ISO 11662-2:2014

(Main)Mobile cranes - Experimental determination of crane performance - Part 2: Structural competence under static loading

Mobile cranes - Experimental determination of crane performance - Part 2: Structural competence under static loading

ISO 11662-2:2014 presents a test method for the structural competence under static loading of mobile cranes. This test method is to provide a systematic, non-destructive procedure for determining the stresses induced in crane structures under specified conditions of static loading through the use of resistance-type electric strain gauges, and to specify appropriate acceptance criteria for specified loading conditions. ISO 11662-2:2014 applies to mobile construction-type lifting cranes utilizing a) rope-supported, lattice boom attachment or lattice boom, and fly jib attachment, b) rope-supported, mast attachment and mast-mounted boom, and fly jib attachment, or c) telescoping boom attachment or telescopic boom and fly jib attachment. Mobile crane manufacturers can use ISO 11662-2:2014 to verify their design for the mobile crane types illustrated in its Annex E.

Grues mobiles — Détermination expérimentale des performances des grues — Partie 2: Compétence structurale sous le chargement statique

General Information

- Status

- Published

- Publication Date

- 29-Oct-2014

- Technical Committee

- ISO/TC 96/SC 6 - Mobile cranes

- Drafting Committee

- ISO/TC 96/SC 6 - Mobile cranes

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 04-Sep-2025

- Completion Date

- 13-Dec-2025

Overview

ISO 11662-2:2014 - "Mobile cranes - Experimental determination of crane performance - Part 2: Structural competence under static loading" - defines a systematic, non‑destructive test method to verify the structural competence of mobile crane load‑supporting structures under specified static loads. The standard applies to common mobile construction‑type cranes including rope‑supported lattice booms, mast‑mounted booms, and telescopic booms, and uses resistance‑type electric strain gauges to measure induced stresses and set acceptance criteria.

Key topics and technical requirements

- Scope and applicability: Targets load‑supporting structures (not power‑transmission mechanisms) for mobile cranes such as lattice booms, mast attachments, fly jibs, and telescopic booms. Illustrative examples are in Annex E.

- Test method: Uses resistance‑type electric strain gauges to record strains under controlled conditions - including a zero/initial reference, dead‑load, working‑load and overload test conditions - enabling calculation of stresses.

- Loading procedures: Defines specific loading conditions (suspended load, side load, deflection criteria) and required test set‑up/conditioning (break‑in, block supports) to establish repeatable baseline readings.

- Stress evaluation and classification: Classifies structural areas into Class I (Uniform stress areas), Class II (Stress concentration areas), Class III (Column buckling areas) and Class IV (Local plate buckling areas) and specifies evaluation procedures and acceptance margins for each class (see Clause 10 and Annexes A–C).

- Data and reporting: Requires defined records, test procedures, and recommended report formats (informative Annex D), ensuring traceability and conformity assessment.

- Limitations and interpretation: Notes that in some cases analytical results may indicate more severe conditions; the standard allows substitution or addition of such conditions where justified.

Practical applications and users

- Mobile crane manufacturers use ISO 11662-2:2014 to verify and validate design assumptions, confirm manufacturing quality, and support product certification for the crane types illustrated.

- Test laboratories and inspection bodies implement the strain‑gauge test procedures to assess structural integrity before delivery or during periodic assessment.

- Fleet owners, rental companies and safety engineers rely on the standard to ensure cranes meet structural performance criteria under static loading and to interpret test reports against defined acceptance criteria.

- Design engineers can use test results to correlate and refine analytical models, particularly for buckling‑sensitive members.

Related standards

- ISO 11662 (Part 1: Tipping loads and radii) - complements this part by addressing stability tests and tipping limits.

- ISO 9373:1989 - referenced for accuracy requirements during testing.

Keywords: ISO 11662-2:2014, mobile cranes, structural competence, static loading, strain gauges, crane testing, boom testing, lattice boom, telescopic boom, stress evaluation, non‑destructive test.

Frequently Asked Questions

ISO 11662-2:2014 is a standard published by the International Organization for Standardization (ISO). Its full title is "Mobile cranes - Experimental determination of crane performance - Part 2: Structural competence under static loading". This standard covers: ISO 11662-2:2014 presents a test method for the structural competence under static loading of mobile cranes. This test method is to provide a systematic, non-destructive procedure for determining the stresses induced in crane structures under specified conditions of static loading through the use of resistance-type electric strain gauges, and to specify appropriate acceptance criteria for specified loading conditions. ISO 11662-2:2014 applies to mobile construction-type lifting cranes utilizing a) rope-supported, lattice boom attachment or lattice boom, and fly jib attachment, b) rope-supported, mast attachment and mast-mounted boom, and fly jib attachment, or c) telescoping boom attachment or telescopic boom and fly jib attachment. Mobile crane manufacturers can use ISO 11662-2:2014 to verify their design for the mobile crane types illustrated in its Annex E.

