ISO 20987:2019

(Main)Simplified design for mechanical connections between precast concrete structural elements in buildings

Simplified design for mechanical connections between precast concrete structural elements in buildings

This document refers to connections in precast frame systems, either for single-storey or multi-storey buildings. The connections for all orders of joints are considered. Large wall panel and three-dimensional cell systems are not considered. According to the position in the overall construction and of the consequent different structural functions, the seven following orders of joints are considered: a) mutual joints between floor or roof elements (floor-to-floor) that, in the seismic behaviour of the structural system, concern the diaphragm action of the floor; b) joints between floor or roof elements and supporting beams (floor-to-beam) that give the peripheral constraints to the floor diaphragm in its seismic behaviour; c) joints between beam and column (beam-to-column) that ensure in any direction the required degree of restraint in the frame system; d) joints between column segments (column-to-column) used for multi-storey buildings usually for dual wall braced systems; e) joints between column and foundation (column-to-foundation), able to ensure in any plane a fixed full support of the column; f) fastenings of cladding panels to the structure (panel-to-structure) that ensure the stability of the panels under the high forces or the large drifts expected under seismic action; g) joints between adjacent cladding panels (panel-to-panel) possibly used to increase the stiffness of the peripheral wall system and provide an additional source of energy dissipation. Simple bearings working by gravity load friction are not considered. Sliding and elastic deformable supporting devices neither, being all these types of connections not suitable for the transmission of seismic actions. The document provides formulae for the strength design of a large number of joint typologies.

Conception simplifiée pour les assemblages mécaniques entre éléments structurels en béton préfabriqué dans les bâtiments

General Information

- Status

- Published

- Publication Date

- 10-Oct-2019

- Technical Committee

- ISO/TC 71/SC 5 - Simplified design standard for concrete structures

- Drafting Committee

- ISO/TC 71/SC 5 - Simplified design standard for concrete structures

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 08-Dec-2025

- Completion Date

- 13-Dec-2025

Overview

ISO 20987:2019 - "Simplified design for mechanical connections between precast concrete structural elements in buildings" - is an international standard that provides guidance and strength-design formulae for mechanical joints in precast frame systems. It covers single‑storey and multi‑storey precast buildings and focuses on connections that must transfer seismic actions. The standard does not cover large wall-panel or three-dimensional cell systems, nor simple gravity bearings, sliding supports or elastic deformable devices (these are considered unsuitable for seismic force transmission).

Key topics and technical requirements

- Scope of joints: seven orders of joints are explicitly considered:

- Floor-to-floor (diaphragm-related)

- Floor-to-beam (peripheral diaphragm restraints)

- Beam-to-column (frame restraint)

- Column-to-column (multi-storey, dual wall/braced systems)

- Column-to-foundation (full fixed support)

- Panel-to-structure (cladding fastenings for drift and seismic loads)

- Panel-to-panel (stiffness and energy dissipation of peripheral walls)

- Design content: classification of connections, material and component properties, and strength-design formulae for many joint typologies.

- Performance parameters: guidance and checks for strength, ductility, energy dissipation, deformation capacity, cyclic decay, and damage under seismic loading.

- Connection types addressed: cast‑in‑situ toppings and joints, welded and bolted steel connectors, supports using steel angles or shoes, dowel connections, mechanical couplers, hybrid solutions and pocket foundations.

- Limitations: excludes connections that rely on friction-only gravity bearing or sliding/elastic devices for seismic action transmission.

Practical applications

- Use ISO 20987:2019 to:

- Size and detail mechanical connections between precast elements for seismic resistance

- Select and specify appropriate connector types (bolted, welded, couplers, dowels)

- Evaluate ductility and energy dissipation capacity of joints during design reviews

- Inform erection detailing, quality control, and tender specifications for precast projects

- Support retrofit or assessment work where mechanical connections are critical to structural performance

Who should use this standard

- Structural and seismic engineers designing precast frame systems

- Precast manufacturers and connector suppliers developing product solutions

- Contractors and erectors preparing shop drawings and sequence plans

- Building officials and reviewers assessing compliance for seismic performance

- Researchers and educators focused on precast connection behavior

Related standards and practice

ISO 20987:2019 is intended to be used alongside applicable national and international structural and seismic design codes and standards and with project-specific specifications. It provides practical formulae and classifications to complement code-based load and performance requirements.

Keywords: ISO 20987:2019, precast concrete connections, mechanical connections, precast frame systems, seismic design, joint typologies, strength design formulae, ductility, beam-to-column, floor-to-beam.

ISO 20987:2019 - Simplified design for mechanical connections between precast concrete structural elements in buildings

REDLINE ISO 20987:2019 - Simplified design for mechanical connections between precast concrete structural elements in buildings Released:10/11/2019

Frequently Asked Questions

ISO 20987:2019 is a standard published by the International Organization for Standardization (ISO). Its full title is "Simplified design for mechanical connections between precast concrete structural elements in buildings". This standard covers: This document refers to connections in precast frame systems, either for single-storey or multi-storey buildings. The connections for all orders of joints are considered. Large wall panel and three-dimensional cell systems are not considered. According to the position in the overall construction and of the consequent different structural functions, the seven following orders of joints are considered: a) mutual joints between floor or roof elements (floor-to-floor) that, in the seismic behaviour of the structural system, concern the diaphragm action of the floor; b) joints between floor or roof elements and supporting beams (floor-to-beam) that give the peripheral constraints to the floor diaphragm in its seismic behaviour; c) joints between beam and column (beam-to-column) that ensure in any direction the required degree of restraint in the frame system; d) joints between column segments (column-to-column) used for multi-storey buildings usually for dual wall braced systems; e) joints between column and foundation (column-to-foundation), able to ensure in any plane a fixed full support of the column; f) fastenings of cladding panels to the structure (panel-to-structure) that ensure the stability of the panels under the high forces or the large drifts expected under seismic action; g) joints between adjacent cladding panels (panel-to-panel) possibly used to increase the stiffness of the peripheral wall system and provide an additional source of energy dissipation. Simple bearings working by gravity load friction are not considered. Sliding and elastic deformable supporting devices neither, being all these types of connections not suitable for the transmission of seismic actions. The document provides formulae for the strength design of a large number of joint typologies.

