SIST EN 13173:2003

(Main)Cathodic protection for steel offshore floating structures

Cathodic protection for steel offshore floating structures

This EN defines the means to be used to cathodically protect the submerged metallic surfaces of steel offshore floating structures and appurtenances in sea water and saline mud.

Kathodischer Korrosionsschutz für schwimmende Offshore-Anlagen aus Stahl

Diese Europäische Norm definiert die Mittel, die für den kathodischen Korrosionsschutz der eingetauchten metallischen Oberflächen von schwimmenden Offshore-Anlagen aus Stahl und Anlagenzubehör in Meerwasser und salzhaltigem Schlick einzusetzen sind.

Protection cathodique des structures en acier flottant en mer

La présente EN définit les moyens à mettre en oeuvre pour assurer la protection cathodique des parties métalliques submergées des structures en acier flottant en mer et de leurs parties annexes contre la corrosion due à l'eau de mer ou aux fonds marins.

Katodna zaščita za plavajoče jeklene priobalne konstrukcije

General Information

- Status

- Published

- Publication Date

- 30-Nov-2003

- Technical Committee

- IPKZ - Protection of metals against corrosion

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Dec-2003

- Due Date

- 01-Dec-2003

- Completion Date

- 01-Dec-2003

Overview

EN 13173:2001 (adopted as SIST EN 13173:2003) is a CEN standard that defines the methods to cathodically protect submerged metallic surfaces of steel offshore floating structures and their appurtenances when exposed to sea water and saline mud. The standard sits within the general standards for shipbuilding and marine structures and relates to metallic coatings. It is intended to guide designers, operators and maintainers on appropriate cathodic protection approaches for offshore floating applications.

Key Topics

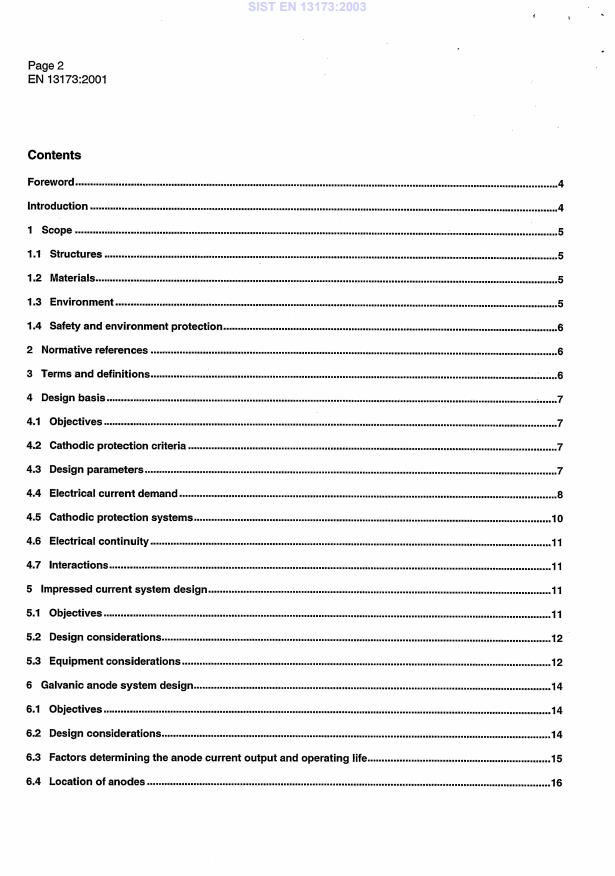

The standard focuses on the practical means to achieve and manage cathodic protection for steel floating structures. Key topics and requirements include:

- Scope of application - protection of submerged steel components of floating offshore units and associated fittings in marine and muddy saline conditions.

- System selection - identification of appropriate cathodic protection approaches for offshore floating structures.

- Materials and components - criteria for selecting corrosion-protection materials and metallic coatings compatible with marine environments.

- Design and installation principles - provisions for implementing cathodic protection systems on floating hulls and appurtenances.

- Monitoring and inspection - guidance on verifying system performance and maintaining protection over service life.

- Interaction with coatings and structures - integration of cathodic protection with other corrosion-control measures in shipbuilding and marine construction contexts.

(These topics reflect the scope and typical content areas covered by EN 13173; the standard provides the specific technical requirements and procedures for each.)

Applications

EN 13173 is directly applicable to:

- Offshore floating platforms, production vessels and other floating steel structures that have submerged components in seawater or saline mud.

- Design offices specifying corrosion protection for new structures.

- Shipyards and offshore fabrication yards installing cathodic protection systems.

- Asset owners, operators and maintenance teams responsible for long-term integrity and corrosion management.

- Third‑party inspectors and certification bodies assessing compliance with marine corrosion standards.

Using this standard helps reduce corrosion risk, extend service life of submerged steel, and ensure compatibility between coatings and cathodic protection measures.

Related Standards

- Classified under ICS: 47.020.01 (shipbuilding and marine structures) and 25.220.40 (metallic coatings).

- EN 13173:2001 is a CEN standard adopted by national bodies (e.g., SIST EN 13173:2003 in Slovenia).

- For full technical requirements, implementation details and measurement methods, refer to the official EN 13173 document and related CEN standards on marine corrosion protection and metallic coatings.

Keywords: EN 13173, cathodic protection, steel offshore floating structures, offshore corrosion protection, marine corrosion, sea water, saline mud, CEN standard.

Frequently Asked Questions

SIST EN 13173:2003 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Cathodic protection for steel offshore floating structures". This standard covers: This EN defines the means to be used to cathodically protect the submerged metallic surfaces of steel offshore floating structures and appurtenances in sea water and saline mud.

This EN defines the means to be used to cathodically protect the submerged metallic surfaces of steel offshore floating structures and appurtenances in sea water and saline mud.

SIST EN 13173:2003 is classified under the following ICS (International Classification for Standards) categories: 25.220.40 - Metallic coatings; 47.020.01 - General standards related to shipbuilding and marine structures. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13173:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kathodischer Korrosionsschutz für schwimmende Offshore-Anlagen aus StahlProtection cathodique des structures en acier flottant en merCathodic protection for steel offshore floating structures47.020.01Splošni standardi v zvezi z ladjedelništvom in konstrukcijami na morjuGeneral standards related to shipbuilding and marine structures25.220.40Kovinske prevlekeMetallic coatingsICS:Ta slovenski standard je istoveten z:EN 13173:2001SIST EN 13173:2003en01-december-2003SIST EN 13173:200

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...