EN 14531-1:2005

(Main)Railway applications - Methods for calculation of stopping distances, slowing distances and immobilization braking - Part 1: General algorithms

Railway applications - Methods for calculation of stopping distances, slowing distances and immobilization braking - Part 1: General algorithms

This document specifies a general algorithm to be used in any type of vehicle application. It enables the calculation of the various aspects of the performance: stopping or slowing distances, dissipated energy, force calculations, immobilization braking.

Typical examples of calculations for freight wagon, coach and locomotive are given in Parts 2 to 6 of this European Standard.

NOTE This document does not specify the performance requirements which can be found in the different standards specified in Clause 2.

This document enables the verification that the design respects the requirements according to the railway application type.

Bahnanwendungen - Verfahren zur Berechnung der Anhalte- und Verzögerungsbremswege und der Feststellbremsung - Teil 1: Grundlagen

Diese Europäische Norm beschreibt ein allgemeines Berechnungsverfahren, das für alle Fahrzeugtypen gilt. Es ermöglicht die Berechnung der verschiedenen leistungsbezogenen Aspekte: Anhalte- oder Verzögerungswege, umgewandelte Energie, Berechnungen von Kräften, Feststellbremsungen.

Typische Berechnungsbeispiele für Güterwagen, Reisezugwagen und Lokomotiven werden in den Teilen 2 bis 6 dieser Normenreihe behandelt.

ANMERKUNG Diese Europäische Norm beschreibt nicht die Leistungsanforderungen, die in den verschiedenen in Abschnitt 2 angegebenen Normen angegeben sind.

Diese Europäische Norm ermöglicht den Nachweis, dass die Auslegung und Konstruktion die für das jeweilige Schienenfahrzeug spezifischen Anforderungen berücksichtigt.

Applications ferroviaires - Méthodes de calcul des distances d'arrêt, de ralentissement et d'immobilisation - Partie 1: Algorithmes généraux

La présente Norme européenne spécifie un algorithme général à utiliser pour les applications à tout type de véhicule. Il permet de calculer les différents aspects des performances : distances d'arrêt ou de ralentissement, énergie dissipée, calcul des efforts, freinage d'immobilisation.

Des exemples typiques pour les wagons de fret, les voitures, les locomotives sont indiqués dans les Parties 2 à 6 de la présente Norme européenne.

NOTE La présente Norme européenne ne spécifie pas les exigences de performances que l'on peut trouver dans les différentes Normes indiquées à l'Article 2.

La présente Norme européenne permet de vérifier que la conception respecte les exigences en fonction du type d'application ferroviaire.

Železniške naprave – Metode za izračune zavornih poti, poti za kontrolo hitrosti in zavarovanj stoječih vozil – 1. del: Splošni algoritmi

General Information

- Status

- Withdrawn

- Publication Date

- 19-Apr-2005

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 256 - Railway applications

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 23-Dec-2015

- Completion Date

- 21-Jan-2026

Relations

- Effective Date

- 11-Apr-2012

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish national quality association.

Sponsored listings

Frequently Asked Questions

EN 14531-1:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Methods for calculation of stopping distances, slowing distances and immobilization braking - Part 1: General algorithms". This standard covers: This document specifies a general algorithm to be used in any type of vehicle application. It enables the calculation of the various aspects of the performance: stopping or slowing distances, dissipated energy, force calculations, immobilization braking. Typical examples of calculations for freight wagon, coach and locomotive are given in Parts 2 to 6 of this European Standard. NOTE This document does not specify the performance requirements which can be found in the different standards specified in Clause 2. This document enables the verification that the design respects the requirements according to the railway application type.

This document specifies a general algorithm to be used in any type of vehicle application. It enables the calculation of the various aspects of the performance: stopping or slowing distances, dissipated energy, force calculations, immobilization braking. Typical examples of calculations for freight wagon, coach and locomotive are given in Parts 2 to 6 of this European Standard. NOTE This document does not specify the performance requirements which can be found in the different standards specified in Clause 2. This document enables the verification that the design respects the requirements according to the railway application type.

