ISO 12743:2018

(Main)Copper, lead, zinc and nickel concentrates - Sampling procedures for determination of metal and moisture content

Copper, lead, zinc and nickel concentrates - Sampling procedures for determination of metal and moisture content

This document sets out the basic methods for sampling copper, lead, zinc and nickel concentrates from moving streams and stationary lots, including stopped-belt sampling, to provide samples for chemical analysis, physical testing and determination of moisture content, in accordance with the relevant International Standards. Where the concentrates are susceptible to significant oxidation or decomposition, a common sample that is sufficiently representative, i.e. unbiased and sufficiently precise, is used for moisture determination and chemical analysis to eliminate bias (see ISO 10251). Any large agglomerates (>10 mm) present in the primary sample are crushed prior to further sample processing. Sampling of concentrates in slurry form is specifically excluded from this document. Stopped-belt sampling is the reference method for collecting concentrate samples against which mechanical and manual-sampling procedures can be compared. Sampling from moving streams is the preferred method. Both falling-stream and cross-belt samplers are described. Sampling from stationary lots is used only where sampling from moving streams is not possible. The procedures described in this document, for sampling from stationary lots, only minimize some of the systematic sampling errors.

Concentrés de cuivre, de plomb, de zinc et de nickel — Procédures d'échantillonnage pour la détermination de la teneur en métal et de l'humidité

General Information

- Status

- Withdrawn

- Publication Date

- 07-Jun-2018

- Withdrawal Date

- 07-Jun-2018

- Technical Committee

- ISO/TC 183 - Copper, lead, zinc and nickel ores and concentrates

- Drafting Committee

- ISO/TC 183/WG 9 - Sampling of copper, lead and zinc concentrates

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 10-May-2021

- Completion Date

- 13-Dec-2025

Relations

- Effective Date

- 24-Jul-2021

- Effective Date

- 04-Nov-2015

Frequently Asked Questions

ISO 12743:2018 is a standard published by the International Organization for Standardization (ISO). Its full title is "Copper, lead, zinc and nickel concentrates - Sampling procedures for determination of metal and moisture content". This standard covers: This document sets out the basic methods for sampling copper, lead, zinc and nickel concentrates from moving streams and stationary lots, including stopped-belt sampling, to provide samples for chemical analysis, physical testing and determination of moisture content, in accordance with the relevant International Standards. Where the concentrates are susceptible to significant oxidation or decomposition, a common sample that is sufficiently representative, i.e. unbiased and sufficiently precise, is used for moisture determination and chemical analysis to eliminate bias (see ISO 10251). Any large agglomerates (>10 mm) present in the primary sample are crushed prior to further sample processing. Sampling of concentrates in slurry form is specifically excluded from this document. Stopped-belt sampling is the reference method for collecting concentrate samples against which mechanical and manual-sampling procedures can be compared. Sampling from moving streams is the preferred method. Both falling-stream and cross-belt samplers are described. Sampling from stationary lots is used only where sampling from moving streams is not possible. The procedures described in this document, for sampling from stationary lots, only minimize some of the systematic sampling errors.

This document sets out the basic methods for sampling copper, lead, zinc and nickel concentrates from moving streams and stationary lots, including stopped-belt sampling, to provide samples for chemical analysis, physical testing and determination of moisture content, in accordance with the relevant International Standards. Where the concentrates are susceptible to significant oxidation or decomposition, a common sample that is sufficiently representative, i.e. unbiased and sufficiently precise, is used for moisture determination and chemical analysis to eliminate bias (see ISO 10251). Any large agglomerates (>10 mm) present in the primary sample are crushed prior to further sample processing. Sampling of concentrates in slurry form is specifically excluded from this document. Stopped-belt sampling is the reference method for collecting concentrate samples against which mechanical and manual-sampling procedures can be compared. Sampling from moving streams is the preferred method. Both falling-stream and cross-belt samplers are described. Sampling from stationary lots is used only where sampling from moving streams is not possible. The procedures described in this document, for sampling from stationary lots, only minimize some of the systematic sampling errors.

