EN 12966-1:2005

(Main)Road vertical signs - Variable message traffic signs - Part 1: Product standard

Road vertical signs - Variable message traffic signs - Part 1: Product standard

This document specifies requirements and test methods for new Variable Message Signs (VMS).

VMS comprise two types, continuous and discontinuous signs:

- continuous signs are those that are similar to fixed signs, the only difference being that by some electro mechanical means they can show various messages.

NOTE 1 For example rotating prism signs, roller blinds.

- discontinuous signs create messages using individual elements that can be in one of two states (or more) and can thereby create various messages on the same sign face.

NOTE 2 For example fibre optic signs, LED signs.

This document covers the performance requirements for Variable Message Signs used for the instruction and guidance of road users on public and private land, including tunnels. In this document a number of different performance requirements (visual performance, EMC, environmental performance, etc) are covered, as well as durability.

The EMC, safety and environmental requirements for both types of VMS are included in this document together with the visual performance for the discontinuous types VMS.

The visual performance for continuous signs and discontinuous signs which are externally illuminated is covered by EN 12899-1.

This document defines performance limits and a range of performance classes for both sign assemblies without vertical support and assemblies complete with vertical support.

Not covered by this document are:

a) sign gantries, cantilevers and foundations;

b) portable and temporary VMS;

c) signal heads;

d) sizes and shapes of VMS messages;

e) control units and monitoring units unless inside the test module.

Vertikale Verkehrszeichen - Wechselverkehrszeichen - Teil 1: Produktnorm

Dieses Dokument legt Anforderungen an neue Wechselverkehrszeichen (WVZ) fest.

WVZ umfassen zwei Typen, kontinuierliche und nicht kontinuierliche Verkehrszeichen:

- kontinuierliche Verkehrszeichen ähneln ortsfesten Verkehrszeichen; der einzige Unterschied besteht

darin, dass sie durch bestimmte elektromechanische Mittel verschiedene Zeicheninhalte anzeigen

können.

ANMERKUNG 1 Beispielsweise Wechselverkehrszeichen in Prismentechnik, Rollotechnik.

- nicht kontinuierliche Verkehrszeichen erzeugen Zeicheninhalte durch die Nutzung einzelner Elemente,

die sich in einem von zwei (oder mehr) Zuständen befinden können; auf diese Weise können sie auf

derselben Zeichenfront verschiedene Zeicheninhalte erzeugen.

ANMERKUNG 2 Beispielsweise glasfaseroptische Verkehrszeichen, LED-Verkehrszeichen.

In diesem Dokument werden die Qualitätsanforderungen an Wechselverkehrszeichen für die Anweisung und

Leitung von Benutzern öffentlicher und privater Straßen, einschließlich Tunneln, behandelt. Das Dokument

enthält eine Reihe von verschiedenen Qualitätsanforderungen, die erfüllt werden müssen (optische Qualität,

EMV, Umweltverhalten usw.), es werden jedoch auch Fragen hinsichtlich der Lebensdauer behandelt.

Die Anforderungen an die EMV, Sicherheit und das Umweltverhalten für beide Typen von WVZ sind in diesem

Dokument ebenso enthalten wie die optische Qualität von nicht kontinuierlichen WVZ.

Die optische Qualität von kontinuierlichen und nicht kontinuierlichen Verkehrszeichen, die von außen beleuch-

tet werden, muss die Anforderungen von EN 12899-1 erfüllen.

In diesem Dokument werden sowohl für hergestellte Zeichen ohne vertikale Aufhängungen als auch für

Zeichen mit vertikalen Aufhängungen Qualitätsgrenzen sowie eine Reihe von QualitätsAnforderungen von EN 12899 1 erfüllen.

In diesem Dokument werden sowohl für hergestellte Zeichen ohne vertikale Aufhängungen als auch für Zeichen mit vertikalen Aufhängungen Qualitätsgrenzen sowie eine Reihe von Qualitätsklassen bestimmt.

