SIST ISO 19302:2020

Graphic technology - Colour conformity of printing workflows

Graphic technology - Colour conformity of printing workflows

This document defines the requirements of printing workflows and evaluation methods for their tone and colour reproduction.

It applies to any printing process using any colourant, such as CMYK, CMYK with spot, non-CMYK, spot only or multicolour.

This document refers and points to international or national standards and can be used to define, evaluate and audit any printing workflow in whole or in part.

Technologie graphique -- Évaluation de la conformité des couleurs des produits imprimés

Grafična tehnologija - Barvna skladnost grafičnih procesov

General Information

- Status

- Published

- Publication Date

- 10-Mar-2020

- Technical Committee

- GRT - Graphical technology

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 27-Feb-2020

- Due Date

- 03-May-2020

- Completion Date

- 11-Mar-2020

Overview - ISO 19302:2018 (Graphic technology - Colour conformity of printing workflows)

ISO 19302:2018 defines requirements and evaluation methods for tone and colour reproduction across printing workflows. It applies to any printing process and colourant mix - CMYK, CMYK + spot, spot-only, non‑CMYK and multicolour - and provides a reference framework to define, evaluate and audit whole or partial printing workflows. The standard organizes a printing job into three main stages: colour definition, colour reproduction, and colour conformity.

Key topics and technical requirements

- Printing workflow requirements: Specifies job colour definition, digital file creation, graphic content handling, and spot/device colour builds.

- Process colour reproduction: Addresses colour management, prepress tasks, and process control needed to achieve consistent tone and colour reproduction.

- Product colour conformity: Defines print control and colour control activities for verifying that printed output meets the specified aims.

- Measurement and evaluation: Includes measurement conditions, viewing and illumination requirements, sampling strategies, scoring schemas and reporting formats for conformity assessment.

- Proofing and validation: Covers conditions and test methods for soft proofing, hard proofing and validation print production.

- Interoperability and data exchange: Refers to established file exchange and spot colour characterisation formats to support reliable data transfer between stakeholders.

- Practical scope: Points to applicable international and national standards and clarifies where additional specifications are required for auditing and certification.

Applications - who uses ISO 19302 and why

- Print service providers use ISO 19302 to standardize production processes, set up calibration and process control, and demonstrate conformity to customers or auditors.

- Print buyers and brand owners rely on the standard to define job colour aims, approve proofs, and ensure consistent brand colour reproduction across vendors.

- Prepress and colour management specialists apply the requirements for file creation, colour separation and device profile management.

- Proofing and display manufacturers use the guidance for soft/hard proof validation and viewing condition compliance.

- Certification bodies and auditors use the standard as a framework to evaluate and score workflow conformity for quality assurance and supplier assessment.

Related standards (normative references)

Key referenced documents include:

- ISO 12647 (all parts) - Process control for halftone separations, proofs and production prints

- ISO 13655 - Spectral measurement and colorimetric computation

- ISO 3664 - Viewing conditions

- ISO 12646 - Displays for colour proofing

- ISO 14861 - Colour soft proofing requirements

- ISO 15930 - PDF/X prepress data exchange

- ISO 17972-4 - CxF/X-4 spot colour characterisation

- CIE 15 - Colourimetry

ISO 19302:2018 is a practical, cross‑process standard for achieving reliable colour conformity in modern printing workflows.

Frequently Asked Questions

SIST ISO 19302:2020 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Graphic technology - Colour conformity of printing workflows". This standard covers: This document defines the requirements of printing workflows and evaluation methods for their tone and colour reproduction. It applies to any printing process using any colourant, such as CMYK, CMYK with spot, non-CMYK, spot only or multicolour. This document refers and points to international or national standards and can be used to define, evaluate and audit any printing workflow in whole or in part.

This document defines the requirements of printing workflows and evaluation methods for their tone and colour reproduction. It applies to any printing process using any colourant, such as CMYK, CMYK with spot, non-CMYK, spot only or multicolour. This document refers and points to international or national standards and can be used to define, evaluate and audit any printing workflow in whole or in part.

