ISO 21780:2020

(Main)Road vehicles — Supply voltage of 48 V — Electrical requirements and tests

Road vehicles — Supply voltage of 48 V — Electrical requirements and tests

This document covers requirements and tests for the electric and electronic components in road vehicles equipped with an electrical system operating at a nominal voltage of 48 V DC. This includes the following: — general requirements on 48 V DC electrical systems; — voltage ranges; — slow voltage transients and fluctuations (not including EMC).

Véhicules routiers — Tension d'alimentation de 48 V — Exigences électriques et essais

Cestna vozila - Napajalna napetost 48 V - Električne zahteve in preskusi

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 21780

First edition

2020-08

Road vehicles — Supply voltage of

48 V — Electrical requirements and

tests

Véhicules routiers — Tension d'alimentation de 48 V — Exigences

électriques et essais

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Functional status . 2

4.1 General . 2

4.2 Functional status 1 (FS1) . 3

4.3 Functional status 2 (FS2) . 3

4.4 Functional status 3 (FS3) . 3

4.5 Functional status 4 (FS4) . 3

4.6 Functional status 5 (FS5) . 3

5 Supply voltage range . 3

6 Functional categories . 5

7 Operating modes . 6

8 General tests conditions . 6

8.1 Standard tolerances . 6

8.2 General values. 7

8.3 Sampling rate and value resolution . 7

8.4 Description of interfaces . 7

8.5 Restrictions on performing the tests . 7

8.6 Number of tested samples . 7

8.7 Test voltages . 7

8.8 Test procedure . 8

8.9 Parameter check . 8

8.10 Continuous parameter monitoring with drift analysis . 9

8.11 Physical analysis . 9

9 General requirements .10

9.1 General .10

9.2 Prerequisites regarding the system in which the component is applied .10

9.3 Component requirements .10

10 Tests and requirements .11

10.1 Test-01: nominal voltage range .11

10.1.1 Purpose .11

10.1.2 Test .11

10.1.3 Procedure .11

10.1.4 Requirement .12

10.2 Test-02: lower and upper transitory voltage ranges .12

10.2.1 Purpose .12

10.2.2 Test .12

10.2.3 Procedure .13

10.2.4 Requirement .14

10.3 Test-03: short term overvoltage.14

10.3.1 Purpose .14

10.3.2 Test .14

10.3.3 Procedure .15

10.3.4 Requirement .15

10.4 Test-04: supply component load dump control test .15

10.4.1 Purpose .15

10.4.2 Test .15

10.4.3 Procedure .16

10.4.4 Requirement .16

10.5 Test-05: starting profile .17

10.5.1 Purpose .17

10.5.2 Test .17

10.5.3 Procedure .18

10.5.4 Requirement .18

10.6 Test-06: long term overvoltage .18

10.6.1 Purpose .18

10.6.2 Test .18

10.6.3 Requirement .19

10.7 Test-07: overvoltage with consumer components which may supply electrical energy .19

10.7.1 Purpose .19

10.7.2 Test .19

10.7.3 Requirements for part 1 and part 2 .22

10.8 Test-08: decrease and increase of supply voltage .23

10.8.1 Purpose .23

10.8.2 Test .23

10.8.3 Requirement .23

10.9 Test-09: voltage ripples .23

10.9.1 Purpose .23

10.9.2 Test .24

10.9.3 Requirement .25

10.10 Test-10: reinitialisation .25

10.10.1 Purpose .25

10.10.2 Test .26

10.10.3 Requirement .26

10.11 Test-11: discontinuities in supply voltage .27

10.11.1 Purpose .27

10.11.2 Test .27

10.11.3 Requirements .28

10.12 Test-12: ground loss .28

10.12.1 Purpose .28

10.12.2 Requirements .32

10.13 Test-13: fault current .33

10.13.1 Purpose .33

10.13.2 Test .33

10.13.3 Requirement .34

10.14 Test-14: ground offset .35

10.14.1 Purpose .35

10.14.2 Test .35

10.14.3 Requirement .37

10.15 Test-15: short circuit in signal line and load circuit .37

10.15.1 Purpose .37

10.15.2 Test .37

10.15.3 Procedure .38

10.15.4 Requirements .38

10.16 Test-16: quiescent current .39

10.16.1 Purpose .39

10.16.2 Test .39

10.16.3 Requirements .40

Annex A (informative) Example of functional status and functional categories.41

Annex B (informative) Loss of GND using the example CAN communication .43

iv © ISO 2020 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 32,

Electrical and electronic equipment and general system aspects.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