Signaux de signalisation routière verticale - Panneaux à messages variables - Partie 1: Norme produit

Ce document spécifie les exigences et les méthodes de tests pour les nouveaux panneaux à messages variables (PMV).

Les PMV peuvent être de deux types, continu ou discontinu :

- les panneaux continus sont similaires aux panneaux fixes. La seule différence réside dans le fait qu'ils intègrent des dispositifs éléctro-mécaniques capables d'afficher différents messages ;

NOTE 1 Par exemple, panneaux à prismes rotatifs, panneaux à volets.

- les panneaux discontinus peuvent créer des messages en utilisant des éléments individuels qui peuvent être dans un état sur deux (ou plus) possible, ce qui permet d'afficher divers messages sur la même face du panneau.

NOTE 2 Par exemple, les panneaux à fibres optiques, les panneaux à LEDs.

Ce document couvrent les exigences fonctionnelles applicables pour les Panneaux à Messages Variables utilisés pour l'information et le guidage des usagers routiers sur les domaines publics et privé, y compris les tunnels. Dans ce document, un certain nombre d'exigences de performances (caractéristiques visuelles et environnementales, CEM,) sont couvertes, ainsi que la durée de vie.

Les exigences liées à la CEM, la sécurité et à l'environnement sont spécifiées pour les deux types de PMV, de même que les performances visuelles pour les PMV de type discontinu.

Les performances visuelles des panneaux de type continu ou discontinu qui sont éclairés par l'extérieur sont couverts par la norme EN 12899-1.

Cette norme définit les limites de performances, ainsi que des classes de performances pour les deux types de panneaux assemblés avec ou sans support vertical.

Cette norme ne couvre pas les points suivants :

a) portiques, potences et fondations des panneaux ;

b) PMV mobiles ou temporaires ;

c) têtes de feux ;

d) tailles et formes des messages PMV ;

organes de contrôle et de surveillance sauf si ceux-ci sont intégrés au module d'essai PMV

Pokončni cestni znaki – Prometni znaki s spremenljivim sporočilom – 1. del: Standard za proizvod

General Information

- Status

- Withdrawn

- Publication Date

- 19-Apr-2005

- Withdrawal Date

- 10-Nov-2009

- Technical Committee

- CEN/TC 226 - Road equipment

- Drafting Committee

- CEN/TC 226/WG 3 - Vertical signs

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 11-Nov-2009

- Completion Date

- 11-Nov-2009

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 22-Dec-2008

Frequently Asked Questions

EN 12966-1:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Road vertical signs - Variable message traffic signs - Part 1: Product standard". This standard covers: This document specifies requirements and test methods for new Variable Message Signs (VMS). VMS comprise two types, continuous and discontinuous signs: - continuous signs are those that are similar to fixed signs, the only difference being that by some electro mechanical means they can show various messages. NOTE 1 For example rotating prism signs, roller blinds. - discontinuous signs create messages using individual elements that can be in one of two states (or more) and can thereby create various messages on the same sign face. NOTE 2 For example fibre optic signs, LED signs. This document covers the performance requirements for Variable Message Signs used for the instruction and guidance of road users on public and private land, including tunnels. In this document a number of different performance requirements (visual performance, EMC, environmental performance, etc) are covered, as well as durability. The EMC, safety and environmental requirements for both types of VMS are included in this document together with the visual performance for the discontinuous types VMS. The visual performance for continuous signs and discontinuous signs which are externally illuminated is covered by EN 12899-1. This document defines performance limits and a range of performance classes for both sign assemblies without vertical support and assemblies complete with vertical support. Not covered by this document are: a) sign gantries, cantilevers and foundations; b) portable and temporary VMS; c) signal heads; d) sizes and shapes of VMS messages; e) control units and monitoring units unless inside the test module.