This document refers to connections in precast frame systems, either for single-storey or multi-storey buildings. The connections for all orders of joints are considered. Large wall panel and three-dimensional cell systems are not considered. According to the position in the overall construction and of the consequent different structural functions, the seven following orders of joints are considered: a) mutual joints between floor or roof elements (floor-to-floor) that, in the seismic behaviour of the structural system, concern the diaphragm action of the floor; b) joints between floor or roof elements and supporting beams (floor-to-beam) that give the peripheral constraints to the floor diaphragm in its seismic behaviour; c) joints between beam and column (beam-to-column) that ensure in any direction the required degree of restraint in the frame system; d) joints between column segments (column-to-column) used for multi-storey buildings usually for dual wall braced systems; e) joints between column and foundation (column-to-foundation), able to ensure in any plane a fixed full support of the column; f) fastenings of cladding panels to the structure (panel-to-structure) that ensure the stability of the panels under the high forces or the large drifts expected under seismic action; g) joints between adjacent cladding panels (panel-to-panel) possibly used to increase the stiffness of the peripheral wall system and provide an additional source of energy dissipation. Simple bearings working by gravity load friction are not considered. Sliding and elastic deformable supporting devices neither, being all these types of connections not suitable for the transmission of seismic actions. The document provides formulae for the strength design of a large number of joint typologies.

ISO 20987:2019 is classified under the following ICS (International Classification for Standards) categories: 91.080.40 - Concrete structures. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 20987:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 20987