ISO 12743:2018 is classified under the following ICS (International Classification for Standards) categories: 73.060.99 - Other metalliferous minerals. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 12743:2018 has the following relationships with other standards: It is inter standard links to ISO 12743:2021, ISO 12743:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 12743:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 12743

Third edition

2018-06

Copper, lead, zinc and nickel

concentrates — Sampling procedures

for determination of metal and

moisture content

Concentrés de cuivre, de plomb, de zinc et de nickel — Procédures

d'échantillonnage pour la détermination de la teneur en métal et de

l'humidité

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

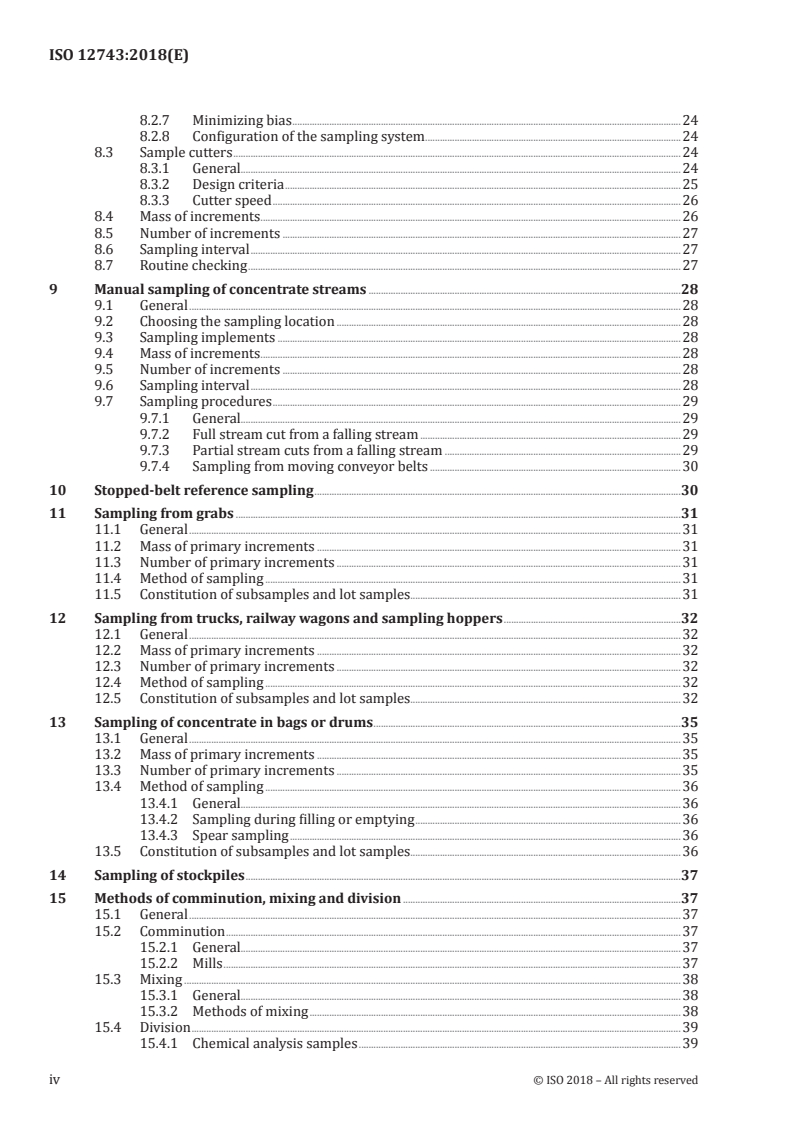

Contents Page

Foreword .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Sampling theory . 4