EN 14531-1:2005 is classified under the following ICS (International Classification for Standards) categories: 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14531-1:2005 has the following relationships with other standards: It is inter standard links to EN 14531-1:2015, EN ISO 24478:2024, EN 14531-6:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14531-1:2005 is associated with the following European legislation: EU Directives/Regulations: 2001/16/EC, 93/38/EEC, 96/48/EC; Standardization Mandates: M/024, M/275, M/334. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14531-1:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Bahnanwendungen -

Verfahren zur Berechnung der Anhalte- und Verzögerungsbremswege und der Feststellbremsung - Teil 1: GrundlagenApplications ferroviaires - Méthodes de calcul des distances d'arret, de ralentissement et d'immobilisation - Partie 1: Algorithmes générauxRailway applications - Methods for calculation of stopping distances, slowing distances and immobilization braking - Part 1: General algorithms45.020Železniška tehnika na splošnoRailway engineering in generalICS:Ta slovenski standard je istoveten z:EN 14531-1:2005SIST EN 14531-1:2005en01-julij-2005SIST EN 14531-1:2005SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14531-1April 2005ICS 45.060.01English versionRailway applications - Methods for calculation of stoppingdistances, slowing distances and immobilization braking - Part 1:General algorithmsApplications ferroviaires - Freinage - Méthodes de calculdes distances d'arrêt et de ralentissement - Méthodes decalcul du freinage d'immobilisation - Partie 1: AlgorithmesgénérauxBahnanwendungen - Bremsen - Verfahren zur Berechnungder Anhalte- und Verzögerungsbremswege - Verfahren zurBerechnung der Feststellbremsung - Teil 1: GrundlagenThis European Standard was approved by CEN on 15 March 2005.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2005 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14531-1:2005: ESIST EN 14531-1:2005

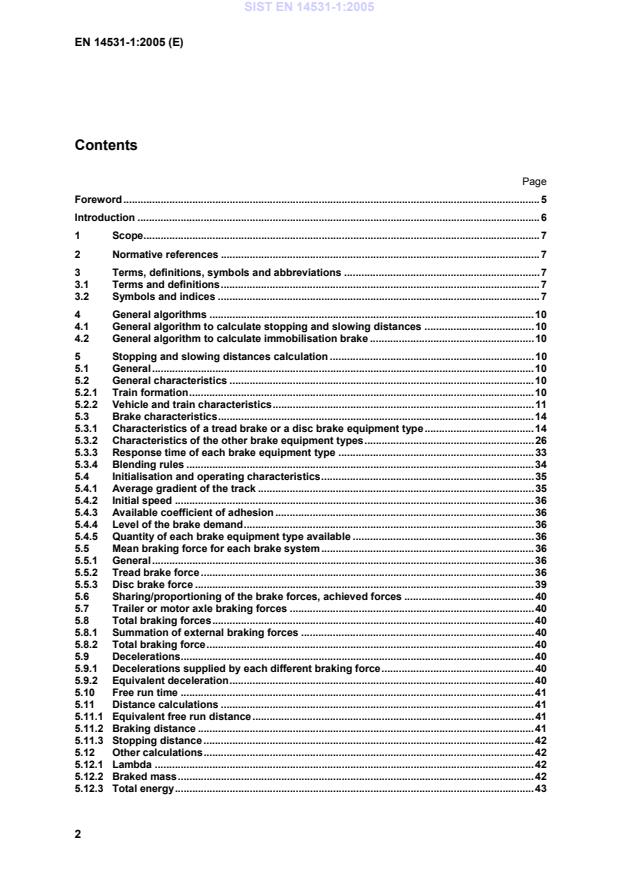

General algorithm to calculate stopping and slowing distances.65 Annex B (normative)

General algorithm to calculate immobilization braking.68 Annex C (informative)