SIST ISO 19302:2020 is classified under the following ICS (International Classification for Standards) categories: 37.100.01 - Graphic technology in general. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST ISO 19302:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2020

Grafična tehnologija - Barvna skladnost grafičnih procesov

Graphic technology - Colour conformity of printing workflows

Technologie graphique -- Évaluation de la conformité des couleurs des produits

imprimés

Ta slovenski standard je istoveten z: ISO 19302:2018

ICS:

37.100.01 Grafična tehnologija na Graphic technology in

splošno general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

INTERNATIONAL ISO

STANDARD 19302

First edition

2018-12

Graphic technology — Colour

conformity of printing workflows

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

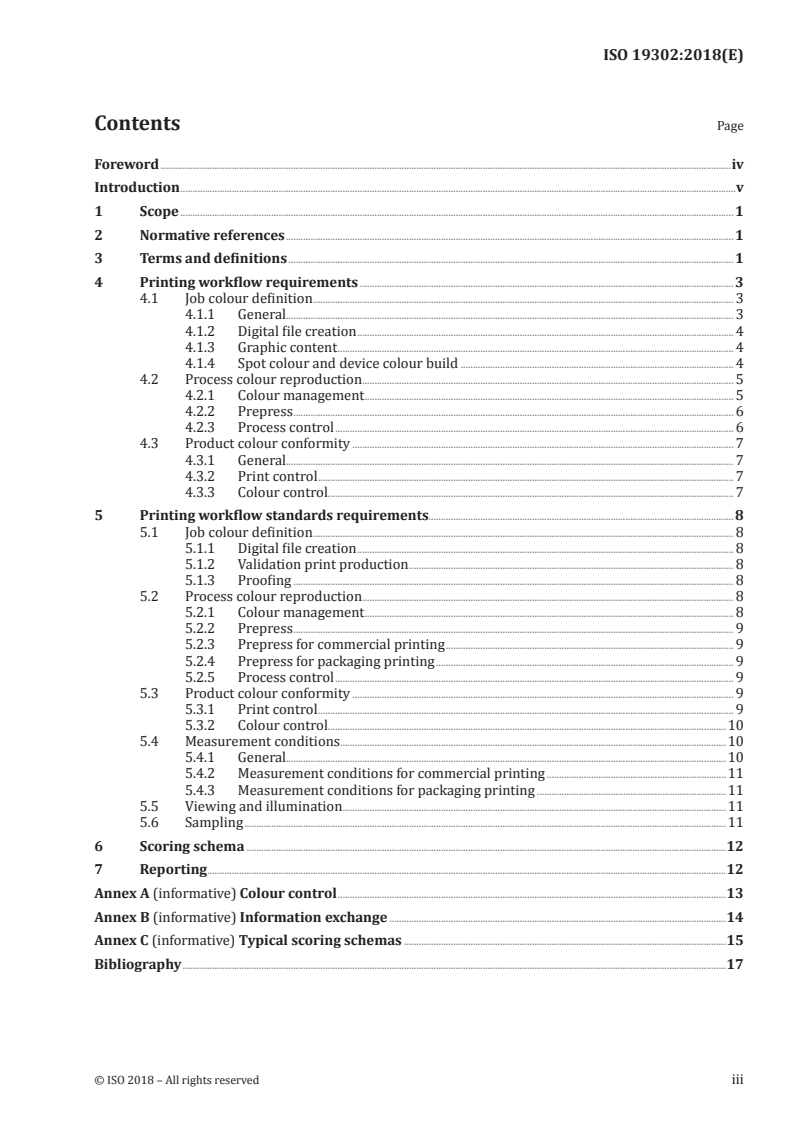

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Printing workflow requirements . 3

4.1 Job colour definition . 3

4.1.1 General. 3

4.1.2 Digital file creation . 4

4.1.3 Graphic content . 4

4.1.4 Spot colour and device colour build . 4

4.2 Process colour reproduction . 5

4.2.1 Colour management . 5

4.2.2 Prepress . 6

4.2.3 Process control . 6

4.3 Product colour conformity . 7

4.3.1 General. 7

4.3.2 Print control . 7

4.3.3 Colour control. 7

5 Printing workflow standards requirements. 8

5.1 Job colour definition . 8

5.1.1 Digital file creation . 8

5.1.2 Validation print production . 8

5.1.3 Proofing . 8

5.2 Process colour reproduction . 8

5.2.1 Colour management . 8

5.2.2 Prepress . 9

5.2.3 Prepress for commercial printing . 9

5.2.4 Prepress for packaging printing . 9

5.2.5 Process control . 9

5.3 Product colour conformity . 9

5.3.1 Print control . 9

5.3.2 Colour control.10

5.4 Measurement conditions . .10

5.4.1 General.10

5.4.2 Measurement conditions for commercial printing .11

5.4.3 Measurement conditions for packaging printing .11

5.5 Viewing and illumination .11

5.6 Sampling .11

6 Scoring schema .12

7 Reporting .12

Annex A (informative) Colour control .13

Annex B (informative) Information exchange .14

Annex C (informative) Typical scoring schemas .15

Bibliography .17

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso

.org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 130, Graphic technology.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

iv © ISO 2018 – All rights reserved

Introduction

The printing industry comprises a variety of workflows that produce a variety of printed products. For

tone and colour reproduction, many ISO standards specify aims and tolerances and they are necessary

for the implementation of a colour-managed and standardized workflow.

