prEN 18068

(Main)Agricultural machinery - Safety - Compact carriers

Agricultural machinery - Safety - Compact carriers

This document specifies the safety requirements and their verification for the design and construction of compact carriers used in agriculture. It is intended to be used together with EN ISO 4254-1:20152. When provisions of this document are different from those which are stated in EN ISO 4254-1:2015, the provisions of this document take precedence over the provisions of EN ISO 4254-1:2015 for machines that have been designed and built according to the provisions of this document.

This document deals with the significant hazards, hazardous situations and events relevant to compact carriers, when they are used as intended and under the conditions foreseen by the manufacturer but also taking into account any reasonably foreseeable misuse thereof (see Annex A).

In addition, this document specifies the type of information on safe working practices that is provided by the manufacturer.

This document does not deal with hazards related to:

- pesticide application;

- lifting operations;

- lifting of persons.

While this document does not deal with the design and construction of interchangeable equipment, requirements in this document also address hazards which can occur from the combination of compact carriers with interchangeable equipment as per multiple uses intended by the manufacturer of the compact carrier.

Compact carriers when provided with cab and provisions for fitting a cab are not dealt with this document.

Compact carriers intended for a seated operator are not dealt with this document.

Agricultural tractors and machines falling within the scope of standards EN 474 are excluded by this document.

This document is not applicable to machines manufactured before the date of its publication.

Landmaschinen - Sicherheit - Kompakt-Geräteträger

Dieses Dokument legt Sicherheitsanforderungen und ihre Verifizierung für die Konstruktion von Kompakt-Geräteträgern fest, die in der Landwirtschaft eingesetzt werden. Dieses Dokument ist zur Verwendung mit EN ISO 4254-1:2015² bestimmt. Wenn Anforderungen dieses Dokuments von den Anforderungen in EN ISO 4254-1:2015 abweichen, haben die Anforderungen dieses Dokuments Vorrang gegenüber den Anforderungen von EN ISO 4254-1:2015 für Maschinen, die nach den Bestimmungen dieses Dokuments konzipiert und gebaut worden sind.

Dieses Dokument behandelt die signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse, die auf Kompakt-Geräteträger zutreffen, wenn sie bestimmungsgemäß und unter den vom Hersteller vorhersehbaren Bedingungen verwendet werden, aber auch unter Berücksichtigung einer vernünftigerweise vorhersehbaren Fehlanwendung (siehe Anhang A).

Zusätzlich legt dieses Dokument die Informationen über sicheres Arbeiten fest, die vom Hersteller zur Verfügung zu stellen sind.

Dieses Dokument behandelt keine Gefährdungen im Zusammenhang mit:

- Ausbringung von Pestiziden;

- Hebebetrieb;

- Heben von Personen.

Obwohl sich dieses Dokument nicht mit der Auslegung und Konstruktion von auswechselbarer Ausrüstung beschäftigt, befassen sich die Anforderungen in diesem Dokument auch mit Gefährdungen, die aus der Kombination von Kompakt-Geräteträgern mit auswechselbarer Ausrüstung nach mehrerer vom Hersteller des Kompakt-Geräteträgers vorgesehener Verwendungsmöglichkeiten entstehen können.

Kompakt-Geräteträger, die mit einer Kabine und Vorrichtungen zum Befestigen einer Kabine ausgestattet sind, werden in diesem Dokument nicht behandelt.

Kompakt-Geräteträger für einen sitzenden Bediener werden in diesem Dokument nicht behandelt.

Landmaschinen und Traktoren, deren Anwendungsbereich unter die Norm EN 474 fällt, sind von diesem Dokument ausgenommen.

Dieses Dokument gilt nicht für Maschinen, die vor dem Veröffentlichungsdatum dieses Dokuments hergestellt wurden.

Matériel agricole - Sécurité - Porte-outils compacts

Le présent document spécifie les exigences de sécurité et leur vérification pour la conception et la construction de porte-outils compacts utilisés en agriculture. Il est destiné à être utilisé conjointement avec l’EN ISO 4254-1:2015². Lorsque les dispositions du présent document diffèrent de celles énoncées dans l’EN ISO 4254-1:2015, les dispositions du présent document prévalent sur les dispositions de l’EN ISO 4254-1:2015 applicables aux machines conçues et construites conformément aux dispositions du présent document.

Le présent document traite des phénomènes dangereux, situations dangereuses et événements dangereux significatifs se rapportant aux porte-outils compacts, lorsqu’ils sont utilisés normalement et dans les conditions prévues par le fabricant, mais en tenant également compte des mauvais usages raisonnablement prévisibles (voir Annexe A).

En outre, le présent document spécifie le type d’informations sur les pratiques d’utilisation sûre fournies par le fabricant.

Le présent document ne traite pas des phénomènes dangereux liés :

- à l’application de pesticides ;

- aux opérations de levage ;

- au levage de personnes.