This document specifies requirements and test methods for new Variable Message Signs (VMS). VMS comprise two types, continuous and discontinuous signs: - continuous signs are those that are similar to fixed signs, the only difference being that by some electro mechanical means they can show various messages. NOTE 1 For example rotating prism signs, roller blinds. - discontinuous signs create messages using individual elements that can be in one of two states (or more) and can thereby create various messages on the same sign face. NOTE 2 For example fibre optic signs, LED signs. This document covers the performance requirements for Variable Message Signs used for the instruction and guidance of road users on public and private land, including tunnels. In this document a number of different performance requirements (visual performance, EMC, environmental performance, etc) are covered, as well as durability. The EMC, safety and environmental requirements for both types of VMS are included in this document together with the visual performance for the discontinuous types VMS. The visual performance for continuous signs and discontinuous signs which are externally illuminated is covered by EN 12899-1. This document defines performance limits and a range of performance classes for both sign assemblies without vertical support and assemblies complete with vertical support. Not covered by this document are: a) sign gantries, cantilevers and foundations; b) portable and temporary VMS; c) signal heads; d) sizes and shapes of VMS messages; e) control units and monitoring units unless inside the test module.

EN 12966-1:2005 is classified under the following ICS (International Classification for Standards) categories: 93.080.30 - Road equipment and installations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12966-1:2005 has the following relationships with other standards: It is inter standard links to EN 12966-1:2005+A1:2009, EN 12966-1:2005/prA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12966-1:2005 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/111. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12966-1:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Road vertical signs - Variable message traffic signs - Part 1: Product standardSignaux de signalisation routiere verticale - Panneaux a messages variables - Partie 1: Norme produitVertikale Verkehrszeichen - Wechselverkehrszeichen - Teil 1: ProduktnormTa slovenski standard je istoveten z:EN 12966-1:2005SIST EN 12966-1:2005en93.080.30ICS:SLOVENSKI

STANDARDSIST EN 12966-1:200501-julij-2005

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12966-1April 2005ICS 93.080.30English versionRoad vertical signs - Variable message traffic signs - Part 1:Product standardSignaux de signalisation routière verticale - Panneaux àmessages variables - Partie 1: Norme de produitVertikale Verkehrszeichen - Wechselverkehrszeichen - Teil1: ProduktnormThis European Standard was approved by CEN on 15 March 2005.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2005 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12966-1:2005: E

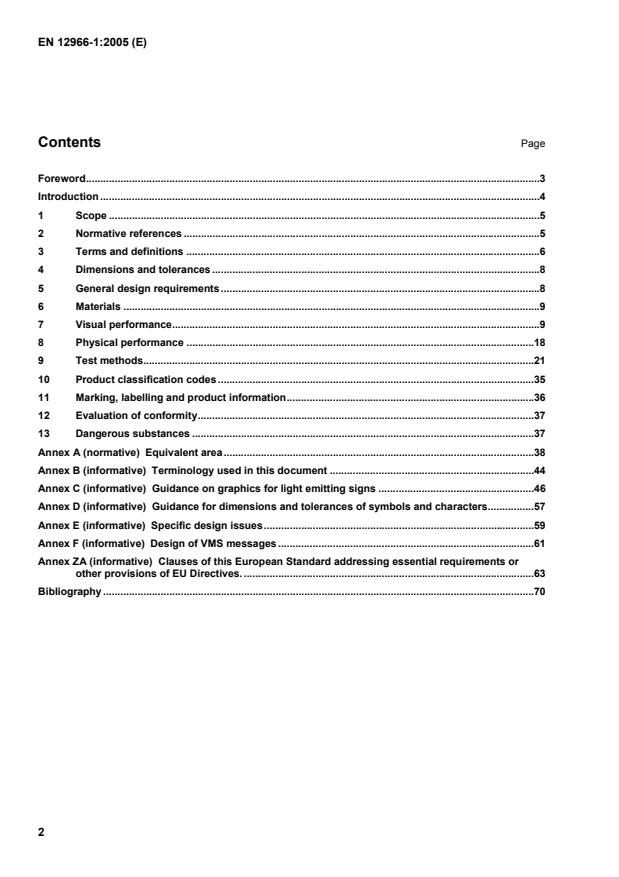

Equivalent area.38 Annex B (informative)

