FprEN 18143

(Main)Food processing machinery - Pizza dough sheeter machines - Safety and hygiene requirements

Food processing machinery - Pizza dough sheeter machines - Safety and hygiene requirements

1.1 This document specifies safety and hygiene requirements for the design and manufacture of pizza dough sheeters which:

a) are intended to be used:

1) for producing pizza dough bases in shops and craft activities (i.e. pizzerias, takeaway pizza shops, craft bakeries and/or pastries, catering facilities etc.);

2) for flattening and shaping lumps;

3) only for professional use;

4) by one operator at a time;

5) as standalone table-top machines only;

6) only with manual feeding of the lumps by gravity;

7) only with manual unloading of the flattened and enlarged lumps;

b) are fitted with:

1) at most two pairs of flattening rollers, the rollers of a pair having the same diameter and the same length;

2) flattening rollers having:

i. diameter ≤ 60 mm;

ii. fixed direction of the rotation such as to move the pizza dough from top to bottom;

iii. motor(s) for the rotation of the flattening rollers which transmit a power ≤ 0,50 kW to each pair of rollers.

1.2 The following relevant hazards are not covered by this document:

- hazards due to packaging, handling and transport;

- hazards due to ambiguous and/or not easily understandable information needed to control the machine.

A description of these machines is given in Annex A, and examples for positioning them are given in Annex C.

This document does not deal with any specific requirement on noise emitted from pizza dough sheeters as the generated noise does not cause a relevant hazard.

The significant hazards covered by this document are described in Annex B.

1.3 The following machines are excluded from the scope of this document:

- domestic (household) appliances;

- machines with automatic feeding of the lumps and/or unloading of the pizza bases;

- machines with feeding of the lumps other than by gravity;

- machines to process other products than pizza dough;

- bagel machines;

- dough sheeters (see EN 1674:2015);

- moulders (see EN 12041:2014);

- sheeters for pasta dough processing;

- experimental and testing machines under development by the manufacturer.

1.4 This document is not applicable to machines which are manufactured before the date of publication of this document by CEN.

Nahrungsmittelmaschinen - Pizzateig-Ausrollmaschinen - Sicherheits- und Hygieneanforderungen

1.1 Dieses Dokument legt Sicherheits- und Hygieneanforderungen für die Konstruktion und Herstellung von Pizzateigausrollmaschinen fest, die:

a) verwendet werden sollen:

1) zum Herstellen hauptsächlich von Pizzateigböden in Geschäften und Handwerksbetrieben (z. B. Pizzerien, Pizza-Imbissbuden, Handwerksbäckereien und/oder Feinbäckereien, Catering-Betrieben usw.);

2) zum Ebnen oder Vergrößern von Teigstücken;

3) ausschließlich für den professionellen Gebrauch;

4) durch jeweils einen Bediener;

5) nur als eigenes Tischgerät;

6) nur mit manueller Zufuhr der Pizzateigstücke durch Schwerkraft;

7) Nur mit Handentnahme der geebneten und vergrößerten Teigstücke;

b) ausgestattet sind mit:

1) nicht mehr als zwei Paaren von Glättwalzen, bei denen die Walzen eines Paares die gleichen Durchmesser und Länge aufweisen;

2) Glättwalzen mit:

i) Durchmessern von ≤ 60 mm;

ii) fester Drehrichtung beispielsweise zum Befördern des Pizzateigs von oben nach unten;

iii) Motor(en) zum Drehen der Glättwalzen, die eine Leistung von ≤ 0,50 kW auf jedes Walzenpaar übertragen

1.2 Die folgenden relevanten Gefährdungen werden in diesem Dokument nicht behandelt:

- Gefahren, die sich aus der Verwendung eines automatischen Lade- und/oder Entladesystems ergeben;

- Gefährdungen durch Verpackung, Handhabung und Transport;

- Gefahren aufgrund mehrdeutiger oder nicht leicht verständlicher zur Steuerung der Maschine benötigter Informationen.

Dieses Dokument behandelt keine spezifischen Anforderungen an die Geräuschemissionen von Pizzateigausrollmaschinen, da der erzeugte Lärm keine relevante Gefährdung darstellt.

Die von diesem Dokument behandelten signifikanten Gefährdungen sind in Anhang A beschrieben.

1.3 Die folgenden Maschinen liegen nicht im Anwendungsbereich dieses Dokuments:

- Haushaltsgeräte;

- Maschine mit automatischer Zufuhr der Pizzateigstücke und oder Entladen der Pizzaböden;

- Maschinen mit anderer Zufuhr der Teigstücke als durch Schwerkraft;

- Maschinen zum Bearbeiten anderer Produkte als Pizzateig;

- Bagel-Maschinen;

- Teigausrollmaschinen (siehe EN 1674:2015);

- Langwirkmaschinen (siehe EN 12041:2014);

- Ausrollmaschinen zur Nudelteigverarbeitung;

- Versuchs- und Prüfmaschinen, die beim Hersteller in Entwicklung sind.

1.4 Dieses Dokument gilt nicht für Maschinen, die vor dem Datum der Veröffentlichung dieser Europäischen Norm hergestellt wurden.