Bien que le présent document ne traite pas de la conception et de la construction d’équipements interchangeables, les exigences du présent document abordent également des phénomènes dangereux qui peuvent se produire lors de la combinaison de porte-outils compacts avec des équipements interchangeables selon les usages multiples prévus par le fabricant du porte-outils compact.

Les porte-outils compacts, lorsqu’ils sont équipés d’une cabine et des dispositions pour fixer une cabine, ne sont pas traités au sein du présent document.

Les porte-outils compacts destinés à un opérateur assis ne sont pas traités dans le présent document.

Les tracteurs et machines agricoles relevant du domaine d’application des normes EN 474 sont exclus du présent document.

Le présent document ne s’applique pas aux machines fabriquées avant la date de sa publication.

Kmetijski stroji - Varnost - Kompaktni nosilci

General Information

- Status

- Not Published

- Publication Date

- 09-Dec-2026

- Technical Committee

- CEN/TC 144 - Tractors and machinery for agriculture and forestry

- Drafting Committee

- CEN/TC 144/WG 9 - Compact tool carriers for agriculture and forestry

- Current Stage

- 4060 - Closure of enquiry - Enquiry

- Start Date

- 04-Dec-2025

- Completion Date

- 04-Dec-2025

Overview

prEN 18068 - "Agricultural machinery - Safety - Compact carriers" is a draft CEN standard that specifies safety requirements and verification for the design and construction of compact carriers used in agriculture. It is intended to be used together with EN ISO 4254-1:2015, with prEN 18068 taking precedence where provisions differ for machines designed to this document. The standard addresses significant hazards when compact carriers are used as intended or under reasonably foreseeable misuse, and requires manufacturers to provide information on safe working practices.

Scope highlights

- Applies to compact carriers (excluding those with cabs or intended for seated operators).

- Excludes hazards from pesticide application, lifting operations and lifting of persons.

- Addresses combinations with interchangeable equipment and multiple uses.

- Not applicable to agricultural tractors, EN 474 machines, or machines manufactured before publication.

Key Topics and Requirements

The standard is structured to cover design, verification and information for use, including:

- Operator station and controls: access, control layout, prevention of inadvertent activation, emergency lowering, remote control and safeguards for ride-on and pedestrian-operated machines.

- Travel and braking: travel speed categories (notably a 6 km/h threshold) and brake system requirements tailored to speed.

- Visibility and lighting: operator field of view, lighting, signalling and marking devices.

- Stability and coupling: stability testing (including tilt-table methods), and safety of coupling systems for interchangeable equipment.

- Protective measures: guarding of moving parts, hot surfaces, exhaust fumes, sharp edges and barriers.

- Electrical, fire and maintenance: wiring, insulation, connectors, battery disconnection, fire protection, access for routine maintenance and support devices.

- Noise and vibration: normative annexes define measurement and reporting procedures for airborne noise, hand‑arm and whole‑body vibrations.

- Verification and testing: procedures for verification (compression force tests, hot surface tests, stability, noise and vibration tests) and acceptance criteria are specified in annexes.

- Information for use: required marking, safety signs and comprehensive instruction handbook content (including multiple-use scenarios).

Practical Applications and Users

prEN 18068 is practical for:

- Manufacturers and designers of compact carriers for ensuring designs meet European safety expectations.

- Test laboratories and certification bodies performing stability, noise, vibration and safety verifications.

- Safety engineers and compliance officers conducting risk assessments and preparing instruction handbooks and markings.

- Procurement teams and fleet managers specifying safe agricultural machinery and interchangeable equipment compatibility.

Using prEN 18068 helps reduce operator risk, improve machine interoperability with interchangeable equipment, and support conformity with EU machinery safety objectives.

Related Standards

- EN ISO 4254-1:2015 (used together; prEN 18068 overrides where different)

- EN 474 (machines falling within its scope are excluded)

- Directive 2006/42/EC (relationship addressed in Annex ZA)

Get Certified

Connect with accredited certification bodies for this standard

Control Union Certifications

Global certification for agriculture and sustainability.

ECOCERT

Organic and sustainability certification.

Rainforest Alliance Certification

Sustainable agriculture and forestry certification.

Sponsored listings

Frequently Asked Questions

prEN 18068 is a draft published by the European Committee for Standardization (CEN). Its full title is "Agricultural machinery - Safety - Compact carriers". This standard covers: This document specifies the safety requirements and their verification for the design and construction of compact carriers used in agriculture. It is intended to be used together with EN ISO 4254-1:20152. When provisions of this document are different from those which are stated in EN ISO 4254-1:2015, the provisions of this document take precedence over the provisions of EN ISO 4254-1:2015 for machines that have been designed and built according to the provisions of this document. This document deals with the significant hazards, hazardous situations and events relevant to compact carriers, when they are used as intended and under the conditions foreseen by the manufacturer but also taking into account any reasonably foreseeable misuse thereof (see Annex A). In addition, this document specifies the type of information on safe working practices that is provided by the manufacturer. This document does not deal with hazards related to: - pesticide application; - lifting operations; - lifting of persons. While this document does not deal with the design and construction of interchangeable equipment, requirements in this document also address hazards which can occur from the combination of compact carriers with interchangeable equipment as per multiple uses intended by the manufacturer of the compact carrier. Compact carriers when provided with cab and provisions for fitting a cab are not dealt with this document. Compact carriers intended for a seated operator are not dealt with this document. Agricultural tractors and machines falling within the scope of standards EN 474 are excluded by this document. This document is not applicable to machines manufactured before the date of its publication.