INTERNATIONAL STANDARD ISO 21780:2020(E)

Road vehicles — Supply voltage of 48 V — Electrical

requirements and tests

1 Scope

This document covers requirements and tests for the electric and electronic components in road

vehicles equipped with an electrical system operating at a nominal voltage of 48 V DC.

This includes the following:

— general requirements on 48 V DC electrical systems;

— voltage ranges;

— slow voltage transients and fluctuations (not including EMC).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 16750-1, Road vehicles — Environmental conditions and testing for electrical and electronic

equipment — Part 1: General

ISO 16750-2, Road vehicles — Environmental conditions and testing for electrical and electronic

equipment — Part 2: Electrical loads

ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories

EN 13018, Non-destructive testing — Visual testing — General principles

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

component

a part that is directly installed in a vehicle and is the Device Under Test (DUT)

3.2

fire

self-supporting combustion which spreads, uncontrolled, with time and in space and may result in

bright light, heat, smoke, burning or a combination of all the above

3.3

ground for 12 V/24 V electrical system

GND

12/24

ground pin on the 12 V/24 V electrical system

3.4

ground for 48 V electrical system

GND

ground pin on the 48 V electrical system

3.5

12 V/24 V positive voltage connection pin

U

12/24

positive voltage connection pin on the 12 V/24 V electrical system

3.6

48 V positive voltage connection pin

U

positive voltage connection pin on the 48 V electrical system

3.7

nominal 12 V/24 V supply voltage

U

N

voltage of the 12 V/24 V external supply distribution system

3.8

nominal 48 V supply voltage

U

48N

voltage of the 48 V external supply distribution system

3.9

maximum operating temperature

T

max

highest temperature of operation of the DUT

3.10

minimum operating temperature

T

min

lowest temperature of operation of the DUT

3.11

room temperature

T

RT

ambient temperature at which the test is performed

3.12

test temperature

T

test

temperature of the DUT at which the test is performed

4 Functional status

4.1 General

A component may include several functions which might have different functional statuses for the same

value of the influencing parameter. For the purpose of this document the influencing parameter is the

supply voltage.

The functional status is a minimum requirement.

The component functional behaviour, (including derating), relating to each chosen functional status

level and the customer perception (e.g. visual, acoustic, tactile and thermal), shall be defined and

agreed between the customer and supplier and described in the required component documentation.

See Annex A for application examples.

2 © ISO 2020 – All rights reserved

4.2 Functional status 1 (FS1)

The function shall meet a specified performance without deviation. Derating or switch-off is not

allowed.

4.3 Functional status 2 (FS2)

The function shall meet a specified performance with a specified variation below or above the specified

performance of FS1. Derating is allowed, switch-off is not allowed.

4.4 Functional status 3 (FS3)

The function may not provide the specified performance. Derating or switch-off is allowed. The function

shall automatically recover and return to the specified performance level if the necessary operating

conditions are met.

4.5 Functional status 4 (FS4)

The function may not provide the specified performance. Derating or switch-off is allowed. The function

shall recover and return to specified performance only after a change in vehicle operational status (e.g.

change of ignition status, vehicle restart) has occurred and if the necessary operating conditions are met.

4.6 Functional status 5 (FS5)

The DUT fails to perform one or more functions whilst the test parameters are applied, the DUT does

not set itself on fire as defined in 3.2. After application is terminated, the DUT can no longer be used