Machines pour les produits alimentaires - Laminoirs pour pâte à pizza - Exigences relatives à la sécurité et l'hygiène

1.1 Le présent document spécifie les exigences en matière d'hygiène et de sécurité pour la conception et la fabrication de laminoirs pour pâte à pizza qui :

a) sont destinés à être utilisés :

1) pour produire des bases de pâte à pizza dans les magasins et dans le cadre d'activités artisanales (c'est-à-dire des pizzerias, des pizzerias à emporter, des boulangeries et/ou pâtisseries artisanales, la restauration, etc.) ;

2) pour le laminage et le façonnage des pâtons ;

3) uniquement pour un usage professionnel ;

4) par un opérateur à la fois ;

5) comme machines sur table autonomes uniquement ;

6) uniquement avec alimentation manuelle des pâtons par gravité ;

7) uniquement avec le déchargement manuel des pâtons laminés et agrandis ;

b) sont équipés :

1) de deux paires de rouleaux laminoirs tout au plus, les rouleaux d'une même paire ayant le même diamètre et la même longueur ;

2) de rouleaux laminoirs ayant :

i. diamètre ≤ 60 mm ;

ii. direction fixe de la rotation de sorte que le déplacement de la pâte à pizza s'effectue de haut en bas ;

iii. moteur(s) pour la rotation des rouleaux laminoirs qui transmettent une puissance ≤ 0,50 kW à chaque paire de rouleaux.

1.2 Le présent document ne couvre pas les phénomènes dangereux pertinents suivants :

- phénomènes dangereux dus à l'emballage, à la manutention et au transport ;

- phénomènes dangereux dus à des informations ambiguës et/ou difficilement compréhensibles nécessaires pour commander la machine.

Une description de ces machines est donnée en Annexe A, et des exemples de leurs positionnements sont donnés en Annexe C.

Le présent document ne traite d'aucune exigence spécifique relative au bruit émis par les laminoirs pour pâte à pizza, car le bruit généré n'engendre pas de phénomène dangereux pertinent.

Les phénomènes dangereux significatifs couverts par le présent document sont décrits à l'Annexe B.

1.3 Les machines suivantes sont exclues du domaine d'application du présent document :

- appareils ménagers ;

- machines avec alimentation automatique des pâtons et/ou déchargement des bases de pizza ;

- machines dont l'alimentation des pâtons se fait autrement que par gravité ;

- machines destinées à traiter d'autres produits que la pâte à pizza ;

- façonneuses pour bagel ;

- laminoirs à pâte (voir EN 1674:2015) ;

- façonneuses (voir EN 12041:2014) ;

- laminoirs destinés à traiter des pâtes alimentaires ;

- machines expérimentales et d'essais, en cours de mise au point par le fabricant.

1.4 Le présent document ne s'applique pas aux machines fabriquées avant la date de publication par le CEN du présent document.

Stroji za predelavo hrane - Stroji za valjanje testa za pico - Varnostne in higienske zahteve

General Information

- Status

- Not Published

- Publication Date

- 08-Apr-2026

- Technical Committee

- CEN/TC 153 - Food processing machinery - Safety and hygiene specifications

- Drafting Committee

- CEN/TC 153/WG 4 - Catering equipment

- Current Stage

- 4599 - Dispatch of FV draft to CMC - Finalization for Vote

- Start Date

- 19-Nov-2025

- Due Date

- 02-Oct-2024

- Completion Date

- 19-Nov-2025

Relations

- Effective Date

- 28-Jan-2026

Overview

FprEN 18143 is a European standard developed by CEN that specifies safety and hygiene requirements for pizza dough sheeter machines. These machines are designed primarily for professional use in small-scale food businesses such as pizzerias, takeaway shops, craft bakeries, and catering facilities. The standard applies exclusively to table-top, standalone pizza dough sheeters operated manually by one person to flatten and shape pizza dough lumps.

This standard ensures that machinery used to produce and shape pizza dough bases meets stringent safety guidelines to protect operators and maintain hygienic processing conditions, thereby improving food safety and workplace safety in pizza dough production.

Key Topics

Scope and Applicability: Covers pizza dough sheeter machines with at most two pairs of flattening rollers, each pair having identical roller diameter and length, with rollers rotating in a fixed direction to move dough downwards. The machine power is limited to 0.50 kW per roller pair. Exclusions include machines for other dough products, domestic appliances, and devices with automatic feeding or unloading.

Safety Requirements:

- Mechanical hazard prevention such as risks of drawing-in, crushing, shearing, and entanglement around roller zones and transmission systems.

- Electrical safety including motor enclosures, controls, power supply disconnecting devices, and prevention of unexpected machine startup.

- Ergonomic risk mitigation ensuring operator comfort and safe handling.

Hygiene Requirements:

- Design features to minimize contamination risks via food contact surfaces.

- Easy cleaning access for food and splash zones to maintain high levels of cleanliness.

- Materials and construction that support hygienic practices in professional food production.

Verification and Information:

- Protocols for verifying safety and hygiene compliance.

- Clear instructions, markings, and signal devices for operator guidance.

Exclusions:

- Machines with automated systems for feeding or unloading dough lumps.