This document specifies the safety requirements and their verification for the design and construction of compact carriers used in agriculture. It is intended to be used together with EN ISO 4254-1:20152. When provisions of this document are different from those which are stated in EN ISO 4254-1:2015, the provisions of this document take precedence over the provisions of EN ISO 4254-1:2015 for machines that have been designed and built according to the provisions of this document. This document deals with the significant hazards, hazardous situations and events relevant to compact carriers, when they are used as intended and under the conditions foreseen by the manufacturer but also taking into account any reasonably foreseeable misuse thereof (see Annex A). In addition, this document specifies the type of information on safe working practices that is provided by the manufacturer. This document does not deal with hazards related to: - pesticide application; - lifting operations; - lifting of persons. While this document does not deal with the design and construction of interchangeable equipment, requirements in this document also address hazards which can occur from the combination of compact carriers with interchangeable equipment as per multiple uses intended by the manufacturer of the compact carrier. Compact carriers when provided with cab and provisions for fitting a cab are not dealt with this document. Compact carriers intended for a seated operator are not dealt with this document. Agricultural tractors and machines falling within the scope of standards EN 474 are excluded by this document. This document is not applicable to machines manufactured before the date of its publication.

prEN 18068 is classified under the following ICS (International Classification for Standards) categories: 65.060.01 - Agricultural machines and equipment in general; 65.060.99 - Other agricultural machines and equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 18068 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2023/1230; Standardization Mandates: M/396, M/605. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 18068 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2024

Kmetijski stroji - Varnost - Kompaktni nosilci

Agricultural machinery - Safety - Compact carriers

Landmaschinen - Sicherheit - Kompakt-Geräteträger

Matériel agricole - Sécurité - Porte-outils compacts

Ta slovenski standard je istoveten z: prEN 18068

ICS:

65.060.01 Kmetijski stroji in oprema na Agricultural machines and

splošno equipment in general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

April 2024

ICS 65.060.01

English Version

Agricultural machinery - Safety - Compact carriers

Matériel agricole - Sécurité - Porteurs compacts Landmaschinen - Sicherheit - Kompakt-Geräteträger

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 144.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 18068:2024 E

worldwide for CEN national Members.