unless it is repaired or replaced

5 Supply voltage range

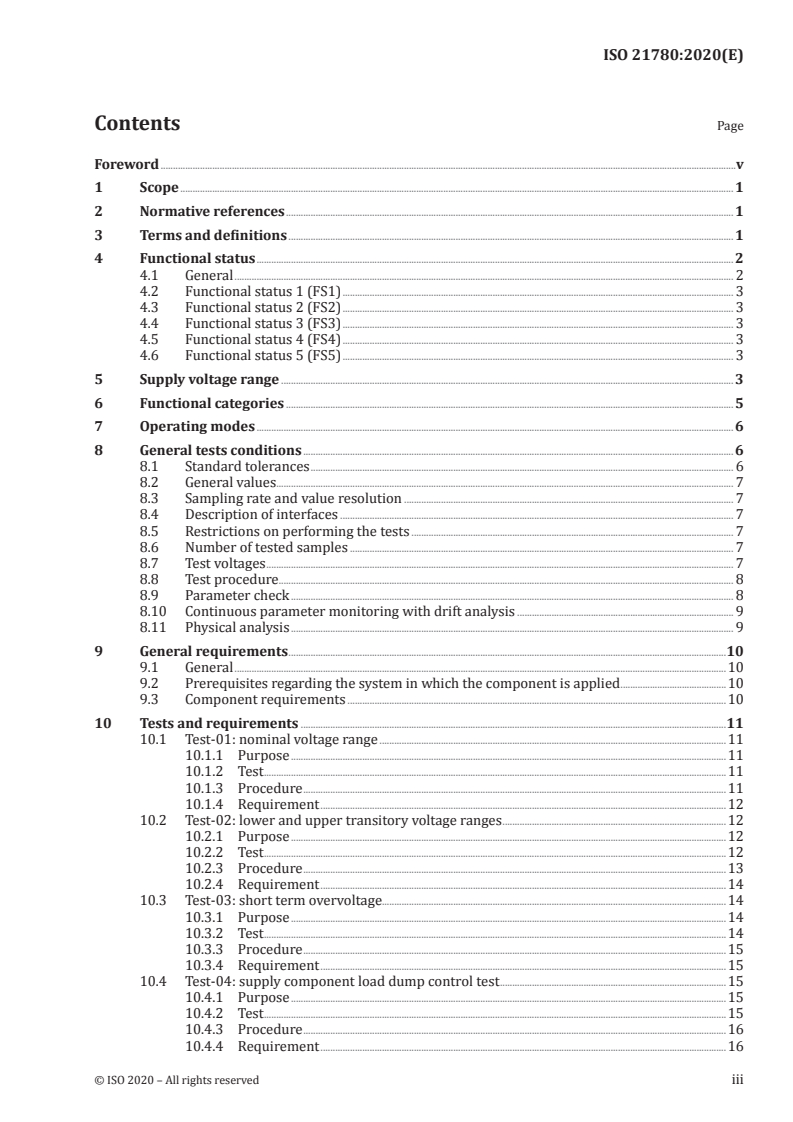

The supply voltage ranges are described in Figure 1.

Figure 1 — Supply voltage ranges

Upper overvoltage range (58 V – 60 V):

Reason for being in this voltage range could be a control error.

Overvoltage range (54 V – 58 V):

This voltage range may occur due to (short term) return of electrical energy or maybe a control error.

The system may operate only temporarily in this range.

Upper transitory voltage range (52 V – 54 V):

This range is intended for calibrating the storage media and for uptake of recovered energy.

The system may operate only temporarily in this range.

Nominal voltage range (36 V – 52 V):

The system is expected to operate in this range most of the time.

Lower transitory voltage range (31 V – 36 V):

The voltage may for example be in this range during boost or during cold crank.

The system may operate only temporarily in this range.

Undervoltage range (24 V – 31 V):

The voltage may for example be in this range during cold crank.

4 © ISO 2020 – All rights reserved

The system may operate only temporarily in this range.

Lower undervoltage range (0 V – 24 V):

Storage protection.

The voltage is not expected to be in this range except for short term discontinuities in the supply voltage

or due to long term parking.

6 Functional categories

The required performance, (e.g. torque of an electrical motor or flow rate of a water pump), shall be

specified for each relevant function of the DUT. The performance specified is then used as a reference

to enable the selection of a functional status level for each relevant function. The functional categories

which specify the changes in functional status of the DUT as a function of the 48 V supply voltage are

described in Table 2. Use Table 2 to select the required category for each function of the DUT. Examples

for the different functional categories are given in Table 1.