- Noise emission requirements are not addressed as the noise levels are deemed non-hazardous.

Applications

FprEN 18143 is essential for manufacturers designing and producing pizza dough sheeter machines intended for professional commercial environments. Its adoption benefits:

- Pizzerias and Takeaway Shops: Ensures the machines used are safe for single-operator use and maintain hygienic dough processing.

- Craft Bakeries and Pastry Shops: Enables consistent flattening and shaping of dough while minimizing contamination risks.

- Catering Facilities: Facilitates reliable dough preparation with controlled operational safety.

- Equipment Manufacturers: Provides a clear framework for engineering machines compliant with European safety and hygiene legislation.

- Food Safety Auditors and Inspectors: Offers standardized criteria for evaluating machinery safety and cleanliness in food service establishments.

Related Standards

FprEN 18143 references and aligns with several key standards in machinery safety and food processing hygiene, including:

- EN ISO 12100:2010 – General principles for machine safety design and risk reduction.

- EN 1672-2:2020 – Hygiene and cleanability requirements for food processing machinery.

- EN ISO 13849-1:2023 – Design of safety-related control systems.

- EN ISO 14118:2018 – Prevention of unexpected machine startup.

- EN ISO 14120:2015 – Requirements for machine guards.

- EN ISO 7010:2020 – Safety signs and symbols for hazard communication.

Additionally, the standard complements related standards that cover dough sheeters for other products and machinery types, such as EN 1674:2015 for general dough sheeters and EN 12041:2014 for moulding machines.

By adhering to FprEN 18143, businesses and manufacturers ensure pizza dough sheeter machines meet high safety and hygiene standards, contributing to safer food production environments and compliance with European regulatory requirements. This standard ultimately supports safer operations and higher quality in professional pizza dough preparation.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

FprEN 18143 is a draft published by the European Committee for Standardization (CEN). Its full title is "Food processing machinery - Pizza dough sheeter machines - Safety and hygiene requirements". This standard covers: 1.1 This document specifies safety and hygiene requirements for the design and manufacture of pizza dough sheeters which: a) are intended to be used: 1) for producing pizza dough bases in shops and craft activities (i.e. pizzerias, takeaway pizza shops, craft bakeries and/or pastries, catering facilities etc.); 2) for flattening and shaping lumps; 3) only for professional use; 4) by one operator at a time; 5) as standalone table-top machines only; 6) only with manual feeding of the lumps by gravity; 7) only with manual unloading of the flattened and enlarged lumps; b) are fitted with: 1) at most two pairs of flattening rollers, the rollers of a pair having the same diameter and the same length; 2) flattening rollers having: i. diameter ≤ 60 mm; ii. fixed direction of the rotation such as to move the pizza dough from top to bottom; iii. motor(s) for the rotation of the flattening rollers which transmit a power ≤ 0,50 kW to each pair of rollers. 1.2 The following relevant hazards are not covered by this document: - hazards due to packaging, handling and transport; - hazards due to ambiguous and/or not easily understandable information needed to control the machine. A description of these machines is given in Annex A, and examples for positioning them are given in Annex C. This document does not deal with any specific requirement on noise emitted from pizza dough sheeters as the generated noise does not cause a relevant hazard. The significant hazards covered by this document are described in Annex B. 1.3 The following machines are excluded from the scope of this document: - domestic (household) appliances; - machines with automatic feeding of the lumps and/or unloading of the pizza bases; - machines with feeding of the lumps other than by gravity; - machines to process other products than pizza dough; - bagel machines; - dough sheeters (see EN 1674:2015); - moulders (see EN 12041:2014); - sheeters for pasta dough processing; - experimental and testing machines under development by the manufacturer. 1.4 This document is not applicable to machines which are manufactured before the date of publication of this document by CEN.

1.1 This document specifies safety and hygiene requirements for the design and manufacture of pizza dough sheeters which: a) are intended to be used: 1) for producing pizza dough bases in shops and craft activities (i.e. pizzerias, takeaway pizza shops, craft bakeries and/or pastries, catering facilities etc.); 2) for flattening and shaping lumps; 3) only for professional use; 4) by one operator at a time; 5) as standalone table-top machines only; 6) only with manual feeding of the lumps by gravity; 7) only with manual unloading of the flattened and enlarged lumps; b) are fitted with: 1) at most two pairs of flattening rollers, the rollers of a pair having the same diameter and the same length; 2) flattening rollers having: i. diameter ≤ 60 mm; ii. fixed direction of the rotation such as to move the pizza dough from top to bottom; iii. motor(s) for the rotation of the flattening rollers which transmit a power ≤ 0,50 kW to each pair of rollers. 1.2 The following relevant hazards are not covered by this document: - hazards due to packaging, handling and transport; - hazards due to ambiguous and/or not easily understandable information needed to control the machine. A description of these machines is given in Annex A, and examples for positioning them are given in Annex C. This document does not deal with any specific requirement on noise emitted from pizza dough sheeters as the generated noise does not cause a relevant hazard. The significant hazards covered by this document are described in Annex B. 1.3 The following machines are excluded from the scope of this document: - domestic (household) appliances; - machines with automatic feeding of the lumps and/or unloading of the pizza bases; - machines with feeding of the lumps other than by gravity; - machines to process other products than pizza dough; - bagel machines; - dough sheeters (see EN 1674:2015); - moulders (see EN 12041:2014); - sheeters for pasta dough processing; - experimental and testing machines under development by the manufacturer. 1.4 This document is not applicable to machines which are manufactured before the date of publication of this document by CEN.