ISO 11662-2:2014 presents a test method for the structural competence under static loading of mobile cranes. This test method is to provide a systematic, non-destructive procedure for determining the stresses induced in crane structures under specified conditions of static loading through the use of resistance-type electric strain gauges, and to specify appropriate acceptance criteria for specified loading conditions. ISO 11662-2:2014 applies to mobile construction-type lifting cranes utilizing a) rope-supported, lattice boom attachment or lattice boom, and fly jib attachment, b) rope-supported, mast attachment and mast-mounted boom, and fly jib attachment, or c) telescoping boom attachment or telescopic boom and fly jib attachment. Mobile crane manufacturers can use ISO 11662-2:2014 to verify their design for the mobile crane types illustrated in its Annex E.

ISO 11662-2:2014 is classified under the following ICS (International Classification for Standards) categories: 53.020.20 - Cranes. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 11662-2:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 11662-2

First edition

2014-11-01

Mobile cranes — Experimental

determination of crane

performance —

Part 2:

Structural competence under static

loading

Grues mobiles — Détermination expérimentale des performances des

grues —

Partie 2: Compétence structurale sous le chargement statique

Reference number

©

ISO 2014

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

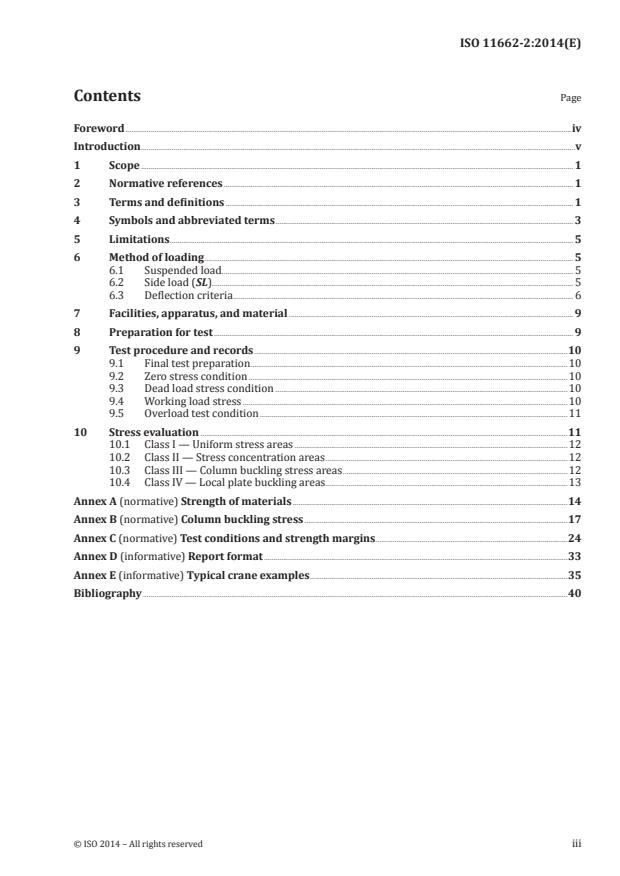

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols and abbreviated terms . 3

5 Limitations . 5

6 Method of loading . 5

6.1 Suspended load. 5

6.2 Side load (SL). 5

6.3 Deflection criteria . 6

7 Facilities, apparatus, and material . 9

8 Preparation for test . 9

9 Test procedure and records .10

9.1 Final test preparation .10

9.2 Zero stress condition .10

9.3 Dead load stress condition .10

9.4 Working load stress .10

9.5 Overload test condition .11

10 Stress evaluation .11

10.1 Class I — Uniform stress areas .12

10.2 Class II — Stress concentration areas .12

10.3 Class III — Column buckling stress areas .12

10.4 Class IV — Local plate buckling areas .13

Annex A (normative) Strength of materials .14

Annex B (normative) Column buckling stress .17

Annex C (normative) Test conditions and strength margins .24

Annex D (informative) Report format .33

Annex E (informative) Typical crane examples .35

Bibliography .40

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 96, Cranes, Subcommittee SC 6, Mobile Cranes.

ISO 11662 consists of the following parts, under the general title Mobile cranes — Experimental

determination of crane performance:

— Part 1: Tipping loads and radii

— Part 2: Structural competence under static loading

iv © ISO 2014 – All rights reserved

Introduction

When design calculations are made for mobile cranes, they are based on an ideal model in which all

members and components are perfectly straight and fabrication has been exact. For tension members

and members subjected to bending, the difference between the real crane and the ideal model is usually

not significant. But, for compression members subject to column buckling, an allowance for deviation in

straightness and fabrication is necessary.

When mobile cranes are tested non-destructively by means of strain gauges, the stresses determined

intrinsically include these effects of deviations in straightness and accuracy of fabrication.

