EN 4660-004:2011

(Main)Aerospace series - Modular and Open Avionics Architectures - Part 004: Packaging

Aerospace series - Modular and Open Avionics Architectures - Part 004: Packaging

The purpose of this standard is to establish uniform requirements for Packaging for the Common Functional Modules (CFM) within an Integrated Modular Avionic (IMA) system, as defined per ASAAC. It comprises the module physical properties and the Module Physical Interface (MPI) definitions together with guidelines for IMA rack and the operational environment.

The characteristics addressed by the Packaging Standard are:

Interchangeability:

For a given cooling method all modules conforming to the packaging standard will function correctly when inserted into any rack slot conforming to the standard for the cooling method.

- All modules conforming to the Module Physical Interface (MPI) definitions for connector, IED and cooling interface will function correctly when inserted into any rack slot conforming to the same MPI definition.

Maintainability:

- All modules are easily removable at first line.

- No special tools required at first line.

- No manual adjustment is necessary when installing modules. No tool is required for installation or removal of the modules.

- Mechanical keying is provided that prevents insertion of a module into a rack slot that may cause an unsafe condition.

The Module Physical Interface definition, contained within this standard, does not include the properties of the signalling used in the optical interface (e.g. wavelength). These are covered in EN 4660-003.

Luft- und Raumfahrt - Modulare und offene Avionikarchitekturen - Teil 004: Paketierung

Zweck der vorliegenden Norm ist die Festlegung einheitlicher Anforderungen an die Paketierung der Stan-dardfunktionsmodule (CFM) innerhalb eines IMA-Systems entsprechend der ASAAC-Definition. Dieses Dokument umfasst die physikalischen Moduleigenschaften und die physikalische Modulschnittstelle (MPI) und gibt Empfehlungen für das IMA-Gestell und die Betriebsumgebung. Die behandelten Paketierungsmerkmale sind: Austauschbarkeit: ⎯ Bei einem gegebenen Kühlverfahren funktionieren alle Module nach der vorliegenden Norm ordnungs-gemäß, wenn sie in einen beliebigen Gestellsteckplatz eingesetzt sind, der den Vorgaben für das Kühlver-fahren entspricht; ⎯ Alle den MPI-Definitionen für Steckverbinder, IED und Kühlschnittstelle entsprechenden Module funktio-nieren ordnungsgemäß, wenn sie in einen beliebigen Gestellsteckplatz eingesetzt sind, der derselben MPI-Definition entspricht. Wartbarkeit: ⎯ Alle Module sind vor Ort leicht auszubauen. ⎯ Vor Ort sind keine speziellen Werkzeuge erforderlich. ⎯ Beim Einbau von Modulen ist keine manuelle Anpassung notwendig. Zum Ein- und Ausbau der Module ist kein Werkzeug erforderlich. ⎯ Es ist eine mechanische Sicherung vorgesehen, die verhindert, dass das Modul in einen Steckplatz ein-gesetzt wird, der einen unsicheren Zustand bewirken könnte. Die in dieser Norm enthaltene Definition der physikalischen Modulschnittstelle umfasst nicht die Signalisie-rungseigenschaften der optischen Schnittstelle (z. B. Wellenlänge). Diese sind in EN 4660-003 behandelt.

Série aérospatiale - Architectures Avioniques Modulaires et Ouvertes - Partie 004: Packaging

Le but de la présente norme est d'établir des exigences uniformes pour le Packaging relative aux Modules Fonctionnels Communs (CFM) dans le cadre d'un système avionique modulaire intégré (IMA) tel que défini par l'ASAAC. Il comprend les propriétés physiques de modules et les définitions de l'interface physique des modules (MPI) conjointement avec les lignes directrices pour rack IMA et l'environnement opérationnel

Les caractéristiques traitées par la norme pour le Packaging sont :

Interchangeabilité :

- Pour une méthode de refroidissement donnée, tous les modules conformes à la norme pour le packaging fonctionneront correctement après insertion dans une fente de rack conforme à la norme de la méthode de refroidissement.

- Tous les modules conformes aux définitions de l'interface physique du module (MPI) pour le connecteur, l'IED et l'interface de refroidissement fonctionneront correctement après insertion dans une fente de rack conforme à la même définition de la MPI.

Maintenabilité :

- Tous les modules doivent être facilement démontables en première ligne.

- Aucun outil spécial n’est exigé en première ligne.