FprEN 18143 is classified under the following ICS (International Classification for Standards) categories: 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

FprEN 18143 has the following relationships with other standards: It is inter standard links to EN ISO 10297:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

FprEN 18143 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2023/1230; Standardization Mandates: M/396, M/605. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

FprEN 18143 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2025

Stroji za predelavo hrane - Stroji za valjanje testa za pico - Varnostne in higienske

zahteve

Food processing machinery - Pizza dough sheeter machines - Safety and hygiene

requirements

Nahrungsmittelmaschinen - Pizzateig-Ausrollmaschinen - Sicherheits- und

Hygieneanforderungen

Machines pour les produits alimentaires - Laminoirs pour pâte à pizza - Exigences

relatives à la sécurité et l'hygiène

Ta slovenski standard je istoveten z: prEN 18143

ICS:

67.260 Tovarne in oprema za Plants and equipment for the

živilsko industrijo food industry

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

prEN 18143

NORME EUROPÉENNE

EUROPÄISCHE NORM

November 2024

ICS 67.260

English Version

Food processing machinery - Pizza dough sheeter

machines - Safety and hygiene requirements

Machines pour les produits alimentaires - Laminoirs Nahrungsmittelmaschinen - Pizzateig-

pour pâte à pizza - Exigences relatives à la sécurité et Ausrollmaschinen - Sicherheits- und

l'hygiène Hygieneanforderungen

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 153.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 18143:2024 E

worldwide for CEN national Members.

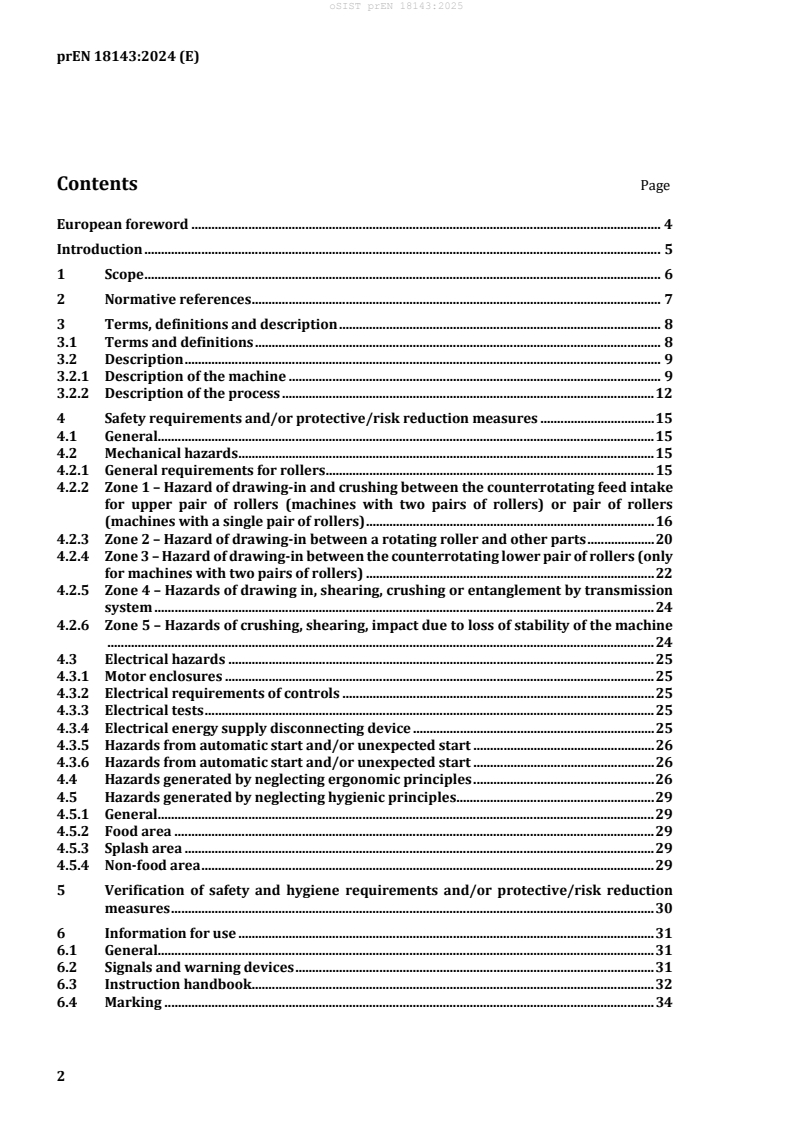

prEN 18143:2024 (E)

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 7

3 Terms, definitions and description . 8

3.1 Terms and definitions . 8

3.2 Description . 9

3.2.1 Description of the machine . 9

3.2.2 Description of the process . 12

4 Safety requirements and/or protective/risk reduction measures . 15

4.1 General. 15

4.2 Mechanical hazards . 15

4.2.1 General requirements for rollers. 15

4.2.2 Zone 1 – Hazard of drawing-in and crushing between the counterrotating feed intake

for upper pair of rollers (machines with two pairs of rollers) or pair of rollers