Table 1 — Functional categories

Functional category Example of functions or components

FC I Communication, diagnostic

Voltage conversion from 48 V to 12 V

Functions relevant to vehicle safety

FC II

Functions relevant to propulsion.

Components which act as 48 V sources.

Components/functions relevant to starting.

FC III Components/functions that need to operate during starting

(cranking).

FC IV Comfort functions

To be used if the above definitions of functional categories are

FC Z judged to be unsuitable for the DUT. In this case, functional status is

to be agreed between supplier and customer for each test.

Table 2 — Functional status

Functional category

Voltage range Test

I II III IV Z

As

60 V < U ≤ 70 V Test-03 Short term overvoltage FS1 FS2 FS2 FS3

agreed

As

58 V < U ≤ 60 V Test-06 Long term overvoltage FS3 FS3 FS3 FS3

agreed

Test-07 Overvoltage with consumer components As

54 V < U ≤ 58 V FS1 FS2 FS3 FS3

which may supply electrical energy agreed

As

52 V < U ≤ 54 V Test-02 Lower and upper transitory voltage ranges FS1 FS2 FS3 FS2

agreed

As

52 V < U ≤ 54 V Test-09 Voltage ripples FS1 FS2 FS3 FS2

agreed

As

36 V ≤ U ≤ 52 V Test-01 Nominal voltage range FS1 FS1 FS1 FS1

agreed

As

31 V ≤ U < 36 V Test-02 Lower and upper transitory voltage ranges FS1 FS2 FS2 FS3

agreed

As

31 V ≤ U < 36 V Test-08 Decrease and increase of supply voltage FS1 FS2 FS2 FS3

agreed

Table 2 (continued)

Functional category

Voltage range Test

I II III IV Z

As

31 V ≤ U < 36 V Test-09 Voltage ripples FS1 FS2 FS2 FS3

agreed

As

31 V ≤ U < 36 V Test-10 Reinitialization FS1 FS2 FS2 FS3

agreed

As

24 V ≤ U < 31 V Test-05 Starting profile FS1 FS2 FS2 FS3

agreed

As

24 V ≤ U < 31 V Test-08 Decrease and increase of supply voltage FS1 FS3 FS3 FS3

agreed

As

24 V ≤ U < 31 V Test-10 Reinitialization FS1 FS2 FS2 FS3

agreed

As

0 V ≤ U < 24 V Test-08 Decrease and increase of supply voltage FS3 FS3 FS3 FS3

agreed

As

0 V ≤ U < 24 V Test-10 Reinitialization FS3 FS3 FS3 FS3

agreed

NOTE Not all of the tests in this document are listed in Table 2. Tests that are not listed in the table state

their requirements in the individual test clauses.

7 Operating modes

The following operating modes apply.

The DUT is electrically operated with test voltage U and U as defined in 3.7 and 3.8 (unless

N 48N

otherwise specified in the test procedure) with all electrical connections made.

If the component requires a cooling system, it shall be operated and adjusted if necessary, as described

in the component specifications:

— operating mode 2.1: system/component functions are not activated (e.g. sleep mode);

— operating mode 2.2: electrical systems/components controlled to and operating at typical

operating mode;

— operating mode 2.3: electrical systems/components controlled to and operating at minimum load.

No activated loads (e.g. standby);

— operating mode 2.4: electrical systems/components controlled to and operating at maximum load.

Minimum, typical and maximum operating loads should be defined for each function by agreement

between the supplier and customer.

NOTE Since the application scope is different, these operating modes definitions are not strictly identical

to the definitions of the ISO 16750-1. Operating modes 1, 3 are used in ISO 16750-1 but are not needed in this

document.

8 General tests conditions

8.1 Standard tolerances

Unless otherwise stated, the tolerances specified in Table 3 apply for the measurement values in all the

tests given in this standard.