Terminology used in this document.44 Annex C (informative)

Guidance on graphics for light emitting signs.46 Annex D (informative)

Guidance for dimensions and tolerances of symbols and characters.57 Annex E (informative)

Specific design issues.59 Annex F (informative)

Design of VMS messages.61 Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or other provisions of EU Directives.63 Bibliography.70

– Part 1: Product standard - Part 2: Variable message traffic signs – Part 2: Initial type testing - Part 3: Variable message traffic signs – Part 3: Factory production control It derives from performance requirements and test methods published in CEN, CENELEC, CIE and ISO documents together with standards of the CEN member organisations. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

HD 638 S1, Road traffic signal systems 3 Terms and definitions For the purposes of this document, the terms and definitions given in CIE 15.2:1986 and CIE 17.4:1987 and the following apply. NOTE When reading this document for the first time, particular attention should be paid to Annex B.

3.1 backing-board surround to the VMS, used depending on local circumstances, providing improved visibility of the VMS by means of broadening its size and by providing suitable visible contrast with the VMS background 3.2 cantilever support support system with a single post and a cantilever arm supporting VMS(s) mounted over the traffic lane(s) 3.3 control device equipment used to execute a change of message other than by purely manual means

3.13.1 matrix grid whose intersections hold the centre of the elements used in a VMS. A matrix may cover the whole display surface or part of it. Axes X and Y of the grid may or may not be orthogonal 3.13.2 irregular matrix spacing of intersections on either X or Y or both axes is not constant

This is the only occasion where tests may be carried out on material and not the whole test module. 7 Visual performance 7.1 Classification The manufacturer shall declare the relevant class designations for his products. This shall be in accordance with those photometric parameter classes listed in Table 1. Table 1 — Class designation of the photometric parameters of the VMS Photometric parameter Class designation Remarks Colour C1, C2 C2 is the more restrictive L1, L2, L3, L3(*) L3 has the highest luminance (*) for specific situations

Luminance (La) L1(T), L2(T), L3(T) These classes are for tunnel use Luminance ratio (LR) R1, R2, R3 R3 has the highest luminance ratio Beam width B1, B2, B3, B4, B5, B6, B7 B7 has the widest beam NOTE 1 The purchaser should select the appropriate parameter classes relevant to the application. Care is needed because some class-combinations are not possible and/or not effective. NOTE 2 Specific design issues are covered in Annex E, where guidelines are given on effective class-combinations

7.2 Colour The colour coordinates shall be measured in accordance with 9.3.5. The chromaticity of the colours is defined in accordance with the CIE 1931 Standard Colorimetric Observer as referenced in CIE publication 15.2. The chromaticity for the colours of the colour class C1 shall conform to Table 2. The chromaticity for the colours of the colour class C2 shall conform to Table 3. In Figure 1 these chromaticity areas are plotted in a CIE 1931 chromaticity diagram. The colour white/yellow shall not be used when there is a need to differentiate between white and yellow. When there is a need to differentiate between white and yellow the colours shall conform to the specified chromaticities in Table 2 or Table 3 for white and yellow respectively.

Green x y 0,310 0,684 0,310 0,562 0,209 0,400 0,028 0,400 - - - - Blue x y 0,109 0,087 0,204 0,196 0,233 0,167 0,149 0,025 - - - - Table 3 — Corner points (CIE 1931 chromaticity co-ordinates x, y) of the chromaticity areas for the colours of class C2 Colour co-ordinates Colour corner point = > 1 2 3 4 5 Red x y 0,660 0,320 0,680 0,320 0,710 0,290 0,690 0,290 - - Yellow x y 0,536 0,444 0,547 0,452 0,613 0,387 0,593 0,387 - - White x y 0,300 0,342 0,440 0,432 0,440 0,382 0,300 0,276 - - White/yellow x y 0,479 0,520 0,300 0,342 0,300 0,276 0,440 0,382 0,618 0,382 Green x y 0,009 0,720 0,284 0,520 0,209 0,400 0,028 0,400 - - Blue x y 0,109 0,087 0,173 0,160 0,208 0,125 0,149 0,025 - -