(machines with a single pair of rollers) . 16

4.2.3 Zone 2 – Hazard of drawing-in between a rotating roller and other parts . 20

4.2.4 Zone 3 – Hazard of drawing-in between the counterrotating lower pair of rollers (only

for machines with two pairs of rollers) . 22

4.2.5 Zone 4 – Hazards of drawing in, shearing, crushing or entanglement by transmission

system . 24

4.2.6 Zone 5 – Hazards of crushing, shearing, impact due to loss of stability of the machine

................................................................................................................................................................... 24

4.3 Electrical hazards . 25

4.3.1 Motor enclosures . 25

4.3.2 Electrical requirements of controls . 25

4.3.3 Electrical tests . 25

4.3.4 Electrical energy supply disconnecting device . 25

4.3.5 Hazards from automatic start and/or unexpected start . 26

4.3.6 Hazards from automatic start and/or unexpected start . 26

4.4 Hazards generated by neglecting ergonomic principles . 26

4.5 Hazards generated by neglecting hygienic principles . 29

4.5.1 General. 29

4.5.2 Food area . 29

4.5.3 Splash area . 29

4.5.4 Non-food area . 29

5 Verification of safety and hygiene requirements and/or protective/risk reduction

measures . 30

6 Information for use . 31

6.1 General. 31

6.2 Signals and warning devices . 31

6.3 Instruction handbook. 32

6.4 Marking . 34

prEN 18143:2024 (E)

Annex A (informative) List of significant hazards . 35

Annex B (informative) Examples of positioning of pizza dough sheeters . 38

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/CE aimed to be covered . 39

Annex ZB (informative) Relationship between this European Standard and the essential

requirements of regulation (EU) 2023/1230 aimed to be covered . 41

Bibliography . 43

prEN 18143:2024 (E)

European foreword

This document (prEN 18143:2024) has been prepared by Technical Committee CEN/TC 153 “Machinery

intended for use with foodstuffs and feed”, the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annexes ZA and ZB, which are integral parts of

this document.

prEN 18143:2024 (E)

Introduction

This document is a type-C-standard as stated in EN ISO 12100:2010.

The machinery concerned and the extent to which hazards, hazardous situations and events are covered

are indicated in the scope of this European Standard. When provisions of this type-C-standard are

different from those which are stated in type-A- or -B-standards, the provisions of this type-C-standard

take precedence over the provisions of the other standards, for machines that have been designed and

built according to the provisions of this type-C-standard.

prEN 18143:2024 (E)

1 Scope

1.1 This document specifies safety and hygiene requirements for the design and manufacture of pizza

dough sheeters which:

a) are intended to be used:

1) for producing mainly pizza dough bases in shops and craft activities (i.e. pizzerias, takeaway

pizza shops, craft bakeries and/or pastries, catering facilities, etc.);

2) for flattening and enlarging pieces of dough;

3) only for professional use;

4) by one operator at a time;

5) as standalone table-top machines only;

6) only with manual feeding of the pieces of pizza dough by gravity;

7) only with manual unloading of the flattened and enlarged pieces of pizza dough;

b) are fitted with:

1) at most two pairs of flattening rollers, the rollers of a pair having the same diameter and the

same length;

2) flattening rollers having:

i. diameter ≤ 60 mm;

ii. fixed direction of the rotation such as to move the pizza dough from top to bottom;

iii. motor(s) for the rotation of the flattening rollers which transmit a power ≤ 0,50 kW to each

pair of rollers

1.2 The following relevant hazards are not covered by this document:

— hazards arising from the use of an automatic loading and/or unloading system;

— hazards due to packaging, handling and transport;

— hazards due to ambiguous and/or not easily understandable information needed to control the

machine.

This document does not deal with any specific requirement on noise emitted from pizza dough sheeters

as the generated noise does not cause a relevant hazard.

The significant hazards covered by this document are described in Annex A.

1.3 The following machines are excluded from the scope of this document:

— domestic (household) appliances;

— machines with automatic feeding of the pizza dough pieces and/or unloading of the pizza bases;

— machines with feeding of the lumps other than by gravity;

prEN 18143:2024 (E)

— machines to process other products than pizza dough;

— bagel machines;

— dough sheeters (see EN 1674:2015);

— moulders (see EN 12041:2014);

— sheeters for pasta dough processing;

— experimental and testing machines under development by the manufacturer.