This test method is intended to describe the approximate maximum loading conditions to which any

component of the entire load-supporting structure of a crane is subjected (See Annex D). In some

cases, a more severe loading condition(s) can be indicated by analysis. In these cases, the more severe

condition(s) can be added to or substituted for the specified test loading condition(s). This test method

also classifies stress areas as Types I (Uniform Stress Areas), II (Stress Concentration Areas), III (Column

Buckling Areas), and IV (Local Plate Buckling Areas; see Clause 10), and defines limits for each class.

Results can be used to correlate boom system calculation results for Class III stress areas as given by

boom system calculations. Test results for Class I stress areas throughout the structure can be used to

check any available calculations. This test method evaluates Class II stress areas for which calculations

are seldom available. Class IV stress areas, where disproportionately high stress readings can occur, can

be reviewed for better insight by calculation methods.

A production boom system that has been rated by the methods of this part of ISO 11662 can be used

on another machine without re-testing by the methods specified herein, provided the same analytical

procedure shows its stress levels will be less than or equal to the stress levels in the original application,

and provided that the supporting structure is as rigid as the original mounting. Rigidity of the supporting

structure is determined by the change in the slope of the jib foot axis as test loads are applied.

INTERNATIONAL STANDARD ISO 11662-2:2014(E)

Mobile cranes — Experimental determination of crane

performance —

Part 2:

Structural competence under static loading

1 Scope

This part of ISO 11662 applies to mobile construction-type lifting cranes utilizing

a) rope supported, lattice boom attachment or lattice boom, and fly jib attachment (see Annex E,

Figure E.3),

b) rope supported, mast attachment and mast mounted boom, and fly jib attachment (see Annex E,

Figures E.1 and E.2), or

c) telescoping boom attachment or telescopic boom and fly jib attachment (see Figure E.4).

Mobile crane manufacturers can use this part of ISO 11662 to verify their design for the mobile crane

types illustrated in Figures E.1 through E.4.

This test method is to provide a systematic, non-destructive procedure for determining the stresses

induced in crane structures under specified conditions of static loading through the use of resistance-

type electric strain gauges, and to specify appropriate acceptance criteria for specified loading

conditions.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 9373:1989, Cranes and related equipment — Accuracy requirements for measuring parameters during

testing

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

strain

relative elongation or compression of material at any given point with respect to a specific plane passing

through that point, expressed as change in length per unit length (m/m)

3.2

stress

S

internal force per unit area resulting from strain, expressed in pascals (Pa) or newtons/square meter

Note 1 to entry: For this document, megapascals (Mpa) will be used for brevity.

3.3

yield point

S

y

stress at which a disproportionate increase in strain occurs without a corresponding increase in stress

Note 1 to entry: For purposes of this code, yield point is to be considered as the minimum 0,2 % offset tensile yield

point or yield strength specified by the appropriate standard for the material used.

3.4

critical buckling stress

S

cr

average stress which produces an incipient buckling condition in column-type members (See Annex C)

3.5

initial reference test condition

defined no-stress or zero-stress condition of the crane structure after the “break-in” as established by

a) supporting the structure on blocking to minimize the effects of gravity, or

b) the crane structure components in an unassembled state or any alternate method that will establish

the zero-stress condition. Under this condition, the initial reference reading for each gauge is

obtained, N

3.6

dead load stress condition

completely assembled crane structure on the test site and in the position or attitude, ready to apply the

specified live load at the specified radius

Note 1 to entry: Under this condition, the second reading for each gauge is obtained, N .

Note 2 to entry: The hook, hook block, slings, etc. are considered part of the suspended load but may be supported

by the crane when this reading is taken. For dead load purposes, the hook in the “home” position – suspended

from the crane without lifting the test load. This position has to be repeated after placing the load back on the

ground (see 9.4.4).

3.7

dead load stress

S

stress computed as defined in Clause 10 by using the difference in the readings obtained in 3.6 and 3.5

for each gauge (N – N )

2 1

3.8

working load stress condition

completely assembled crane structure on the test site and in the specified position, supporting the

specified rated load

Note 1 to entry: Under this condition, the third reading for each gauge is obtained, N .

3.9

working load stress

S

stress computed as defined in Clause 10 by using the difference in the readings obtained in 3.8 and 3.5

for each gauge (N – N )

3 1

3.10

resultant stress

S

r

stress induced in the structure as a result of dead load stress (S ) or the working load stress (S ),

1 2

whichever is greater in absolute magnitude

2 © ISO 2014 – All rights reserved

3.11

column average stress

S

ra

direct compression stress in a column or the average stress computed from several gauges located at the

section (see Annex B)

3.12

column maximum stress

S

rm

maximum compression stress in a column computed from the plane of buckling as established from

several gauges located at the section (see Annex B)

3.13

loadings

application of weights and/or forces of the magnitude specified under the condition specified

