Test enclosure . 39Annex C (normative)

Target panels - Specification for corrugated fibreboard (see 5.9.2) . 41SIST EN 13683:2004+A1:2009

Safety instructions . 44D.1General . 44D.2Safe operating practices . 44D.2.1Training . 44D.2.2Preparation . 44D.2.3Operation . 45D.2.4Maintenance and storage . 46D.2.5Additional safety instructions for units with bagging attachments . 46Annex E (normative)

Symbols and/or pictograms . 47E.1General . 47E.2Pictograms . 47Annex F (normative)

Noise test code – Engineering method (grade 2) . 49F.1Scope. 49F.2A-weighted sound power level determination . 49F.3A-weighted emission sound pressure level measurement . 50F.4Requirements for test floor . 54F.4.1Artificial surface . 54F.4.2Natural grass . 54F.5Installation, mounting and operating conditions . 54F.6Measurement uncertainties and declaration of noise emission values . 55F.7Information to be recorded and reported . 55Annex G (informative)

Example of a material and construction fulfilling the requirements for an artificial surface. 56G.1Material . 56G.2Construction . 56Annex ZA (informative)

####Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC$$$$ . 58Annex ZB (informative)

####Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC$$$$ . 59Bibliography . 60 SIST EN 13683:2004+A1:2009

This document includes a Bibliography. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom. SIST EN 13683:2004+A1:2009

This European Standard incorporates, by dated or undated reference, provisions from other publications. These normative references are cited at the appropriate places in the text and the publications are listed hereafter. For dated references, subsequent amendments to or revisions of any of these publications apply to this European Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the publication referred to applies (including amendments). EN 294: 1992, Safety of machinery — Safety distance to prevent danger zones being reached by the upper limbs. EN 954-1:1996, Safety of machinery - Safety-related parts of control systems - Part 1: General principles for design. SIST EN 13683:2004+A1:2009

Key 1 Feed intake opening 2 Discharge chute Figure 1

Key 1 Feed intake opening 2 Discharge chute Figure 2

Key 1 Feed intake opening 2 Discharge chute Figure 3

Figures 1, 2 and 3 — Examples of typical shredders/chippers

intended use of the machine including maintenance, setting and cleaning and its reasonably foreseeable misuse;

identification of all significant hazards associated with the machine. Table 1 — List of significant hazards associated with shredders/chippers

Ref. No. Hazard Location or event Reference of this standard Hazards, hazardous situations and hazardous events

Mechanical hazards due to:

- machine parts or workpieces, e.g.:

a) relative location; Safe positioning of the machine 6.1; annex D

b) mass and velocity (kinetic energy of elements in controlled or uncontrolled motion); Dynamic stability of machine 5.9.4

c) inadequacy of mechanical strength; Guard failure/strength 5.2.3.2 1.3 Cutting or severing hazard Feeding material into the machine. 5.2.1; 6.1; annex D Clearing processed material from discharge chute 5.2.2; 6.1; annex D 1.4 Entanglement hazard Feeding material into the cutting means 6.1; 6.2; annex D 1.5 Drawing-in or trapping hazard Feeding material into the cutting means 5.2.1; 6.1; annex D 1.6 Impact hazard Thrown objects 5.2.3.1; 5.9.2; 6.1; annex D 2 Electrical hazards due to:

2.1 Contact of persons with live parts (direct contact) High voltage and ignition parts 5.6.4 2.2 Contact of persons with parts which have become live under faulty conditions (indirect contact) Damage caused by oil, fuel, abrasion etc 5.6.2.1 3 Thermal hazards, resulting in:

3.1 Burns, scalds and other injuries by a possible contact of persons with objects or materials with an extreme high or low temperature, by flames or explosions and also by the radiation of heat sources Contact with hot parts 5.3 4 Hazards generated by noise, resulting in:

4.1 Hearing loss (deafness), other physiological disorders (e.g. loss of balance, loss of awareness) Hearing damage due to machine and/or processing of material 5.10; 6.1; 6.2; annexes D, F and G SIST EN 13683:2004+A1:2009

7 Hazards generated by materials and substances (and their constituent elements) processed or used by the machinery

7.1 Hazards from contact with or inhalation of harmful fluids, gases, mists, fumes, and dusts Breathing of engine exhaust fumes 5.5; 6.1 and annex D 7.2 Fire or explosion hazard Refuelling 6.1 and annex D 8 Hazards generated by neglecting ergonomic principles in machinery design as, e.g. hazards from:

8.1 Unhealthy postures or excessive effort Handling during moving machine 5.8; 6.1; annex D 8.3 Neglected use of personal protection equipment Protect against noise and thrown objects, 5.10; 6.1; annex D 8.6 Human error, human behaviour Incorrect use etc. Keep bystanders away 6.1; annex D 6.2 8.7 Inadequate design, location or identification of manual controls Location of stop/start contol(s) 5.4.1 Identification of control(s) 5.4.3 10 Unexpected start-up, unexpected over-run/over-speed (or any similar malfunction) from:

10.2 Restoration of energy supply after an interruption Unexpected starting of cutting means after power failure 5.4.2 10.6 Errors made by the operator (due to mismatch of machinery with human characteristics and abilities, see 8.6) Feeding non-vegetable material 6.1; 6.2; annex D

Removing guards before stopping the cutting means 5.2.4; 6.1; 6.2; annex D 13 Failure of the power supply Unexpected start up of cutting means after power failure 5.4.2 14 Failure of the control circuit Durability of interlock devices 5.2.3.1 15 Errors of fitting Using the machine without guards or with guards fitted incorrectly 5.2.3.1; 6.1; annex D 16 Break-up during operation Cutters breaking in use 5.9.4.2 17 Falling or ejected objects or fluids Thrown objects from feed intake 5.9.2; 6.1; annex D 18 Loss of stability / overturning of machinery Static stability 5.9.3 19 Slip, trip and fall of persons (related to machinery) Operating position 6.1; annex D Additional hazards, hazardous situations and hazardous events due to mobility 24 Due to the power source and to the transmission of power

24.1 Hazards from the engine and the batteries Harm from battery vapoursSpillage of battery and fluid containers 5.6.2.2; 5.7 Battery overload 5.6.3 25 From/to third persons

25.1 Unauthorised start-up/use Unauthorised start up of battery start machines 5.4.2; 6.1; annex D 26 Insufficient instructions for the driver/operator Unfamiliar or dangerous usage 6.1; annex D SIST EN 13683:2004+A1:2009

5.2.1.1 General To safeguard against contact with the cutting means through the feed safety opening(s) the machine shall: either be constructed to meet the dimensional requirements given in 5.2.1.2 and Table 2, or

if a straight rod of 1 m length and 12 mm diameter will not pass through the opening to contact the cutting means then the tortuous path test of 5.2.1.3 shall apply. 5.2.1.2 Dimensional requirements Where a feed intake opening is divided into two or more feed safety openings the device that creates the divisions shall be rigidly and permanently attached to the feed intake opening. Where a feed safety opening is not a slot, square or round, the overall size of opening is considered to be a slot, square, or round envelope that contains the opening. The shortest safety distance of the respective envelope shall be used. Where a combination of slots, squares, and/or rounds are used and they create a pinch point of less than or equal to 30 mm, each shape shall be considered separately for opening size and safety distance (see Table 2). Annex A gives some examples of such combinations. SIST EN 13683:2004+A1:2009

D is reduced to ≥ 200 mm if the longest side of the slot is ≤ 65 mm. However where the shortest side of the slot is in combination with another aperture and if it is considered separately (see 5.2.1) the longest side shall be ≤ 50 mm.

b

(i)