Examples of calculations for stopping and slowing distances.70 C.1 Example calculations for rolling resistance for wagons with bogies.70 C.1.1 Example 1 Open hopper wagon E7.70 C.1.2 Example 2 Covered wagon G10.70 C.1.3 Example 3 Covered wagon G50.70 C.1.4 Example 4 Flat wagon R18.70 C.2 Example calculations for tread brake force with rigging.70 C.2.1 Application to conventional two axle wagon equipped with mechanical empty-load device with UIC Bg block from 100 km/h.70 C.2.2 Application to conventional two axle wagon equipped with a pneumatic empty-load device with UIC Bg block from 100 km/h.71 C.2.3 Application to conventional two bogie wagon equipped with pneumatic empty-load device with UIC Bgu blocks from 100 km/h.72 C.3 Tread brake force with cylinder.73 SIST EN 14531-1:2005

×

×

× na/Mst).76 C.5.2 Deceleration provided by the disc brake (a = FB/Mdyn = FB,a ×

×

×

× na/Mst).76 C.6 Distance calculations.76 C.6.1 Example 1.76 C.6.2 Example 2.77 C.6.3 Example 3.77 C.6.4 Example 4.77 C.7 Examples of other calculations.77 C.7.1 Example 1.77 C.7.2 Example 2.79 C.7.3 Example 3.81 C.7.4 Example 4.82 Annex D (informative)

Examples of calculations for immobilization braking.85 D.1 Examples of immobilization calculations for hand brake equipment acting on tread.85 D.1.1 General.85 D.1.2 Gearing output force.85 D.1.3 Application force on the blocks.85 D.1.4 Immobilization force provided to the axle.86 D.2 Examples of immobilization calculations for hand brake equipment acting on disc.86 D.2.1 General.86 D.2.2 Gearing output force per cylinder.86 D.2.3 Force provided by each cylinder.86 D.2.4 Application force on pads of one cylinder.87 D.2.5 Immobilization force provided to the axle.87 D.3 Cylinder brake equipment acting on disc.87 D.3.1 General.87 D.3.2 Application force on pads.88 D.3.3 Immobilization force per disc.88 D.3.4 Immobilization force provided to the axle.88 D.4 Cylinder brake equipment acting on tread.89 D.4.1 General.89 D.4.2 Immobilization force provided to the axle.89 D.5 Permanent magnetic track brake equipment.89 D.5.1 General.89 D.5.2 Immobilization force provided to the bogie.89 D.6 External forces and final results.89 D.6.1 General.89 D.6.2 Example based on case of a two bogie wagon which is braked on only one bogies with a hand brake equipment acting on tread.90 D.6.3 Example based on case of a two bogie wagon which is braked on only one bogie with a hand brake equipment acting on disc.90 D.6.4 Example based on case of a two bogie wagon which is braked with a cylinder brake equipment acting on a disc.91 D.6.5 Example based on case of cylinder brake equipment acting on tread.91 ANNEX ZA

(informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 96/48.93 Annex ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2001/16.94 Bibliography.95 SIST EN 14531-1:2005

Foreword This European Standard (EN 14531-1:2005) has been prepared by Technical Committee CEN/TC 256 “Railway applications”, the secretariat of which is held by DIN. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by October 2005, and conflicting national standards shall be withdrawn at the latest by October 2005. This European Standard has been prepared under a mandate given to CEN/CENELEC/ETSI by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directive 96/48 and Directive 2001/16. For relationship with EU Directives, see informative Annexes ZA and ZB, which are integral parts of this European Standard. This European Standard is one part of the European Standard as listed below: EN 14531, Railway applications – Methods for calculation of stopping, slowing distances and immobilization braking Part 1: General algorithms Part 2: Application to single freight wagon Part 3: Application to mass transit (LRV's and D- and E- MU's) Part 4: Application to single passengers coach Part 5: Application to locomotive Part 6: Application to high speed trains According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EN 14198:2003 and EN 14478:2004 apply. NOTE If there are inconsistencies between this European Standard and the definitions given in EN 14478, then the definitions given in EN 14478 take precedence. 3.2 Symbols and indices For the purposes of this European Standard, the general symbols given in Table 1 and indices given in Table 2 apply. NOTE Specific symbols are defined in the relevant clauses. SIST EN 14531-1:2005

