SIST EN 12373-1:2002

(Main)Aluminium and aluminium alloys - Anodizing - Part 1: Method for specifying decorative and protective anodic oxidation coatings on aluminium

Aluminium and aluminium alloys - Anodizing - Part 1: Method for specifying decorative and protective anodic oxidation coatings on aluminium

This Part of this European Standard describes a method for specifying decorative and protective anodic oxidation coatings on aluminium. It is applicable to the specification of coatings mainly of aluminium oxide, which are formed on aluminium by an electrolytic oxidation process in which the aluminium acts as the anode.

Aluminium und Aluminiumlegierungen - Anodisieren - Teil 1: Methode zur Spezifizierung dekorativer und schützender anodisch erzeugter Oxidschichten auf Aluminium

Anwendungsbereich

Dieser Teil dieser Europäischen Norm beschreibt eine Methode zur Spezifizierung dekorativer und

schützender anodisch erzeugter Oxidschichten auf Aluminium.

Er gilt für die Spezifizierung von Schichten, hauptsächlich aus Aluminiumoxid, die auf Aluminium durch

einen elektrolytischen Oxidationsprozess erzeugt werden, in dem das Aluminium als Anode geschaltet

wird.

Er gilt nicht zur Spezifizierung von:

a) porenfreien Oxidschichten, die als Sperrschicht wirken;

b) Schichten, die durch Anodisieren mit Chrom- oder Phosphorsäure erzeugt wurden;

c) Oxidschichten, die lediglich dazu vorgesehen sind, das Grundmetall für die nachfolgende Aufbrin-

gung organischer Schichten oder die elektrolytische Abscheidung von Metallen vorzubereiten;

d) ¿ hartanodisierte " Schichten, die überwiegend für technische Zwecke verwendet werden, für die Abrieb

und Verschleißfestigkeit die primären Eigenschaften sind (siehe ISO 10074).

WARNHINWEIS Diese Norm ist für Kunden gedacht, die die Anodisierung eines Erzeugnisses fordern, und

umfasst eine Checkliste von Eigenschaften, die möglicherweise relevant oder nichtrelevant sein können. Sie

enthält Anforderungen, die zwischen den interessierten Parteien zu vereinbaren sind und wird als eine

Methode zur Spezifizierung und nicht als Spezifikation vorgelegt. Es kann nicht gefordert werden, dass eine

anodisch erzeugte Oxidschicht mit dieser Norm übereinstimmt.

Aluminium et alliages d'aluminium - Anodisation - Partie 1: Méthode de spécification des caractéristiques des revetements décoratifs et protecteurs obtenus par oxydation anodique sur aluminium

Domaine d'application

Cette partie de la présente Norme européenne décrit une méthode de spécification des revêtements décoratifs et protecteurs obtenus par oxydation anodique sur aluminium.

Elle s'applique à la spécification des revêtements d'oxyde d'aluminium principalement, qui sont formés sur l'aluminium par un procédé d'oxydation électrolytique, dans lequel l'aluminium agit comme l'anode.

La présente Norme européenne ne s'applique pas :

a) aux revêtements d'oxyde non poreux, de type couche de barrière ;

b) aux revêtements obtenus par anodisation à l'acide chromique ou acide phosphorique ;

c) aux revêtements d'oxyde destinés uniquement à la préparation du substrat pour application ultérieure de revêtements organiques pour dépôt électrolytiques de métaux ;

d) aux revêtements « anodisés durs », utilisés principalement dans des applications techniques, pour lesquels la résistance à l'abrasion et à l'usure sont les principales caractéristiques (voir ISO 10074).

AVERTISSEMENT La présente Norme européenne est destinée à un acheteur qui demande un produit anodisé, et elle donne une liste de contrôle des propriétés qui sont ou non pertinentes. Elle contient des prescriptions à convenir entre les parties intéressées ; elle est présentée comme méthode de spécification et non comme spécification ; elle n'est pas appropriée par conséquent de prétendre qu'un revêtement par oxydation anodique réponde à la présente Norme européenne.