3.14

load radius

horizontal distance between the axis of rotation of the turntable of the crane and the vertical axis of the

hoist line or load block when the crane is erected on a level site

4 Symbols and abbreviated terms

E modulus of elasticity

K effective length factor for a column

L un-braced length of column

L length of boom

b

L length of fly jib

j

L small arbitrary projected length of fly jib along x-axis

L projected length of fly jib strut along y-axis

n strength margin

n strength margin, Class I area, ratio of yield strength to resultant or equivalent stress

n strength margin, Class II area, ratio of yield strength to resultant or equivalent stress

n strength margin, Class III area, derived from an interaction relationship

N strain reading at initial reference test condition

N strain reading at dead load stress condition

N strain reading at working load stress condition

r radius of gyration

RL rated load as specified by manufacturer

“R” plane (Figure 1) perpendicular to boom foot pin centreline (CL)

RR rated radius as specified by manufacturer

S stress

S dead load stress

S working load stress

S column average stress computed from several gauges at a cross section

ra

S critical buckling stress for axially loaded columns

cr

SL side load, i.e. 0,02 × RL;

percentage of side load expressed as a percentage of rated load or %RL = Percentage of

%SL

rated load

SLL side load left

SLR side load right

S maximum compression stress in a column

rm

S stress at the proportional limit

p

S resultant stress

r

S maximum residual stress in compression

RC

S stress at the yield point

y

S’ equivalent uniaxial stress

t horiz. distance from the load centre to the front pad reaction centre for each box jib section

σ tensile yield stress

σ maximum principal stress

x

σ minimum principle stress

y

Z’ lattice boom tip slope (out of plane)

Z lattice boom tip deflection from plane “R”

b

Z fly jib tip deflection from plane “R”

j

Z boom deflection at a point l back from the boom tip

1 1

Z fly jib strut deflection at its tip

α imperfection factor

β fly jib offset angle from centreline (CL) jib

ε strain

ε strain recorded from leg “a” of rosette

a

ε strain recorded from leg “b” of rosette

b

ε strain recorded from leg “c” of rosette

c

ε strain recorded from leg “d” of rosette

d

ε maximum principal strain

x

4 © ISO 2014 – All rights reserved

ε minimum principal strain

y

µ units of strain, 10

θ fly jib tip rotation about x-axis (radians)

π Pi = 3,1416

τ shear yield stress

ν Poisson’s ratio

X relative buckling stress ( = S /S )

cr y

initial relative slenderness

λ

relative slenderness (= λ/λ )

c

λ

slenderness ratio (= KL/r)

λ

E

λ reference slenderness ratio =π

c

S

y

S allowable buckling stress

k

S Euler’s buckling stress

ci

S Jager’s buckling stress

ck

5 Limitations

5.1 This method applies to load-supporting structures as differentiated from power transmitting

mechanisms. It is restricted to measuring stresses under static conditions and a general observation after

overload conditions.

5.2 Personnel competent in the analysis of structures and the use of strain-measuring instruments are

required to perform the tests.

6 Method of loading

6.1 Suspended load

The specified load suspended at the specified radius and held stationary a short distance above the

ground. The weight of the hook, block, slings, etc., shall be included as part of the specified suspended

load.

6.2 Side load (SL)

When the test specification requires side loading, the force displacing the suspended load should

be horizontal and perpendicular to the plane containing the axis of upper structure rotation and

the centreline of the undeflected boom. The side load shall be applied in each direction. Side loading

is applied to simulate the various effects associated with machine operation including a 9 m/s wind

loading that might be encountered.

6.2.1 Lattice boom attachment

For lattice boom attachments, the side load that is to be applied for the conditions listed in Table C2 is as

follows. The side load shall be applied as 2 % (0,02 RL) of the rated load in each direction.

6.2.2 Mast attachments

For mast attachments, the side load percentage that is to be applied in each direction at the load

attachment point for the conditions listed in Table C1 is to be a minimum of 2 % (0,02 RL) of the rated

load in each direction.

6.2.3 Telescoping boom attachment

For telescoping boom attachments, the side load that is to be applied for the conditions listed in Table C3

is as follows. The side load shall be applied as 3 % (0,03 RL) of the rated load in each direction with the

boom over the end of the machine.

6.3 Deflection criteria

The usability of a latticed column [i.e. lattice boom and fly jib(s) combination] or a telescoping boom

attachment is sometimes affected by the elastic stability of the overall column as well as of the individual

members. Incipient out of plane elastic instability is indicated by excessive boom and/or fly jib tip

deflection (sideways) as the attachment is side loaded when suspending a rated load. The following

lateral deflection limits are therefore imposed.

6.3.1 Lattice boom attachments

The lateral deflection criteria for the rated load and side load of Table C2 are as follows. First, the

deflection of the total boom and jib combination shall be less than or equal to 2 % of the total combination

length. Furthermore, the deflection of each individual boom or fly jib member shall be less than or equal

to 2 % of the length of that member. To satisfy these criteria, it should be noted that the deflection of

an individual member does not include the deflection, rotation, or slope of the member to which it is

mounted.

