EN 13001-2:2011

(Main)Crane safety - General design - Part 2: Load actions

Crane safety - General design - Part 2: Load actions

This European Standard is to be used together with Part 1 and series of Part 3 and as such they specify general conditions, requirements and methods to prevent hazards of cranes by design and theoretical verification.

NOTE Specific requirements for particular types of crane are given in the appropriate European Standard for the particular crane type.

The following is a list of significant hazardous situations and hazardous events that could result in risks to persons during normal use and foreseeable misuse. Clause 4 is necessary to reduce or eliminate the risks associated with the following hazards:

a) rigid body instability of the crane or its parts (tilting and shifting);

b) exceeding the limits of strength (yield, ultimate, fatigue);

c) elastic instability of the crane or its parts (buckling, bulging);

d) exceeding temperature limits of material or components;

e) exceeding the deformation limits.

This European Standard is applicable to cranes which are manufactured after the date of approval by CEN of this standard and serves as reference base for the European Standards for particular crane types.

Kransicherheit - Konstruktion allgemein - Teil 2: Lasteinwirkungen

Diese Europäische Norm ist zusammen mit Teil 1 und der Serie von Teil 3 anzuwenden und spezifiziert allgemeine Bedingungen, Anforderungen und Methoden zur Vermeidung von Gefahren bei Kranen durch die Konstruktion und theoretische Überprüfung. ANMERKUNG Besondere Anforderungen für spezielle Krantypen sind in der zugehörigen Europäischen Norm für den speziellen Krantyp angegeben. Im Folgenden ist eine Auflistung von wichtigen gefährlichen Situationen und gefährlichen Ereignissen gegeben, die Risiken für Personen während des normalen Gebrauchs (des Krans) und vorhersehbarem Missbrauch zur Folge haben könnten. Abschnitt 4 dieser Norm wird zur Reduzierung oder Eliminierung der mit den folgenden Gefahrensituationen verbundenen Risiken benötigt: a) Starrkörperinstabilität des Krans oder seiner Teile (kippen und verschieben); b) Überschreitung der Festigkeitsgrenzwerte (Fließen, Bruch, Ermüdung); c) Überschreitung von Temperaturgrenzwerten des Werkstoffs oder der Komponenten (ausbeulen und ausknicken); d) elastische Instabilität des Krans oder seiner Teile; e) Überschreitung der Verformungsgrenzwerte. Diese Europäische Norm ist anwendbar für Krane, die nach dem Datum der Genehmigung dieser Norm durch CEN hergestellt werden, und dient als Referenzgrundlage für die Europäischen Normen für spezielle Krantypen.

Sécurité des appareils de levage à charge suspendue - Conception générale - Partie 2: Effets de charge

La présente Norme européenne doit être utilisée conjointement avec la partie 1 et les séries de la partie 3 qui

spécifient les conditions, prescriptions et méthodes générales afin d'éviter les risques mécaniques dus aux

appareils de levage à charge suspendue, en utilisant la conception et la vérification théorique.

NOTE Les prescriptions spécifiques relatives aux types particuliers d’appareils de levage à charge suspendue sont

données dans la Norme européenne appropriée pour le type particulier d’appareil de levage à charge suspendue.

La liste suivante spécifie les situations et les événements dangereux significatifs susceptibles d'entraîner des

risques pour les personnes lors d'une utilisation normale et d'une mauvaise utilisation prévisible. L'Article 4 est

nécessaire pour réduire ou éliminer les risques associés à ces phénomènes dangereux :

a) instabilité de corps rigide de l’appareil de levage à charge suspendue ou de ses éléments (inclinaison,

déplacement) ;

b) dépassement des limites de résistance (élasticité, rupture, fatigue) ;

c) instabilité élastique de l’appareil de levage à charge suspendue ou de ses éléments (flambage, voilement) ;

d) dépassement des limites de température du matériau ou des composants ;

e) dépassement des limites de déformation.

La présente Norme européenne s'applique aux appareils de levage à charge suspendues construites après sa

date d'approbation par le CEN et sert de référence pour les normes européennes sur les types d’appareils

particuliers.