4.1 General . 4

4.2 Total variance . 4

4.3 Sampling-stage method of estimating sampling and total variance . 6

4.4 Simplified method of estimating sampling and total variance . 9

4.5 Interleaved sample method of measuring total variance .10

5 Establishing a sampling scheme .12

6 Mass of increment .17

6.1 General .17

6.2 Mass of increment for falling-stream samplers .17

6.3 Mass of increment for cross-belt samplers .17

6.4 Mass of increment for manual sampling from stationary lots .17

6.4.1 Primary increments .17

6.4.2 Mass of secondary and subsequent increments .18

6.5 Mass of increment for stopped-belt reference sampling .18

7 Methods of sampling from concentrate streams .18

7.1 General .18

7.2 Mass-basis systematic sampling .18

7.2.1 General.18

7.2.2 Sampling interval .19

7.2.3 Sample cutter .19

7.2.4 Taking of primary increments .19

7.2.5 Constitution of subsamples and lot samples .19

7.2.6 Types of division .20

7.2.7 Division of increments .20

7.2.8 Division of subsamples .20

7.2.9 Division of lot samples .20

7.3 Time-basis systematic sampling .21

7.3.1 General.21

7.3.2 Sampling interval .21

7.3.3 Sample cutter .21

7.3.4 Taking of primary increments .22

7.3.5 Constitution of subsamples and lot samples .22

7.3.6 Types of division .22

7.3.7 Division of increments and subsamples .22

7.3.8 Division of lot samples .22

7.4 Stratified random sampling .22

7.4.1 Fixed mass intervals .22

7.4.2 Fixed time intervals .23

8 Mechanical sampling of concentrate streams .23

8.1 General .23

8.2 Design of the sampling system .23

8.2.1 Safety of operators .23

8.2.2 Location of sample cutters .23

8.2.3 Provision for interleaved sampling .23

8.2.4 Provision for stratified random sampling .24

8.2.5 Checking precision and bias.24

8.2.6 Avoiding bias .24

8.2.7 Minimizing bias .24

8.2.8 Configuration of the sampling system .24

8.3 Sample cutters .24

8.3.1 General.24

8.3.2 Design criteria .25

8.3.3 Cutter speed .26

8.4 Mass of increments.26

8.5 Number of increments .27

8.6 Sampling interval .27

8.7 Routine checking .27

9 Manual sampling of concentrate streams .28

9.1 General .28

9.2 Choosing the sampling location .28

9.3 Sampling implements .28

9.4 Mass of increments.28

9.5 Number of increments .28

9.6 Sampling interval .28

9.7 Sampling procedures .29

9.7.1 General.29

9.7.2 Full stream cut from a falling stream .29

9.7.3 Partial stream cuts from a falling stream .29

9.7.4 Sampling from moving conveyor belts .30

10 Stopped-belt reference sampling .30

11 Sampling from grabs .31

11.1 General .31

11.2 Mass of primary increments .31

11.3 Number of primary increments .31

11.4 Method of sampling .31

11.5 Constitution of subsamples and lot samples.31

12 Sampling from trucks, railway wagons and sampling hoppers .32

12.1 General .32

12.2 Mass of primary increments .32

12.3 Number of primary increments .32

12.4 Method of sampling .32

12.5 Constitution of subsamples and lot samples.32

13 Sampling of concentrate in bags or drums .35

13.1 General .35

13.2 Mass of primary increments .35

13.3 Number of primary increments .35

13.4 Method of sampling .36

13.4.1 General.36

13.4.2 Sampling during filling or emptying .36

13.4.3 Spear sampling .36

13.5 Constitution of subsamples and lot samples.36

14 Sampling of stockpiles .37

15 Methods of comminution, mixing and division .37

15.1 General .37

15.2 Comminution .37

15.2.1 General.37

15.2.2 Mills .37

15.3 Mixing .38

15.3.1 General.38

15.3.2 Methods of mixing .38

15.4 Division .39

15.4.1 Chemical analysis samples .39

iv © ISO 2018 – All rights reserved

15.4.2 Moisture samples .40

15.4.3 Number of increments for division .40

15.4.4 Minimum mass of divided sample .40

15.4.5 Rotary sample division .41

15.4.6 Cutter-type division.42

15.4.7 Manual increment division .42

15.4.8 Spear division .42

15.4.9 Fractional shovelling .43

15.4.10 Ribbon division .44

15.4.11 Riffle division .46

16 Sample requirements .49

16.1 Moisture samples .49

16.1.1 Mass of test portion .49

16.1.2 Processing of samples .49

16.2 Chemical analysis samples . .49

16.3 Physical test samples .50

17 Packing and marking of samples .50

Annex A (normative) Sampling stage method of estimating sampling and total variance .51

Annex B (informative) Estimation of total variance — Barge unloading using a grab .59

Annex C (informative) Mechanical sample cutters .63

Annex D (informative) Checklist for mechanical sampling systems .68

Annex E (normative) Manual sampling devices .72

Annex F (informative) Apparatus for manual sampling of concentrates from stopped belts .74

Annex G (informative) Sampling of stockpiles .75

Annex H (normative) Increment division scoops for conducting manual increment division .77

Bibliography .78

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 183, Copper, lead, zinc and nickel ores and

concentrates.

This third edition cancels and replaces the second edition (ISO 12743:2006), which has been technically

revised.

The main changes to the previous edition are as follows:

— The minimum cutting aperture for cross-belt cutters in 8.3.2.3 i) has been reduced to 30 mm.