For a single fly jib mounted on a boom, the following relationship is given (Figure 1):

ZL≤′00,c2 ++ZZ LLosβθ+ sinβ (1)

() ()

jj bj j

The following values are measured.

Z fly jib tip deflection

j

Z lattice boom tip deflection

b

Z lattice boom deflection at a distance L down from the boom tip

1 1

Z fly jib strut deflection at the tip

The following values are calculated.

6 © ISO 2014 – All rights reserved

Slope:

ZZ′=()−ZL/ (2)

b 11

Rotation:

θ= ZZ− L (3)

()

b 22

If slope (Z′) and rotation (θ) are not measured, the last two terms of Formula (1) may be deleted.

Figure 1 — Deflection measurement related terms —

Lattice boom with fly jib

6.3.2 Telescoping boom attachments

For telescoping boom attachment crane structures, no tip deflection limitations have been established.

Deflection of the mast attachment, the mast mounted boom, and fly jib shall be measured and recorded

when the system is stable.

8 © ISO 2014 – All rights reserved

6.3.3 Mast attachments

For mast attachment crane structures, no tip deflection limitations have been established. The deflection

of the telescopic boom attachment and fly jib shall be measured and recorded when the system is stable.

7 Facilities, apparatus, and material

7.1 A concrete or other firm supporting surface, sufficiently large to provide for unobstructed

accomplishment of the tests required. Where tests are to be performed on crawler tracks, the machine

shall be level within 0,25 % grade.

7.2 Means to measure levelness of the axis of the jib foot; accuracy 0,1 % of grade (see ISO 9373).

7.3 Means for determining the load radius to an accuracy of ±1 %, not to exceed 150 mm.

7.4 Means for producing traverse displacement of the suspended load and means for measuring the

magnitude of the displacing force; accuracy ±3 % of measured force.

7.5 Temperature compensated strain gauges, cement, waterproofing compounds, and other necessary

gauge installation equipment.

7.6 Strain recording system. It is the intent that commercially available, high quality, reliable instruments

be used in the performance of this test. Accuracy of the recording system shall be determined to be ±2 %

of the reading over the range of 500 μ m/m to 3 000 μ m/m strain (determined in suitable increments).

Calibration can be accomplished by electrical shunts or by pre-calibrated strain bar.

7.7 Test weights and lifting apparatus of known weights accurate to within ±1 %.

7.8 Means for measuring side deflection of the boom and fly jib within 50 mm.

8 Preparation for test

8.1 An analysis of each structure sufficient to locate highly stressed areas shall be made. The strain

gauge location and direction shall be determined from this analysis as well as from the use of other

experimental techniques where necessary.

8.2 Perform a detailed inspection of the crane to ensure that all mechanical adjustments and condition

of load supporting components conform to manufacturers’ published recommendations. Check that the

crane is equipped in compliance with the test specifications.

8.3 A previously un-worked crane should be given a “break-in” run at or near each anticipated test

loading to mechanically relieve residual stresses that might have developed during manufacture and to

minimize the possibility of “gauge zero shift” during the test.

8.4 Perform a thorough inspection after the “break-in” to reveal areas of high stress as evidenced by

paint checking, scale flaking, or other indications of deformation.

8.5 Bond strain gauges at the points determined by prior analysis (see 8.1) and any areas selected as a

result of the inspection conducted in 8.4. Only competent personnel using proven materials and practices

can be employed to ensure that all gauges are of the correct type, properly oriented, and securely bonded

to measure strains correctly.

8.6 Determine the minimum yield strength and the modulus of elasticity for the material at each

gauge location by referring to the material certifications, if available, applicable standards, or Annex B.

Determine the critical buckling stress when applicable (see Annex B).

9 Test procedure and records

9.1 Final test preparation

9.1.1 Locate the machine on the test course and lock travel brakes and latches. Level the machine to

within 0,25 % grade in the unloaded condition by shimming or by jacking. Do not re-level after the load

has been applied to the machine.

NOTE If the test is for operation on outriggers, jack the crane to a position where all the tires or tracks are

unloaded, unless the manufacturer’s rating chart requires some other conditions.

9.1.2 Connect strain measuring system and calibrate gauges and instruments. Correct any malfunctions.

9.2 Zero stress condition

If the assembled crane is to be used as the initial reference test condition, obtain these readings. If the

unassembled components are to be used as the initial reference test condition, obtain these readings.

Reassemble the crane and make all mechanical adjustments.

9.3 Dead load stress condition

9.3.1 Set the revolving upper structure to the specified position relative to the lower structure. Lock the

swing brake or latch.

9.3.2 Set the attachment angles and lengths to develop the specified load radius.

9.3.3 Read all strain gauges for dead load stress condition (see 3.6). Compute the dead load stress (S ) at

each gauge (see 3.7) and record on the test data sheet (see Annex D).

NOTE A new dead load stress condition is established each time the position, attitude, or configuration

is changed to suit the specified tests and operations: therefore, 9.3.1 to 9.3.3 shall be repeated for each new

condition.