- Aucun réglage manuel n'est nécessaire lors de l'installation des modules. Aucun outil n'est exigé pour l'installation ou la dépose des modules.

- Une manipulation mécanique est prévue de façon à empêcher l'insertion d'un module dans une fente de rack susceptible de provoquer une situation dangereuse.

La définition de l'interface physique de modules incluse dans la présente norme ne comprend pas les propriétés de signalisation utilisées dans l'interface optique (par exemple, longueur d'onde). Celles-ci sont couvertes dans l'EN 4660-003.

Aeronavtika - Modularne in odprte letalske elektronske arhitekture - 004. del: Pakiranje

Namen tega standarda je vzpostaviti enotne zahteve za pakiranje splošnih funkcionalnih modulov (CFM) znotraj integriranega modularnega letalskega (IMA) sistema, kot je določeno z ASAAC. Obsega fizične lastnosti modula in definicije fizičnega vmesnika modula (MPI), skupaj s smernicami za stojalo IMA in delovno okolje.

Značilnosti, obravnavane v standardu za pakiranje, so:

a) zamenljivost:

1) Za dano metodo hlajenja bodo vsi moduli, ki so v skladu s standardom za pakiranje, delovali pravilno, če bodo vstavljeni v katero koli odprtino stojala, ki je v skladu s standardom za metodo hlajenja.

2) Vsi moduli, ki so v skladu z definicijami konektorja fizičnega vmesnika modula (MPI), IED in hladilne vmesnike, bodo delovali pravilno, če bodo vstavljeni v kakršno koli odprtino stojala, ki je v skladu z isto definicijo MPI.

b) Vzdrževalno-tehnične zahteve:

1) Vsi moduli se zlahka odstranijo pri prvi liniji.

2) Ni potrebno posebno orodje pri prvi liniji.

3) Ni potrebna ročna prilagoditev pri vgradnji modulov. Nobeno orodje ni potrebno pri vgradnji ali odstranitvi modulov.

4) Zagotovljeno je mehansko odpiranje, ki preprečuje vstavitev modula v odprtino stojala, kar lahko povzroči nevarne pogoje.

Definicija fizičnega vmesnika modula, ki jo vključuje ta standard, ne vključuje lastnosti signalizacije, uporabljenih pri optičnem vmesniku (npr. valovna dolžina). Ti so zajeti v EN 4660-003.

General Information

- Status

- Withdrawn

- Publication Date

- 22-Feb-2011

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- ASD-STAN - Aerospace

- Drafting Committee

- ASD-STAN/D 1 - General

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 21-Aug-2019

- Completion Date

- 21-Jan-2026

Relations

- Replaced By

EN 4660-004:2019 - Aerospace series - Modular and Open Avionics Architectures - Part 004: Packaging - Effective Date

- 04-Feb-2015

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 4660-005:2019 - Aerospace series - Modular and Open Avionics Architectures - Part 005: Software - Effective Date

- 28-Jan-2026

- Refers

EN 2101:1991 - Aerospace series - Chromic acid anodizing of aluminium and wrought aluminium alloys - Effective Date

- 28-Jan-2026

- Refers

EN 2284:1991 - Aerospace series - Sulphuric acid anodizing of aluminium and wrought aluminium alloys - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

NSF-ISR

NSF International Strategic Registrations.

Orion Registrar Inc.

US-based certification body for management systems.

Sponsored listings

Frequently Asked Questions

EN 4660-004:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Aerospace series - Modular and Open Avionics Architectures - Part 004: Packaging". This standard covers: The purpose of this standard is to establish uniform requirements for Packaging for the Common Functional Modules (CFM) within an Integrated Modular Avionic (IMA) system, as defined per ASAAC. It comprises the module physical properties and the Module Physical Interface (MPI) definitions together with guidelines for IMA rack and the operational environment. The characteristics addressed by the Packaging Standard are: Interchangeability: For a given cooling method all modules conforming to the packaging standard will function correctly when inserted into any rack slot conforming to the standard for the cooling method. - All modules conforming to the Module Physical Interface (MPI) definitions for connector, IED and cooling interface will function correctly when inserted into any rack slot conforming to the same MPI definition. Maintainability: - All modules are easily removable at first line. - No special tools required at first line. - No manual adjustment is necessary when installing modules. No tool is required for installation or removal of the modules. - Mechanical keying is provided that prevents insertion of a module into a rack slot that may cause an unsafe condition. The Module Physical Interface definition, contained within this standard, does not include the properties of the signalling used in the optical interface (e.g. wavelength). These are covered in EN 4660-003.