Where the height (h) is < 1200 mm and (α) ≤ 40°, D shall be 850 mm measured as the shortest distance to the cutting means.(See Figures 4a and 4b). (ii)

Where the height (h) is < 1200 mm and 90° ≥ (α) > 40°, D shall be measured as the shortest distance from the outer edge of the feed opening to the cutting means subject to the following conditions (see Figure 4c): L + 150 (2 + sin α)

≥ 850 mm; and L

≥

550 mm. c

(i)

Where the height (h) is ≥ 1200 mm, and (α) ≤ 40°, D shall be measured as a chain measurement, subject to the following two conditions (see Figures 4d, 4e and 4f): d1 + d2 … + dn

≥

[ 850 - ½ (h -1200) ] mm; and L

≥

550 mm. (ii)

Where the height (h) is ≥ 1200 mm and

90° ≥ (α) > 40°, D shall be measured as a chain measurement, subject to the following two conditions (see Figures 4g and 4h): d1 + d2 … + dn

≥

[ L

+ 150 (2 + sin α) ] - ½ (h -1200) mm; and L

≥

550 mm. d

Where a round opening of ≤ 40 mm is used without combination or overlap with any other shape, D shall be ≥ 120 mm. SIST EN 13683:2004+A1:2009

a)

b)

c)

d) SIST EN 13683:2004+A1:2009

e)

f) SIST EN 13683:2004+A1:2009

g) SIST EN 13683:2004+A1:2009

h) Key h

height of lowest point of feed intake opening from ground L

minimum distance from the highest point of the cutting means to (W) P

point on the feed intake with distance ≥ 1200 mm from the ground. P is starting point for the chain

Measurement from the feed intake opening to the highest point of the cutting means W

feed safety opening α

angle between a vertical line through the centre of the cutting means and a straight line from the point of the cutting means nearest to the opening to the highest point on the lower side of the inside of the feed inlet

Figure 4— Distance from feed safety opening to cutting means (D mm) SIST EN 13683:2004+A1:2009

Key 1 Axis of rotation of “elbow” joint 2 Axis of rotation of “wrist” joint 3 Axes of rotation of “finger” joints

NOTE This Figure is not to scale Figure 5 — Arm probe for testing tortuous path guarding of cutting means through the feed intake opening

Except as stated in 5.2.3, the discharge chute shall be designed so as to prevent direct access to and accidental contact with the cutting means. Compliance shall be achieved according to one of the following: 1) if no part of the outer edge of the discharge chute is more than 350 mm from the ground, the lowest point of the end of the discharge chute nearest the cutting means shall be at least 3 mm above the highest part of the outer edge of the discharge chute. In addition the minimum distance from any point of the outer edge of the discharge chute to the cutting means shall be 230 mm (see Figures 6a, 6b and 6c). If the lowest part of the cutting means is above the lowest point of the end of the discharge chute nearest the cutting means then the 3 mm dimension shall apply to the vertical distance between the highest part of the outer edge of the discharge chute and the lowest point of the cutting means (see Figure 6d); or 2) if the highest edge of the discharge opening is greater than 350 mm from the ground and the opening size is not more than 120 mm × 120 mm, the safety distance shall conform to the principles set out in 4.5.1

or 4.5.3 of EN 294:1992 as appropriate; or 3) if the highest edge of the discharge opening is greater than 350 mm from the ground and the opening size is larger than 120 mm × l20 mm, the safety distance shall be ≥ 850 mm. The maximum discharge opening size shall be 250 mm × 250 mm; or 4) it shall not be possible to come into contact with the cutting means by using the probe shown in Figure 7. The probe shall be inserted a maximum of 850 mm inside the discharge opening towards the cutting means, measured from the most unfavourable point on the discharge opening, with a force of not more than 20N. NOTE The safety distances of 5.2.1 and 5.2.2 have been developed on the basis of EN 294:1992 and amended as necessary according to established current practice. SIST EN 13683:2004+A1:2009

a) b)

c) d) Key

1 Cutting means

2 Ground surface

3 Discharge direction d1 + d2 = 230 min. Figure 6 — Examples of discharge chute distance requirements SIST EN 13683:2004+A1:2009