9.4 Working load stress

9.4.1 Prepare a test load which together with the hook, block, slings, etc., weighs within ±1 % of the

specified load.

9.4.2 Suspend the test load (see 6.1) and apply side load (see 6.2) as required by specifications.

9.4.3 Read required strain gauges for working load stress condition. Compute the working load stresses

(S ) for each required gauge and record the test data. Measure and record tip side deflection due to

suspended load and side load.

9.4.4 Release side load and lower suspended load, returning crane to dead load condition. Read required

strain gauges and compare with reading taken under 9.3. If the deviation for any gauge exceeds ±0,03 S /E,

y

determine cause, correct, and repeat all procedures until consistent readings are obtained.

10 © ISO 2014 – All rights reserved

NOTE Since temperature changes and the loading from even a moderate wind on long booms and fly jibs

affects strain gauge readings, testing should be done under as favourable atmospheric conditions as possible.

Position the machine so wind loading does not reduce the stress induced by side loading.

Compute resultant stress (S ) per 3.10, for combined dead load and working load stresses and record.

r

Thoroughly examine the crane for any evidence which suggests a possibility of plastic deformation or

other damage having occurred during the test.

9.5 Overload test condition

9.5.1 Repeat 9.1.1, if applicable.

9.5.2 Position the crane (upper structure, boom) in the specified test position.

9.5.3 Set attachment angles and lengths to develop the specified load radius and record dead load

readings for Class IV gauges.

9.5.4 Prepare the test load (see 9.4.1).

9.5.5 Suspend the specified test load and adjust the boom angle(s; if necessary) to obtain the rated load

radius.

9.5.6 Observe the performance of the structure and note any evidence of possible failure.

9.5.7 Release the suspended load and return the crane to the dead load stress condition. Record the dead

load readings for Class IV gauges. (See 9.4.4)

At the completion of all applicable overload tests, the crane structures should be thoroughly examined

by eye using straight edges and other references, where appropriate, to determine any evidence of

buckling, permanent deformation, element out of line, etc. Scale flaking or paint checking can also be

indicative of stresses beyond the yield point. Disassemble the boom structure to the state necessary

to be ensured that all boom elements, extension cylinders, or elements, hoist mechanisms, suspension

systems, and other load-carrying elements can be inspected.

Record all pertinent data regarding the test equipment, crane being tested, results, and observations.

Suggested forms are presented in Annex D.

10 Stress evaluation

For purposes of this test method, stress is related to measured strain by the uniaxial stress equation

(see Formula 4):

SE= ⋅ε withinproportionallimits (4)

()

NOTE The simple uniaxial stress formula might not be sufficiently accurate for some areas of crane structures

under biaxial stress, and special consideration should be given in such cases (see Annex A).

Stresses in different parts of crane structures are evaluated for acceptability on the basis of criteria

appropriate to the area in question. These stress areas can be classed as follows (see Table 1 or 10.1

through 10.4 for minimum strength margins).

Table 1 — Minimum strength margins

a

Class III (column buckling area) Class IV

Class I (uni- Class II (stress

(local plate

form stress concentration

Curves Curves

buckling

Alternative

area) area)

A, B, C, D a, b, c

area)

Gauges must

b

X (erection n ≥ 1,3 and return to

n ≥ 1,3 n ≥ 1,0 n ≥ 1,4 n ≥ 1,2

1 2 3 3

c

loads) 2,2 ±0,03 S /E at

y

dead load.

Gauges must

a

n ≥ 1,5 and return to

Y (rated loads) n ≥ 1,5 n ≥ 1,1 n ≥ 1,6 n ≥ 1,3

1 2 3 3

b

2,5 ±0,03 S /E at

y

dead load.

Gauges must

Observation Observation Observation Observation Observation return to

Z (over loads)

only only only only only ±0,03 S /E at

y

dead load.

a

Refer to Annex B.

b

Critical buckling stress S is calculated by Jager’s equation.

cr

c

Critical buckling stress S is calculated by Euler’s equation.

cr

10.1 Class I — Uniform stress areas

Large areas of nearly uniform stress where exceeding the yield strength or yield point values will

produce permanent deformation of the member as a whole. Strength margin:

— n = S /S or S /S′ (refer to Annex A for S′);

1 y r y

— n ≥ 1,50 for rated loads;

— n ≥ 1,30 for erection loadings.

10.2 Class II — Stress concentration areas

Small areas of high stress surrounded by larger areas of considerably lower stress where exceeding

the yield strength or yield point values will not produce permanent deformation of the member as a

whole. Examples are points of rapid section change such as sharp corners, holes, or weld fillets. Strength

margins:

— n = S /S or S/S′ (refer to Annex A for S′);

2 y r y

— n ≥ 1,10 for rated loads;

— n ≥ 1,00 for erection loadings.