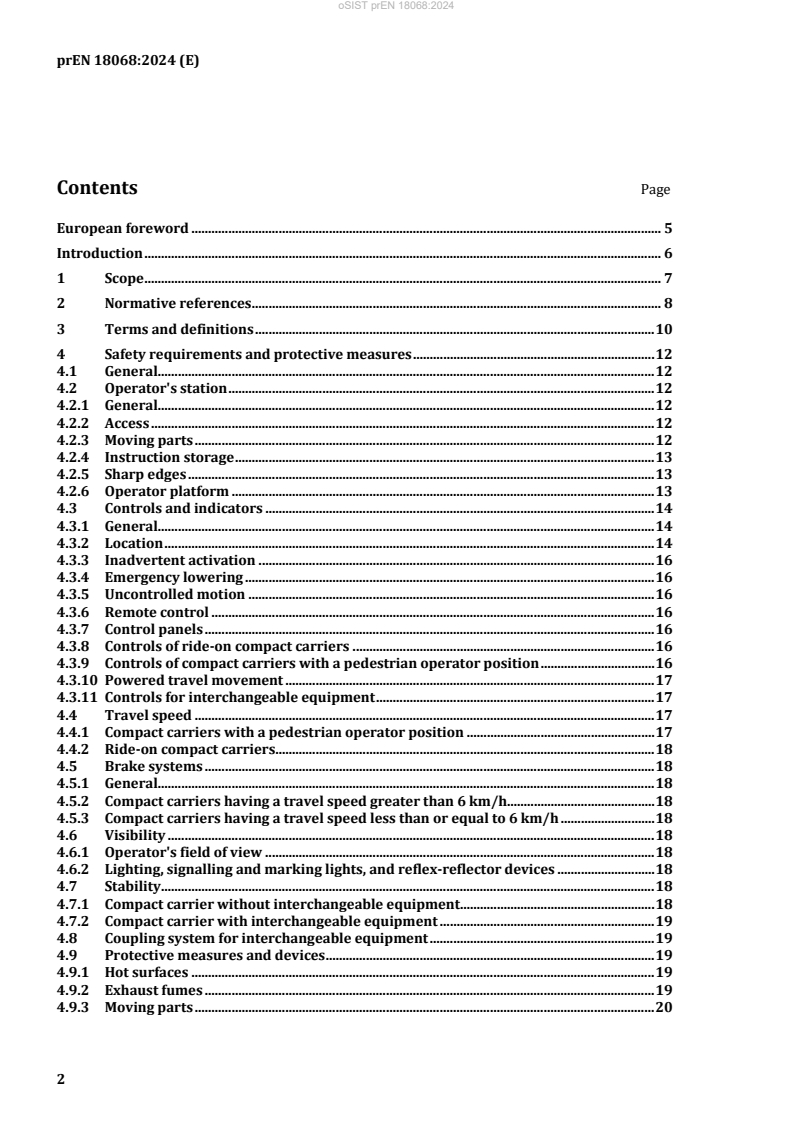

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 8

3 Terms and definitions . 10

4 Safety requirements and protective measures . 12

4.1 General. 12

4.2 Operator's station . 12

4.2.1 General. 12

4.2.2 Access . 12

4.2.3 Moving parts . 12

4.2.4 Instruction storage . 13

4.2.5 Sharp edges . 13

4.2.6 Operator platform . 13

4.3 Controls and indicators . 14

4.3.1 General. 14

4.3.2 Location . 14

4.3.3 Inadvertent activation . 16

4.3.4 Emergency lowering . 16

4.3.5 Uncontrolled motion . 16

4.3.6 Remote control . 16

4.3.7 Control panels . 16

4.3.8 Controls of ride-on compact carriers . 16

4.3.9 Controls of compact carriers with a pedestrian operator position . 16

4.3.10 Powered travel movement . 17

4.3.11 Controls for interchangeable equipment . 17

4.4 Travel speed . 17

4.4.1 Compact carriers with a pedestrian operator position . 17

4.4.2 Ride-on compact carriers. 18

4.5 Brake systems . 18

4.5.1 General. 18

4.5.2 Compact carriers having a travel speed greater than 6 km/h . 18

4.5.3 Compact carriers having a travel speed less than or equal to 6 km/h . 18

4.6 Visibility . 18

4.6.1 Operator's field of view . 18

4.6.2 Lighting, signalling and marking lights, and reflex-reflector devices . 18

4.7 Stability . 18

4.7.1 Compact carrier without interchangeable equipment. 18

4.7.2 Compact carrier with interchangeable equipment . 19

4.8 Coupling system for interchangeable equipment . 19

4.9 Protective measures and devices . 19

4.9.1 Hot surfaces . 19

4.9.2 Exhaust fumes . 19

4.9.3 Moving parts . 20

4.9.4 Guards and barriers . 20

4.9.5 Sharp edges and acute angles. 20

4.10 Electrical and electronic systems . 20

4.10.1 General . 20

4.10.2 Insulation . 21

4.10.3 Electrical wires/cables routing . 21

4.10.4 Degree of protection . 21

4.10.5 Detachable connections . 21

4.10.6 Over-current protection device . 22

4.10.7 Battery disconnection . 22

4.10.8 Electrical connector for auxiliary starting aids . 22

4.10.9 Electric socket for lighting. 22

4.11 Fire protection . 22

4.12 Maintenance . 23

4.12.1 General . 23

4.12.2 Routine maintenance . 23

4.12.3 Support devices . 23

4.12.4 Access to the engine compartment . 23

4.13 Noise . 23

4.14 Vibrations . 23

5 Verification of the safety requirements and protective measures . 23

5.1 General . 23

5.2 Compression force for operator platform . 26

5.3 Hot surfaces . 27

5.3.1 Test method . 27

5.3.2 Test acceptance . 28

6 Information for use . 29

6.1 Safety and instructional signs . 29

6.2 Instruction handbook . 29

6.2.1 General . 29

6.2.2 Information concerning airborne noise emission . 29

6.2.3 Information concerning hand-arm and whole-body vibration emission . 29

6.2.4 Instructions and information for use and maintenance . 29

6.2.5 Multiple uses . 31

6.3 Marking . 31

6.3.1 General . 31

6.3.2 Warning signs . 32

Annex A (informative) List of significant hazards . 33

Annex B (normative) Stability test . 38

B.1 General requirements . 38

B.2 Tilt table . 38

B.3 Alternative methods . 40

B.4 Acceptance criteria . 40

Annex C (informative) Testing configuration of compact carrier with interchangeable

equipment . 41

C.1 Non-load carrying for ground use . 41

C.2 Non-load carrying for non-ground use . 41

C.3 Load carrying for ground use . 41

C.4 Load carrying for non-ground use . 42

C.5 Stationary use. 42

Annex D (normative) Determination of noise emission for compact carriers . 45

D.1 General. 45

D.2 Test surface and positioning of machine. 45

D.3 Machine set-up . 48

D.4 Machine operation. 49

D.5 Calculation for combined cycle of travel, stationary work cycle and stationary low-

idle modes . 50

Annex E (normative) Determination of hand-arm and whole-body vibrations for compact

carriers . 51

E.1 General. 51

E.2 Test surface and positioning of machine. 51

E.3 Machine set-up . 53

E.4 Machine operation. 53

Annex F (informative) Examples of compact carrier . 54

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered . 55

European foreword

This document (prEN 18068:2024) has been prepared by Technical Committee CEN/TC 144 “Tractors

and machinery for agriculture and forestry”, the secretariat of which is held by AFNOR.