Key 1 Flexible handle 2 All edges to be rounded Material: metal except where otherwise specified. Both joints shall permit movement in the same plane and in the same direction through an angle of 90° with a 0° to + 10° tolerance. Tolerances: - dimensions = without tolerances specified; - angles = ± 10’; - linear dimensions up to 25 mm = 0/-0,05 mm; - linear dimensions over 25 mm = ± 0,2 mm. NOTE This probe is essentially as used in IEC/CLC (e.g. see Figure 1 of EN 60335-1:1994) but with a flexible handle and the top flange removed. Figure 7 — Probe for checking discharge chute (see 5.2.2 4) SIST EN 13683:2004+A1:2009

Unless otherwise stated all guards shall conform to the relevant parts of 3.22 and 3.23 of

EN ISO 12100-1:2003. 5.2.3.2 Strength Guards shall have adequate strength and be constructed to withstand such rough handling that may be expected in normal use. Guards shall be checked by the following test. Each of three samples of the complete machine shall be subjected to an impact of (6,5 ± 0,2) J on a part of the relevant guard likely to be the weakest, with the machine standing on a level surface. The tests shall be so conducted that in each test the sample receives an impact in a location different from the other two tests. The impact shall be produced with a smooth solid steel sphere (as used for ball bearings) having a diameter of 50 mm. If the part being tested is at an angle of up to 45° to the horizontal, the sphere shall be allowed to fall vertically from rest to strike the part. Otherwise, the sphere shall be suspended by a cord and shall be allowed to fall from rest as a pendulum to strike the part. In either case, the vertical travel of the sphere shall be 1,3 m. After the test there shall be no visible signs of cracking and the requirements of 5.2.1 and 5.2.2 shall be maintained. 5.2.4 Power driven components except cutting means All power driven components except the cutting means (see 5.2.1, 5.2.2 and 5.2.3) shall be guarded to prevent contact with these parts during normal operation. Guards designed to be opened or removed shall have a sign warning of the relevant hazard visible on the machine both when the guard is closed and when it is opened or removed.

Unless otherwise stated in this standard all openings and safety distances shall conform to 4.5.1 or 4.5.3 of EN 294:1992 as applicable 5.3 Hot exhaust surfaces 5.3.1 General Exposed components of the power source exhaust system having a surface temperature greater than 80 °C at (20 ± 3) °C ambient temperature shall be considered hot and shall be guarded so that they are not accessible to unintentional contact during normal use. These parts, which shall also include SIST EN 13683:2004+A1:2009

When the distance between the identified hot area and the nearest control is > l00 mm, Cone A in Figure 8 shall be used. For a distance ≤ l00 mm between the identified hot area and the nearest control, Cone B in Figure 8 shall be used.

For Cone A, with the axis of the cone anywhere between 0° and 180° to the horizontal and with the nose or point of the cone in a downward to horizontal direction, move the cone towards the hot surface. Cone A shall not be moved in an upward direction. Cone B shall be moved in any direction.

When moving the cone(s), determine if contact is made with the hot surface area(s) by the cone tip or conical surface of the cone. 5.3.3 Test acceptance The tip or conical surface of Cones A or B shall not be able to make contact with a hot surface area greater than 10 cm2. SIST EN 13683:2004+A1:2009

Cone A

Cone B Key 1 Horizontal plane SR Spherical radius Figure 8 — Test cones (see 5.3.2.2) SIST EN 13683:2004+A1:2009

Machines shall not be equipped with a starter operated by means of a loose rope. 5.4.3 Identification of controls Controls, whose purpose is not obvious, shall have the function, direction and/or method of operation clearly identified by a durable label

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...