The purpose of this standard is to establish uniform requirements for Packaging for the Common Functional Modules (CFM) within an Integrated Modular Avionic (IMA) system, as defined per ASAAC. It comprises the module physical properties and the Module Physical Interface (MPI) definitions together with guidelines for IMA rack and the operational environment. The characteristics addressed by the Packaging Standard are: Interchangeability: For a given cooling method all modules conforming to the packaging standard will function correctly when inserted into any rack slot conforming to the standard for the cooling method. - All modules conforming to the Module Physical Interface (MPI) definitions for connector, IED and cooling interface will function correctly when inserted into any rack slot conforming to the same MPI definition. Maintainability: - All modules are easily removable at first line. - No special tools required at first line. - No manual adjustment is necessary when installing modules. No tool is required for installation or removal of the modules. - Mechanical keying is provided that prevents insertion of a module into a rack slot that may cause an unsafe condition. The Module Physical Interface definition, contained within this standard, does not include the properties of the signalling used in the optical interface (e.g. wavelength). These are covered in EN 4660-003.

EN 4660-004:2011 is classified under the following ICS (International Classification for Standards) categories: 49.090 - On-board equipment and instruments. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 4660-004:2011 has the following relationships with other standards: It is inter standard links to EN 4660-004:2019, EN 4660-001:2011, EN 2437:2001, EN 4660-003:2019, EN 4660-005:2019, EN 2101:1991, EN 2284:1991, EN 4660-002:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 4660-004:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Aeronavtika - Modularne in odprte letalske elektronske arhitekture - 004. del: PakiranjeLuft- und Raumfahrt - Modulare und offene Avionikarchitekturen - Teil 004: PaketierungSérie aérospatiale - Architectures Avioniques Modulaires et Ouvertes - Partie 004: PackagingAerospace series - Modular and Open Avionics Architectures - Part 004: Packaging49.090On-board equipment and instrumentsICS:Ta slovenski standard je istoveten z:EN 4660-004:2011SIST EN 4660-004:2011en01-december-2011SIST EN 4660-004:2011SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 4660-004

February 2011 ICS 49.090 English Version

Aerospace series - Modular and Open Avionics Architectures - Part 004: Packaging

Série aérospatiale - Architectures Avioniques Modulaires et Ouvertes - Partie 004: Packaging

Luft- und Raumfahrt - Modulare und offene Avionikarchitekturen - Teil 004: Packaging This European Standard was approved by CEN on 26 June 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 4660-004:2011: ESIST EN 4660-004:2011