This document is currently submitted to the CEN Enquiry.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

Introduction

This document is a type-C standard as stated in ISO 12100:2010.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the Scope of this document.

Significant hazards that are common to all of the agricultural machines (self-propelled, mounted, semi-

mounted and trailed) are dealt with in EN ISO 4254-1.

When requirements of this type-C standard are different from those which are stated in type-A or type-

B standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.)

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

1 Scope

This document specifies the safety requirements and their verification for the design and construction of

. When provisions of this

compact carriers. It is intended to be used together with EN ISO 4254-1:2015

document are different from those which are stated in EN ISO 4254-1:2015, the provisions of this

document take precedence over the provisions of EN ISO 4254-1:2015 for machines that have been

designed and built according to the provisions of this document.

This document deals with the significant hazards, hazardous situations and events relevant to compact

carriers, when they are used as intended and under the conditions foreseen by the manufacturer but also

taking into account any reasonably foreseeable misuse thereof (see Annex A).

In addition, this document specifies the type of information on safe working practices that is provided by

the manufacturer.

The following significant and relevant hazards are not covered in this document:

— design of machinery to facilitate its handling;

— external radiation;

— laser radiation;

— lightning;

— falling objects;

— towing devices;

— transmission of power between self-propelled machinery (or tractor) and recipient machinery;

and hazards related to:

— the presence of a seated operator;

— the environment on compact carrier intended for pesticide application;

— lifting operations;

— lifting of persons.

While this document does not deal with the design and construction of interchangeable equipment,

requirements in this document also address hazards which can occur from the combination of compact

carriers with interchangeable equipment as per multiple uses intended by the manufacturer of the

compact carrier.

Compact carriers when provided with cab and provisions for fitting a cab are not dealt with this

document.

This document is not applicable to machines manufactured before the date of its publication.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1032:2003+A1:2008, Mechanical vibration - Testing of mobile machinery in order to determine the

vibration emission value

EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN ISO 2860:2008, Earth-moving machinery - Minimum access dimensions (ISO 2860:1992)

EN ISO 3450:2011, Earth-moving machinery - Wheeled or high-speed rubber-tracked machines -

Performance requirements and test procedures for brake systems (ISO 3450:2011)

EN ISO 3457:2008, Earth-moving machinery - Guards - Definitions and requirements (ISO 3457:2003)

EN ISO 4254-1:2015, Agricultural machinery - Safety - Part 1: General requirements (ISO 4254-1:2013)

EN ISO 6682:2008, Earth-moving machinery - Zones of comfort and reach for controls (ISO 6682:1986,

including Amd 1:1989)

EN ISO 12100:2010, Safety of machinery - General principles for design - Risk assessment and risk reduction

(ISO 12100:2010)

EN ISO 13850:2015, Safety of machinery - Emergency stop function - Principles for design (ISO 13850:2015)

EN ISO 13856-1:2013, Safety of machinery - Pressure-sensitive protective devices - Part 1: General

principles for design and testing of pressure-sensitive mats and pressure-sensitive floors (ISO 13856-1:2013)

EN ISO 13856-2:2013, Safety of machinery - Pressure-sensitive protective devices - Part 2: General

principles for design and testing of pressure-sensitive edges and pressure-sensitive bars (ISO 13856-2:2013)

EN ISO 13856-3:2013, Safety of machinery - Pressure-sensitive protective devices - Part 3: General

principles for design and testing of pressure-sensitive bumpers, plates, wires and similar devices (ISO 13856-

3:2013)

EN ISO 13857:2019, Safety of machinery - Safety distances to prevent hazard zones being reached by upper

and lower limbs (ISO 13857:2019)

EN ISO 14119:2013, Safety of machinery - Interlocking devices associated with guards - Principles for

design and selection (ISO 14119:2013)

EN ISO 14120:2015, Safety of machinery - Guards - General requirements for the design and construction

of fixed and movable guards (ISO 14120:2015)

EN ISO 16231-2:2015, Self-propelled agricultural machinery - Assessment of stability - Part 2:

Determination of static stability and test procedures (ISO 16231-2:2015)

As impacted by EN 60529:1991/A1:2000 and EN 60529:1991/A2:2013.

As impacted by EN ISO 4254-1:2015/A1:2021.