— A NOTE has been added to 15.4.10 indicating that ribbons with smaller dimensions can be formed

depending on the mass of sample to be divided, and that the ribbon division method is particularly

suitable for dividing chemical analysis samples.

— The requirements for preparation of chemical analysis samples in 16.2 have been expanded.

vi © ISO 2018 – All rights reserved

INTERNATIONAL STANDARD ISO 12743:2018(E)

Copper, lead, zinc and nickel concentrates — Sampling

procedures for determination of metal and moisture

content

WARNING — This document can involve hazardous materials, operations and equipment. It

is the responsibility of the user of this document to establish appropriate health and safety

practices and to ensure compliance with any other restrictions.

1 Scope

This document sets out the basic methods for sampling copper, lead, zinc and nickel concentrates

from moving streams and stationary lots, including stopped-belt sampling, to provide samples for

chemical analysis, physical testing and determination of moisture content, in accordance with the

relevant International Standards. Where the concentrates are susceptible to significant oxidation

or decomposition, a common sample that is sufficiently representative, i.e. unbiased and sufficiently

precise, is used for moisture determination and chemical analysis to eliminate bias (see ISO 10251).

Any large agglomerates (>10 mm) present in the primary sample are crushed prior to further sample

processing. Sampling of concentrates in slurry form is specifically excluded from this document.

Stopped-belt sampling is the reference method for collecting concentrate samples against which

mechanical and manual-sampling procedures can be compared. Sampling from moving streams is the

preferred method. Both falling-stream and cross-belt samplers are described.

Sampling from stationary lots is used only where sampling from moving streams is not possible. The

procedures described in this document, for sampling from stationary lots, only minimize some of the

systematic sampling errors.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 10251, Copper, lead, zinc and nickel concentrates — Determination of mass loss of bulk material on drying

ISO 12744, Copper, lead, zinc and nickel concentrates — Experimental methods for checking the precision

of sampling

ISO 13292, Copper, lead, zinc and nickel concentrates — Experimental methods for checking the bias of

sampling

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1

representative sample

quantity of concentrate representing a larger mass of concentrate with both precision and bias within

acceptable limits

3.2

lot

quantity of concentrate to be sampled

3.3

lot sample

quantity of concentrate representative of the lot

3.4

sub-lot

subdivided parts of a lot which are processed separately, each of them producing a subsample which is

analysed separately, for example for moisture determination

3.5

subsample

quantity of concentrate representative of the sub-lot

3.6

sampling

sequence of operations aimed at obtaining a sample representative of a lot

Note 1 to entry: It comprises a series of sampling stages, each stage usually comprising operations of selection

and preparation.

3.7

selection

operation by which a smaller quantity of concentrate is taken from a larger quantity of concentrate

3.8

increment

quantity of concentrate selected by a sampling device in one operation

3.9

division

operation of decreasing sample mass, without change of particle size, where a representative part of

the sample is retained

3.10

constant-mass division

method of division in which the retained portions from individual increments or subsamples are of

uniform mass

3.11

proportional division

method of division in which the retained portions from individual increments or subsamples are a

constant proportion of their original mass

3.12

preparation

nonselective operation without division such as sample transfer, drying, comminution or

homogenization

3.13

sample processing

whole sequence of selection and preparation operations which transforms a stage i sample into a

test sample

2 © ISO 2018 – All rights reserved

3.14

comminution

operation of reducing particle size by crushing, grinding or pulverisation

3.15

stage i sample

sample obtained at the ith stage of the sampling scheme

3.16

moisture sample

representative quantity of concentrate from which test portions are taken for moisture determination

Note 1 to entry: Alternatively, the whole moisture sample may be dried to determine its moisture content.

3.17

laboratory sample

sample that is processed so that it can be sent to the laboratory and used for further processing and

selection of one or more test samples for analysis

3.18

common sample

representative quantity of concentrate which is dried to determine its mass loss and subsequently used

for further processing and selection of one or more test samples for chemical analysis