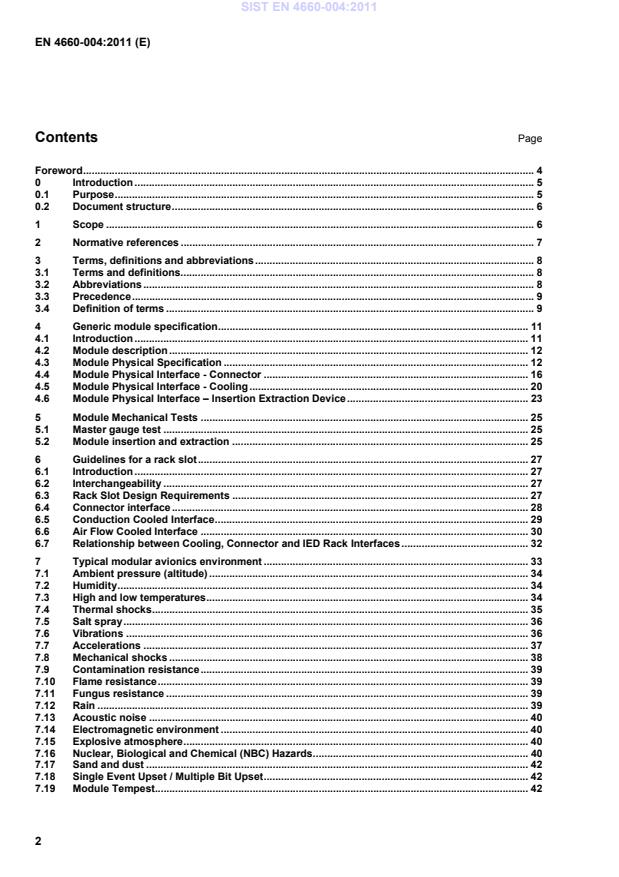

Tables

Page Table 1 — Allowed aluminium protective treatments . 14 Table 2 — Ambient pressure in relation to altitude . 34 Table 3 — Temperature environmental conditions - Conditioned bay . 35 Table 4 — Temperature environmental conditions - Unconditioned bay . 35 Table 5 — Temperature environmental conditions - Storage . 35 Table 6 — Thermal shocks . 36 Table 7 — Sinusoidal vibrations . 36 Table 8 — Rotational accelerations . 37 Table 9 — Transversal accelerations . 38 Table 10 — Functional Shocks . 38 Table 11 — Summary of environment and bonding environmental Conditions . 40 Table 12 — Initial Nuclear radiation conditions . 41 Table 13 — Nuclear hardening conditions . 41

The purpose of the ASAAC Programme is to define and validate a set of open architecture standards, concepts and guidelines for Advanced Avionics Architectures (A3) in order to meet the three main ASAAC drivers. The standards, concepts and guidelines produced by the Programme are to be applicable to both new aircraft and update programmes from 2005. The three main goals for the ASAAC Programme are: 1.

Reduced life cycle costs. 2.

Improved mission performance. 3.

Improved operational performance. The ASAAC standards are organised as a set of documents including: A set of agreed standards that describe, using a top down approach, the Architecture overview to all interfaces required to implement the core within avionics system. The guidelines for system implementation through application of the standards. The document hierarchy is given hereafter: (in this figure the document is highlighted)

Guidelines for System Issues • System Management • Fault Management • Initialisation / Shutdown • Configuration / Reconfiguration • Time Management • Security • Safety Standard for Architecture Standard for Common Functional ModulesStandard for Communications and Network Standard for Packaging Standard for Software

Figure 1 — ASAAC Standard Documentation Hierarchy SIST EN 4660-004:2011

The characteristics addressed by the Packaging Standard are: Interchangeability: For a given cooling method all modules conforming to the packaging standard will function correctly when inserted into any rack slot conforming to the standard for the cooling method. All modules conforming to the Module Physical Interface (MPI) definitions for connector, IED and cooling interface will function correctly when inserted into any rack slot conforming to the same MPI definition. Maintainability: All modules are easily removable at first line. No special tools required at first line. No manual adjustment is necessary when installing modules. No tool is required for installation or removal of the modules. Mechanical keying is provided that prevents insertion of a module into a rack slot that may cause an unsafe condition. The Module Physical Interface definition, contained within this standard, does not include the properties of the signalling used in the optical interface (e.g. wavelength). These are covered in EN 4660-003. SIST EN 4660-004:2011

— Volume 1 — System Management. — Volume 2 — Fault Management. — Volume 3 — Initialisation and Shutdown. — Volume 4 — Configuration / Reconfiguration. — Volume 5 — Time Management. — Volume 6 — Security. — Volume 7 — Safety. ARINC 600, Air transport avionics — Equipment interfaces. Def Stan 03-18, Chromate Conversion Coatings (Chromate Filming Treatments) Grades: Standard and Brushing for Aluminium and Aluminium Alloys. Def Stan 03-24, Chromic Acid Anodizing of Aluminium and Aluminium Alloys. Def Stan 03-25, Sulphuric Acid Anodizing of Aluminium and Aluminium Alloys.

1) In preparation at the date of publication of this standard. SIST EN 4660-004:2011

MIL-C-26074E, Coatings, Electroless Nickel Requirements. MIL-A-8625E, Anodic Coatings for Aluminium and Aluminium Alloys. MIL-C-81706, Chemical Conversion Materials for Coating Aluminium and Aluminium Alloys. MIL-C-5541, Chemical Conversion Coatings on Aluminium and Aluminium Alloys. 3 Terms, definitions and abbreviations 3.1 Terms and definitions Use of “shall”, “should” and “may” within the standards observe the following rules: The word SHALL in the text express a mandatory requirement of the standard. The word SHOULD in the text expresses a recommendation or advice on implementing such a requirement of the standard. It is expected that such recommendations or advice will be followed unless good reasons are stated for not doing so. The word MAY in the text expresses a permissible practice or action. It does not express a requirement of the standard. 3.2 Abbreviations AFA Air Flow Around AFT Air Flow Through ARINC Aeronautical Radio Inc ASAAC Allied Standard Avionics Architecture Council CC Conduction Cooled CFM Common Functional Module DAF Direct Air Flow EMC ElectroMagnetic Compatibility IED