Aluminij in aluminijeve zlitine - Anodizacija - 1. del: Metoda za opis dekorativne in zaščitne anodizirane plasti na aluminiju

General Information

- Status

- Withdrawn

- Publication Date

- 31-Jan-2002

- Withdrawal Date

- 13-Jul-2010

- Technical Committee

- INEK - Nonferrous metals

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 13-Jul-2010

- Due Date

- 05-Aug-2010

- Completion Date

- 14-Jul-2010

Relations

- Effective Date

- 01-Sep-2010

Frequently Asked Questions

SIST EN 12373-1:2002 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Aluminium and aluminium alloys - Anodizing - Part 1: Method for specifying decorative and protective anodic oxidation coatings on aluminium". This standard covers: This Part of this European Standard describes a method for specifying decorative and protective anodic oxidation coatings on aluminium. It is applicable to the specification of coatings mainly of aluminium oxide, which are formed on aluminium by an electrolytic oxidation process in which the aluminium acts as the anode.

This Part of this European Standard describes a method for specifying decorative and protective anodic oxidation coatings on aluminium. It is applicable to the specification of coatings mainly of aluminium oxide, which are formed on aluminium by an electrolytic oxidation process in which the aluminium acts as the anode.

SIST EN 12373-1:2002 is classified under the following ICS (International Classification for Standards) categories: 25.220.20 - Surface treatment; 77.120.10 - Aluminium and aluminium alloys. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 12373-1:2002 has the following relationships with other standards: It is inter standard links to SIST EN ISO 7599:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 12373-1:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Aluminium und Aluminiumlegierungen - Anodisieren - Teil 1: Methode zur Spezifizierung dekorativer und schützender anodisch erzeugter Oxidschichten auf AluminiumAluminium et alliages d'aluminium - Anodisation - Partie 1: Méthode de spécification des caractéristiques des revetements décoratifs et protecteurs obtenus par oxydation anodique sur aluminiumAluminium and aluminium alloys - Anodizing - Part 1: Method for specifying decorative and protective anodic oxidation coatings on aluminium77.120.10Aluminij in aluminijeve zlitineAluminium and aluminium alloys25.220.20Površinska obdelavaSurface treatmentICS:Ta slovenski standard je istoveten z:EN 12373-1:2001SIST EN 12373-1:2002en01-februar-2002SIST EN 12373-1:2002SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12373-1May 2001ICS 25.220.20; 77.120.10English versionAluminium and aluminium alloys - Anodizing - Part 1: Method forspecifying decorative and protective anodic oxidation coatingson aluminiumAluminium et alliages d'aluminium - Anodisation - Partie 1:Méthode de spécification des caractéristiques desrevêtements décoratifs et protecteurs obtenus paroxydation anodique sur aluminiumAluminium und Aluminiumlegierungen - Anodisieren - Teil1: Methode zur Spezifizierung dekorativer und schützenderanodisch erzeugter Oxidschichten auf AluminiumThis European Standard was approved by CEN on 20 April 2001.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2001 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12373-1:2001 ESIST EN 12373-1:2002