Even though relevant standards can specify aims and tolerances, the printer’s ability to demonstrate

conformity of their entire production workflow to these standards often becomes a technical issue as

well as a business issue.

Printed colour reproduction quality depends on printing workflow operation. Printing workflow

operation is made up of colour definition (what colour to specify), process colour reproduction

requirements (what to control) and colour conformity (verify the outcome of the process).

There is a need to provide printers, suppliers, customers and independent bodies with guidelines that

will allow them to implement and/or assess a printing workflow in order to achieve and demonstrate

conformity of printed products.

This document recognizes and makes provisions for the following:

a) conditions and test methods for file generation conformity;

b) conditions and test methods for file colour separation conformity;

c) conditions and test methods for spot colour and/or composite colour conformity;

d) conditions and test methods for soft proofing conformity;

e) conditions and test methods for hard proofing conformity;

f) conditions and test methods for viewing conditions conformity;

g) conditions and test methods for the evaluation of process, print and colour conformity with respect

to specified reference printing conditions (RPCs).

This document is applicable to all printing applications including CMYK, CMYK + spot, spot only, non-

CMYK-based processes and multicolour printing.

This document defines the three main production stages of a printed product as follows:

1) colour definition: the first stage where the customer and design services choose the desired brand

and visual colours;

2) colour reproduction: the production process which starts upon reception of the job file and ends

when the job is printed;

3) colour conformity: the stage which is necessary for the evaluation of the conformity of a printed job.

This document provides:

— a reference framework description for a typical standardized printing workflow (CMYK, CMYK

with spot, non CMYK, spot only and multicolour);

— required International Standards applicable at each stage of a standardized printing workflow;

— a description of expected setup, calibration and process control operations required at each stage of

printing workflow according to the appropriate International Standards;

— a definition of test conditions for colour conformity activities when these are not clearly mentioned

in the relevant standard.

INTERNATIONAL STANDARD ISO 19302:2018(E)

Graphic technology — Colour conformity of printing

workflows

1 Scope

This document defines the requirements of printing workflows and evaluation methods for their tone

and colour reproduction.

It applies to any printing process using any colourant, such as CMYK, CMYK with spot, non-CMYK, spot

only or multicolour.

This document refers and points to international or national standards and can be used to define,

evaluate and audit any printing workflow in whole or in part.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3664, Graphic technology and photography — Viewing conditions

ISO 12646, Graphic technology — Displays for colour proofing — Characteristics

ISO 12647 (all parts), Graphic technology — Process control for the production of halftone colour

separations, proof and production prints

ISO 13655, Graphic technology — Spectral measurement and colorimetric computation for graphic

arts images

ISO 14861, Graphic technology — Requirements for colour soft proofing systems

ISO 15930 (all parts), Graphic technology — Prepress digital data exchange using PDF

ISO 17972-4, Graphic technology — Colour data exchange format (CxF/X) — Part 4: Spot colour

characterisation data (CxF/X-4)

CIE 15, Colourimetry – Third edition

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1

actual printing condition

APC

printing condition of the actual printing device or printing process

3.2

colourant

physical substance such as ink or toner which is used alone or as part of a set of colourants in order to

produce a colour

3.3

comp

mock-up

proof formed to the shape of the final product indicating whether or not it is colour accurate

3.4

device colour build

colour destined to be printed using a process colourant combination

Note 1 to entry: It is typically used to define device-specific values that allow reproduction of a colour using only

process colourants.

3.5

preflight check

file inspection to determine that the digital data contained therein will process such that all data can be

accurately imaged to an image carrier or substrate

3.6

print buyer

person or organization that prepares job data and files in order to deliver them to a print service

provider

3.7

print service provider

person or company that receives job data and files for the purpose of printing them

3.8

printing condition

set of primary process parameters which describe the conditions associated with a specific printed

output and define spectrally or colourimetrically aim values

Note 1 to entry: Such parameters include printing process, substrate, colourant, colourant sequence and

screening. Aim values typically comprise colourants and tone reproduction curves description.