IEC 60204-1:2016+AMD1:2021 CSV, Safety of machinery — Electrical equipment of machines —

Part 1: General requirements

IEC 60364-1:2005, Low-voltage electrical installations — Part 1: Fundamental principles, assessment of

general characteristics, definitions

IEC 60364-5-51:2005, Electrical installations of buildings — Part 5-51: Selection and erection of electrical

equipment — Common rules

IEC 60364-5-52:2009, Low-voltage electrical installations — Part 5-52: Selection and erection of electrical

equipment — Wiring systems

IEC 61496-1:2020, Safety of machinery — Electro-sensitive protective equipment — Part 1: General

requirements and tests

ISO 789-6:2019, Agricultural tractors — Test procedures — Part 6: Centre of gravity

ISO 3600:2022, Tractors, machinery for agriculture and forestry, powered lawn and garden equipment —

Operator's manuals — Content and format

ISO 3864-1:2011, Graphical symbols — Safety colours and safety signs — Part 1: Design principles for safety

signs and safety markings

ISO 3864-2:2016, Graphical symbols — Safety colours and safety signs — Part 2: Design principles for

product safety labels

ISO 3864-3:2012, Graphical symbols — Safety colours and safety signs — Part 3: Design principles for

graphical symbols for use in safety signs

ISO 3864-4:2011, Graphical symbols — Safety colours and safety signs — Part 4: Colorimetric and

photometric properties of safety sign materials

6011:2023, Earth-moving machinery — Visual display of machine operation

ISO

ISO 6016:2008, Earth-moving machinery — Methods of measuring the masses of whole machines, their

equipment and components

ISO 6405-1:2017, Earth-moving machinery — Symbols for operator controls and other displays — Part 1:

Common symbols

ISO 6749:1984, Earth-moving machinery — Preservation and storage

ISO 9244:2008, Earth-moving machinery — Machine safety labels — General principles

ISO 9247:1990, Earth-moving machinery — Electrical wires and cables — Principles of identification and

marking

ISO 10261:2021, Earth-moving machinery — Product identification numbering system

As impacted by ISO 9244:2008/Amd 1:2016.

As impacted by ISO 9247:1990/Amd 1:1998.

ISO 10265:2008, Earth-moving machinery — Crawler machines — Performance requirements and test

procedures for braking systems

ISO 10968:2020, Earth-moving machinery — Operator's controls

ISO 11862:1993, Earth-moving machinery — Auxiliary starting aid electrical connector

ISO 12508:1994, Earth-moving machinery — Operator station and maintenance areas — Bluntness of

edges

ISO 14396:2002, Reciprocating internal combustion engines — Determination and method for the

measurement of engine power — Additional requirements for exhaust emission tests in accordance with ISO

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 4254-1:2015 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/

3.1

compact carrier

CC

self-propelled crawler or wheeled machine primarily designed for operation with interchangeable

equipment, having an operating mass of less than 2 000 kg, having either a pedestrian operating position

or a standing operator platform at the rear of the machine, provided with coupling system for

interchangeable equipment or with lift arms/structure equipped with coupling system for

interchangeable equipment

Note 1 to entry: Examples of a compact carrier are illustrated in Annex F.

3.2

operating mass

mass of the compact carrier (3.1) as specified by the manufacturer without interchangeable equipment

(3.8) and ballast, and with the operator (75 kg) if the machine is provided with an operator platform (3.4),

half empty fuel tank and all fluid systems at the levels specified by the manufacturer

3.3

gross mass

combined mass of the operating mass (3.2) of the machine and the maximum mass that can be carried as

foreseen by the CC’s manufacturer

Note 1 to entry: Maximum mass that can be carried includes ballast, the mass of the interchangeable equipment

(3.8) and its rated payload, if any. Additional fluid systems of the interchangeable equipment at the levels specified

by the manufacturer are included in the mass of the interchangeable equipment.

3.4

operator platform

surface provided for a ride-on, standing operator to operate the compact carrier (3.1)

3.5

ground-supported operator platform

operator platform (3.1) that pivots about a connection on the base machine and is supported with one or

more trail wheels or skid surfaces that follows the contour of the ground

3.6

lift arms/structure for interchangeable equipment

moving arms or structures equipped with coupling system for interchangeable equipment (3.7) and

installed on compact carrier (3.1)

3.7

coupling system for interchangeable equipment

means for coupling interchangeable equipment (3.8) or device mounted on the compact carrier (3.1) to

facilitate the quick interchange of interchangeable equipment (3.8) from the base machine

Note 1 to entry: Coupling system for interchangeable equipment could be a quick coupler.

3.8

interchangeable equipment

device which, after the putting into service of compact carrier (3.1), is assembled with that machinery by

the operator himself in order to change its function or attribute a new function, in so far as this equipment

is not a tool

3.8.1

non-load carrying interchangeable equipment

interchangeable equipment (3.8) that during its normal use would not contain or support a payload

Note 1 to entry: Examples of non-load carrying interchangeable equipment are snow blade, snow blower, planer,

auger, mower, etc.

