ISO 3592:2000

(Main)Industrial automation systems - Numerical control of machines - NC processor output - File structure and language format

Industrial automation systems - Numerical control of machines - NC processor output - File structure and language format

This International Standard defines a file structure format and a language format for the representation of CLDATA on physical media. The CLDATA reference language (RL) is used for the machining of parts. It provides for the control of technological functions and movement at the numerical control machine. Each processor using one of the numerical control programming languages shall be capable of producing CLDATA as defined in this International Standard. Each post processor shall be capable of using the CLDATA defined in this International Standard as input. The RL has been developed primarily for numerically controlled machine tools.

Systèmes d'automatisation industrielle — Commande numérique des machines — Informations de sortie des processeurs CN — Structure de fichier et format de langage

General Information

- Status

- Published

- Publication Date

- 20-Sep-2000

- Technical Committee

- ISO/TC 184/SC 1 - Industrial cyber and physical device control

- Drafting Committee

- ISO/TC 184/SC 1 - Industrial cyber and physical device control

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 07-Jun-2021

- Completion Date

- 13-Dec-2025

Relations

- Effective Date

- 06-Jun-2022

- Effective Date

- 15-Apr-2008

- Effective Date

- 15-Apr-2008

Overview - ISO 3592:2000 (NC processor output, file structure & language format)

ISO 3592:2000 specifies a standardized file structure and language format for CLDATA (originally “cutter location data”) used to transfer machining information from an NC (numerical control) processor to a post processor. The document defines the CLDATA Reference Language (RL) - a stream-oriented representation of tool location, orientation and technological control information - and the rules for representing that RL on physical, record‑oriented media. The standard was developed primarily for numerically controlled machine tools to ensure consistent exchange of machining data between systems.

Key topics and technical requirements

- CLDATA file model: a CLDATA file is composed of records; each record contains up to 245 elements. Elements represent integers, reals, literal character strings or keywords.

- Record and element semantics: the first element is a sequence number (starting at 1); the second element is a record type code. Remaining elements follow record-specific syntax and semantics.

- Record types: standardized record types include original program identification, post‑processor commands (integer/literal), surface and tool position data, relative tool direction, unsegmented tool path, part contour description, termination records and proprietary records.

- Coordinate system: uses a right‑handed Cartesian system with reference axes X, Y, Z and tool orientation components (i, j, k). Angles are given in degrees and decimals.

- Character set & delimiters: defines letters, digits, special characters and literal delimiters (apostrophe), and makes use of ISO/IEC 646 character set rules.

- Syntax rules: formal syntax for integers, reals, unary operators, literal strings, element separators (comma), record separators (semicolon) and file delimiter (colon). Annexes provide representation rules for record‑oriented media and syntax conventions.

Practical applications

- Enables interoperable data exchange between NC processors, CAD/CAM systems and post processors.

- Standardizes tool path, cutter location and machine command representation for multi‑axis CNC machine tools.

- Useful for post processor development, CAM output formatting, archival of NC programs, and automated tool‑path verification or conversion.

- Supports portability of manufacturing programs between different NC equipment and software environments.

Who should use it

- NC/NC‑processor and post‑processor developers

- CAM/CAD system integrators and CNC software engineers

- Machine tool manufacturers and production engineering teams

- Standards and interoperability engineers working with CNC data exchange

Related standards

- ISO 4342 (basic part program reference language)

- ISO 4343 (NC processor output - post processor)

- ISO 841 (axis and motion nomenclature)

- ISO/IEC 646 (7‑bit coded character set)

Keywords: ISO 3592, CLDATA, reference language (RL), NC processor output, file structure, language format, numerical control, CNC, post processor, tool position, cutter location data.

Frequently Asked Questions

ISO 3592:2000 is a standard published by the International Organization for Standardization (ISO). Its full title is "Industrial automation systems - Numerical control of machines - NC processor output - File structure and language format". This standard covers: This International Standard defines a file structure format and a language format for the representation of CLDATA on physical media. The CLDATA reference language (RL) is used for the machining of parts. It provides for the control of technological functions and movement at the numerical control machine. Each processor using one of the numerical control programming languages shall be capable of producing CLDATA as defined in this International Standard. Each post processor shall be capable of using the CLDATA defined in this International Standard as input. The RL has been developed primarily for numerically controlled machine tools.

This International Standard defines a file structure format and a language format for the representation of CLDATA on physical media. The CLDATA reference language (RL) is used for the machining of parts. It provides for the control of technological functions and movement at the numerical control machine. Each processor using one of the numerical control programming languages shall be capable of producing CLDATA as defined in this International Standard. Each post processor shall be capable of using the CLDATA defined in this International Standard as input. The RL has been developed primarily for numerically controlled machine tools.