6 © ISO 2020 – All rights reserved

Table 3 — Standard tolerances

Abbreviation Meaning Tolerance limits

f Frequency ±1 %

T Temperature ±2 °C

RH Relative humidity ±5 %

t Time +5 % to 0 %

U Voltage ±0,5 %

I Current ±2 %

R Resistor ±10 %

8.2 General values

Unless otherwise specified, all tests shall be performed at:

— nominal 12 V/24 V voltage (U ) as defined in ISO 16750-1;

N

— nominal 48 V voltage (U ): 48 V;

48N

— room temperature (T ): +23 °C ±5 °C;

RT

— relative humidity (RH ): 25 % to 75 %;

test

— test temperature (T ): room temperature.

test

8.3 Sampling rate and value resolution

Before each test, it shall be ensured that the sampling rate/bandwidth, the measurement range of the

measuring system and the resolution of the measured values are set to values appropriate for the test

to be performed and, where necessary, adjusted to suit. All measured values shall be recorded along

with the maximum and minimum, or peak, values.

8.4 Description of interfaces

All interfaces to the DUT which enable functional performance of the DUT along with the specific

test parameters to be met shall be defined. Examples of such are, electrical connectors and wiring,

mechanical attachments, coolant mechanisms, etc.

8.5 Restrictions on performing the tests

The testing laboratory shall be organised and operated in accordance with ISO/IEC 17025. All the

testing equipment used for making measurements shall be calibrated in accordance with ISO/IEC 17025

(or as determined or recommended by the manufacturer) and shall be traceable to a national metrology

laboratory.

8.6 Number of tested samples

Final validation shall be performed with at least two DUTs, during initial design validation phases this

requirement is waived.

8.7 Test voltages

Unless explicitly specified otherwise, voltage profiles indicated refer to the terminal voltages of the DUT

and shall be measured and documented in the test report. The specified voltages shall be measured

referenced to their respective grounds at connector or terminals of the DUT.

All 48 V components that are equipped with an interface for 12 V/24 V supply, or communication

interfaces, shall also satisfy the corresponding requirements for the 12 V/24 V supply:

— during the 12 V/24 V supply system tests, the voltage in the 48 V supply system is U , unless

48N

required otherwise in the individual tests;

— during the 48 V supply system tests, the voltage in the 12 V/24 V supply system is U , unless indicated

N

otherwise in the individual tests.

All 48 V components that are equipped with an interface to any other supply voltage level shall also

satisfy the corresponding standards.

8.8 Test procedure

The test procedure shall be defined in conjunction with the customer and documented within a test

plan. For each test, as applicable, the permitted error memory entries and the functional statuses for

each function of the component shall be agreed with the customer and documented within the test plan.

Details of the test setup, operating loads (e.g. triggering, original sensors, original actuators and

replacement circuitry) and the required boundary conditions shall be agreed between the customer

and the supplier and documented in a test plan and in the resultant test report. Components that are

electrically both a source and a sink shall be tested in both modes of operation.

The test equipment shall ensure that all interfaces which are required to meet the specified performance

of the DUT are populated and functional to the required level. Signals or messages which shall be

received from or transmitted to the vehicle controller in order to ensure the DUT functions as expected

may be simulated if a full vehicle or HIL simulation is not used.

In all cases, program and data storage devices shall remain in FS1 until the component is deactivated.

If the device has non-volatile memory, the integrity (not the current status) of the non-volatile memory

shall be ensured at all times.

Damage to the DUT is not permitted in FS1 to FS4. The permissible limit values specified in the data

sheets (e.g. electrical, thermal or mechanical) of the electric/electronic components in the DUT shall

not be exceeded. Evidence of this is provided at least by the parameter check as described in 8.9.

An electrical test begins when the DUT has started up completely and is in FS1.

Before and after every test, the DUTs shall be subjected to a parameter check as described in 8.9 in

accordance with specifications. The DUT shall be in a steady state of temperature at the beginning of

each test.

During each test, the key parameters to be monitored shall be recorded as described in 8.10. Component

resets shall be monitored and documented in an appropriate form to be included in the test report.

Damaged DUTs (FS5) shall be removed from the test cycle, analysed regarding the root cause for the

failure and documented. In such cases, the test shall be repeated with a new DUT, or the following test

in the test plan shall be performed with a new DUT. The procedure shall be agreed with the customer.

The physical analysis as described in 8.11 shall be carried out on at least one DUT following completion

of all the electrical tests. All component parts including hardware, software or calibrations of the DUT

undergoing final validation stage, shall be recorded. Any change in these parts shall require revalidation

or justification of no impact.