1.4 This document is not applicable to machines which are manufactured before the date of

publication of this European Standard.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 614-1:2006+A1:2009, Safety of machinery — Ergonomic design principles — Part 1: Terminology and

general principles

EN 1672-2:2020, Food processing machinery — Basic concepts — Part 2: Hygiene and cleanability

requirements

EN 60204-1:2018, Safety of machinery — Electrical equipment of machines — Part 1: General

requirements (IEC 60204-1:2016)

EN 60529:1991, Degrees of protection provided by enclosures (IP code) (IEC 60529:1989)

EN 61310-1:2008, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for

visual, acoustic and tactile signals (IEC 61310-1:2007)

EN ISO 7010:2020, Graphical symbols — Safety colours and safety signs — Registered safety signs

(ISO 7010:2019, Corrected version 2020-06)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13849-1:2023, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design (ISO 13849-1:2023)

EN ISO 13856-2:2013, Safety of machinery — Pressure-sensitive protective devices — Part 2: General

principles for design and testing of pressure-sensitive edges and pressure-sensitive bars (ISO 13856-2:2013)

EN ISO 13857:2019, Safety of machinery — Safety distances to prevent hazard zones being reached by

upper and lower limbs (ISO 13857:2019)

As impacted by EN 60529:1991/A1:2000, EN 60529:1991/A2:2013, EN 60529:1991/corrigendum May 1993,

EN 60529:1991/A2:2013/AC:2019-02 and EN 60529:1991/AC:2016-12.

As impacted by EN ISO 7010/A1:2020, EN ISO 7010/A2:2022 and EN ISO 7010/A3:2022.

prEN 18143:2024 (E)

EN ISO 14118:2018, Safety of machinery — Prevention of unexpected start-up (ISO 14118:2017)

EN ISO 14119:2013, Safety of machinery — Interlocking devices associated with guards — Principles for

design and selection (ISO 14119:2013)

EN ISO 14120:2015, Safety of machinery — Guards — General requirements for the design and

construction of fixed and movable guards (ISO 14120:2015)

3 Terms, definitions and description

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1 Terms and definitions

3.1.1

pizza dough

homogeneous mass of soft dough obtained by mixing various food ingredients

Note 1 to entry: Most important ingredients are flour and water to achieve an adequate softness of the dough such

that it can be shaped into discs and/or ovals with a very large surface compared to the thickness.

3.1.2

lump

pre-portioned piece of pizza dough

Note 1 to entry: It can have a totally irregular shape or have been previously treated to give it an approximately

regular shape (roundish, oval, rectangular, etc.).

3.1.3

flattening

reduction of the thickness of a lump passing in the space between two counter-rotating rollers and

consequent enlargement of its upper and lower surface

3.1.4

shaping

reduction of the thickness of a pre-flattened lump for achieving an as much regular as possible shape of

the flattened lump through an accurate adjustment of the gap between two counter-rotating rollers

Note 1 to entry: The shape of the resulting flattened lump depends mostly on the form of the lump before being

flattened (for instance, a rounded lump can be transformed into an oval-shaped disc, a more or less oval-shaped

lump can be transformed into a flattened more rounded or even more oval shape depending on the side of insertion

into the rollers).

3.1.5

manual operation

process in which the piece of dough is manually placed to the inlet of the machine by action of the

operator

prEN 18143:2024 (E)

3.1.6

pair of rollers

two cylinders with parallel axis

3.1.7

scraper

device used for removing residual of dough and flour from the roller

3.1.8

fixed distance guard

guard which does not completely enclose a hazard zone, but which prevents or reduces access by virtue

of its dimensions and its distance from the hazard zone (for example perimeter fence or tunnel guard)

and which is affixed in such a manner (for example, by screws, nuts, and welding) that it can only be

opened or removed by the use of tools or by destruction of the means by which the guard is affixed

[SOURCE: EN ISO 14120:2015, 3.2 and 3.2.2]

3.2 Description

3.2.1 Description of the machine

This document covers the following types of machines:

a) machines with a single pair of rollers (see Figure 1);

b) machines with two pairs of rollers, the upper pair inclined with respect to the lower pair (see

Figure 2); these machines are provided with a tilting device, placed between the two pairs of rollers,

whose functioning is ensured by the mass of dough coming out from the upper roller pair and falling

toward the lower rollers feed zone (it is not motor-driven and returns in its resting position by means

of a very weak spring);

c) machines with two parallel pairs of rollers (see Figure 3); these machines are not provided with a

tilting device.

prEN 18143:2024 (E)

Key

1 Lump inlet

2 Flattened lump outlet

3 Rollers

4 Scrapers (optional)

5 Control devices

6 Device for adjusting the gap between the rollers

Figure 1 — Single pair of rollers machine

prEN 18143:2024 (E)

Key

1 Lump inlet of the upper pair of rollers

2 Outlet of the flattened lump from the first pair of rollers

3 Flattened lump inlet of the lower pair of rollers

4 Outlet of the flattened dough from the second pair of rollers

5 Upper pair of rollers

6 Lower pair of rollers Lower pair of rollers

7 Scrapers (optional)

8 Tilting device

9 Control devices

10 Devices for adjusting the gap between the rollers

Figure 2 — Double non-parallel pairs of rollers machine

prEN 18143:2024 (E)

Key

1 Lump inlet of the upper pair of rollers

2 Outlet of the flattened lump from the first pair of rollers

3 Flattened lump inlet of the lower pair of rollers

4 Outlet of the flattened dough from the second pair of rollers

5 Upper pair of rollers

6 Lower pair of rollers Lower pair of rollers

7 Scrapers (optional)

8 Tilting device

9 Control devices

Figure 3 — Parallel double pairs of rollers machine

3.2.2 Description of the process

The flow of the process for a normal duty cycle is shown in:

a) Figure 4, for a machine with parallel double pairs of rollers;

b) Figure 5, for a machine with non-parallel double pairs of rollers;

c) Figure 6, for a machine with a single pair of rollers;

and represents the state of the art on how the machine is used.