Varnost dvigala (žerjava) - Konstrukcija, splošno - 2. del: Učinki obremenitev

Ta evropski standard je namenjen uporabi skupaj s 1. delom in serijo 3. dela in kot tak opredeljuje splošne pogoje, zahteve in metode za preprečevanje nevarnosti pri dvigalih (žerjavih) z načrtovanjem in teoretičnim preverjanjem.

OPOMBA: Posebne zahteve za določene vrste dvigal (žerjavov) so navedene v ustreznem evropskem standardu za določeno vrsto dvigala (žerjava).

Spodaj sledi seznam bistvenih nevarnih situacij in nevarnih dogodkov, ki lahko povzročijo tveganje oseb med normalno uporabo in predvidljivo napačno uporabo. Točka 4 je potrebna za zmanjševanje ali odpravo tveganj, povezanih z naslednjimi nevarnostmi:

a) nestabilnost togega telesa dvigala (žerjava) ali njegovih delov (nagibanje in premikanje);

b) preseganje mejnih vrednosti trdnosti (napetosti, končne trdnosti, utrujenosti);

c) elastična nestabilnost dvigala (žerjava) ali njegovih delov (uklanjanje, izbočenje);

d) preseganje temperaturnih omejitev materiala ali komponent;

e) preseganje omejitev deformacije.

Ta evropski standard velja za dvigala (žerjave), izdelana po datumu, ko je CEN ta standard odobril, in se uporablja kot referenčna podlaga za evropske standarde za nekatere vrste dvigal (žerjavov).

General Information

- Status

- Withdrawn

- Publication Date

- 05-Apr-2011

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 147 - Cranes - Safety

- Drafting Committee

- CEN/TC 147/WG 2 - Design - General

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 06-Aug-2014

- Completion Date

- 28-Jan-2026

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 06-Jun-2009

- Effective Date

- 13-Aug-2014

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 14985:2012 - Cranes - Slewing jib cranes - Effective Date

- 28-Jan-2026

- Effective Date

- 08-Jun-2022

Frequently Asked Questions

EN 13001-2:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Crane safety - General design - Part 2: Load actions". This standard covers: This European Standard is to be used together with Part 1 and series of Part 3 and as such they specify general conditions, requirements and methods to prevent hazards of cranes by design and theoretical verification. NOTE Specific requirements for particular types of crane are given in the appropriate European Standard for the particular crane type. The following is a list of significant hazardous situations and hazardous events that could result in risks to persons during normal use and foreseeable misuse. Clause 4 is necessary to reduce or eliminate the risks associated with the following hazards: a) rigid body instability of the crane or its parts (tilting and shifting); b) exceeding the limits of strength (yield, ultimate, fatigue); c) elastic instability of the crane or its parts (buckling, bulging); d) exceeding temperature limits of material or components; e) exceeding the deformation limits. This European Standard is applicable to cranes which are manufactured after the date of approval by CEN of this standard and serves as reference base for the European Standards for particular crane types.

This European Standard is to be used together with Part 1 and series of Part 3 and as such they specify general conditions, requirements and methods to prevent hazards of cranes by design and theoretical verification. NOTE Specific requirements for particular types of crane are given in the appropriate European Standard for the particular crane type. The following is a list of significant hazardous situations and hazardous events that could result in risks to persons during normal use and foreseeable misuse. Clause 4 is necessary to reduce or eliminate the risks associated with the following hazards: a) rigid body instability of the crane or its parts (tilting and shifting); b) exceeding the limits of strength (yield, ultimate, fatigue); c) elastic instability of the crane or its parts (buckling, bulging); d) exceeding temperature limits of material or components; e) exceeding the deformation limits. This European Standard is applicable to cranes which are manufactured after the date of approval by CEN of this standard and serves as reference base for the European Standards for particular crane types.