Insertion Extraction Device IMA Integrated Modular Avionics MBU

Multiple Bit Upset

2) Replaces Def Stan 03-26. SIST EN 4660-004:2011

Single Event Upset 3.3 Precedence Figures in this document have precedence over text. 3.4 Definition of terms 3.4.1 General terms Backplane A structure containing optical and electrical communication paths and electrical power supply wiring between modules. This shall be a removable structure or integrated into the rack. Cassette Mechanical frame enclosing the electrical components of the module. Connector A device to provide all of the electrical and optical connections between the cassette and the backplane. The connector fixed to the module cassette plugs into the corresponding connector of the backplane. It comprises a shell, inserts contacts and ferrules. Contact A single signal connection, either an electrical pin/socket or a single fibre. In the case of fibre optic contacts this does not necessarily imply the mating parts are in mechanical contact. Cooling Interface Surface which contributes to the removal of heat from the module. Ferrule A housing and alignment device for one or more optical fibres. Insert A section of a connector containing a number of ferrules or contacts. Insertion Extraction Device

(IED) A device to aid the insertion and extraction of the module from the rack and give mechanical advantage over the mating forces associated with the connector.

It also provides the retention system for the module within the rack such that the module connector remains mated under all conditions specified. Module

The module is a grouping of electronic devices, assembled together to perform a specific function, into a flight-line protected hardware assembly. This is the Common Functional Module. The CFM is replaceable at first line. Rack

A mechanical arrangement for housing avionics equipment. This provides physical support, environmental protection and cooling for the modules. Shell The outer mating parts of the connector that provide the structure of the connector, fixings to the module and backplane parts and the support for the Inserts.

Height The cassette dimension in the Z-axis. It is measured from cassette Side C to cassette Side D. Length

The cassette dimension in the X-axis measured from the Reference Plane to the module header (this excludes the Insertion Extraction Device and the connector). Module header The surface of the cassette parallel to the Reference Plane, and opposite to the cassette surface contained within the Reference Plane The IED shall be mounted on this surface.

Side A Surface of the cassette contained within the X, Z plane. Viewing the module in the direction of insertion, with the cassette Side C at the top, Side A is to the left. Side B Surface of the cassette parallel to and furthest from the X, Z plane. Viewing the module in the direction of insertion, with the cassette Side C at the top, Side B is to the right. Side C Surface of the cassette parallel to and furthest from the X, Y plane.It contains one of the two cassette cooling interfaces, the other being within Side D. Side D Surface of the cassette contained within the X, Y plane. It contains one of the two cassette cooling interfaces, the other being within Side C. Reference Plane Plane defined by the Y and Z axis. It is perpendicular to the direction of insertion of the module and passes through the mating surface between the cassette and the connector. Width The cassette dimension in the Y-axis of the module, measured from Side A to Side B.

3.4.3 Tolerances Unless otherwise stated, tolerances shall be ± 0,2 mm. 4 Generic module specification 4.1 Introduction This clause specifies the physical properties and the principle physical interfaces for ASAAC Common Functional Modules, i.e. the Module Physical Interface (MPI). The MPI comprises: The Connector Interface between Common Functional Module and Backplane. The Cooling Interface. The Insertion Extraction Device (IED). SIST EN 4660-004:2011

Provision for a keying method to positively bulk the incorrect insertion of any CFM into a rack and to ensure that an incorrectly fitted CFM shall be prevented from making any electrical connection, Provision for a mechanism that retains the module within the rack under the mechanical and environmental conditions specified herein and yet allows for easy insertion and removal of the module, Provision for a cooling interface that provides for the removal of heat from the CFM, Provision for easy identification. 4.3 Module Physical Specification 4.3.1 Module envelope: height, length, width The module envelope comprises the IED, the cassette and the connector. The principle dimensions for the cassette are as shown in Figure 3. These dimensions shall be: Width: 24 mm +0.0 / -0.2 mm.