Note 2 to entry: For the purposes of colour management, a printing condition should be fully characterized

by giving the relationship between process input values (as stipulated in ISO 12642-2 for CMYK) and the

corresponding measured colourimetric values.

3.9

process colour

colour that is the outcome of a colour separation operation and that typically requires one or more

printing units and process colourants to be reproduced

3.10

process colourant

colourant that is used to print process colours

3.11

reference printing condition

RPC

aim printing condition for the job

2 © ISO 2018 – All rights reserved

3.12

metameric index

difference between spectral radiance distributions within the visible spectrum for two specimens with

identical tristimulus values for a given reference illuminant and reference observer

Note 1 to entry: The procedures concerned with a special metamerism index for a change from a reference

illuminant to a test illuminant of different spectral composition, or that for a change from a reference observer

to a test observer of different colour-matching functions, are called the determination of special metamerism

indices.

Note 2 to entry: Requirements for metameric index are specified in CIE 15.

Note 3 to entry: A measure of metamerism for the two specimens is the colour difference between the two

metameric specimens caused by substituting an illuminant, “special metamerism index: change in illuminant”,

and caused by substituting an observer, “special metamerism index: change in observer”. The colour difference is

evaluated using a CIE colour difference formula and it shall be clearly stated which formula has been used.

Note 4 to entry: It is recommended that for two specimens whose corresponding tristimulus values (X1 = X2,

Y1 = Y2, Z1 = Z2) are identical with respect to a reference illuminant and observer, the metamerism index, M, be

set equal to the colour difference ∆E*ab between the two specimens computed for the test illuminant or for the

test observer.

2 2 2

MI =ΔLL**−Δ +Δaa**−Δ +Δbb**−Δ

() () ()

12 12 12

3.13

spot colour

colour typically used for the definition of brand colours or special design effects that is usually chosen

with the intent of being printed using one printing unit and one spot colourant and that is usually not

blended with other colourants

3.14

spot colourant

colourant that is primarily used to print a spot colour even if it can replace or be blended with process

colourants to obtain a specific colour gamut or colour reproduction

3.15

substrate-corrected colourimetric aim

SCCA

colour data that are corrected in order to compensate for the colourimetric difference between

reference substrate and production substrate colours, assuming that the primary difference between

them lies in the colour of the substrates

3.16

system qualification

assessment operation used to qualify the ability of a print device or a printing process to reproduce a

defined colour data set

Note 1 to entry: This qualification, also named “extended scrutiny”, cannot usually be performed by print

providers during production as it requires specific testing conditions and protocols.

4 Printing workflow requirements

4.1 Job colour definition

4.1.1 General

As illustrated in Figure 1, colour definition is the first step of a printing workflow. This is where a brand

owner or a designer chooses the desired spot and visual colours for the printed product.

Figure 1 — Universal printing workflow — Job colour definition

4.1.2 Digital file creation

File format shall be mutually agreed between provider and receiver. The print service provider should

provide its customers with a detailed specification detailing the technical properties of the digital files

to be received (e.g. format, resolution, metadata, colour definition). If no agreement is present then files

shall be prepared in conformity with the ISO 15930 series.

4.1.3 Graphic content

Print buyer specifications shall be clearly defined and mutually agreed on with the print service

provider in terms of:

— reference printing condition (RPC);

— conformity (process, print, colour conformity, criteria, aims and tolerances).

4.1.4 Spot colour and device colour build

4.1.4.1 General

Spot colour definition is important because it is often associated with a brand or product identification.

A specific colour can also be defined as a device colour build made of process colourant composite.

4.1.4.2 Spot and

...

INTERNATIONAL ISO

STANDARD 19302

First edition

2018-12

Graphic technology — Colour

conformity of printing workflows

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Printing workflow requirements . 3