g acceleration due to gravity m/s2 I rotational inertia kg · m2 i rigging ratio, calliper ratio

m mass kg n quantity

P power W p pressure Pa R wheel radius m r radius m s distance m t time s v speed m/s W energy J WS energy per square unit J/m2 η efficiency

coefficient of rotating mass

λ brake percentage

µ friction coefficient

Table 2 — General indices

Symbol Term Dimensions AMG attraction force for a magnetic brake

a axle

BEC braking force for an eddy current brake

BED electro-dynamic braking force

BFR fluid retarder

BMG braking force for a magnetic brake

b block or pad

bog bogie

C cylinder

disc disc

dyn dynamic

e, 2 final

eq equivalent

ext

external

H hand brake

int internal

m average, mean

max maximal

min minimal

mot motor

M_unsp unsprung mass

MG magnetic brake

park parking, immobilization

R reaction

Ra rolling resistance

rot rotational

R1 return spring

R2 regulator

st static

tot

total

tra trailer

veh vehicle

weig weighing

wind wind

0, 1 initial

NOTE In this European Standard, the wheelset is simply named "axle". 4 General algorithms 4.1 General algorithm to calculate stopping and slowing distances This algorithm is presented in Annex A. The content of each part and the corresponding calculations are explained in Clause 5. This algorithm can be used either with mean values or with instantaneous values of, for example force or retardation which are integrated step by step. 4.2 General algorithm to calculate immobilisation brake This algorithm is presented in Annex B. The content of each part and the corresponding calculations are explained in Clause 6. 5 Stopping and slowing distances calculation 5.1 General All the values which are used shall be justified, for example, by tests, calculations, or engineer's estimations, in accordance with the appropriate standards, for example EN 13452-2. 5.2 General characteristics 5.2.1 Train formation The parameters to define train formation are: quantity of motor axles; quantity of trailer axles; quantity of braked axles for each brake equipment type. In the cases of single wagon, coach or locomotive, the notion of train is restricted to the single wagon, the coach or the locomotive. Brake equipment type shall be taken to mean a group of equipment whose purpose is to provide braking force. SIST EN 14531-1:2005

is given by: strotstMMM+=

(1) where

is the coefficient of the rotating mass; Mst

is the static mass, in tonnes; Mrot

is the rotating mass, in tonnes. In the cases of single wagon, this coefficient is given for two conditions: in tare (about 5 t/axle or

6 t/axle) and laden (about 20 t/axle). EXAMPLE 1 For non-powered axle with ∅920 mm wheel half worn, without disc,

in tare condition: κ = 1,06

in laden condition: κ = 1,02 EXAMPLE 2 For non-powered axle with ∅1 000 mm wheel half worn, without disc,

in tare condition: κ = 1,07

in laden condition: κ = 1,02 EXAMPLE 3 For non-powered axle with ∅850 mm wheel half worn, without disc,

in tare condition: κ = 1,05

in laden condition: κ = 1,02 5.2.2.3 Wheel diameters The wheel diameter is assumed to be measured on the nominated line of contact with the running surface of the rail. Unless otherwise specified, the wheel diameter used in the calculation shall be that of a new wheel which gives the lowest deceleration in the case of disc brakes. NOTE If the train is equipped with different types of wheel, according to the definition of a brake equipment, it is recommended that each type of wheel is considered as being applicable to a specific brake equipment type. 5.2.2.4 Rolling resistance The rolling resistance is the braking force provided by the structure of the train. Unless otherwise specified the effect of wind forces is not taken into account. SIST EN 14531-1:2005

(2) where v

is the instantaneous speed of the vehicle, in metres per second (m/s); A

is the characteristic coefficient of the vehicle, in newtons (N); B

is the characteristic coefficient of the vehicle, in N/(m/s); C

is the characteristic coefficient of the vehicle in N/(m/s)2. NOTE 2 The speed may be expressed in km/h and the rolling resistance in [daN] or [kN]. In this case, A, B, C are expressed in [daN], [daN/(km/h)], [daN/(km/h)2] or [kN], [kN/(km/h)], [kN/(km/h)2]. NOTE 3 Values for A, B and C may be obtained using the test method given in EN 14067-2. b) Calculate the average rolling resistance as a function of the initial speed FRa, in newtons (N), using the following equations. average rolling resistance in the case of braking to a stop: 200mRa,2132vCvBAF××+××+=