Height: 160 mm +0.0 / -0.2 mm. Length: 233.4 mm +0.0 / -0.2 mm. Length + Connector: 262.9 mm +0.0 / -0.2 mm. Detailed dimensions of the connector, IED and mating structure parts are given in 4.4 and 4.6. The modules shall be capable of being mounted on a pitch of 26 mm (modular). SIST EN 4660-004:2011

The modules shall be able to be installed and removed from the rack without the need for special tools nor for manual adjustment of the module once installed in order for it to function. It shall also be possible to perform maintenance in the flight line environment (temperature, humidity etc.). Maintenance shall be possible whilst wearing Nuclear, Biological and Chemical (NBC) protective clothing. Module insertion and extraction shall also be compliant with the tests specified in Clause 5. 4.3.5 Electrical safety Modules containing hazardous voltage shall have exposed surfaces connected to the safety ground. 4.3.6 Materials 4.3.6.1 Use of flammable materials The equipment shall be designed/constructed from materials that do not support combustion. No material used in the construction of the module shall constitute a fire hazard. Under condition of overheating and when exposed to fire no harmful concentrations of noxious products or explosive gases shall emanate. SIST EN 4660-004:2011

4.3.7 Module Identification The module shall be identified and marked with appropriate identifiers as specified herein. SIST EN 4660-004:2011

4.3.7.6 Module Serial number Each module shall have a serial number including the vendor's designation as specified. The serial number shall be located on the top surface of the header used for marking the key code. The serial number shall consist of a number of digits with significant digits prefixed with zeros, as required. The serial number shall be affixed to the module prior to electrical acceptance tests. 4.3.7.7 Module Date Code Each module shall be marked as specified, with a six digit date code on the module header, designating the week and year of manufacture. The first four digits of the code shall indicate the year of manufacture and the remaining two digits shall indicate the calendar week. When the number of the week is a single digit, it shall SIST EN 4660-004:2011

This subclause defines the part of the Module Physical Interface (MPI) Specification associated to the module connector. It defines the interface that will mate to the IMA rack and the backplane connector part defined in Clause 6. The module connector shall provide the following features: Inserts and contacts to provide optical, electrical and power supply connections, within the same shell. Connector keying and polarisation. All mechanisms for connector and module alignment, guide pins, mechanical support and earth bonding. Blind mate (i.e. allowing insertion and mating based only on mechanical guidance). 4.4.1 Connector shell dimensions The connector shell outline shall be as defined in Figure 4.

Top polarising keyBottom polarising keyModule Side CTop polarising keyBottom polarising keyModule Side CTop polarising keyBottom polarising keyModule Side C Figure 4 — Module Connector Interface Definition and Identification

(connector inserts shown for example only) 4.4.2 Module connector shell location The connector shell shall be rigidly mounted on the module as shown in Figure 4 such that no part of the connector protrudes beyond the Side A and Side B surfaces of the module.

Any "float" required between the modules and the backplane at the connector shells shall be provided in the backplane part. 4.4.3 Connector Cavities, Inserts, Ferrules and Contacts The connector shall incorporate three identical cavities with dimensions compatible with ARINC 600 shell size 1. Each cavity shall be capable of containing any one of the following, but not limited to, insert types: ”Guided Optical” - Providing 4 MT fibre optic ferrules, each with 4, 8 or 12 fibre optic contacts. “Electrical - Small signal” - This insert will provide 40 size 22 electrical signal contacts. SIST EN 4660-004:2011

(viewed from outside module, lowest numbered contact is towards Side C of the cassette) 4.4.3.2 Insert Allocation

The mix of connector inserts in the connector shell shall be defined by the System Design Specification. Examples (Informative) include the following: High density optical: Cavity A: Up to 48 guided optical contacts,

Cavity B: Up to 48 guided optical contacts,

Cavity C: Electrical power insert. General purpose:

Cavity A: Up to 48 guided optical contacts,

Cavity B: Spare, Cavity C: Electrical power insert.

Power:

Cavity A: Up to 48 guided optical contacts,

Cavity B: Electrical power insert, Cavity C: Electrical power insert. SIST EN 4660-004:2011

The optical insert may have a "module" and a "back-plane" variant.

Each fibre optic ferrule may provide 4, 8 or 12 optical fibre contacts (see Figure 6). The MT alignment pins shall be retained in the module half of the connector. The module half of the MT connector shall be fixed in position relative to the insert.