3.8.2

load carrying interchangeable equipment

interchangeable equipment (3.8) that during its normal use would contain or support a payload

Note 1 to entry: Examples of load carrying interchangeable equipment are dump body, concrete mixer, bucket,

excavator, sweeper, tank, etc.

3.8.3

interchangeable equipment for ground use

interchangeable equipment (3.8) whose working configuration, provided by the manufacturer, is mainly

in contact with the ground and/or in contact with a surface

Note 1 to entry: Examples of interchangeable equipment for ground use are sweeper, planer, auger, mower, front

blade, trencher, rotary tiller, etc.

3.8.4

interchangeable equipment for non-ground use

interchangeable equipment (3.8) whose working configuration, provided by the manufacturer, is not only

in contact with the ground or a surface

Note 1 to entry: Examples of interchangeable equipment for non-ground use are dumper body, concrete mixer,

bucket, mast with forks, sprayer, etc.

3.8.5

interchangeable equipment for stationary use

interchangeable equipment (3.8) designed to be used only with compact carrier (3.1) in stationary

conditions apart from travelling phase

Note 1 to entry: Examples of interchangeable equipment for stationary use are chipper.

3.9

machine side planes

planes parallel to machine longitudinal median plane passing through the outermost lateral contour of

the machine

3.10

service brake system

primary braking device designed for stopping and holding the machine in a stationary position

3.11

secondary/emergency braking system

braking system designed to stop the machine in the event of any failure in the service brake system (3.10)

3.12

parking brake system

system designed to hold a stopped machine in a stationary position and which, if appropriate, may also

be part of a secondary/emergency braking system (3.11)

4 Safety requirements and protective measures

4.1 General

Compact carrier shall comply with the safety requirements and protective measures

of EN ISO 4254-1:2015, in as far as those are not modified by the specific requirements of this clause.

In addition, the machine shall be designed according to the principles of EN ISO 12100:2010 for relevant

but not significant hazards which are not dealt with by this document.

4.2 Operator's station

4.2.1 General

A suitable device (e.g. handhold) providing a means of support for the operator during machine travel

shall be provided within the operator control zone defined in Figure 1. This device may also be used as

the handhold for access (see 4.2.2). If the compact carrier is equipped with an operator platform, the

device shall not restrict or impede the operator’s access to and egress from the platform.

EN ISO 4254-1:2015, 4.7, does not apply.

4.2.2 Access

In the event the compact carrier is fitted with an operator platform, the machine shall have a handhold

in accordance with ISO 2867:2011 to facilitate ingress to and egress from the platform.

4.2.3 Moving parts

EN ISO 4254-1:2015, 4.2, shall apply with the following addition.

Measures shall be taken to avoid inadvertent contact from the operating position with moving parts, e.g.

the wheels, or track or working equipment and/or attachment.

4.2.4 Instruction storage

EN ISO 4254-1:2015, 8.2.2, shall apply.

4.2.5 Sharp edges

EN ISO 4254-1:2015, 5.1.4, does not apply.

To avoid sharp edges or acute angles/corners at the operator’s space within the operator’s station, radius

of corners and bluntness of edges shall comply with ISO 12508:1994.

4.2.6 Operator platform

4.2.6.1 General

EN ISO 4254-1:2015, 4.7.2, does not apply.

The operator platform, if provided, shall:

a) have a flat and durable, slip-resistance surface;

b) have maximum height of 400 mm above the ground reference plane;

c) have a surface area of at least 1 400 cm and shall be capable of containing a circle with a minimum

diameter of 360 mm or minimum dimensions of 430 mm in width by 315 mm in depth;

d) for compact carriers having an operating mass not above 600 kg and a reverse speed less than

2,5 km/h, the operator platform shall have sufficient space for both of the operator’s feet. Depending

on the machine configuration, it may consist of two separate surfaces and may use machine

components. It shall be positioned so the operator can maintain stability;

e) ensure that the operator when on the platform is inside the machine side planes.

The operator platform shall be capable of withstanding a compression force corresponding to 2,5 times

the operating mass of the compact carrier. In any case, the compression force shall be not less than

1,5 times the gross mass of the compact carrier.

For compact carriers having an operating mass not above 600 kg and a reverse speed less than 2,5 km/h,

the compression force can be equal to 1,5 times the operating mass of the compact carrier. In any case,

the compression force shall be not less than the gross mass of the compact carrier.

Test shall be in accordance with 5.2.

In addition, for compact carriers capable of travelling more than 6 km/h the operator position shall be

provided with a lateral protection at either the sides of the platform. The lateral protections shall be

capable of withstanding a horizontal force of 900 N acting from inside to outside applied in line with the

centre of the lateral protections without permanent deflection. The lateral protections shall be at a

minimum height of 700 mm above the operator platform and in depth shall extend at least to half of the

platform.

NOTE The dimension of 700 mm will be further evaluated.