Key - - - Class C1 and C2 1 green C1 6 yellow C1, C2 −

− Class C1 2 green C2 7 red C1 — Class C2 3 white/yellow C1, C2 8 red C2

4 white C1 9 blue C1

5 white C2 10 blue C2 Figure 1 — Allowed chromaticity areas for the colour classes C1 and C2 plotted in the CIE 1931 chromaticity diagram

Luminance (La) limits for white, on reference axis, for the luminance classes L1, L2, L3 and L3(*) Luminance (cd/m2) Minimum Maximum Sign illuminance (lx) L3 L2 L1 L1, L2, L3 40 000 12 400 6 200 3 100 62 000 10 000 12 400 (*) - - - 4 000 2 200 1 100 550 11 000 400 600 300 150 3 000 40 250 200 100 1 250 ≤ 4 75 60 30 375 Table 4b — Luminance (La) limits for white/yellow, on reference axis, for the luminance classes L1, L2, L3 and L3(*) Luminance (cd/m2) Minimum Maximum Sign illuminance (lx) L3 L2 L1 L1, L2, L3 40 000 10 540 5 270 2 635 52 700 10 000 10 540 (*) - - - 4 000 1 870 935 468 9 350 400 510 255 128 2 550 40 213 170 85 1 065 ≤ 4 64 51 26 320

ratio ≤ 40 000 lx

Table 5 — Minimum luminance ratios (LR) for various colours and classes R1, R2 and R3, at test angles on the reference axis and off the reference axis Minimum luminance ratio R3 R2 R1 Colour on reference axis off reference axis on reference axis off reference axis on reference axis off reference axis White 16,7 8,35 10 5 5 3 white/yellow 14,2 7,1 8,5 4,25 4,25 2,55 Yellow 10 5 6 3 3 1.8 Green 5 2,5 3 1,5 1,5 0,9 Red 4,2 2,1 2,5 1,25 1,25 0,75 Blue 1,7 0,85 1 0,5 0,5 0,3 NOTE For illuminances below 400 lx (e.g. tunnels) there is no luminance ratio requirement. ⇒ below 400 lx ⇒ < 400 lx

Class R3 is only recommended for specific applications, see E.5 Effective class-combinations.

1,5 x 30 000 = 45 000 cd/m2. The minimum luminance at within the beam width angles shall not be lower than

0,5 x 30 000 = 15 000 cd/m2. Outside the beam width angles the luminance is allowed to be zero, but never larger than

57 200 cd/m2.

Key

1 = minimum luminance at reference axis 2 = maximum luminance at reference axis 3 = actual measured luminance (Lmes) at reference axis 4 = maximum luminance at all angles 5 = lower limit (50 % of Lmes) 6 = upper limit (150 % of Lmes) 7 = passed distributions 8 = not passed distributions 9 = horizontal angle (degrees) 10= luminance (cd·m-²)

Figure 2— Examples of passed and not passed luminance distributions for class luminance L3, colour white/yellow, and beam width class B2 at a sign illuminance of 40 000 lx

Class B7 is only recommended for specific applications. 7.6 Uniformity Uniformity measurements shall be done in accordance with 9.3.4. For the luminous intensities of any individual element of the test module the ratio of the average output from the highest 12 % of the elements, to the lowest 12 %, shall be less then 3:1. The ratio of the average output from the highest 4 % of the elements, to the lowest 4 %, shall be less then 5:1. The number of elements in consideration shall be rounded to the next highest whole number. The luminous intensity uniformity shall apply to for each separate colour. 7.7 Visible flicker When the light sources of a test module are operating in a pulse mode, no light flicker shall be visible. In the case of doubt, the frequency of the light emitted shall be measured. This frequency shall not be less than