prEN 18143:2024 (E)

Key

1 Introduction of the lump (by gravity)

2 First processing of the dough – flattening and raw shaping

3 Moving toward the second pair of rollers (by gravity, through the second feed chute)

4 Second processing of the dough – further flattening and shaping

5 Discharge of the processed dough and laying down of it on the table

Figure 4 — Processing flow in a machine with parallel double pairs of rollers

prEN 18143:2024 (E)

Key

1 Introduction of the lump (by gravity)

2 First processing of the dough – flattening and raw shaping

3 Rotation of flattened lump by means of the tilting device and moving toward the second pair of rollers (by

gravity)

4 Second processing of the dough – further flattening and shaping

5 Discharge of the processed dough and laying down of it on the table

Figure 5 — Processing flow in a machine with non-parallel double pairs of rollers

prEN 18143:2024 (E)

Key

1 Introduction of the lump (by gravity)

2 First processing of the dough – flattening and raw shaping

3 Discharge of the processed dough and laying down of it on the table

Figure 6 — Processing flow for the single pair of rollers

Examples of positioning of the pizza dough sheeters are given in informative Annex B.

4 Safety requirements and/or protective/risk reduction measures

4.1 General

Machinery shall comply with the safety requirements and/or protective measures of this clause.

In addition, the machine shall be designed according to the principles of EN ISO 12100:2010 for relevant

but not significant hazards, which are not dealt with by this document.

4.2 Mechanical hazards

4.2.1 General requirements for rollers

If the rollers are grooved, the following requirements shall be met (see Figure 7):

— the grooves shall be circumferential or helicoidal; and the perpendicular axle passing through their

centers shall coincide with the axis of the roller;

— the distance (P) between two consecutive grooves along the same generatrix of the roller shall

be ≤ 2 mm;

— the depth of the grooves (G) shall be ≤ 0,4 mm.

prEN 18143:2024 (E)

Key

P Distance between two consecutive grooves

G Depth of the groove

Figure 7 — Grooves description

4.2.2 Zone 1 – Hazard of drawing-in and crushing between the counterrotating feed intake for

upper pair of rollers (machines with two pairs of rollers) or pair of rollers (machines with a

single pair of rollers)

4.2.2.1 General

Access to the hazard zone (gap between the rollers) shall be prevented or restricted with at least one of

the following:

— a fixed distance guard (see 4.2.2.2);

— an interlocking movable guard (see 4.2.2.3). i.e. in case of frequent opening or removal of the guard

which does not require the use of tools for being removed (e.g. for cleaning reasons and for

reassembling it);

— a hopper or a feed chute with a tripping device (e.g. a pressure-sensitive bar) at the top (see 4.2.2.4).

4.2.2.2 Fixed distance guard

The fixed distance guard shall comply with the following requirements:

— The gap between the rollers shall be ≤ 4 mm;

— The opening at the upper side of the fixed distance guard for the lump inlet shall comply with Table 1

(see also Figure 8).

Table 1 — Dimensions for the lump inlet opening

A ≤ 50 mm

B ≥ 150 mm

The fixed distance guard shall comply with EN ISO 14120:2015, 5.2.4, 5.3.7, 5.3.9 and 5.3.10.

prEN 18143:2024 (E)

If the fixed distance guard has openings other than the dough inlet and outlet ones, they shall comply

with EN ISO 13857:2019, Table 3, Table 4 and Table 6.

If the guard is not permanently fixed, e.g. by welding, its fixing systems shall remain attached to the guard

or to the machinery when the guard is removed.

The manufacturer shall provide information that the machine shall be placed so that the vertical distance

between the floor and the infeed opening upper rim (the upper one in case of two pairs of rollers

machine) shall be ≤ 1650 mm (see 6.3 t)) according to 4.4.

The manufacturer shall provide information about the vertical distance between the upper rim of the

inlet opening and the lower side of the machine (see 6.3 s)).

Key

1 Rollers

2 Fixed distance guard

3 Opening for the lump inlet

4 Reference plane for measuring distance (B)

A Inlet opening maximum width

E Localization of the reference plane (4) where distance from one roller to the other is equal to 25 mm

B Shortest distance between the outer edge of the opening and the reference plane (4)

Figure 8 — Dimensions of lump inlet opening

4.2.2.3 Interlocking movable guard

All following requirements shall apply:

— the opening at the upper side of the guard for the lump inlet shall comply with Table 1 (see also

Figure 8);

— moving the interlocking guard from its normal resting position shall activate the stop of every part

of the machine when the clearance between the guard and other parts of the machine exceeds

10 mm;

prEN 18143:2024 (E)

— the inlet opening width A (see Figure 8) at the upper side of the guard shall not increase when the

interlocking guard is moved from its normal resting position;

— the stopping time after activation of the interlocking device shall be ≤ 1 s;

— the safety related parts of the control system and the combination of these parts which performs the

safety function shall meet at least a performance level “c” specified in accordance with

EN ISO 13849-1:2023;

— the interlocking guard shall comply with EN ISO 14119:2013, Clauses 5 and 6, and

EN ISO 14120:2015, 5.2.4, 5.3.7, 5.3.12 and 5.3.13;

— if the interlocking guard has openings other than the dough inlet and outlet ones, they shall comply

with EN ISO 13857:2019, Table 3, Table 4 and Table 6;

The manufacturer shall provide information that the machine shall be placed so that the vertical distance

between the floor and the infeed opening upper rim (the upper one in case of two pairs of rollers

machine) shall be ≤ 1650 mm (see 6.3 t)) according to 4.4.