8.9 Parameter check

A set of sensitive parameters called key parameters shall be defined both in the component specifications

and in consultation with the customer, e.g. quiescent current consumption, operating currents, output

voltages, contact resistances, input impedances, signal rates (rise and fall times) and bus specifications.

These parameters shall be checked before the start and after the completion of each test to verify that

they match the specification.

8 © ISO 2020 – All rights reserved

The key parameters shall be measured and the functional behaviour of the components at T and

RT

U shall be checked. For components with error memory, the error memory shall be read out and

48N

documented and then deleted before the start of the test. After the test, the error memory shall again

be read out and documented.

The results and data from the before/after tests may differ only within the specified permissible

tolerances. Any changes in the measured values exceeding the measurement accuracies shall be

indicated as such. The results shall be examined for trends and drifts so that any abnormalities, ageing

or malfunctions of the component can be identified.

The components shall be inspected visually in accordance with EN 13018 for external damage/changes,

for example cracks, chipping/peeling, discolouration, distortion, etc., without opening the DUT.

All the results shall be documented in the test report.

8.10 Continuous parameter monitoring with drift analysis

A list of key parameters shall be defined within the specification of the component.

These parameters shall be those which are necessary for the end user to understand, in order to achieve

both full functional performance and reliable operation, when integrated within a vehicle.

The parameters shall also include those which are necessary to be understood to ensure compatibility

with the vehicle systems to which the component is interfaced.

Such specifications may include, but not be limited to, written documents, drawings and/or schematic

diagrams.

Examples of parameters which are recommended to be considered are: quiescent current consumption,

peak and rated operating currents and voltages, contact resistances, input impedances, signal rates

(rise and fall times) and bus specifications.

The key parameters to be monitored shall be recorded throughout the test.

In the case of components with error memory, the error memory shall be monitored at the beginning

and at the end of each test and the entries shall be documented in the test report.

The data collected from the continuous parameter monitoring shall be examined for trends and drifts

in order to identify abnormalities, ageing or malfunctions of the component.

8.11 Physical analysis

DUT (ECU or system) shall be opened and a visual inspection shall be performed in accordance with

EN 13018. Component level physical analysis is optional.

Additional analyses (e.g. x-ray, Scanning Electron Microscope (SEM) analysis, cross section investigation

and metallographic examination of the hardware design and connecting technology) shall be agreed

between the customer and the supplier.

Any changes in the component beyond defined tolerances shall be documented and approved by the

customer.

The results shall be documented and evaluated in the test report.

9 General requirements

9.1 General

This document covers the electric behaviour at the DC terminals of all 48 V DC components. For the

energy storage systems electrochemical part is not tested while the management system is tested alone

as an independent DUT.

9.2 Prerequisites regarding the system in which the component is applied

— Static direct voltages are limited to ≤60 V.

— A short circuit of the 48 V supply to the 12 V/24 V system or any GND due to a single error in the

wiring harness is prevented by appropriate measures in the vehicle.

— There is a common ground for the 12 V/24 V system and the 48 V system, which are connected via

physically separate grounding bolts/connections except for the power ground of components that

convert power between 48 V and 12 V/24 V such as DC/DC converters.

— The polarity of the 48 V supply is prevented from reversing by the use of appropriate measures

within the vehicle (e.g. Poka-Yoke).

— Jump starting by direct connection with the 48 V power supply is prevented by the use of appropriate

measures applied within the vehicle.

— The 48 V system shall not induce additional constraints on existing 12/24 V components as those

are not specifically designed for use upon a vehicle which uses a dual power distribution system.

— If a screwed or plugged 12 V/24 V and a 48 V connection are nearby, the system shall prevent

accidental inversion by design.

9.3 Component requirements

— Any single fault condition within devices or at their external interfaces connecting to both the

48 V and the 12 V/24 V electrical system, shall not create a short circuit between the two electrical

systems nor result in an overvoltage on any part of the 12 V/24 V electrical system.

— Devices with separate GND connections for the 48 V and the 12 V/24 V electrical system shall

provide countermeasures to avoid accidental connection of the two GND domains.

— The loss of any ground connection to the DUT shall not disrupt or destroy the communication within

the connected network interface (e.g. bus system) or any other connected electrical s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.