90 Hz.

Pollution D1, D2, D3, D4 D4 is the most restrictive Protection P1, P2, P3 P3 is the most restrictive 8.2 Environmental requirements 8.2.1 Temperature One of the following temperature classes shall be selected: Table 8 — Temperature range classes ambient temperature (°°°°C) Class Minimum Maximum T1 -15 +60 T2 -25 +55 T3 -40 +40 Temperature performance of the test module shall be tested in accordance with 9.2.3 as relevant to the specific class. 8.2.2 Resistance to pollution The manufacturer shall state the degree of resistance to pollution in accordance with EN 60664-1. In addition to the insulation of electrical parts in all circuits, the design shall conform to the degrees of pollution in accordance with EN 60664-1. For the purpose of evaluating creepage distances and clearances the following four classes have been established. - Pollution degree 1: Class D1 No pollution or only dry, non-conductive pollution occurs. The pollution has no influence. - Pollution degree 2: Class D2 Only non-conductive pollution occurs except that occasionally a temporary conductivity caused by condensation is to be expected. - Pollution degree 3: Class D3. Conductive pollution occurs or dry non-conductive pollution occurs which becomes conductive due to condensation which is to be expected. - Pollution degree 4: Class D4.

EN 12767. If passive safety is not declared, the VMS supports shall be considered as Class 0 of EN 12767. 8.3.4 Impact resistance The test modules shall be capable of withstanding impact, and shall be tested in accordance with 9.2.3, Table 13. After the test the test module front panel or parts of it shall show no damage and the test module shall continue to meet all the requirements of the standard. 8.3.5 Vibration resistance The test modules shall be capable of withstanding vibration, and shall be tested in accordance with 9.2.3, Table 14.

This shall be tested in accordance with 9.2.4. 8.4.1.7 Temporary overvoltage When protection for temporary (not transient) overvoltage is incorporated, the operating voltage range of the protective device shall be stated. This shall be tested in accordance with 9.2.2 Table 11. 8.4.2 Electrical safety The test module shall conform to electrical safety requirements of HD 60364-4-443 and HD 638 as applicable. 8.5 Electromagnetic compatibility 8.5.1 Electromagnetic emission For all types of environment the test module shall conform to EN 50293. 8.5.2 Electromagnetic immunity For all types of environment the test module shall conform to EN 50293. 9 Test methods 9.1 Test modules 9.1.1 General

NOTE In order to allow for future developments in technology and sign design, the standard uses performance requirements which are not dependent on technology and which can be demonstrated on a test module. This document contains a number of defined requirements, some of which have to be demonstrated on the test module, others that are to be certified by the manufacturer. This combination covers not only confirmation of compliance with the standard, which is required to meet the regulatory requirements but also issues of lifetime, quality, maintenance and construction, all of which affect the ability of a sign in its particular application, to meet safety and fitness for purpose. The details in the informative Annexes are provided as useful guidance on the additional aspects relating to VMS for those setting up purchasing contracts for signs or signing systems. The test module ensures that the manufacturer can demonstrate to the purchaser that his requirements have been fulfilled.

Key 1 Power input 2 Control input Figure 3— Examples of variable message sign test modules in front view (a and c) and side view (b) with indications for the dimensions, width (w), height (h) and thickness (t). The shaded squares are equivalent element areas and form the optical test area The spacing between the centres of the elements shall be measured for the test modules, which meet the test requirements and shall be reported as the “element spacing”. The element spacing of the actual VMS shall be within ± 10 % of the element spacing measured on the test module. 9.1.3 Function test 9.1.3.1 General The function test is based on alternate activation/deactivation of all the elements, which is the cyclic change of all elements from one state to another.

Final measurements: Visual inspection and Function tes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...