3.19

test sample

representative quantity of concentrate obtained from a laboratory sample when additional preparation,

such as drying or hygroscopic moisture determination, is needed prior to the selection of one or more

test portions

3.20

test portion

representative quantity of concentrate taken from a moisture sample, a laboratory sample or a test

sample which is submitted to moisture determination or analysis in its entirety

3.21

systematic sampling

selection of increments in which the concentrate being sampled is divided into equal strata and the first

increment is taken at random within the first stratum, the interval between subsequent increments

being equal to the stratum size

3.22

stratified random sampling

selection of increments in which the concentrate being sampled is divided into equal strata, each

increment being taken at random within each stratum

3.23

agglomerate

cluster of particles that are held together by chemical or physical phenomena

3.24

nominal top size

aperture size of a test sieve that retains 5 % of the mass of concentrate

3.25

moisture determination

quantitative measurement of the mass loss of the moisture test portion under the conditions of drying

specified in ISO 10251

3.26

chemical analysis

quantitative determination of the required chemical constituents of the analysis test portion

3.27

error

difference between the true value and the value obtained for an individual measurement in any

quantitative measurement

3.28

bias

statistically significant difference between the mean of the test results and an accepted reference value

Note 1 to entry: See also ISO 13292.

3.29

precision

closeness of agreement between independent test results obtained under stipulated conditions

Note 1 to entry: See also ISO 12744.

3.30

interleaved samples

samples constituted by placing consecutive primary increments alternately into two separate sample

containers

4 Sampling theory

4.1 General

The basic rule for a correct sampling method is that all possible increments from the concentrate

stream or stratum shall have the same probability of being selected and appearing in the sample. Any

deviation from this basic requirement can result in a bias. An incorrect sampling scheme cannot be

relied on to provide representative samples.

Sampling should preferably be carried out on a systematic basis, either on a mass basis (see 7.2) or

on a time basis (see 7.3), but only where it can be shown that no systematic error (or bias) could be

introduced due to any periodic variation in quality or quantity that may coincide with, or approximate

to, any multiples of the proposed sampling interval. In such cases, it is recommended that stratified

random sampling within fixed time or mass intervals be carried out (see 7.4).

The methods for sampling, including sample processing, depend on the final choice of the sampling

scheme and on the steps necessary to minimize possible systematic errors. The aim is always to reduce

the total variance to an acceptable level, while at the same time eliminating any significant biases, for

example minimizing degradation of samples used for determination of size distribution.

Moisture samples shall be processed as soon as possible and test portions shall be weighed immediately.

If this is not possible, samples shall be stored in impervious airtight containers with a minimum of free

air space to minimize any change in moisture content, but should be prepared without delay.

4.2 Total variance

The general aim of a sampling scheme is to provide one or several test portions, sufficiently

representative of a lot, for determination of the quality characteristics of the lot. The total variance of

the final result, denoted by s , consists of the variance of sampling (including sample processing) plus

T

4 © ISO 2018 – All rights reserved

the variance of analysis (chemical analysis, moisture determination, determination of particle size

distribution, etc.) and is given by Formula (1):

22 2

ss=+ s (1)

TS A

where

is the sampling variance (including sample processing);

s

S

is the analytical variance.

s

A

In Formula (1), the sampling variance includes the variances due to all sampling (and sample processing)

steps, except selection of the test portion. The variance due to selection of the test portion is included in

the analytical variance, s , which shall be determined in accordance with ISO 12744, because it is

A

difficult to determine separately the “true” analytical variance.

Often replicate analyses of quality characteristics are carried out, which reduces the total variance. In

this case, if r replicate analyses are made, the total variance is given by Formula (2):

s

22 A

ss=+ (2)

TS

r

The estimation or measurement of the total variance can be carried out in several ways, depending on

the purpose of the exercise. In many respects, the different approaches are complementary.

[3,4]

The first method, which was developed by Gy , is to break up the sampling variance into its

components for each sampling stage, as specified in normative Annex A. The total variance is then

given by Formula (3):

s

22 22 A

ss=+.++ss.++ (3)

T

SS S

11iu−

r

where

is the sampling variance for stage 1, i.e. the primary sampling variance;

s

S

is the sampling variance for stage i;

s

S

i

is the sampling variance for stage u − 1, the second last stage;

s

S

u−1

u is the number of sampling stages, stage u corresponding to selection of the test portion.

This is referred to as the “sampling stage” method (see 4.3) and provides very detailed information on

the variance components, which is particularly useful for designing and assessing sampling schemes.

However, to obtain maximum benefit, it is necessary to collect data at each sampling stage.

The second method, called the “simplified” method (see 4.4), is to break up the total variance into

primary sampling, sample processing and analytical variances only. In this case, the total variance is

given by Formula (4):

s

22 2 A

ss=+s + (4)

T P

S

r

where

is the primary sampling variance;

s

S

2 is the variance due to all subsequent sampling steps, i.e. sample processing, except selection

s

P

of the test portion;

is the analytical variance, including selection of the test portion [at stage u in

s

A

Formula (3)].