(3) where v0 is the speed at which braking is initiated, in metres per second (m/s); A, B, C are the coefficients in Equation (2); NOTE 4 The speed may be expressed in km/h and the rolling resistance in [daN] or [kN]. In this case, A, B, C are expressed in [daN], [daN/(km/h)], [daN/(km/h)2] or [kN], [kN/(km/h)], [kN/(km/h)2]. average rolling resistance in the case of slowing braking: SIST EN 14531-1:2005

(4) where v0

is the speed at which braking is initiated, in metres per second (m/s); ve

is the final speed, in metres per second (m/s); A, B, C are the coefficients in Equation (2). NOTE 5 The speed may be expressed in km/h and the rolling resistance in [daN] or [kN]. In this case, A, B, C are expressed in [daN], [daN/(km/h)], [daN/(km/h)2] or [kN], [kN/(km/h)], [kN/(km/h)2]. NOTE 6 Examples of calculations for for wagons with bogies are presented in C.1. 5.3 Brake characteristics NOTE The following examples illustrate the application of the general algorithm. For specific applications reference should be made to the specific vehicle types covered in the following parts of this European Standard: Part 2: Application to a single freight wagon; Part 3: Application to mass transit (LRV's and D- and E-MU's); Part 4: Application to single passenger coach; Part 5: Application to locomotive; Part 6: Application to high speed trains. 5.3.1 Characteristics of a tread brake or a disc brake equipment type 5.3.1.1 Fixed characteristics of a tread brake equipment type 5.3.1.1.1 General characteristics This item is composed of every component characteristic that contributes to the brake performance of equipment that uses rigging. When a tread brake uses a block mounted on a cylinder, the equipment shall be considered as a disc brake type. NOTE “Fixed” means “not subject to change”. The characteristics of a classical tread brake equipment are given in Table 3: SIST EN 14531-1:2005

a pC [bar]

tare

[bar]

laden

[bar]

b) Brake piston area

AC [cm2]

c) Cylinder efficiency

ηC [-]

d) Total rigging ratio after cylinder

iC [-]

* tare

[-]

* laden

[-]

e) Rigging return spring force b FR1 [N]

f) Total rigging ratio after return spring

iR1 [-]

g) Brake regulator opposing force

FR2 [N]

h) Total rigging ratio after regulator

c iR2 [-]

i) Rigging efficiency in dynamic conditions

ηdyn [-]

j) Friction area of the block

Ab [m²]

k) Quantity of blocks per wheel

nb,w [-]

a May be a continuously variable function of the static mass per axle. b In many cases it is inside the cylinder. In such cases rigging ratio in d) = rigging ratio in f). c Currently, when the wheels are clasp braked, the rigging ratio after regulator for four axle wagons (2 bogies) is equal to 8.

The examples given in 5.3.1.1.2 to 5.3.1.1.4 describe various types of rigging arrangements and support the calculations. SIST EN 14531-1:2005

5.3.1.1.2 Conventional two axle wagon equipped with a mechanical empty load device Conventional Two Axle Wagon equipped with a mechanical empty-load device is shown Figure 1 and Table 4. Dimensions in millimetres 185515400300700 Figure 1 — Conventional two axle wagon equipped with a mechanical empty-load device Table 4 — Conventional two axle wagon equipped with a mechanical empty-load device Characteristic Symbol Unit Value a) Pressure at the brake cylinder

pC

* tare

[bar] = 3,8

* laden

[bar] = 3,8

b) Brake piston area AC [cm2] = 706,9

c) Cylinder efficiency ηC [-] = 1

d) Total rigging ratio after cylinder iC

* tare

[-] = (a/b) × 4 = 5,33

* laden

[-] = (c/d) × 4 = 11,135

e) Rigging return spring force FR1 [N] = 1 500

f) Total rigging ratio after return spring

iR1 [-] = same values as d)

g) Brake regulator opposing force FR2 [N] = 2 000

h) Total rigging ratio after regulator iR2 [-] = 4

i) Rigging efficiency in dynamic conditions ηdyn [-] = 0,83

j) Friction area of the block Ab [m²] 0,027 2 k) Quantity of blocks per wheel nb,w [-] = 2 SIST EN 14531-1:2005