4.1 Job colour definition . 3

4.1.1 General. 3

4.1.2 Digital file creation . 4

4.1.3 Graphic content . 4

4.1.4 Spot colour and device colour build . 4

4.2 Process colour reproduction . 5

4.2.1 Colour management . 5

4.2.2 Prepress . 6

4.2.3 Process control . 6

4.3 Product colour conformity . 7

4.3.1 General. 7

4.3.2 Print control . 7

4.3.3 Colour control. 7

5 Printing workflow standards requirements. 8

5.1 Job colour definition . 8

5.1.1 Digital file creation . 8

5.1.2 Validation print production . 8

5.1.3 Proofing . 8

5.2 Process colour reproduction . 8

5.2.1 Colour management . 8

5.2.2 Prepress . 9

5.2.3 Prepress for commercial printing . 9

5.2.4 Prepress for packaging printing . 9

5.2.5 Process control . 9

5.3 Product colour conformity . 9

5.3.1 Print control . 9

5.3.2 Colour control.10

5.4 Measurement conditions . .10

5.4.1 General.10

5.4.2 Measurement conditions for commercial printing .11

5.4.3 Measurement conditions for packaging printing .11

5.5 Viewing and illumination .11

5.6 Sampling .11

6 Scoring schema .12

7 Reporting .12

Annex A (informative) Colour control .13

Annex B (informative) Information exchange .14

Annex C (informative) Typical scoring schemas .15

Bibliography .17

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso

.org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 130, Graphic technology.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

iv © ISO 2018 – All rights reserved

Introduction

The printing industry comprises a variety of workflows that produce a variety of printed products. For

tone and colour reproduction, many ISO standards specify aims and tolerances and they are necessary

for the implementation of a colour-managed and standardized workflow.

Even though relevant standards can specify aims and tolerances, the printer’s ability to demonstrate

conformity of their entire production workflow to these standards often becomes a technical issue as

well as a business issue.

Printed colour reproduction quality depends on printing workflow operation. Printing workflow

operation is made up of colour definition (what colour to specify), process colour reproduction

requirements (what to control) and colour conformity (verify the outcome of the process).

There is a need to provide printers, suppliers, customers and independent bodies with guidelines that

will allow them to implement and/or assess a printing workflow in order to achieve and demonstrate

conformity of printed products.

This document recognizes and makes provisions for the following:

a) conditions and test methods for file generation conformity;

b) conditions and test methods for file colour separation conformity;

c) conditions and test methods for spot colour and/or composite colour conformity;

d) conditions and test methods for soft proofing conformity;

e) conditions and test methods for hard proofing conformity;

f) conditions and test methods for viewing conditions conformity;

g) conditions and test methods for the evaluation of process, print and colour conformity with respect

to specified reference printing conditions (RPCs).

This document is applicable to all printing applications including CMYK, CMYK + spot, spot only, non-

CMYK-based processes and multicolour printing.

This document defines the three main production stages of a printed product as follows:

1) colour definition: the first stage where the customer and design services choose the desired brand

and visual colours;

2) colour reproduction: the production process which starts upon reception of the job file and ends

when the job is printed;

3) colour conformity: the stage which is necessary for the evaluation of the conformity of a printed job.

This document provides:

— a reference framework description for a typical standardized printing workflow (CMYK, CMYK

with spot, non CMYK, spot only and multicolour);

— required International Standards applicable at each stage of a standardized printing workflow;

— a description of expected setup, calibration and process control operations required at each stage of

printing workflow according to the appropriate International Standards;

— a definition of test conditions for colour conformity activities when these are not clearly mentioned

in the relevant standard.

INTERNATIONAL STANDARD ISO 19302:2018(E)

Graphic technology — Colour conformity of printing

workflows

1 Scope

This document defines the requirements of printing workflows and evaluation methods for their tone

and colour reproduction.

It applies to any printing process using any colourant, such as CMYK, CMYK with spot, non-CMYK, spot

only or multicolour.

This document refers and points to international or national standards and can be used to define,

evaluate and audit any printing workflow in whole or in part.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3664, Graphic technology and photography — Viewing conditions

ISO 12646, Graphic technology — Displays for colour proofing — Characteristics

ISO 12647 (all parts), Graphic technology — Process control for the production of halftone colour

separations, proof and production prints

ISO 13655, Graphic technology — Spectral measurement and colorimetric computation for graphic

arts images

ISO 14861, Graphic technology — Requirements for colour soft proofing systems

ISO 15930 (all parts), Graphic technology — Prepress digital data exchange using PDF

ISO 17972-4, Graphic technology — Colour data exchange format (CxF/X) — Part 4: Spot colour

characterisation data (CxF/X-4)

CIE 15, Colourimetry – Third edition

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1

actual printing condition

APC

printing condition of the actual printing device or printing process

3.2

colourant

physical substance such as ink or toner which is used alone or as part of a set of colourants in order to

produce a colour

3.3

comp

mock-up

proof formed to the shape of the final product indicating whether or not it is colour accurate

3.4

device colour build

colour destined to be printed using a process colourant combination

Note 1 to entry: It is typically used to define device-specific values that allow reproduction of a colour using only

process colourants.