First edition

2019-10

Simplified design for mechanical

connections between precast concrete

structural elements in buildings

Conception simplifiée pour les assemblages mécaniques entre

éléments structurels en béton préfabriqué dans les bâtiments

Reference number

©

ISO 2019

© ISO 2019

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2019 – All rights reserved

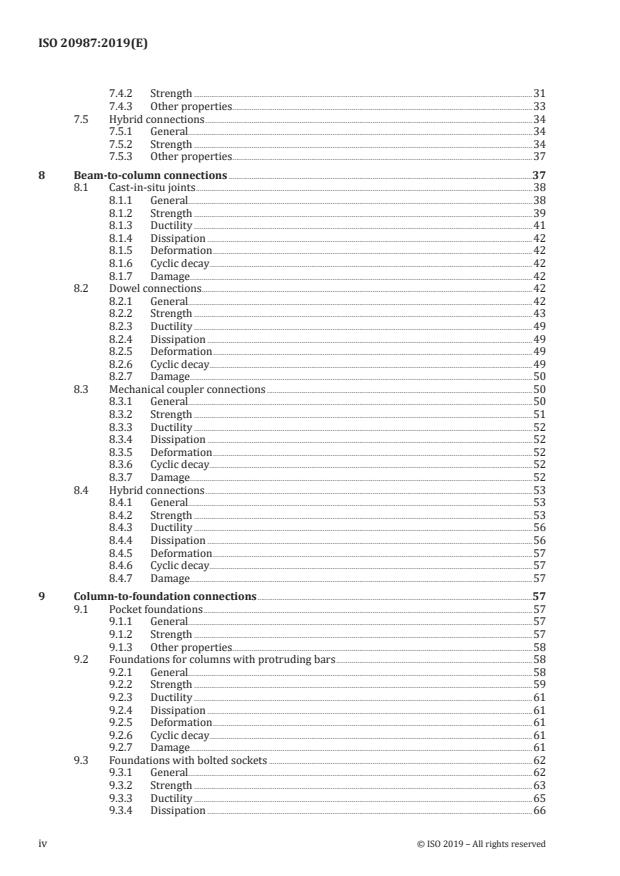

Contents Page

Foreword .vi

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Properties .3

5 Classification .4

5.1 General . 4

5.2 Strength . 4

5.3 Ductility . 4

5.3.1 Ductile connections . 4

5.4 Dissipation . 5

5.5 Deformation . 5

6 Floor-to-floor connections .5

6.1 Cast-in-situ topping . 5

6.1.1 General. 5

6.1.2 Strength . 6

6.1.3 Other properties . 6

6.2 Cast-in-situ joints . 6

6.2.1 General. 6

6.2.2 Strength . 6

6.2.3 Other properties . 7

6.3 Welded steel connectors . 7

6.3.1 General. 7

6.3.2 Strength . 7

6.3.3 Other properties .10

6.4 Bolted steel connectors .10

6.4.1 General.10

6.4.2 Strength .10

6.4.3 Other properties .13

7 Floor-to-beam connections .14

7.1 Cast-in-situ joints .14

7.1.1 General.14

7.1.2 Other properties .14

7.2 Supports with steel angles .14

7.2.1 General.14

7.2.2 Strength .16

7.2.3 Ductility .22

7.2.4 Dissipation .22

7.2.5 Deformation .23

7.2.6 Cyclic decay . . .23

7.2.7 Damage .23

7.3 Supports with steel shoes .23

7.3.1 General.23

7.3.2 Strength .23

7.3.3 Ductility .30

7.3.4 Dissipation .30

7.3.5 Deformation .30

7.3.6 Cyclic decay . . .30

7.3.7 Damage .30

7.4 Welded supports.30

7.4.1 General.30

7.4.2 Strength .31

7.4.3 Other properties .33

7.5 Hybrid connections .34

7.5.1 General.34

7.5.2 Strength .34

7.5.3 Other properties .37

8 Beam-to-column connections .37

8.1 Cast-in-situ joints .38

8.1.1 General.38

8.1.2 Strength .39

8.1.3 Ductility .41

8.1.4 Dissipation .42

8.1.5 Deformation .42

8.1.6 Cyclic decay . . .42

8.1.7 Damage .42

8.2 Dowel connections.42

8.2.1 General.42

8.2.2 Strength .43

8.2.3 Ductility .49

8.2.4 Dissipation .49

8.2.5 Deformation .49

8.2.6 Cyclic decay . . .49

8.2.7 Damage .50

8.3 Mechanical coupler connections .50

8.3.1 General.50

8.3.2 Strength .51

8.3.3 Ductility .52

8.3.4 Dissipation .52

8.3.5 Deformation .52

8.3.6 Cyclic decay . . .52

8.3.7 Damage .52

8.4 Hybrid connections .53

8.4.1 General.53

8.4.2 Strength .53

8.4.3 Ductility .56

8.4.4 Dissipation .56

8.4.5 Deformation .57

8.4.6 Cyclic decay . . .57

8.4.7 Damage .57

9 Column-to-foundation connections .57

9.1 Pocket foundations .57

9.1.1 General.57

9.1.2 Strength .57

9.1.3 Other properties .58

9.2 Foundations for columns with protruding bars .58

9.2.1 General.58

9.2.2 Strength .59

9.2.3 Ductility .61

9.2.4 Dissipation .61

9.2.5 Deformation .61

9.2.6 Cyclic decay . . .61

9.2.7 Damage .61

9.3 Foundations with bolted sockets .62

9.3.1 General.62

9.3.2 Strength .63

9.3.3 Ductility .65

9.3.4 Dissipation .66

iv © ISO 2019 – All rights reserved

9.3.5 Deformation .66

9.3.6 Cyclic decay . . .66

9.3.7 Damage .66

9.4 Foundations with bolted flanges .67

9.4.1 General.67

9.4.2 Strength .67

9.4.3 Other properties .68

9.5 Foundations with mechanical couplers .68

9.5.1 General.68

9.5.2 Strength .68

9.5.3 Ductility .69

9.5.4 Dissipation .70

9.5.5 Deformation .70

9.5.6 Cyclic decay . . .70

9.5.7 Damage .70

10 Calculation of actions.70

10.1 General criteria .70

10.2 Capacity design .70

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso

.org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 71, Concrete, reinforced concrete and pre-

stressed concrete, Subcommittee SC 5, Simplified design standard for concrete structures.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

vi © ISO 2019 – All rights reserved

Introduction

This document contains a set of practical provisions for the design of the mechanical connections in

precast elements under seismic actions. Design of the connections is carried out in terms of strength

verifications. Indications are also provided for defining the actions to be used in design.

If national standards provide alternate formulae for the same typology, those can be used instead of the

ones given in this document.

INTERNATIONAL STANDARD ISO 20987:2019(E)

Simplified design for mechanical connections between

precast concrete structural elements in buildings

1 Scope

This document refers to connections in precast frame systems, either for single-storey or multi-

storey buildings. The connections for all orders of joints are considered. Large wall panel and three-

dimensional cell systems are not considered.

According to the position in the overall construction and of the consequent different structural

functions, the seven following orders of joints are considered:

a) mutual joints between floor or roof elements (floor-to-floor) that, in the seismic behaviour of the

structural system, concern the diaphragm action of the floor;

b) joints between floor or roof elements and supporting beams (floor-to-beam) that give the peripheral

constraints to the floor diaphragm in its seismic behaviour;

c) joints between beam and column (beam-to-column) that ensure in any direction the required degree

of restraint in the frame system;

d) joints between column segments (column-to-column) used for multi-storey buildings usually for

dual wall braced systems;

e) joints between column and foundation (column-to-foundation), able to ensure in any plane a fixed

full support of the column;

f) fastenings of cladding panels to the structure (panel-to-structure) that ensure the stability of the

panels under the high forces or the large drifts expected under seismic action;

g) joints between adjacent cladding panels (panel-to-panel) possibly used to increase the stiffness of

the peripheral wall system and provide an additional source of energy dissipation.

Simple bearings working by gravity load friction are not considered. Sliding and elastic deformable

supporting devices neither, being all these types of connections not suitable for the transmission of

seismic actions.

The document provides formulae for the strength design of a large number of joint typologies.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1

union

generic linking constraint between two or more members

3.2

connection

local region that includes the union (3.1) between two or more members

3.3

connector

linking device (usually metallic) interposed between the parts to be connected

3.4

node

local region of convergence between different members

3.5

joint

equipped interface between adjacent members

3.6

system

set of linking practices classified on the basis of the execution technology

3.7

typical joint

dry joint (3.5) with mechanical connectors (3.3) generally composed of angles, plates, channel bars,

anchors, fasteners, bolts, dowel bars, etc., including joints completed in-situ with mortar for filling

or fixing

3.8

emulative joint

wet joint (3.5) with rebar splices and cast-in-situ concrete restoring the monolithic continuity typical of

cast-in-situ structures and leading usually to “moment-resisting” unions (3.1)

3.9

strength

maximum value of the force which can be transferred between the parts

3.10

ductility

ultimate plastic deformation compared to the yielding limit

Note 1 to entry: The ductility values or ranges provided refer to the connections (3.2) themselves and, in general,

have no direct relation with the global ductility of the structure. Those values are given for the sake of classifying

the connection and are not supposed to intervene in the design, which is carried out in terms of strength (3.10).

Note 2 to entry: Instead of the plastic deformation of steel element beyond the yield limit, other physical

equivalent non-conservative phenomena can be referred to (such as friction).

3.11

dissipation

specific energy dissipated through the load cycles related to the corresponding perfect elastic-

plastic cycle

Note 1 to entry: The values or ranges provided refer to the connections (3.2) themselves and, in general, have

no direct relation with the global energy dissipation of the structure. Those values are given for the sake of

classifying the connection and are not supposed to intervene in the design, which is carried out in terms of

strength (3.10).

3.12

cyclic decay

decay

strength (3.10) loss through the load cycles compared to the force level

2 © ISO 2019 – All rights reserved

3.13

damage

residual deformation at unloading compared to the maximum displacement and/or evidence of rupture

4 Properties

A connection is composed of three parts: two lateral parts A and C, corresponding to the local regions

of the adjacent members close to the connector; and a central part B constituted by the connector itself

with its metallic components (see Figure 1).

Figure 1 — Scheme of connection

The main parameters which characterize the seismic behaviour of the connection, as measured through

monotonic and cyclic tests, refer to the six properties of:

— strength;

— ductility;

— dissipation;

— deformation;

— decay;

— damage.

A ductile dissipative behaviour of the connection can be provided by the steel connector B:

— when parts A and C have a non-ductile non-dissipative behaviour characterized by a brittle failure,

with small displacements, due to the tensile cracking of concrete; and

— if it is correctly designed for a failure involving flexural or tension-compression modes and not

shear modes or by other dissipative phenomena like friction.