The manufacturer shall provide information about the vertical distance between the upper rim of the

inlet opening and the lower side of the machine (see 6.3 s)).

4.2.2.4 Feed hopper with a pressure-sensitive bar at the top of the hopper

If a pressure-sensitive bar is used as a safeguarding measure to stop the hazardous movements, all

following requirements shall apply:

— the pressure sensitive bar shall comply with EN ISO 13856-2:2013;

— the inlet opening shall comply with Table 2 (see also Figure 9);

— the pressure-sensitive bar shall be attached to the upper rim of the chute or to a provided supporting

system;

— the clearance (C) between the sensitive bar and the rim of the hopper shall be ≤ 20 mm (see

Figure 9);

— the pressure-sensitive bar shall control the stop of every moving part of the machine when it has

moved for a linear displacement D ≤ 15 mm from its resting position (see Figure 9);

— in horizontal projection the pressure-sensitive bar shall run parallel at least to the lateral and the

front sides of the inlet opening and outside it;

— the stopping time after activation of the pressure-sensitive bar shall be ≤ 1 s;

— the safety-related parts of the control system and the combination of these parts which performs the

safety function shall meet at least a performance level “c” specified in accordance with

EN ISO 13849-1:2023.

The manufacturer shall provide information that the machine shall be placed so that the vertical distance

between the floor and the upper side of the pressure sensitive bar is ≤ 1650 mm (see 6.3 v)) according to

4.4.

The manufacturer shall provide information about the vertical distance between the upper rim of the

tripping device and the lower side of the machine (see 6.3 u)).

prEN 18143:2024 (E)

Table 2 — Dimensions for the lump inlet opening with tripping device

A ≤ 50 mm

B ≥ 120 mm

C ≤ 20 mm

D ≤ 15 mm

Key

1 Rollers

2 Pressure-sensitive bar

3 Opening for the lump inlet

4 Reference plane for measuring distance (B)

A Inlet opening maximum width

E Localization of the reference plane (4) where distance from one roller to the other is equal to 25 mm

B Shortest distance between the outer edge of the opening and the reference plane (4)

C Linear displacement of the sensitive bar when the safety device actuates

D Clearance between the sensitive bar and the rim of the hopper

Figure 9 — Inlet opening with pressure-sensitive bar

prEN 18143:2024 (E)

4.2.3 Zone 2 – Hazard of drawing-in between a rotating roller and other parts

4.2.3.1 General

The access to hazards of drawing-in zones from the outlet side of:

— the roller pair (single pair of rollers machines);

— both roller pairs (two pairs of rollers machines);

shall be prevented or restricted with:

— a fixed distance guard (see 4.2.3.2), which shall comply with the requirements in 4.2.3.2; or

— an interlocking movable or removable guard (see 4.2.3.3).

4.2.3.2 Fixed distance guard

All following requirements shall apply:

— if the guard is not permanently fixed, e.g. by welding, its fixing systems shall remain attached to the

guard or to the machinery when the guard is removed;

— at least one side of the fixed distance guard shall be parallel to the axis of the relevant roller, and it

shall be located at a distance A ≤ 4 mm from the nearest generatrix of the relevant roller (see

Figure 10);

— any other clearance B (see example in Figure 10) between the fixed distance guard and other parts

of the machine, which allow the access to the hazard zone, shall comply with EN ISO 13857:2019,

Table 3, Table 4 and Table 6 (see Figure 10):

— the fixed distance guards shall comply with EN ISO 14120:2015, 5.2.4, 5.3.7, 5.3.9 and 5.3.10; if the

fixed distance guard has openings other than the dough outlet and inlet ones, they shall comply with

EN ISO 13857:2019, Table 3, Table 4 and Table 6.

In the Figure 10, some examples of fixed distance guards, e.g. ramp and other fixed sheet (see

Figure 10 a)) or spacing bars (see Figure 10 b)), for preventing/restricting the access to the hazard zones

are shown.

prEN 18143:2024 (E)

a) Ramp and other fixed sheet b) Spacing bars

Key

A Clearance between the fixed distance guard and the nearest generatrix of the roller

B Example of clearance B between the fixed distance guard and other parts of the machine

1 Rollers

2 Ramp

3 Fixed sheet

4 Spacing bar

Figure 10 — Examples of fixed distance guards to prevent/restrict the access to hazard zone 2

4.2.3.3 Interlocking movable guard

If the guard is fixed to the machine with m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...