10.3 Class III — Column buckling stress areas

Areas in which failure can be considered to occur at some average stress value less than yield strength

or yield point. Examples are individual unsupported compression elements such as, but not limited to,

masts, struts, jib chords, or lattice, which require consideration as columns.

Strength margin (refer to Annex B).

If curves A, B, C, or D are chosen from Table 1:

— n ≥ 1,60 for rated loads;

— n ≥ 1,40 for erection loading.

12 © ISO 2014 – All rights reserved

For lattice structures, this criteria is intended to apply to lacing elements or chord elements between

lacing points.

It is not intended for evaluation of the overall latticed compression member.

10.4 Class IV — Local plate buckling areas

Plates, when subjected to direct compression, bending, and/or shear in their plane, can buckle locally

before the member as a whole becomes unstable. Local bucking is associated with wrinkling (initial

buckling), which permits the member to redistribute the loading to stiffer edges.

As loading is further increased, the stress in Class IV areas (see Figure 2) does not necessarily increase

in proportion to the load; however, considerable post buckling strength might remain. Requirements

are that Class IV gauges return to the dead load readings for all test conditions, including overload.

Class IV Areas (Typical 4 Sides)

Telescoping jib

Outrigger

box

and beam

Figure 2 — Local plate buckling areas

Annex A

(normative)

Strength of materials

A.1 Biaxial stress fields

In biaxial stress fields, there might be some error if the uniaxial stress given by S = E · ε (see Clause 10)

is compared to tensile yield point to determine the strength margin. The question arises when

consideration is given to the theory of failure applicable to the material being tested.

A.2 Brittle materials

The use of S = E ε (when ε is measured in the direction of maximum principal strain) presumes the

x x

applicability of the maximum strain theory of failure. This is the commonly accepted theory of failure

for brittle materials, and results given are valid for materials of this type.

A.3 Ductile materials

The distortion energy theory of failure generally is accepted as the performance criterion of ductile

materials subjected to biaxial stresses. This assumes that yield failure occurs when the distortion

energy under biaxial stress is equal to the distortion energy at yield stress in pure tension. An equivalent

uniaxial stress (S′) developing the same distortion energy as the actual biaxial stress is determined

for comparison to the yield point (S ) to establish the strength margin against failure. The equivalent

y

uniaxial stress is shown in Formula A.1:

′

S =−σσ σσ+ (A.1)

xx yy

Principal stresses are obtained from strain gauge readings by Formulae (A.2) and (A.3):

σ =+Evεε /1−v (A.2)

() ()

x xy

σ =+Evεε /1−v (A.3)

()

y xy ()

Principal strains are obtained by interpreting rosette gauge readings on Mohr’s circle or other convenient

means. Equivalent stress S’ can also be calculated from principal strains shown in Formula (A.4):

E ()1−−νε()εε++()νε ()εν+ ε

xy xy yx

S′= (A.4)

()1−ν

When three and four gauge rosettes are used (Figure A.1), the following equations can be used directly

to obtain the equivalent stress based on the readings of each of the legs.

Rectangular Rosette (Figure A.1):

14 © ISO 2014 – All rights reserved

c

b

c

b b c

a

a

a

Figure A.1 — Rectangular, delta, and T-delta rosettes

A.4 Ductile material approximate method

In most ductile material biaxial fields, the assumption that the equivalent uniaxial stress S′ equals E ε

x

will be accurate within 10 %. The main factors affecting the accuracy are

a) The ratio of minimum to maximum principal stress, σ /σ , and

y x

b) The ratio of shear yield to tensile yield, τ /σ

o o.

— σ = Tensile yield stress

o

— σ = Maximum principal stress

x

— σ = Minimum principal stress

y

Figure A.2 shows the magnitude of accuracy variance with respect to these two ratios, using Poisson’s

ratio ν = 0,285. The plot shows that as the condition approaches biaxial tension or compression error

can be 25 % to 30 %, as the condition approaches pure shear error can be 0 to 30 % depending on the

ratio τ /σ .

o o

The solid curve line in Figure A.2 is based on the distortion energy theory of failure as compared to

S = E ε . Distortion Energy Theory, while most generally correct, will check with the torsion yield test

x

(pure shear) only if τ /σ = 0,577. For materials in which τ /σ does not equal 0,577, the dashed curve

o o o o

lines (which do not correspond to any theory of failure, but only the tensile and torsion yield tests) give

some idea of the probable error. If a single gauge and S = E ε is to be applied instead of rosettes and more

x

complicated formulation, principal direction must be determined by some other means, such as paint

checking or (better) brittle lacquer.

1,1

y

ε

y

x σ

σ

1,0

τ /σ x

o o

ε

0,9

0,700

0,635

0,8

0,577

0,7

0,520

FAILURE IN SHEAR FAILURE IN TENSION OR COMPRESSION

PURE SHEAR PURE TENSION

0,6

-1,0 -0,8 -0,6 -0,4 -0,2 0 0,2 0,4 0,6 0,8 1,0

PRINCIPAL STRESS RATIO σ /σ

y x

-1,0 -0,8 -0,6 -0,4 -0,2 0 0,2 0,4 0,6 0,8 1,0

/

PRINCIPAL STRAIN RATIO

εy εx

Figure A.2 — Ratio of apparent stress to actual stress versus biaxial stress ratio

Recommended values to be used in calculating stress from measured strain are listed in Table A.1.