EN 13001-2:2011 is classified under the following ICS (International Classification for Standards) categories: 53.020.20 - Cranes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13001-2:2011 has the following relationships with other standards: It is inter standard links to EN 13001-2:2004+A3:2009, EN 13001-2:2014, EN 1990:2002, EN 13001-1:2015, EN 840-3:2012, EN ISO 12100:2010, EN 13852-1:2013, EN 14985:2012, EN 13001-2:2011/AC:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13001-2:2011 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13001-2:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kransicherheit - Konstruktion allgemein - Teil 2: LasteinwirkungenSécurité des appareils de levage à charge suspendue - Conception générale - Partie 2: Effets de chargeCrane safety - General design - Part 2: Load actions53.020.20DvigalaCranesICS:Ta slovenski standard je istoveten z:EN 13001-2:2011SIST EN 13001-2:2011en,fr,de01-junij-2011SIST EN 13001-2:2011SLOVENSKI

STANDARDSIST EN 13001-2:2005+A3:20091DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13001-2

April 2011 ICS 53.020.20 Supersedes EN 13001-2:2004+A3:2009English Version

Crane safety - General design - Part 2: Load actions

Sécurité des appareils de levage à charge suspendue - Conception générale - Partie 2: Effets de charge

Kransicherheit - Konstruktion allgemein - Teil 2: Lasteinwirkungen This European Standard was approved by CEN on 27 February 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13001-2:2011: ESIST EN 13001-2:2011

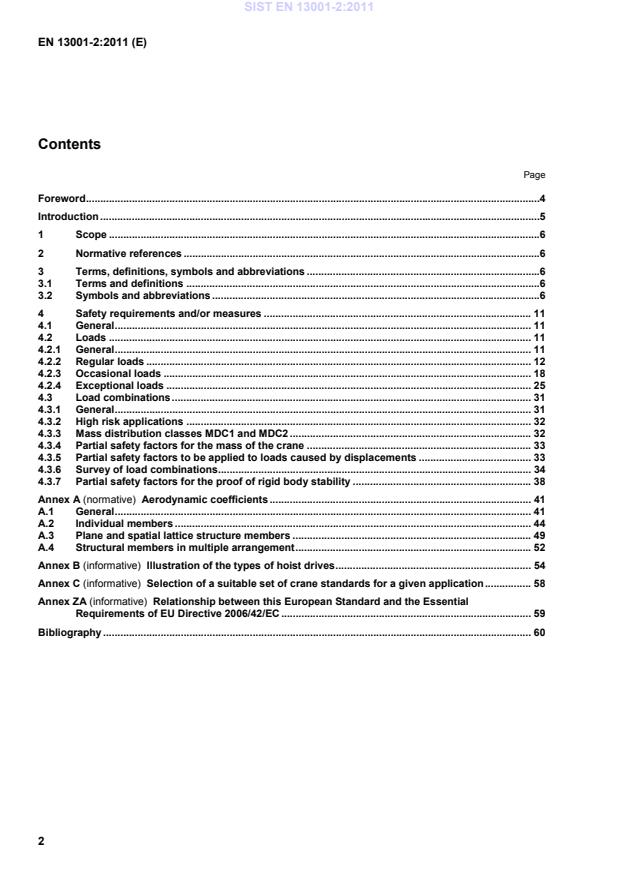

Aerodynamic coefficients . 41A.1 General . 41A.2 Individual members . 44A.3 Plane and spatial lattice structure members . 49A.4 Structural members in multiple arrangement . 52Annex B (informative)

Illustration of the types of hoist drives . 54Annex C (informative)

Selection of a suitable set of crane standards for a given application . 58Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 59Bibliography . 60 SIST EN 13001-2:2011

displacements . 33 Table 9 — Values of the partial safety factor pγ to be applied to loads due to unintended displacements . 34 Table 10 — Loads, load combinations and partial safety factors . 35 Table 11 — Partial safety factors for the proof of rigid body stability . 39 Table A.1 — Relative aerodynamic length ααααr . 43 Table A.2 — Aerodynamic coefficients co for individual members of circular sections . 45 Table A.3 — Aerodynamic coefficients coy, coz for individual flat sided structural members . 46 Table A.4 — Aerodynamic coefficients co for individual structural members of triangular and rectangular hollow sections . 48 Table A.5 — Characteristic areas A and aerodynamic coefficients co for plane and spatial lattice structure members . 49 Table A.6 — Characteristic areas A and aerodynamic coefficients co of structural members in multiple arrangement . 52 Table B.1 — Hoist drive types . 54