In this case, for a ductile connection, in addition to a ductile connector, the criteria of capacity design

shall be applied, under-proportioning the connector with respect to the lateral parts.

Also, the geometric compatibility of deformations shall be checked (e.g. against the loss of bearing).

Non-ductile connections shall be:

— suitably over-proportioned by capacity design with respect to the resistance of the critical

dissipative regions of the structure; or

— proportioned on the basis of the action obtained from a structural analysis that does not account for

any energy dissipation capacity.

The ductility of the connections can contribute to the global ductility of the structure or not depending

on their position in the structural assembly and on their relative stiffness.

5 Classification

5.1 General

For any single type of connection, the strength is quantified by the relevant formulae. The other

behaviour properties listed in this clause are quantified by specific numerical values. When this precise

numerical quantification is not possible, because of lack of experimental data or excessive variability of

performances, the type of connection is classified in qualitative terms corresponding to ranges of values.

5.2 Strength

For strength, the following information shall be given:

— behaviour models corresponding to the working mechanisms of the connection;

— failure modes of the resistant mechanisms;

— calculation formulae for the evaluation of the ultimate strength for any failure mode;

— other data concerning the specific properties of the connection.

Reference is made to the strength obtained from cyclic loading tests.

5.3 Ductility

For ductility, the following classification is deduced from the force-displacement diagrams obtained in

experiments:

— brittle connections, for which failure is reached without relevant plastic deformation;

— over-resisting connections, for which failure has not been reached at the functional deformation limit;

— ductile connections, for which a relevant plastic deformation has been measured.

In this classification, intentional friction mechanism is equal to plastic deformation. Brittle connections

can be used in seismic zones provided they are:

— over-proportioned by capacity design with respect to the critical regions of the overall structure; or

— proportioned with the action deducted from a structural analysis that does not account for any

energy dissipation capacity.

5.3.1 Ductile connections

Furthermore, ductile connections are divided into:

— high ductility connections, with a displacement ductility ratio of at least 4,5;

— medium ductility connections, with a displacement ductility ratio of at least 3,0;

— low ductility connections, with a displacement ductility ratio of at least 1,5.

With ductility ratio lower than 1,5, the connection is classified as brittle.

These definitions refer to the connection itself and, in general, have no direct relation with the global

ductility of the structure. For any single order of connections, specific indications are given on this

aspect, referring both to ductility and dissipation.

4 © ISO 2019 – All rights reserved

5.4 Dissipation

For dissipation, the following classification is deduced from the force-displacement diagrams of cyclic

tests and related enveloped area histograms:

— low dissipation, with specific values of dissipated energy between 0,10 and 0,30;

— medium dissipation, with specific values of dissipated energy between 0,30 and 0,50;

— high dissipation, with specific values of dissipated energy over 0,50.

With dissipated energy lower than 0,1, the connection is classified as not dissipative.

The theoretical value 1,00 would correspond to the maximum energy dissipated through a perfect

elastic-plastic cycle, e.g. by a massive section of ductile steel under alternate flexure, medium dissipation

corresponds to well confined reinforced concrete sections under alternate flexure and high dissipation

can be achieved with the use of special dissipative devices.

5.5 Deformation

For deformation, indications can be given about the order of magnitude of the relative displacements of

the connection at certain relevant limits, such as the first yielding of steel devices, the ultimate failure

limit or the maximum allowable deformation referred to its functionality.

Indications about cyclic decay and damage are given if relevant and when specific experimental

information is available.

6 Floor-to-floor connections

6.1 Cast-in-situ topping

6.1.1 General

Figure 2 shows the details of a floor made of precast elements interconnected by a concrete topping cast

over their upper surface. The concrete topping, with its reinforcing steel mesh, provides a monolithic

continuity to the floor that also involves the precast elements if properly connected to it. The diaphragm

action for the in-plane transmission of the horizontal forces to the bracing vertical elements of the

structure can be allotted entirely to the topping. Unless greater dimensions are defined from design,

for its structural functions, the concrete topping shall have a minimum thickness, t , related also to

min

the maximum aggregate size of the concrete, d , such as t = 2,4 d ≥ 60 mm.

g min g

Figure 2 — Floor made by precast elements

6.1.2 Strength

Interface shear strength of the connection between the precast element and the topping under seismic

action can be evaluated neglecting the friction contribution due to gravity loads. Transverse vertical

shear at the joint between adjacent floor elements is diverted into the topping. For the good behaviour

of the connection, proper steel links crossing the interface shall ensure, with adequate anchorages, an

effective shear tie between the two parts (see Figure 3).

Figure 3 — Precast elements with and without interface connections with topping

6.1.3 Other properties

No specific parameters of seismic behaviour (ductility, dissipation, deformation, decay, damage) have

been experimentally measured for this type of indirect connection provided by the cast-in-situ topping

that can be calculated like an ordinary reinforced concrete element.

6.2 Cast-in-situ joints

6.2.1 General

Figure 4 shows the floor-to-floor connection made with the concrete filling of a continuous joint

between adjacent elements. It is typical of some precast products like hollow-core slabs. The joint has a

proper shape to ensure good interlocking with the transmission of the vertical transverse shear forces,

when filled in. For the transmission of the horizontal longitudinal shear forces, the interface shear

strength can be improved providing the adjoining edges with vertical indentations. With reference to

the diaphragmatic action, this type of connections ensures that the floor has the same performance as

a monolithic cast-in-situ floor, provided that a continuous peripheral tie is placed against the opening

of the joints. For good filling, the maximum size of the aggregate of the cast-in-situ concrete shall be

limited with reference to the joint width.

Figure 4 — Floor-to-floor connection made by concrete filling

Other types of floor-to-floor cast-in-situ connections, possibly provided with spliced tying steel links,

are not considered in this document.

6.2.2 Strength

The type of connection of concern is usually intended as a continuous longitudinal hinge. Its strength is

ensured following the specifications for the erection of the elements given by the manufacturer.

6 © ISO 2019 – All rights reserved

6.2.3 Other properties

No ductility and dissipation capacities are expected from the concerned type of connections that are

located away from the critical regions of the structure.

6.3 Welded steel connectors

6.3.1 General

In Figure 5 two types of floor-to-floor welded connections are represented. The solution a) is constituted

by two steel angles inserted at the edges of the adjacent elements and fixed to them with anchor loops.