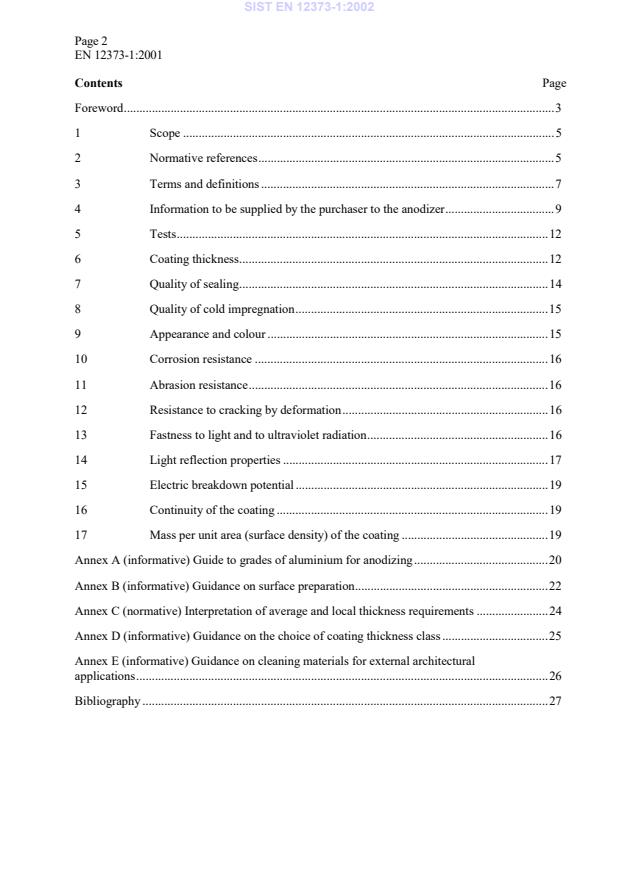

Page 2EN 12373-1:2001ContentsPageForeword.31Scope.52Normative references.53Terms and definitions.74Information to be supplied by the purchaser to the anodizer.95Tests.126Coating thickness.127Quality of sealing.148Quality of cold impregnation.159Appearance and colour.1510Corrosion resistance.1611Abrasion resistance.1612Resistance to cracking by deformation.1613Fastness to light and to ultraviolet radiation.1614Light reflection properties.1715Electric breakdown potential.1916Continuity of the coating.1917Mass per unit area (surface density) of the coating.19Annex A (informative) Guide to grades of aluminium for anodizing.20Annex B (informative) Guidance on surface preparation.22Annex C (normative) Interpretation of average and local thickness requirements.24Annex D (informative) Guidance on the choice of coating thickness class.25Annex E (informative) Guidance on cleaning materials for external architecturalapplications.26Bibliography.27SIST EN 12373-1:2002

Page 3EN 12373-1:2001ForewordThis European Standard has been prepared by Technical Committee CEN/TC 132 “Aluminium andaluminium alloys”, the secretariat of which is held by AFNOR.This European Standard shall be given the status of a national standard, either by publication of anidentical text or by endorsement, at the latest by November 2001, and conflicting nationalstandards shall be withdrawn at the latest by November 2001.In this standard, annex C is normative and annexes A, B, D and E are informative.EN 12373, Aluminium and aluminium alloys – Anodizing, comprises the following parts:Part 1:Method for specifying decorative and protective anodic oxidation coatings onaluminiumPart 2:Determination of mass per unit area (surface density) of anodic oxidationcoatings – Gravimetric methodPart 3:Determination of thickness of anodic oxidation coatings – Non-destructivemeasurement by split beam microscopePart 4:Estimation of loss of absorptive power of anodic oxidation coatings aftersealing by dye spot test with prior acid treatmentPart 5:Assessment of quality of sealed anodic oxidation coatings by measurement ofadmittancePart 6:Assessment of quality of sealed anodic oxidation coatings by measurement of theloss of mass after immersion in phosphoric acid/chromic acid solution withoutprior acid treatmentPart 7:Assessment of quality of sealed anodic oxidation coatings by measurement of theloss of mass after immersion in phosphoric acid/chromic acid solution with prioracid treatmentPart 8:Determination of the comparative fastness to ultra-violet light and heat ofcoloured anodic oxidation coatingsPart 9:Measurement of wear resistance and wear index of anodic oxidation coatingsusing an abrasive wheel wear test apparatusPart 10:Measurement of mean specific abrasion resistance of anodic oxidation coatingsusing an abrasive jet test apparatusPart 11:Measurement of specular reflectance and specular gloss of anodic oxidationcoatings at angles of 20, 45, 60 or 85Part 12:Measurement of reflectance characteristics of aluminium surfaces usingintegrating-sphere instrumentsPart 13:Measurement of reflectivity characteristics of aluminium surfaces using agoniophotometer or an abridged goniophotometerPart 14:Visual determination of image clarity of anodic oxidation coatings – Chart scalemethodPart 15:Assessment of resistance of anodic oxidation coatings to cracking by deformationSIST EN 12373-1:2002

Page 4EN 12373-1:2001Part 16:Check for continuity of thin anodic oxidation coatings – Copper sulfate testPart 17:Determination of electric breakdown potentialPart 18:Rating system for the evaluation of pitting corrosion – Chart methodPart 19:Rating system for the evaluation of pitting corrosion – Grid methodAccording to the CEN/CENELEC Internal Regulations, the national standards organizations ofthe following countries are bound to implement this European Standard: Austria, Belgium, CzechRepublic, Denmark, Finland, France, Germany, Greece, Iceland, Ireland, Italy, Luxembourg,Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and the United Kingdom.SIST EN 12373-1:2002

Page 5EN 12373-1:20011ScopeThis part of this European Standard describes a method for specifying decorative and protectiveanodic oxidation coatings on aluminium.It is applicable to the specification of coatings, mainly of aluminium oxide, which are formed onaluminium by an electrolytic oxidation process in which the aluminium acts as the anode.It is not applicable to the specification of:a) non-porous oxide coatings of the barrier layer type;b) coatings produced by chromic acid or phosphoric acid anodizing;c) oxide coatings intended merely to prepare the substrate for subsequent application oforganic coatings or electrodeposition of metals;d) “hard anodized” coatings, used mainly for engineering purposes, for which abrasion andwear resistance are the primary characteristics (see ISO 10074).WARNING