The MT ferrule shall support and interface all fibre types with a nominal external diameter of 125 µm (cladding diameter). The internal geometry of the fibre, i.e. multimode or single mode, will depend on specific implementations and shall be specified in the System Design Specification. If not all contact locations are to be used, dummy contacts or similar items shall be provided to maintain the environmental performance specified. Guide pins Ø0.127 +0.001/-04,8 or 12 Fibre holes 0.250 spacing aboutguide pin centrelineMT4 has fibres 5,6,7,8MT8 has fibres 3,4,5,6,7,8,9,10MT12 has fibres 1,2,3,4,5,6,7,8,9,10,11,128 +0.1/-06 +0.1/-031.453.001.82.5 +0/-0.13 +/-0.14.66.4 +/-0.17 +/-0.1112 Figure 6 — Contact Identification – MT Ferrule 4.4.3.4 Electrical - Signal Contacts The electrical insert shall provide up to 40 size 22 contacts in accordance with ARINC 600 attachment 19, contact arrangement 19. The back-plane insert shall contain the pins and the module insert shall contain the socket part of the contacts. Normal safety precautions regarding pins supplying high voltages shall be observed. 4.4.3.5 Electrical - Power Contacts This insert shall provide up to 8 size 16 electrical power contacts. SIST EN 4660-004:2011

The two key positions shall provide 36 unique combinations. The identification of the key positions is shown in Figure 7. The allocation of polarisation settings may be related to the module type and shall be defined by the System Design Specification. The key ways shall be positioned asymmetrically to prevent the module being inserted upside down. Dark portion Indicates the solid part of the key.Code BF is shown in the example.ToppolarisingkeyABCDEFBFBottompolarisingkeyDark portion Indicates the solid part of the key.Code BF is shown in the example.ToppolarisingkeyABCDEFBFBottompolarisingkey Figure 7 — Polarisation Key identification 4.4.7 Environmental Protection and Cleaning The module connector shall provide environmental protection of optical termini at all times when disconnected to ensure termini cleanliness.

This may be in the form of a removable cover or an integral shutter. The module connector shall also allow the optical termini to be easily cleaned when required. SIST EN 4660-004:2011

are Critical Interface DimensionsMax. Area for Insert Extract Device.

Includes any Locking Provision on Rack9999Max. Area forThermal Clamping MechanismSide A99Notes:1. Dimensions marked

are Critical Interface DimensionsMax. Area for Insert Extract Device.

Includes any Locking Provision on Rack999999Max. Area forThermal Clamping MechanismSide A9999 Figure 8 — Conduction Cooled Module – Cooling Interface Definition

In order to achieve a good thermal path between the module and the rack, the heat transfer area of the rib shall have the following characteristics: 4.5.1.2.1.1 Flatness The Side A surface of the guide ribs shall have a flatness of +/- 0,05 mm / 25 mm with a maximum overall flatness tolerance of 0,1 mm. 4.5.1.2.1.2 Surface finish The Side A surface of the guide ribs on a conduction cooled module shall be free of any imperfections that have a detrimental effect on the heat transfer capability of the module and shall have a surface finish of 1,6 × 10-3 mm or better. 4.5.1.3 Cooling requirements Modules implementing conduction cooling shall be designed to be conduction cooled through the guide ribs with no other cooling path. The module supplier shall provide graphs of rack coolant temperature against the thermal resistance between the module guide rib surface and the rack coolant, on which he shall indicate the region within which the module meets its specified performance. They may also be used to indicate the regions within which a certain reliability level is achieved. The graphs shall cover the full altitude range for the module specified in the appropriate environmental standard. 4.5.2 Air Cooled Module Interface This subclause defines the cooling interfaces associated with the three air cooled designs: Air Flow Through (AFT), Air Flow Around (AFA) and Direct Air Flow (DAF). 4.5.2.1 Module outline drawings The critical cooling parameters of the module are shown on Figure 9. SIST EN 4660-004:2011

are Critical Interface DimensionsAir Flow Through ModuleAir Flow Around ModuleDirect Air Flow ModuleAir Flow Through ModuleAir Flow Around ModuleDirect Air Flow ModuleAir Cooling Inlet Max.Air Cooling Outlet Max.Air FlowArea for reserved for

Insert Extract Device.

2.4 +0.12.0 +0.1Air Flow Around ModuleBETA EndALPHA

EndSide A2.4 +0.12.0 +0.1REFERENCE PLANEHEADERNotes:1. Dimensions marked

are Critical Interface DimensionsAir Flow Through ModuleAir Flow Around ModuleDirect Air Flow ModuleAir Flow Through ModuleAir Flow Around ModuleDirect Air Flow ModuleAir Cooling Inlet Max.Air C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...