On the joint lap, a bar is placed welded in site to the angles, compensating the erection tolerances. Two

steel plates inserted at the edges of the adjacent elements and fixed to them with anchor loops constitute

the solution b). Over the joint, a middle smaller plate is placed, welded in site to the lateral ones. In both

solutions, the steel components may be placed within a recess in order to save the upper plane surface

of the finishing. In the first solution, the angles may be replaced with plates placed inclined so to leave

in the joint the room for the positioning of the middle bar. These kinds of connections are used to join

ribbed floor elements without topping. They are also used to join special roof elements when placed in

contact one to the other.

a) Steel angles b) Steel plates

Key

1 steel angles 3 steel bar

2 anchor loops 4 steel plates

Figure 5 — Floor-to-floor welded connections

These connections are distributed in some local position along the length of the floor elements. They

provide the transverse deflection consistency with the uniform distribution of the load between the

elements. Under seismic conditions, they mainly provide the transmission of the diaphragm action with

horizontal longitudinal shear forces.

6.3.2 Strength

The following indications about the mechanical behaviour of this type of connections leave out of

consideration the transverse vertical shear forces that are related to the distribution of the loads

between the elements and ref

...

Error! Reference source not found.

ISO/TC 71/SC 5

Date: 2018‐01‐12

Deleted: /FDIS

ISO/TC 71/SC 5/WG 4

Secretariat: ICONTEC

Simplified design for mechanical connections between precast

concrete structural elements in buildings

Document type: Error! Reference source not found.

Document subtype: Error! Reference source not found.

Document stage: Error! Reference source not found.

Document language: Error! Reference source not found.

D:\temp\macroserver\DOCX2PDFRGB\DOCX2PDFRGB.gavoille@W13183_241\C069686e_trackchang

es.docx Error! Reference source not found.

Error! Reference source not found.

COPYRIGHT PROTECTED DOCUMENT

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or

utilized otherwise in any form or by any means, electronic or mechanical, including photocopying,

or posting on the internet or an intranet, without prior written permission. Permission can be

requested from either ISO at the address below or ISO’s member body in the country of the

requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH‐1214 Vernier, Geneva, Switzerland

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

copyright@iso.org

www.iso.org

Error! Reference source not found.

ii

Error! Reference source not found.

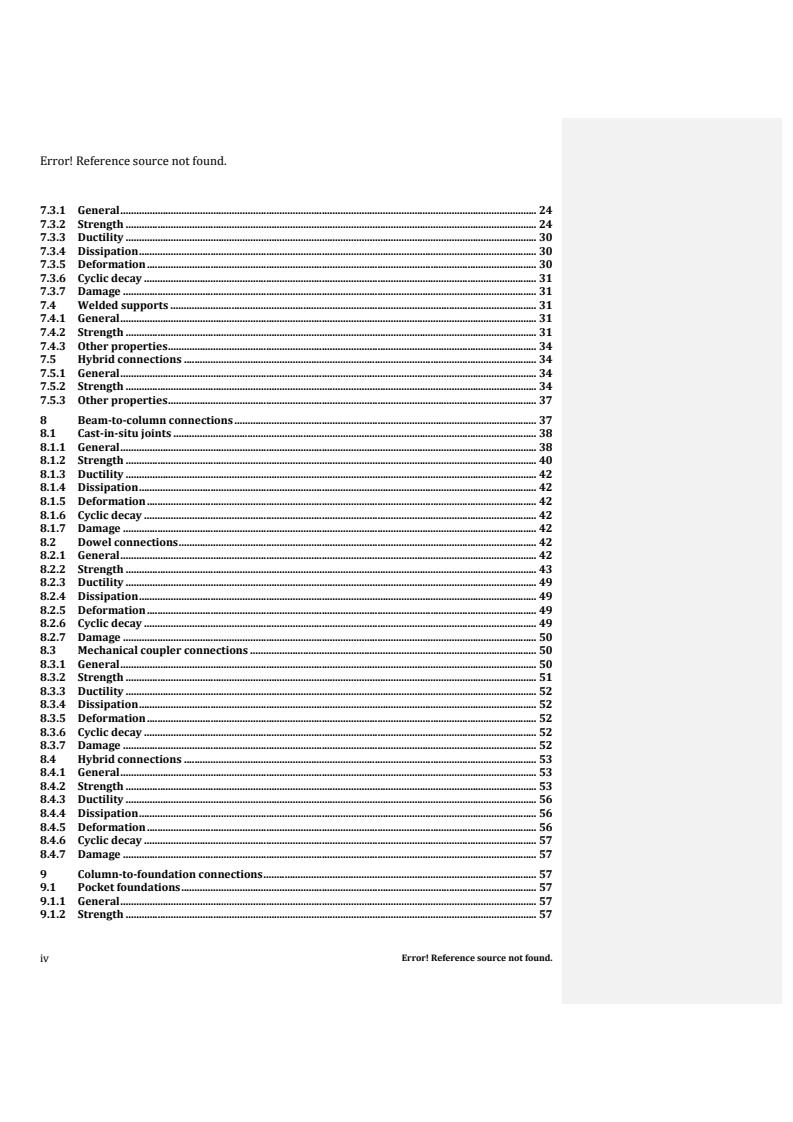

Contents Page

Foreword . 6

Introduction . 7

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Properties . 3

5 Classification . 4

5.1 General . 4

5.2 Strength . 4

5.3 Ductility . 4

5.3.1 Ductile connections . 5

5.4 Dissipation . 5

5.5 Deformation . 5

6 Floor-to-floor connections . 6

6.1 Cast-in-situ topping . 6

6.1.1 General . 6

6.1.2 Strength . 6

6.1.3 Other properties . 6

6.2 Cast-in-situ joints . 7

6.2.1 General . 7

6.2.2 Strength . 7

6.2.3 Other properties . 7

6.3 Welded steel connectors . 7

6.3.1 General . 7

6.3.2 Strength . 8

6.3.3 Other properties . 11

6.4 Bolted steel connectors . 11

6.4.1 General . 11

6.4.2 Strength . 11

6.4.3 Other properties . 14

7 Floor-to-beam connections . 14

7.1 Cast-in-situ joints . 14

7.1.1 General . 14

7.1.2 Other properties . 15

7.2 Supports with steel angles . 15

7.2.1 General . 15

7.2.2 Strength . 17

7.2.3 Ductility . 23

7.2.4 Dissipation . 23

7.2.5 Deformation . 23

7.2.6 Cyclic decay . 23

7.2.7 Damage . 24

7.3 Supports with steel shoes . 24

Error! Reference source not found.

iii

Error! Reference source not found.