This standard is intended for use by purchasers requiring a product to be anodized andprovides a checklist of properties which might or might not be relevant. It contains requirements tobe agreed between the interested parties and is presented as a method for specifying and not as aspecification; it is therefore not appropriate to claim that an anodic oxidation coating conforms tothis standard.2Normative referencesThis European Standard incorporates, by dated or undated reference, provisions from otherpublications. These normative references are cited at the appropriate places in the text and thepublications are listed hereafter. For dated references, subsequent amendments to, or revisions of,any of these publications apply to this European Standard only when incorporated in it byamendment or revision. For undated references, the latest edition of the publication referred toapplies (including amendments).EN 12373-2Aluminium and aluminium alloys — Anodizing — Part 2:Determination of mass per unit area (surface density) of anodicoxidation coatings — Gravimetric methodEN 12373-3Aluminium and aluminium alloys — Anodizing — Part 3:Determination of thickness of anodic oxidation coatings — Non-destructive measurement by split beam microscopeEN 12373-4Aluminium and aluminium alloys — Anodizing – Part 4:

Estimation of loss of absorptive power of anodic oxidation coatingsafter sealing by dye spot test with prior acid treatmentEN 12373-5Aluminium and aluminium alloys — Anodizing – Part 5:

Assessment of quality of sealed anodic oxidation coatings bymeasurement of admittanceSIST EN 12373-1:2002

Page 6EN 12373-1:2001EN 12373-6Aluminium and aluminium alloys — Anodizing – Part 6:

Assessment of quality of sealed anodic oxidation coatings bymeasurement of the loss of mass after immersion in phosphoricacid/chromic acid solution without prior acid treatmentEN 12373-7Aluminium and aluminium alloys — Anodizing — Part 7: Assessmentof quality of sealed anodic oxidation coatings by measurement of theloss in mass after immersion in phosphoric acid/chromic acid solutionwith prior acid treatmentEN 12373-8Aluminium and aluminium alloys – Anodizing – Part 8: Determinationof the comparative fastness to ultra-violet light and heat of colouredanodic oxidation coatingsEN 12373-9Aluminium and aluminium alloys — Anodizing — Part 9:Measurement of wear resistance and wear index of anodic oxidationcoatings using an abrasive wheel wear test apparatusEN 12373-10Aluminium and aluminium alloys — Anodizing — Part 10:Measurement of mean specific abrasion resistance of anodic oxidationcoatings using an abrasive jet test apparatusEN 12373-11Aluminium and aluminium alloys – Anodizing – Measurement ofspecular reflectance and specular gloss of anodic oxidation coatings atangles of 20, 45, 60 or 85EN 12373-12Aluminium and aluminium alloys – Anodizing – Measurement ofreflectance characteristics of aluminium surfaces using integrating-sphere instrumentsEN 12373-13Aluminium and aluminium alloys – Anodizing – Measurement ofreflectivity characteristics of aluminium surfaces using agoniophotometer or an abridged goniophotometerEN 12373-14Aluminium and aluminium alloys – Anodizing – Visual determinationof image clarity of anodic oxidation coatings –Chart scale methodEN 12373-15Aluminium and aluminium alloys — Anodizing — Part 15:Assessment of resistance of anodic oxidation coatings to cracking bydeformationEN 12373-16:2001Aluminium and aluminium alloys — Anodizing — Part 16: Check forcontinuity of thin anodic oxidation coatings — Copper sulfate testEN 12373-17:2001Aluminium and aluminium alloys — Anodizing — Part 17:Determination of electric breakdown potentialEN ISO 1463 Metallic and oxide coatings — Measurement of coating thickness —Microscopical method (ISO 1463:1982)EN ISO 2360 Non-conductive coatings on non-magnetic basis metals — Measurementof coating thickness — Eddy current method (ISO 2360:1982)NOTE

Informative references to documents used in the preparation of this standard, and cited at theappropriate places in the text, are listed in the bibliography.SIST EN 12373-1:2002

Page 7EN 12373-1:20013Terms and definitionsFor the purposes of this European Standard the following terms and definitions apply.NOTE