Table A.1 — Elastic properties of materials

Modulus ofe- Modulus of Poisson’s ratio

lasticity rigidity

a

(E) (G; Shear)

(Young’s; (10 Mpa)

10 Mpa)

Steel

Carbon and alloy structural 206,7 79,2 0,285

Cast 206,7 77,2 0,265

Stainless 137,8/192,9 0,305

Aluminium, structural 72,3 27,6 0,333

Magnesium, structural 44,8

Titanium, structural 89,6/110,2

a

The modulus of elasticity generally is quoted as a range; the figures listed are towards

the high and of the range for conservatism. The modulus of elasticity of some materials

varies widely with chemistry, heat treatment, or stress level. In such cases a range is listed,

and the proper value must be selected for the particular conditions in each case.

16 © ISO 2014 – All rights reserved

Єx

APPARENT STRESS S-E

Actual Stress S'

Annex B

(normative)

Column buckling stress

B.1 General comments

In deriving buckling curves or numerical tables for use in practical design, one has to be aware of some

inevitable imperfections of the member being considered, such as non-homogeneity of the material,

deviation from the assumed geometric form (initial crookedness), unintentional eccentricities of axial

load due to the unavoidable imperfection of shop and erection work. Each of these imperfections varies

over a wide range and combines with the others in each individual case in a particular manner. In order

to compensate all uncertainties encountered in practice, proper factors of safety or load factors should

be utilized.

Each compression member in a structure represents an individual case that must be designed according

to its particular loading and end restraint conditions.

B.2 Critical buckling curves related to residual stress

Various column buckling curves are shown in Figure B.2. Curves A, B, C, and D are the curves that are

related to residual stress and are used with the allowable stress method of calculation. A safety factor

must be applied to the critical buckling strength obtained from Figure B.2. Table B.1 lists the Yield

Strength, S , the Proportional Limit, S , and the Residual Stress, S for each of the four material types

y p RC

(A, B, C, and D).

The shape of these curves can be defined by three parameters: the modulus of elasticity E, the proportional

limit S and the material yield strength S . Axially loaded members can buckle elastically or inelastically,

p y

depending on the stress levels. At stress levels below the proportional limit S , axially loaded members

p

buckle elastically. Inelastic buckling of the axially loaded members occurs at stress levels above the

proportional limit S . For inelastic buckling, relative buckling stress (ratio of buckling stress to yield

p

strength) is a function of the ratio of residual stress to yield strength as shown in Formula (B.5).

The residual stress is included directly in the buckling formulae. No factor of the uncertainties such

as out-of-straightness. is incorporated in the formulae. The buckling curves are indeed for “specially

straightened material”. Nevertheless, a strength margin of 1,6 (see Table 1) must be applied to the

critical buckling curves. This strength margin overcomes such uncertainties that would affect the

buckling strength of the members.

Applicable formulae for the elastic buckling of columns (S ≤ S ):

cr p

π E

S = (B.1)

cr

(/KL r)

or

X = (B.2)

λ

Applicable formulae for the inelastic buckling of columns (S ≥ S ):

cr p

SS()−S

py p

SS=− (/KL r) (B.3)

cr y

π E

SS=−S (B.4)

py RC

or

S S

RC RC 2

X =−11()− λ (B.5)

S S

y y

As shown in Table C.1, a value of S = 103 Mpa can be assumed in lieu of specific residual stress

RC

information on the following steel materials:

a) hot finished shapes in the as-rolled condition;

b) quenched and tempered shapes with stress relief heat treatment;

c) cold-drawn shapes with stress relief heat treatment;

d) fabricated welded shapes with stress relief heat treatment.

On other materials, a value of S = 0,5 × S can be assumed in lieu of specific residual stress information.

RC y

Table B.1 — Residual stress assumption

S S

y p

Residual stress assump- Yield stress Proportional

a

Curve

tion (Mpa) lLimit

(Mpa)

S = 103 Mpa A 690 586

RC

(lowresidualstress)

B 483 379

C 345 241

D 248 145

S = 0,5 S D 690 345

RC y

(highresidualstress)

D 483 241

D 345 172

D 248 124

a

Refer to Figure B.2, Critical buckling curves. Steels other than those listed can be used,

provided it can be shown they are suitable for the application intended.

The following values can be used for the end restraint factor K.

a) For chord members, K = 1,00.

b) For lacing members with full section connection to tubular chords, K = 0,75.

c) For lacing members with full section connection to angle or tee chords, K = 0,90.

d) For lacing members with reduced section connec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...