4.2.6.2 Compact carrier also provided with a pedestrian operating position

The operator platform fitted on a compact carrier also provided with a pedestrian operating position, in

addition to 4.2.6, shall be capable of being folded or pivoted to an upright position when the operator

leaves the platform; this may be done automatically.

The foldable/pivoting operator platform, including when ground-supported, shall lock in upright and

horizontal positions. When the operator platform moves automatically (e.g. by means of a spring) and it

is locked in upright position, a minimum space of 25 mm between platform and parts of the machine shall

remain.

When operator platform is locked in upright position, 4.4.1 shall apply.

4.3 Controls and indicators

4.3.1 General

EN ISO 4254-1:2015, 4.5 and 5.1.3, do not apply.

The controls (e.g. hand levers, pedals, switches etc.) and indicators of the machine, equipment,

attachment, shall be chosen, designed, constructed and arranged so that:

a) access to controls and indicators shall be designed in accordance with EN ISO 6682:2008 and

ISO 15077:2020;

b) neutral positions of controls shall be in accordance with ISO 15077:2020;

c) they are clearly identified (see ISO 6405-1:2017 and ISO 6405-2:2017) in the operator's station and

explained in the operator’s manual;

d) the movement of the controls to activate the functions and indicators shall correspond to the

intended effect or common practice whenever possible;

e) an engine stop device shall be within the operator control zone when the operator is on the platform

or on the ground (see Figure 1);

f) when a control is designed and constructed to carry out several functions of the machine, e.g.

keyboard or joystick control, the activated function shall be clearly identified.

Where there is more than one control position the control system shall be designed in such a way that

the use of one of them precludes the use of the other(s), except for stop controls.

Compact carrier movements shall be controlled with hold-to-run controls.

Travel and directional controls shall be designed to allow the operator to support himself, reducing the

risk of inadvertent contact with the controls, according to 4.2.1.

EN ISO 4254-1:2015, 5.1.8, shall apply.

4.3.2 Location

The location of operator hold-to-run controls shall be within the gripping area of the handhold.

The location of operator controls that do not require sustained activation shall be within the zones shown

in Figure 1.

Dimensions in mm, tolerance ± 3 mm

Key

1 operator control zone

2 operator control zone when leaning against handhold

3 handhold

Figure 1 — Operator control zone

4.3.3 Inadvertent activation

Controls which can cause a hazard due to inadvertent activation shall be arranged, deactivated or

guarded to minimize the risk when the operator gets into or out of the operator's station.

Any deactivation system shall:

a) be designed such that the risk of inadvertent reactivation of the controls (e.g. through a control being

caught by clothing, being used instead of a hand-hold, being mistaken for another control) is

minimized and;

b) either be self-acting or acting by compulsory actuation of the relevant device.

4.3.4 Emergency lowering

For machines equipped with lift arms, if the engine is stopped it shall be possible to:

a) lower the attachment to the ground/frame;

b) see the attachment lowering from the operator actuating position of the lowering control;

c) release the residual pressure in the hydraulic and pneumatic circuits.

The means to lower the attachment and the device to release the residual pressure can be located outside

the operator's station.

Means for emergency lowering may be replaced by lock valves.

4.3.5 Uncontrolled motion

Machine and equipment or attachment movement from the holding position, other than by actuation of

the controls by the operator, due to drift or creep (e.g. by leaking) or when power supply stops, shall be

limited to the extent that it cannot create a risk to exposed persons.

4.3.6 Remote control

Remote controls, if any, shall be in accordance with ISO 15817:2012.

4.3.7 Control panels

The operator shall be able to see from the operator’s station, in both daylight and darkness, the necessary

indicators to check the proper function of the machine. Glare shall be minimized.

Control indicators for operation of the machine shall comply with ISO 6011:2023.

Symbols for use on operator controls and other displays shall follow ISO 6405-1:2017

and ISO 6405-2:2017.

4.3.8 Controls of ride-on compact carriers

Ride-on compact carriers controls that are not intended to be operated from the ground shall have means

to minimize the possibility of actuating the controls from the ground (e.g. protection by physical barrier,

interlocking systems).

4.3.9 Controls of compact carriers with a pedestrian operator position

Compact carriers with a pedestrian operator position shall be equipped with a hold-to-run device to stop

machine travel and hazardous movement if the operator releases the operator’s controls. Design of the

controls shall take into account the hazards from movement of the machine towards the operator.

4.3.10 Powered travel movement

EN ISO 4254-1:2015, 5.1.8, shall apply with the following addition.

Powered travel movement of a compact carrier with a ride-on operator having a travel speed greater

than 6 km/h (see also 4.2.6.2) shall be possible only if the operator is on the operator platform.

Powered travel movements shall not occur automatically when the operator returns to the normal

operating position without an intentional actuation of a control (e.g. by requiring a resetting of the

direction control or reactivation of the speed control). Hold-to-run controls are deemed compliant with

this requirement.

4.3.11 Controls for interchangeable equipment

Interchangeable equipment controls fitted on compact carrier shall be of the hold-to-run type

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...