7.3.1 General . 24

7.3.2 Strength . 24

7.3.3 Ductility . 30

7.3.4 Dissipation . 30

7.3.5 Deformation . 30

7.3.6 Cyclic decay . 31

7.3.7 Damage . 31

7.4 Welded supports . 31

7.4.1 General . 31

7.4.2 Strength . 31

7.4.3 Other properties . 34

7.5 Hybrid connections . 34

7.5.1 General . 34

7.5.2 Strength . 34

7.5.3 Other properties . 37

8 Beam-to-column connections . 37

8.1 Cast-in-situ joints . 38

8.1.1 General . 38

8.1.2 Strength . 40

8.1.3 Ductility . 42

8.1.4 Dissipation . 42

8.1.5 Deformation . 42

8.1.6 Cyclic decay . 42

8.1.7 Damage . 42

8.2 Dowel connections . 42

8.2.1 General . 42

8.2.2 Strength . 43

8.2.3 Ductility . 49

8.2.4 Dissipation . 49

8.2.5 Deformation . 49

8.2.6 Cyclic decay . 49

8.2.7 Damage . 50

8.3 Mechanical coupler connections . 50

8.3.1 General . 50

8.3.2 Strength . 51

8.3.3 Ductility . 52

8.3.4 Dissipation . 52

8.3.5 Deformation . 52

8.3.6 Cyclic decay . 52

8.3.7 Damage . 52

8.4 Hybrid connections . 53

8.4.1 General . 53

8.4.2 Strength . 53

8.4.3 Ductility . 56

8.4.4 Dissipation . 56

8.4.5 Deformation . 56

8.4.6 Cyclic decay . 57

8.4.7 Damage . 57

9 Column-to-foundation connections . 57

9.1 Pocket foundations . 57

9.1.1 General . 57

9.1.2 Strength . 57

Error! Reference source not found.

iv

Error! Reference source not found.

9.1.3 Other properties . 58

9.2 Foundations for columns with protruding bars . 58

9.2.1 General . 58

9.2.2 Strength . 59

9.2.3 Ductility . 61

9.2.4 Dissipation . 61

9.2.5 Deformation . 61

9.2.6 Cyclic decay . 61

9.2.7 Damage . 61

9.3 Foundations with bolted sockets . 62

9.3.1 General . 62

9.3.2 Strength . 63

9.3.3 Ductility . 65

9.3.4 Dissipation . 66

9.3.5 Deformation . 66

9.3.6 Cyclic decay . 66

9.3.7 Damage . 66

9.4 Foundations with bolted flanges . 67

9.4.1 General . 67

9.4.2 Strength . 68

9.4.3 Other properties . 68

9.5 Foundations with mechanical couplers . 68

9.5.1 General . 68

9.5.2 Strength . 68

9.5.3 Ductility . 70

9.5.4 Dissipation . 70

9.5.5 Deformation . 70

9.5.6 Cyclic decay . 70

9.5.7 Damage . 70

10 Calculation of actions . 70

10.1 General criteria . 70

10.2 Capacity design . 70

Error! Reference source not found.

v

Error! Reference source not found.

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national

standards bodies (ISO member bodies). The work of preparing International Standards is normally

carried out through ISO technical committees. Each member body interested in a subject for which a

technical committee has been established has the right to be represented on that committee.

International organizations, governmental and non‐governmental, in liaison with ISO, also take part in

the work. ISO collaborates closely with the International Electrotechnical Commission (IEC) on all

matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT)

see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 71, Concrete, reinforced concrete and pre-

stressed concrete, Subcommittee SC 5, Simplified design standard for concrete structures.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

Error! Reference source not found.

vi

Error! Reference source not found.

Introduction

This document contains a set of practical provisions for the design of the mechanical connections in

precast elements under seismic actions. Design of the connections is carried out in terms of strength

verifications. Indications are also provided for defining the actions to be used in design.

If national standards provide alternate formulae for the same typology, those can be used instead of the

ones given in this document.

Error! Reference source not found.

vii

Error! Reference source not found. Error! Reference source not found.

Simplified design for mechanical connections between precast

concrete structural elements in buildings

1 Scope

This document refers to connections in precast frame systems, either for single‐storey or multi‐storey

buildings. The connections for all orders of joints are considered. Large wall panel and three‐

dimensional cell systems are not considered.

According to the position in the overall construction and of the consequent different structural

functions, the seven following orders of joints are considered:

a) mutual joints between floor or roof elements (floor‐to‐floor) that, in the seismic behaviour of the

structural system, concern the diaphragm action of the floor;

b) joints between floor or roof elements and supporting beams (floor‐to‐beam) that give the peripheral

constraints to the floor diaphragm in its seismic behaviour;

c) joints between beam and column (beam‐to‐column) that ensure in any direction the required degree

of restraint in the frame system;

d) joints between column segments (column‐to‐column) used for multi‐storey buildings usually for

dual wall braced systems;

e) joints between column and foundation (column‐to‐foundation), able to ensure in any plane a fixed

full support of the column;

f) fastenings of cladding panels to the structure (panel‐to‐structure) that ensure the stability of the

panels under the high forces or the large drifts expected under seismic action;

g) joints between adjacent cladding panels (panel‐to‐panel) possibly used to increase the stiffness of

the peripheral wall system and provide an additional source of energy dissipation.

Simple bearings working by gravity load friction are not considered. Sliding and elastic deformable

supporting devices neither, being all these types of connections not suitable for the transmission of

seismic actions.

The document provides formulae for the strength design of a large number of joint typologies.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

Error! Reference source not found.

Error! Reference source not found.