4 Safety requirements and/or measures 4.1 General Machinery shall conform to the safety requirements and/or measures of this clause. In addition, the machine shall be designed according to the principles of EN ISO 12100 for hazards relevant but not significant which are not dealt with by this document (e.g. sharp edges). 4.2 Loads 4.2.1 General 4.2.1.1 Introduction The loads acting on a crane are divided into the categories of regular, occasional and exceptional as given in 4.2.1.2, 4.2.1.3 and 4.2.1.4. For the proof calculation of means of access loads only acting locally are given in 4.2.5. These loads shall be considered in proof against failure by uncontrolled movement, yielding, elastic instability and, where applicable, against fatigue. 4.2.1.2 Regular loads a) Hoisting and gravity effects acting on the mass of the crane; b) inertial and gravity effects acting vertically on the hoist load; c) loads caused by travelling on uneven surface; d) loads caused by acceleration of all crane drives; e) loads induced by displacements. Regular loads occur frequently under normal operation. SIST EN 13001-2:2011

Figure 1 — Factor φ2 The factor φ2 shall be taken as follows: h2min,22v+=φφ (3) φ2,min and β2 are given in Table 2 for the appropriate hoisting class. For the purposes of this European Standard, cranes are assigned to hoisting classes ranging from HC1 to HC4 according to their dynamic and elastic characteristics. HC1 requires a flexible structure and a drive system with smooth dynamic characteristics, whereas a rigid structure and a drive system with sudden speed changes imply HC4. The selection of hoisting classes depends on the particular type of cranes and is dealt with in the European Standards for specific crane types, see Annex B. Equally, values of φ2 can be determined by experiments or analysis without reference to hoisting class. vh is the characteristic hoisting speed, in meters per second, related to the lifting attachment. Values of vh in relation to steady hoisting speeds and hoist drive classes are given in Table 3. Table 2 — Values of β2 and φ2,min Hoisting class of appliance β2 φ2,min HC1 0,17 1,05 HC2 0,34 1,10 HC3 0,51 1,15 HC4 0,68 1,20

where HD1 is the creep speed is not available or the start of the drive without creep speed is possible; HD2 is the hoist drive can only start at creep speed of at least a preset duration; HD3 is the hoist drive control maintains creep speed until the load is lifted off the ground; HD4 is the step-less hoist drive control, which performs with continuously increasing speed; HD5 is the step-less hoist drive control automatically ensures that the dynamic factor ϕ2 does not exceed ϕ2,min; vh,max is the maximum steady hoisting speed; vh,CS is the steady hoisting creep speed. See Annex B for illustration of the types of hoist drives. 4.2.2.2.2 Sudden release of a part of the hoist load For cranes that release a part of the hoist load as a normal working procedure, the peak dynamic action on the crane can be taken into account by multiplying the hoist load by the factor φ3 (see Figure 2).

Figure 2 — Factor φ3 SIST EN 13001-2:2011

Key m mass of the crane and the hoist load v constant horizontal travelling speed of the crane c spring constant z(t) coordinate of the mass centre h(t) unevenness function describing the step or gap of the rail Figure 3 — Single mass model of a crane for determining the factor φ4 φ4 may be calculated as follows: s22421ξπφg rv+= (5) for travelling over a step (see Figure 4 a)); SIST EN 13001-2:2011

a) Travelling over a step b)Travelling over a gap Figure 4 — Movement of the wheel centre SIST EN 13001-2:2011

a) Travelling over a stepb)Travelling over a gapFigure 5 — Curve factors ξs(αs) and ξG(αG) NOTE The use of this simple model is restricted to cranes whose actual dynamic behaviour corresponds to that of the model. If more than one natural mode contributes a significant response and/or rotation occurs, the designer should estimate the dynamic loads using an appropriate model for the circumstances. 4.2.2.4 Loads caused by acceleration of drives Loads induced in a crane by acceleration or decelerations caused by drive forces may be calculated using rigid body kinetic models. For this purpose, the gross load is taken to be fixed at the top of the jib or immediately below the crab. The load effect Sˆ shall be applied to the components exposed to the drive forces and where applicable to the crane and the gross load as well. As a rigid body analysis does not directly reflect elastic effects, the load effect Sˆ shall be calculated by using a factor φ5 as follows (see Figure 6): SSS∆+=5iˆφ (7) where ∆S = Sf − Si is the change of the load effect due to the change of the drive force ∆F = Ff − Fi; Si, Sf are the initial (i) and final (f) load effects caused by Fi and Ff; Fi, Ff are the initial (i) and final (f) drive forces. SIST EN 13001-2:2011