3.5

preflight check

file inspection to determine that the digital data contained therein will process such that all data can be

accurately imaged to an image carrier or substrate

3.6

print buyer

person or organization that prepares job data and files in order to deliver them to a print service

provider

3.7

print service provider

person or company that receives job data and files for the purpose of printing them

3.8

printing condition

set of primary process parameters which describe the conditions associated with a specific printed

output and define spectrally or colourimetrically aim values

Note 1 to entry: Such parameters include printing process, substrate, colourant, colourant sequence and

screening. Aim values typically comprise colourants and tone reproduction curves description.

Note 2 to entry: For the purposes of colour management, a printing condition should be fully characterized

by giving the relationship between process input values (as stipulated in ISO 12642-2 for CMYK) and the

corresponding measured colourimetric values.

3.9

process colour

colour that is the outcome of a colour separation operation and that typically requires one or more

printing units and process colourants to be reproduced

3.10

process colourant

colourant that is used to print process colours

3.11

reference printing condition

RPC

aim printing condition for the job

2 © ISO 2018 – All rights reserved

3.12

metameric index

difference between spectral radiance distributions within the visible spectrum for two specimens with

identical tristimulus values for a given reference illuminant and reference observer

Note 1 to entry: The procedures concerned with a special metamerism index for a change from a reference

illuminant to a test illuminant of different spectral composition, or that for a change from a reference observer

to a test observer of different colour-matching functions, are called the determination of special metamerism

indices.

Note 2 to entry: Requirements for metameric index are specified in CIE 15.

Note 3 to entry: A measure of metamerism for the two specimens is the colour difference between the two

metameric specimens caused by substituting an illuminant, “special metamerism index: change in illuminant”,

and caused by substituting an observer, “special metamerism index: change in observer”. The colour difference is

evaluated using a CIE colour difference formula and it shall be clearly stated which formula has been used.

Note 4 to entry: It is recommended that for two specimens whose corresponding tristimulus values (X1 = X2,

Y1 = Y2, Z1 = Z2) are identical with respect to a reference illuminant and observer, the metamerism index, M, be

set equal to the colour difference ∆E*ab between the two specimens computed for the test illuminant or for the

test observer.

2 2 2

MI =ΔLL**−Δ +Δaa**−Δ +Δbb**−Δ

() () ()

12 12 12

3.13

spot colour

colour typically used for the definition of brand colours or special design effects that is usually chosen

with the intent of being printed using one printing unit and one spot colourant and that is usually not

blended with other colourants

3.14

spot colourant

colourant that is primarily used to print a spot colour even if it can replace or be blended with process

colourants to obtain a specific colour gamut or colour reproduction

3.15

substrate-corrected colourimetric aim

SCCA

colour data that are corrected in order to compensate for the colourimetric difference between

reference substrate and production substrate colours, assuming that the primary difference between

them lies in the colour of the substrates

3.16

system qualification

assessment operation used to qualify the ability of a print device or a printing process to reproduce a

defined colour data set

Note 1 to entry: This qualification, also named “extended scrutiny”, cannot usually be performed by print

providers during production as it requires specific testing conditions and protocols.

4 Printing workflow requirements

4.1 Job colour definition

4.1.1 General

As illustrated in Figure 1, colour definition is the first step of a printing workflow. This is where a brand

owner or a designer chooses the desired spot and visual colours for the printed product.

Figure 1 — Universal printing workflow — Job colour definition

4.1.2 Digital file creation

File format shall be mutually agreed between provider and receiver. The print service provider should

provide its customers with a detailed specification detailing the technical properties of the digital files

to be received (e.g. format, resolution, metadata, colour definition). If no agreement is present then files

shall be prepared in conformity with the ISO 15930 series.

4.1.3 Graphic content

Print buyer specifications shall be clearly defined and mutually agreed on with the print service

provider in terms of:

— reference printing condition (RPC);

— conformity (process, print, colour conformity, criteria, aims and tolerances).

4.1.4 Spot colour and device colour build

4.1.4.1 General

Spot colour definition is important because it is often associated with a brand or product identification.

A specific colour can also be defined as a device colour build made of process colourant composite.

4.1.4.2 Spot and device colour for commercial printing

In commercial applications, spot colours shall be defined by colourimetric values (CIELAB, CIELCh) and

should be defined by spectral values.

4.1.4.3 Spot and device colour for packaging printing

In packaging applications spot colours shall be defined by their spectral response curves.

4 © ISO 2018 – All rights reserved

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...