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1

union

generic linking constraint between two or more members

3.2

connection

local region that includes the union (3.1) between two or more members

3.3

connector

linking device (usually metallic) interposed between the parts to be connected

3.4

node

local region of convergence between different members

3.5

joint

equipped interface between adjacent members

3.6

system

set of linking practices classified on the basis of the execution technology

3.7

typical joint

dry joint (3.5) with mechanical connectors (3.3) generally composed of angles, plates, channel bars,

anchors, fasteners, bolts, dowel bars, etc., including joints completed in‐situ with mortar for filling or

fixing

3.8

emulative joint

wet joint (3.5) with rebar splices and cast‐in‐situ concrete restoring the monolithic continuity typical of

cast‐in‐situ structures and leading usually to “moment‐resisting” unions (3.1)

3.9

strength

maximum value of the force which can be transferred between the parts

3.10

ductility

ultimate plastic deformation compared to the yielding limit

Note 1 to entry: The ductility values or ranges provided refer to the connections (3.2) themselves and, in general,

have no direct relation with the global ductility of the structure. Those values are given for the sake of classifying

the connection and are not supposed to intervene in the design, which is carried out in terms of strength (3.10).

Note 2 to entry: Instead of the plastic deformation of steel element beyond the yield limit, other physical

equivalent non‐conservative phenomena can be referred to (such as friction).

Error! Reference source not found.

Error! Reference source not found.

3.11

dissipation

specific energy dissipated through the load cycles related to the corresponding perfect elastic‐plastic

cycle

Note 1 to entry: The values or ranges provided refer to the connections (3.2) themselves and, in general, have no

direct relation with the global energy dissipation of the structure. Those values are given for the sake of classifying

the connection and are not supposed to intervene in the design, which is carried out in terms of strength (3.10).

3.12

cyclic decay

decay

strength (3.10) loss through the load cycles compared to the force level

3.13

damage

residual deformation at unloading compared to the maximum displacement and/or evidence of rupture

4 Properties

A connection is composed of three parts: two lateral parts A and C, corresponding to the local regions of

the adjacent members close to the connector; and a central part B constituted by the connector itself

with its metallic components (see Figure 1).

Deleted:

Formatted: Font:

Figure 1 — Scheme of connection

The main parameters which characterize the seismic behaviour of the connection, as measured through

monotonic and cyclic tests, refer to the six properties of:

— strength;

— ductility;

— dissipation;

— deformation;

— decay;

— damage.

A ductile dissipative behaviour of the connection can be provided by the steel connector B:

Error! Reference source not found.

Error! Reference source not found.

— when parts A and C have a non‐ductile non‐dissipative behaviour characterized by a brittle failure,

with small displacements, due to the tensile cracking of concrete; and

— if it is correctly designed for a failure involving flexural or tension‐compression modes and not

shear modes or by other dissipative phenomena like friction.

In this case, for a ductile connection, in addition to a ductile connector, the criteria of capacity design

shall be applied, under‐proportioning the connector with respect to the lateral parts.

Also, the geometric compatibility of deformations shall be checked (e.g. against the loss of bearing).

Non‐ductile connections shall be:

— suitably over‐proportioned by capacity design with respect to the resistance of the critical

dissipative regions of the structure; or

— proportioned on the basis of the action obtained from a structural analysis that does not account

for any energy dissipation capacity.

The ductility of the connections can contribute to the global ductility of the structure or not depending

on their position in the structural assembly and on their relative stiffness.

5 Classification

5.1 General

For any single type of connection, the strength is quantified by the relevant formulae. The other

behaviour properties listed in this clause are quantified by specific numerical values. When this precise

numerical quantification is not possible, because of lack of experimental data or excessive variability of

performances, the type of connection is classified in qualitative terms corresponding to ranges of

values.

5.2 Strength

For strength, the following information shall be given:

— behaviour models corresponding to the working mechanisms of the connection;

— failure modes of the resistant mechanisms;

— calculation formulae for the evaluation of the ultimate strength for any failure mode;

— other data concerning the specific properties of the connection.

Reference is made to the strength obtained from cyclic loading tests.

5.3 Ductility

For ductility, the following classification is deduced from the force‐displacement diagrams obtained in

experiments:

— brittle connections, for which failure is reached without relevant plastic deformation;

— over-resisting connections, for which failure has not been reached at the functional deformation

limit;

— ductile connections, for which a relevant plastic deformation has been measured.

Error! Reference source not found.

Error! Reference source not found.

In this classification, intentional friction mechanism is equal to plastic deformation. Brittle connections

can be used in seismic zones provided they are:

— over‐proportioned by capacity design with respect to the critical regions of the overall structure; or

— proportioned with the action deducted from a structural analysis that does not account for any

energy dissipation capacity.

5.3.1 Ductile connections

Furthermore, ductile connections are divided into:

— high ductility connections, with a displacement ductility ratio of at least 4,5;

— medium ductility connections, with a displacement ductility ratio of at least 3,0;

— low ductility connections, with a displacement ductility ratio of at least 1,5.

With ductility ratio lower than 1,5, the connection is classified as brittle.

These definitions refer to the connection itself and, in general, have no direct relation with the global

ductility of the structure. For any single order of connections, specific indications are given on this

aspect, referring both to ductility and dissipation.

5.4 Dissipation

For dissipation, the following classification is deduced from the force‐displacement diagrams of cyclic

tests and related enveloped area histograms:

— low dissipation, with specific values of dissipated energy between 0,10 and 0,30;

— medium dissipation, with specific values of dissipated energy between 0,30 and 0,50;

— high dissipation, with specific values of dissipated energy over 0,50.

With dissipated energy lower than 0,1, the connection is classified as not dissipative.

The theoretical value 1,00 would correspond to the maximum energy dissipated through a perfect

elastic‐plastic cycle, e.g. by a massive section of ductile steel under alternate flexure, medium

dissipation corresponds to well confined reinforced concrete sections under alternate flexure and high

dissipation can be achieved with the use of special dissipative devices.

5.5 Deformation

For deformation, indications can be given about the order of magnitude of the relative displacements of

the connection at certain relevant limits, such as the first yielding of steel devices, the ultimate failure

limit or the maximum allowable deformation referred to its functionality.

Indications about cyclic decay and damage are given if relevant and when specific experimental

information is available.

Error! Reference source not found.

Error! Reference source not found.