Definitions identified by an asterisk are taken from EN ISO 2064.3.1aluminiumaluminium and aluminium-based alloys3.2anodized aluminiumaluminium with an anodic coating, produced by an electrolytic oxidation process in which thesurface of the aluminium is converted to a mainly oxide coating having protective, decorative orfunctional properties3.3clear anodized aluminiumanodized aluminium with a substantially colourless, translucent anodic oxidation coating3.4colour anodized aluminiumanodized aluminium coloured either during anodizing or by subsequent colouring processes3.5integral colour anodized aluminiumanodized aluminium that has been anodized using an appropriate (usually organic acid based)electrolyte which produces a coloured coating during the anodizing process itself3.6electrolytically coloured anodized aluminiumanodized aluminium with an anodic oxidation coating that has been coloured by the electrolyticdeposition of a metal or metal oxide into the pore structure3.7dyed anodized aluminiumanodized aluminium with an anodic oxidation coating coloured by absorption of dye-stuff orpigments into the pore structure3.8combination colour anodized aluminiumanodized aluminium with an anodic oxidation coating that has been coloured by electrolyticcolouring, or produced by integral colour anodizing, followed by absorption dyeing3.9interference colour anodized aluminiumanodized aluminium with an anodic oxidation coating coloured by means of optical interferenceeffectsSIST EN 12373-1:2002

Page 8EN 12373-1:20013.10bright anodized aluminiumanodized aluminium with a high specular reflectance as the primary characteristic3.11protective anodizinganodizing where protection against corrosion or wear is the primary characteristic and appearance isof secondary or no importance3.12decorative anodizinganodizing where a decorative finish with a uniform or aesthetically pleasing appearance is theprimary characteristic3.13sealingtreatment of anodic oxidation coatings on aluminium to reduce porosity and the absorption capacityof the coating by hydrothermal processes carried out after anodizing3.14cold impregnationcold sealingtreatment of anodic oxidation coatings on aluminium to plug the pores and reduce the absorptioncapacity of the coating by chemical processes carried out at low temperatures after anodizing3.15significant surface*part of the article covered or to be covered by the coating and for which the coating is essential forserviceability and/or appearance3.16measuring areaarea of the significant surface over which a single measurement is madeNOTE

The measuring area is the point at which a single measurement is made for the microscopical method,and is the probe area, or area influencing the reading, for non-destructive methods.3.17reference area*area within which a specified number of single measurements is required to be made3.18local thickness*mean of the thickness measurements of which a specified number is made within a reference area3.19minimum local thickness*lowest value of the local thickness found on the significant surface of a single articleSIST EN 12373-1:2002

Page 9EN 12373-1:20013.20maximum local thickness*highest value of the local thickness found on the significant surface of a single article3.21average thicknessmean value of a specified number of local thickness measurements that are evenly distributed overthe significant surface of a single anodized piece4Information to be supplied by the purchaser to the anodizer4.1 GeneralInformation which the anodizer requires from the purchaser in order to anodize the product correctlyis given in 4.2 and 4.3; 4.2 specifies information that is essential whenever a product is to beanodized, and 4.3 identifies additional information which will be required for particular productapplications. A summary of the subclause references relating to this information is given in table 1.NOTE

Certain properties (for example high specular reflectance) are only obtainable by the use of specialalloys, and some properties can be incompatible with others.4.2 Essential informationThe following information shall be supplied by the purchaser to the anodizer, if necessary inconsultation with the aluminium supplier and/or anodizer:a) reference to this European Standard;b) the intended service use of the article to be anodized;c) the specification of the aluminium to be anodized;NOTE 1

Guidance on the choice of aluminium is given in annex A.d) an indication of the significant surface(s) of the article to be anodized;NOTE 2

Significant surfaces are indicated preferably by drawings or by suitably marked samples; in somecases, there can be different requirements for the finish on different parts of the significant surface(s).e) the surface preparation to be used on the aluminium before anodizing;NOTE 3

The surface preparation is indicated preferably by agreed samples; guidance on surface preparationis given in annex B.f) the anodic oxidation coating thickness required;g) whether a clear or coloured anodized finish is required;SIST EN 12373-1:2002

Page 10EN 12373-1:2001h) whether the product is to be hydrothermally sealed, cold impregnated or left unsealed.4.3 Additional informationAdditional information will be required for certain applications, and, if so, this shall be specified bythe purchaser, if necessary in consultation with the anodizer:a) the type of anodizing and the colouring process to be used;b) details of any formal sampling plans required;c) the preferred position and maximum size of contact marks;d) any limits of variation of final surface finish on the significant surface(s);NOTE 1

Acceptable limits of variation of final surface finish are identified preferably by agreed limitsamples.e) the colour of the anodized article(s) and maximum limits of colour variation;NOTE 2