The primary sampling variance is identical to the sampling variance for stage 1 in Formula (3), while

s is equal to the total sampling variance for the remaining sampling stages, except for selection of the

P

test portion which is included in the analytical variance. The relative magnitudes of the variance

components in Formula (4) indicate where additional effort is required to reduce the total variance.

However, it is not possible to separate the variances of the separate sample-processing stages. This

method is suitable for estimating the total variance for new sampling schemes based on the same

sample-processing procedures, where the numbers of primary increments, sample processings and

analyses are varied.

Finally, the total variance s can be estimated experimentally by collecting interpenetrating duplicate

T

samples (see 4.5). This is called the “interleaved sample” method and gives valuable information on the

total variance actually achieved for a given sampling scheme with no extra effort, provided facilities

[5]

are available for collecting duplicate samples (Merks ). It gives no information on variance

components, but the total variance can be compared with the analytical variance to ascertain whether

the sampling scheme used was optimized or not. It is therefore of limited use for designing sampling

schemes, but it can be used to monitor whether a sampling scheme is in control.

4.3 Sampling-stage method of estimating sampling and total variance

The sampling variance for stage i is given by Formula (5) (see normative Annex A):

s

b

2 i

s = (5)

S

i

n

i

where

is the variance between increments for stage i;

s

b

i

n

is the number of increments for stage i.

i

The variance between increments for stage i, s , can be estimated using Formula (6):

b

i

n

()xx−

∑ j

j=1

2 2

s = −s (6)

PA

b

i

n −1

i

where

is the test result for increment j;

x

j

is the mean test result for all increments;

x

is the variance of subsequent sample processing and analysis.

s

PA

6 © ISO 2018 – All rights reserved

The variance of subsequent sample processing and analysis of each increment, s , has been taken into

PA

account in Formula (6) to obtain an unbiased estimate of s .

b

i

NOTE Care is needed in subtracting variances. The difference is significant only when the F ratio of the

variances being subtracted is statistically significant.

Remembering that the variance due to selection of the test portion is included in the analytical variance

s , the total sampling variance is given by Formula (7):

A

u−1

s

b

2 i

s = (7)

S ∑

n

i

i=1

Combining Formulae (2) and (7) provides the total variance s , which is given by Formula (8):

T

u−1

s 2

b s

i A

s =+ (8)

T

∑

n r

i

i=1

For a three-stage sampling scheme (including selection of the test portion), Formula (8) reduces to

Formula (9):

2 2

s s 2

bb s

i 2 A

s =+ + (9)

T

n n r

1 2

The best way of reducing the value of s to an acceptable level is to reduce the largest terms in (8) first.

T

Clearly sn/ for a given sampling stage can be reduced by increasing the number of increments n or

i

i

b

i

reducing s by homogenizing the concentrate prior to sampling. The last term can be reduced by

b

i

reducing the particle size prior to selection of the test portion, or performing replicate analyses.

Selecting the optimum number of increments n for each sampling stage may require several iterations

i

to obtain the required total variance s .

T

EXAMPLE Consider a four-stage sampling scheme for determining the metal content of a copper concentrate

containing 31,2 % Cu. Assume that the concentrate is being conveyed at 500 t/h on a conveyor belt, that the lot

size is 500 t, and that the following parameters have been determined using Formula (6) where appropriate:

s =03,%Cu

b

s =02,%Cu

b

s =01,%Cu

b

s =00,%5 Cu

A

NOTE Many measurements might be required to obtain good estimates of s , s , s and s .

b b b A

1 2 3

Stage 1

Assume that the primary cutter takes increments of 12 kg mass at 2 min intervals. Thus:

n = 30

Primary sample mass = 360 kg

Formula (5) gives:

s = (0,3) /30 = 0,003 0

S

Stage 2

The primary increments are collected in a hopper, and then fed to the secondary cutter at a rate of

360 kg/h. Secondary increments of 0,01 kg are taken at 30 s intervals. Thus:

n = 120

Divided sample mass = 1,2 kg

s = (0,2) /120 = 0,000 333

S

Stage 3

The 1,2 kg sample is transported to the sample-processing laboratory and fed through a rotary sample

divider with a sample-collection canister divided into eight equal sectors rotating at 30 rev/min

−1

(0,5 s )

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...