a) for the change of drive forces from steady state b)for the positioning case Figure 6 — Factor φ5 Following values of φ5 shall be applied: φ5 = 1 for centrifugal forces; 1 ≤ φ5 ≤ 1,5 for drives with no backlash or in cases where existing backlash does not affect the dynamic forces and with smooth change of forces; 1,5 ≤ φ5 ≤ 2 for drives with no backlash or in cases where existing backlash does not affect the dynamic forces and with sudden change of forces; φ5 = 3 for drives with considerable backlash, if not estimated more accurate by using a spring-mass-model. Where a force that can be transmitted is limited by friction or by the nature of the drive mechanism, the limited force and a factor φ5 appropriate to that system shall be used. 4.2.2.5 Loads induced by displacements Account shall be taken of loads arising from displacements included in the design such as those within the limits necessary to initiate response from compensating systems (e.g. skewing) or those resulting from prestressing. Other loads to be considered include those that can arise from displacements that are within defined limits such as those set for the variations in the height or the gauge between rails or uneven settlement of supports. 4.2.3 Occasional loads 4.2.3.1 Loads due to in-service wind The wind loads assumed to act perpendicularly to the longitudinal axis of a crane member are calculated by AcqF××=)3( (8) regarding the structure of the crane; AcqF×××=)3(Sε (9) regarding the required starting drive forces; AcqF×××=)3(Mε (10) regarding the drive forces during controlled movement; SIST EN 13001-2:2011

The correlation of the mean wind velocity v, the Beaufort scale and the in-service wind states is shown in Figure 7.

Key X Beaufort 1 wind states 1 2 wind states 2 3 wind states 3 Figure 7 — Correlation of the mean wind velocity v, the Beaufort scale and the in-service wind states The design is based on the following requirement for the operation of the crane: If the wind velocity, measured at the highest point of the crane, increases and tends to reach v(3), the crane shall be secured or its configuration shall be transformed into a safe configuration. As the methods and/or means for this securing are different and need different time (locking devices at special locations of the crane runway, hand-operated or automatic rail clamps) a lower level of mean wind velocity shall be chosen to start the securing. NOTE Any slender structural member, when placed in a windstream with its longitudinal axis perpendicular to this stream, may become aeroelastically unstable. Means to prevent these effects (e.g. galloping or formation of eddies) by design should be considered both for in-service and out-of-service wind conditions. 4.2.3.2 Snow and ice loads Where relevant, snow and ice loads shall be specified and taken into account. The increased wind exposure surfaces shall be considered. SIST EN 13001-2:2011

Coupled (C) Independent (I) Fixed/Fixed

CFF

IFF (F/F) Fixed/Movable

CFM

IFM (F/M) SIST EN 13001-2:2011

Key 1 wheel pair 1 2 wheel pair 2 3 wheel pair I 4 wheel pair n

5 rail 2 6 rail 1 7 travelling direction 8 guide means Figure 9 — Positions of wheel pairs The crane model is assumed to be travelling at constant speed and to have skewed to an angle α, as shown in Figure 10. The crane may be guided horizontally by external means or by wheel flanges. SIST EN 13001-2:2011