Acceptable maximum limits of colour variation are identified preferably by agreed limit samples.f) any requirements for corrosion resistance and the method of test to be used;g) any requirements for abrasion resistance, the property to be tested and the measurementsrequired (i.e. wear index, mass wear index, mean specific abrasion resistance, relative meanspecific abrasion resistance) and the method of test to be used;h) any requirements for resistance to cracking by deformation;i) any requirements for fastness to ultraviolet radiation of coloured anodic oxidationcoatings;j) any requirements for light reflection properties, i.e. total reflectance, specular reflectance,specular gloss, diffuse reflectance and image clarity;k) any requirements for electric breakdown potential;l) any requirements for the continuity of the anodic oxidation coating;m) any requirements for the mass per unit area (surface density) of the coating.SIST EN 12373-1:2002

Page 11EN 12373-1:2001Table 1 — Summary of information requiredInformation requiredSubclause referenceOther relatedclauses/annexesEssentialinformationAdditionalinformationReference to this European Standard4.2 a)Intended service use4.2 b)Aluminium specification4.2 c)annex ASignificant surface(s)4.2 d)Surface preparation before anodizing4.2 e)annex BAnodic oxidation coating thickness4.2 f)clause 6; annex DClear or colour anodized finish4.2 g)Sealing or cold impregnation4.2 h)clauses 7 and 8Type of anodizing and/or colouring process4.3 a)Sampling plan4.3 b)clause 5Position and maximum size of contact marks4.3 c)Limits of variation of final surface finish onsignificant surfaces4.3 d)clause 9; annex BColour of anodized articles and maximum limits ofcolour variation4.3 e)clause 9Requirements for corrosion resistance4.3 f)clause 10Requirements

for abrasion resistance4.3 g)clause 11Requirements

for resistance to cracking bydeformation4.3 h)clause 12Requirements

for fastness to ultra-violet light4.3 i)clause 13Requirements

for light reflection properties4.3 j)clause 14Requirements for electric breakdown potential4.3 k)clause 15Requirements for continuity4.3 l)clause 16Requirements for mass per unit area (surfacedensity)4.3 m)clause 17SIST EN 12373-1:2002

Page 12EN 12373-1:20015Tests5.1 Sampling proceduresWhere appropriate, sampling procedures shall be specified by the purchaser. Guidance on thechoice of suitable sampling procedures is given in ISO 2859-1.NOTE

As an example, the Qualanod specification [1] provides an indication of a suitable samplingprocedure for external architectural finishes.5.2 Test piecesWherever practicable, test pieces shall be production components. However, if by agreementspecial test pieces are prepared for convenience in reference or acceptance tests, they shall beproduced in the same way as the production components.5.3 Acceptance testsAcceptance tests shall be specified by the purchaser.5.4 Reference testsIn cases of dispute, the appropriate reference tests specified in this European Standard shall beused.5.5 Production control testsTests for production control purposes are at the discretion of the anodizer.6Coating thickness6.1 GeneralAnodic oxidation coatings are designated by their thickness class, in micrometres; the requiredthickness of a coating is of the utmost importance and shall always be specified.6.2 ClassificationAnodic oxidation coatings are graded according to the minimum allowed value of the averagethickness (minimum average thickness) in micrometres. Typical thickness classes are given inTable 2 and guidance on the use of appropriate thickness classes is given in annex D.For anodic oxidation coatings designed to impart particular surface properties, a higher averagethickness can be selected, and additional intermediate values of average thickness can be specifiedif necessary, but in no case shall the minimum local thickness on a single piece be less than 80 %of the minimum average thickness.SIST EN 12373-1:2002

Page 13EN 12373-1:2001NOTE

With the higher thickness classes (20 µm to 25 µm) used in architectural applications, care shouldbe taken to avoid excessively thick films as they can give unsatisfactory weathering performance.Table 2 — Anodic oxidation coating thickness classesMinimum average thicknessMinimum local thicknessClassµmµm55410108151512202016252520The interpretation of average and local thickness requirements on a piece being tested shall bein accordance with annex C.6.3 Measurement of coating thicknessCoating thickness measurements shall be carried out by one or more of the following methods:a) microscopical examination of cross-section in accordance with EN ISO 1463;b) eddy current method in accordance with EN ISO 2360;c) split beam microscope method in accordance with EN 12373-3.In cases of dispute, method a) shall be the reference method for coatings of thickness 5 µm andgreater. For coatings of thickness less than 5 µm, the microscopical method cannot normally beused and a minimum mass of coating per unit area, measured by the gravimetric method (seecl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...