* tare

[bar] = 1,75

* laden

[bar] = 3,8

b) Brake piston area AC [cm2] = 706,9

c) Cylinder efficiency ηC [-] = 1

d) Total rigging ratio after cylinder iC [-] = (a/b) × 4 = 11,91

e) Rigging return spring force FR1 [N] = 1 500

f) Total rigging ratio after return spring iR1 [-] = 11,91

g) Brake regulator opposing force FR2 [N] = 2 000

h) Total rigging ratio after regulator

iR2 [-] = 4

i) Rigging efficiency in dynamic conditions ηdyn [-] = 0,83

j) Friction area of the block Ab [m²] 0,027 2 k) Quantity of blocks per wheel nb,w [-] = 2 SIST EN 14531-1:2005

pC [bar]

* tare

[bar] = 1,27

* laden

[bar] = 3,8

b) Brake piston area AC [cm²] = 1 295,0

c) Cylinder efficiency ηC [-] = 1

d) Total rigging ratio after cylinder iC [-] = (a/b) × 8 = 12,68

e) Rigging return spring force FR1 [N] = 1 500

f) Total rigging ratio after return spring iR1 [-] = 12,68

g) Brake regulator opposing force FR2 [N] = 2 000

h) Total rigging ratio after regulator

iR2 [-] = 8

i) Rigging efficiency in dynamic conditions ηdyn [-] = 0,83

j) Friction area of the block Ab [m²] = 0,042 5 k) Quantity of blocks per wheel nb,w [-] = 2

5.3.1.2 Fixed characteristics of a disc brake equipment type 5.3.1.2.1 General characteristics This item is composed of every component characteristic that contributes to the brake performance. SIST EN 14531-1:2005

* tare

[bar]

* laden

[bar]

b) Brake piston area AC [cm²]

c) Cylinder efficiency ηC [-]

d) Rigging return spring force FR1 [N]

e) Brake regulator opposing force b FR2 [N]

f) Output cylinder force c FC [N]

g) Rigging efficiency in dynamic conditions ηdyn [-]

h) Calliper ratio iC [-]

i) Type and area of the pad per face of disc Ab [m²]

j) Mean swept radius rs [m]

k) Swept area (2 faces) of the disc As [m²]

l) Quantity of discs per cylinder ndisc,C [-]

m) Quantity of friction faces per disc ns [-]

n) Quantity of cylinders per axle nC,a [-]

o) Quantity of pads per cylinder nb,C [-]

a May be as a continuously variable function of the static mass per axle. b Generally included in d). c In the case of a classic pneumatic cylinder, this is calculated from the data a), b), c), d), e) or is given by the supplier as a function of the brake cylinder pressure.

5.3.1.2.2 Disc braked vehicle with one cylinder per disc Disc braked vehicle with one cylinder per disc is shown in Figure 4 and Table 8. SIST EN 14531-1:2005

Generally, in these applications, the pressure is varied continuously depending on the static mass per axle. b) Brake piston area AC [cm²] = 510,7

c) Cylinder efficiency ηC [-] = 0,97

d) Rigging return spring force FR1 [N]

= 1 500

e) Brake regulator opposing force FR2 [N]

= 0

f) Output cylinder force FC [N]

= Has to be calculated

g) Rigging efficiency in dynamic conditions ηdyn [-] = 0,95

h) Calliper ratio iC [-] = 2 (where a = b)

i) Area of the pad per face of disc Ab [m²] = 0,017 5 × 2

j) Mean swept radius rs

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...