Key 1 direction of motion 2 direction of rail 3 wheel pair i 4 rail 2

5 instantaneous slide pole 6 rail 1 7 slip 8 guide means Figure 10 — Loads acting on crane in skewed position A guide force Fy is in balance with the wheel forces Fx1i, Fy1i, Fx2i, Fy2i, which are caused by rotation of the crane about the instantaneous slide pole. With the maximum lateral slip sy = α at the guide means and a linear distribution of the lateral slip syi between guide means and instantaneous slide pole, the corresponding skewing forces may be calculated as follows: The guide force Fy may be calculated by gmfF⋅⋅⋅=νy (11) where m ⋅ g is the gravitational force due to the mass of the loaded crane; f = 0,3 ()−−α250el is the friction coefficient of the rolling wheel; where α is the skewing angle (see Figure 10), in radians. The skewing angle α, which should not exceed 0,015 radians, shall be chosen taking into account the space between the guide means and the rail as well as reasonable dimensional variation and wear of the appliance wheels and the rails as follows: twgαααα++= SIST EN 13001-2:2011

is the part of the skewing angle due to the slack of the guide; sg

is the slack of the guide (see Figure 10); wb

is the distance between the guide means; αw = 0,1 (bh/wb)

is the part of the skewing angle due to wear; bh

is the width of the rail head (see Figure 9); αt = 0,001 rad

is the part of the skewing angle due to tolerances;

= 1 − ∑di/nh

for systems F/F (see Figure 8); ()∑−′=nhd/1iµ

for systems F/M (see Figure 8); where h

is the distance between the instantaneous slide pole and the guide means; h = (pµµ′l2 + ∑2id)/∑ di for systems F/F; h = (pµl2 + ∑2id)/∑ di for systems F/M; n

is the number of wheels at each side of the crane runway; p

is the number of pairs of coupled wheels; l

is the span of the crane (see Figure 9); µ, µ′

are parts of the span l (see Figure 9); di

is the distance of wheel pair i from the guide means (see Figure 9). The forces Fx1i, Fx2i, Fy1i and Fy2i may be calculated by gmfvFgmfvFgmfFgmfF×××=×××=×××=×××=2iy2ii1y1ii2x2ii1x1iξξ (12) where ξ1i, ξ2i, ν1i and ν2i are as given in Table 5. Table 5 — Values of ξ1i, ξ2i, ν1i and ν2i Combinations of wheel pairs (see Figure 8) ξ1i = ξ2i ν1i ν2i CFF µµ′l/nh

−hdni1µ IFF 0 −hdni1'µ CFM µµ′l/nh

0 IFM 0

NOTE The drive forces F acting on a crane or a trolley with asymmetrical mass distribution induce the forces H1 and H2, as shown in Figure 11. They are taken into account as regular loads in accordance with 4.2.2.4.

Key 1 gravity centre Figure 11 — Forces acting on a bridge crane with asymmetrical mass distribution, that are induced by acceleration of the travelling drives 4.2.4 Exceptional loads 4.2.4.1 Loads caused by hoisting a grounded load at maximum hoisting speed With reference to 4.2.2.2.1 and Table 10 loads caused by dynamic effects on the crane by transferring an unrestrained grounded load from the ground to the crane are considered as exceptional loads in load combination C1. For this case the estimation of the dynamic factor φ2 is shown in Table 3. 4.2.4.2 Loads due to out-of-service wind The out-of-service wind loads assumed to act on a member of a crane or on the hoist load remaining suspended from the crane are calculated by AczqF××=)( (13) where in case of considering a member of the crane: F is the wind load acting perpendicularly to the longitudinal axis of the crane member; c is the aerodynamic coefficient of the member under consideration; it has to be used in combination with the characteristic area A; values of c are given in Annex A; A is the characteristic area of the member under consideration (see Annex A); in case of considering the gross load remaining suspended from the crane: F is the wind load, acting on the remaining hoist load in direction of the wind velocity; c is the aerodynamic coefficient of the remaining hoist load in direction of the wind velocity; SIST EN 13001-2:2011

is a factor depending on the recurrence interval R; for crane design in general an out-of-service wind, which may recur once in intervals of 5 years to 50 years (R = 5 to R = 50) may be selected: frec = 0,815 5 for R = 5; frec = 0,873 3 for R = 10; frec = 0,946 3 for R = 25; frec = 1,0 for R = 50; vm(z)

is the 10 min mean storm wind velocity in the height z, in metres per second; SIST EN 13001-2:2011

is the reference storm wind velocit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...