6 Floor-to-floor connections

6.1 Cast-in-situ topping

6.1.1 General

Figure 2 shows the details of a floor made of precast elements interconnected by a concrete topping

cast over their upper surface. The concrete topping, with its reinforcing steel mesh, provides a

monolithic continuity to the floor that also involves the precast elements if properly connected to it. The

diaphragm action for the in‐plane transmission of the horizontal forces to the bracing vertical elements

of the structure can be allotted entirely to the topping. Unless greater dimensions are defined from

design, for its structural functions, the concrete topping shall have a minimum thickness, t , related

min

also to the maximum aggregate size of the concrete, d, such as t = 2,4 d ≥ 60 mm.

g min g

Deleted:

Formatted: Font:

Figure 2— Floor made by precast elements

6.1.2 Strength

Interface shear strength of the connection between the precast element and the topping under seismic

action can be evaluated neglecting the friction contribution due to gravity loads. Transverse vertical

shear at the joint between adjacent floor elements is diverted into the topping. For the good behaviour

of the connection, proper steel links crossing the interface shall ensure, with adequate anchorages, an

effective shear tie between the two parts (see Figure 3).

Deleted:

Formatted: Font:

Figure 3— Precast elements with and without interface connections with topping

6.1.3 Other properties

No specific parameters of seismic behaviour (ductility, dissipation, deformation, decay, damage) have

been experimentally measured for this type of indirect connection provided by the cast‐in‐situ topping

that can be calculated like an ordinary reinforced concrete element.

Error! Reference source not found.

Error! Reference source not found.

6.2 Cast-in-situ joints

6.2.1 General

Figure 4 shows the floor‐to‐floor connection made with the concrete filling of a continuous joint

between adjacent elements. It is typical of some precast products like hollow‐core slabs. The joint has a

proper shape to ensure good interlocking with the transmission of the vertical transverse shear forces,

when filled in. For the transmission of the horizontal longitudinal shear forces, the interface shear

strength can be improved providing the adjoining edges with vertical indentations. With reference to

the diaphragmatic action, this type of connections ensures that the floor has the same performance as a

monolithic cast‐in‐situ floor, provided that a continuous peripheral tie is placed against the opening of

the joints. For good filling, the maximum size of the aggregate of the cast‐in‐situ concrete shall be

limited with reference to the joint width.

Deleted:

Formatted: Font:

Figure 4 — Floor-to-floor connection made by concrete filling

Other types of floor‐to‐floor cast‐in‐situ connections, possibly provided with spliced tying steel links,

are not considered in this document.

6.2.2 Strength

The type of connection of concern is usually intended as a continuous longitudinal hinge. Its strength is

ensured following the specifications for the erection of the elements given by the manufacturer.

6.2.3 Other properties

No ductility and dissipation capacities are expected from the concerned type of connections that are

located away from the critical regions of the structure.

6.3 Welded steel connectors

6.3.1 General

In Figure 5 two types of floor‐to‐floor welded connections are represented. The solution a) is

constituted by two steel angles inserted at the edges of the adjacent elements and fixed to them with

anchor loops. On the joint lap, a bar is placed welded in site to the angles, compensating the erection

tolerances. Two steel plates inserted at the edges of the adjacent elements and fixed to them with

anchor loops constitute the solution b). Over the joint, a middle smaller plate is placed, welded in site to

the lateral ones. In both solutions, the steel components may be placed within a recess in order to save

the upper plane surface of the finishing. In the first solution, the angles may be replaced with plates

placed inclined so to leave in the joint the room for the positioning of the middle bar. These kinds of

connections are used to join ribbed floor elements without topping. They are also used to join special

roof elements when placed in contact one to the other.

Error! Reference source not found.

Error! Reference source not found.

Deleted:

Formatted: Font: Bold

a) Steel angles b) Steel plates

Key

1 steel angles 3 steel bar

2 anchor loops 4 steel plates

Figure 5 — Floor-to-floor welded connections

These connections are distributed in some local position along the length of the floor elements. They

provide the transverse deflection consistency with the uniform distribution of the load between the

elements. Under seismic conditions, they mainly provide the transmission of the diaphragm action with

horizontal longitudinal shear forces.

6.3.2 Strength

The following indications about the mechanical behaviour of this type of connections leave out of

consideration the transverse vertical shear forces that are related to the distribution of the loads

between the elements and refer to a non‐seismic action. Proper combinations of effects should be added

Deleted:

to evaluate the compatibility with the seismic action.

Formatted: Font: Bold

6.3.2.1 Behaviour models

With reference to the transmission of the diaphragm action under seismic conditions, the behaviour

model is given in Figure 6 both for the solutions a) and b) described in 6.3.1. The longitudinal shear

force, R, shall be mainly transmitted, with no relevant transverse normal forces.

Error! Reference source not found.

Error! Reference source not found.

Deleted:

Formatted: Font:

a) Action of the connection b) Action with normal forces c) Free body diagram

Key

Fc normal compression force

Ft normal tension force

Figure 6 — Behaviour models for welded steel connectors

6.3.2.2 Failure modes

The principal failure modes are as follows:

a) rupture of the welding between the angles and the interposed bar or plate;

b) failure of the interposed plate for solution b); Deleted:

Formatted: Font:

c) failure of the anchor loops for tensile yielding (see NOTE);

d) failure of the anchor loops for pull‐out(see NOTE);

Deleted:

e) spalling of concrete edges due to tensile stresses.

Formatted: Font:

NOTE It is assumed that the anchor loops are fixed to the angles with an adequate welding.

6.3.2.3 Calculation formulae

In expectation of a brittle behaviour of the connection, the action R is evaluated through the analysis of

the overall structural system with an adequately reduced behaviour factor or through a reliable model

of capacity design with respect to the resistance of the critical sections of the structure, using the due

overstrength factor, γ.

R

NOTE Values γR = 1,20 for medium ductility structures and γR = 1,35 for high ductility structures.

a) welding. For the verification of the welding the usual rules shall be applied.

b) plate. Formulae (1) and (2) apply.

RR (1)

vR

Error! Reference source not found.

Error! Reference source not found.

with

f

yd

Rt0,67a (2)

vR p

where

t is the plate thickness;

p

a is the plate width;

fyd is the design tensile yielding

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...