ISO 3592:2000 is classified under the following ICS (International Classification for Standards) categories: 25.040.20 - Numerically controlled machines. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 3592:2000 has the following relationships with other standards: It is inter standard links to ISO 3592:2000/Cor 1:2001, ISO 3592:1978; is excused to ISO 3592:2000/Cor 1:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 3592:2000 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 3592

Second edition

2000-09-15

Corrected

2001-03-15

Industrial automation systems — Numerical

control of machines — NC processor

output — File structure and language

format

Systèmes d'automatisation industrielle — Commande numérique des

machines — Informations de sortie des processeurs CN — Structure de

fichier et format de langage

Reference number

©

ISO 2000

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 � CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO 2000 – All rights reserved

Contents

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

1Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Normative references. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Co-ordinate system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4 General structure of CLDATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

5 CLDATA file structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5.1 General comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5.2 Letters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5.3 Digits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.4 Special characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.5 Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.6 Symbol for literal delimiter . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.7 Literal character strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.8 Symbol for unary operator . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.9 Integer numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.10 Real numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.11 Keywords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.12 Symbol for element separator . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.13 Elements

5.14 Symbol for record separator . . . . . . . . . . . . . . . . . . . . . . . . 16

5.15 Records. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.16 Symbol for file separator . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.17 File

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Record structure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.1 General comments

6.2 Original program sequence identification . . . . . . . . . . . . . 21

6.3 Integer code type post processor command . . . . . . . . . . . 22

6.4 Surface data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.5 Relative tool position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.6 Tool position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

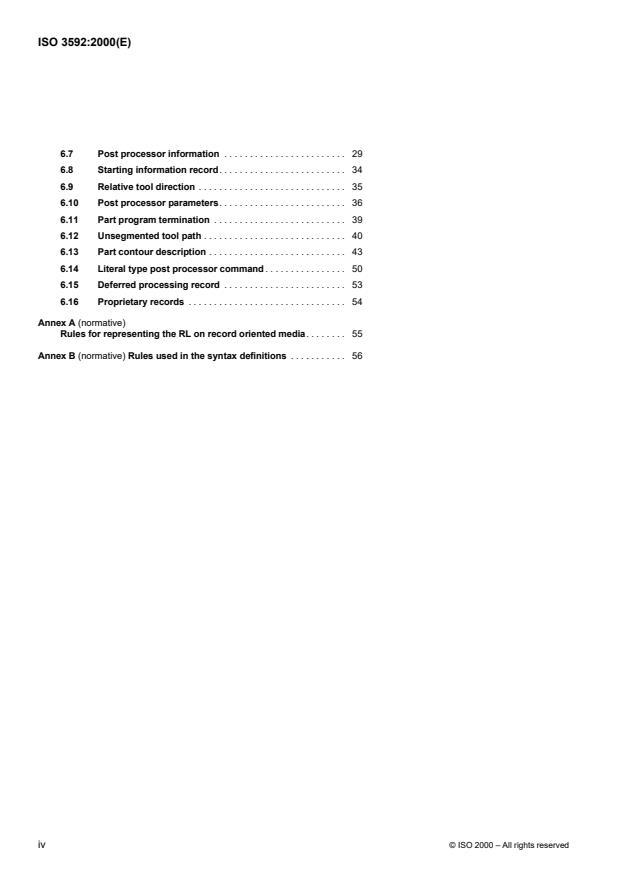

6.7 Post processor information . . . . . . . . . . . . . . . . . . . . . . . . 29

6.8 Starting information record. . . . . . . . . . . . . . . . . . . . . . . . . 34

6.9 Relative tool direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.10 Post processor parameters. . . . . . . . . . . . . . . . . . . . . . . . . 36

6.11 Part program termination . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.12 Unsegmented tool path . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.13 Part contour description . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.14 Literal type post processor command . . . . . . . . . . . . . . . . 50

6.15 Deferred processing record . . . . . . . . . . . . . . . . . . . . . . . . 53

6.16 Proprietary records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Annex A (normative)

Rules for representing the RL on record oriented media. . . . . . . . 55

Annex B (normative) Rules used in the syntax definitions . . . . . . . . . . . 56

iv © ISO 2000 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide

federation of national standards bodies (ISO member bodies). The work

of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for

which a technical committee has been established has the right to be

represented on that committee. International organizations, governmental

and non-governmental, in liaison with ISO, also take part in the work. ISO

collaborates closely with the International Electrotechnical Commission

(IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in

the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are

circulated to the member bodies for voting. Publication as an International

Standard requires approval by at least 75 % of the member bodies

casting a vote.

Attention is drawn to the possibility that some of the elements of this

International Standard may be the subject of patent rights. ISO shall not

be held responsible for identifying any or all such patent rights.

International Standard ISO 3592 was prepared by Technical Committee

ISO/TC 184, Industrial automation systems and integration, Subcommittee

SC 1, Physical device control.

This second edition cancels and replaces the first edition (ISO 3592:1978),

which has been technically revised.

Annexes A and B form a normative part of this International Standard.

Introduction

The output of a general purpose numerical control processor is information used as

input to a post processor. This information is called CLDATA, which was originally

derived from “cutter location data.”

CLDATA provides a general language to pass manufacturing information from a

numerical control processor to a post processor, where the general language is

converted to the specific format required by the particular numerical control equip-

ment.

Numerical control is applied to many types of machines, but the language defined

in this International Standard has been developed primarily for numerically control-

led machine tools – hence the words “tool” and “part” are used in the description of

the language to indicate the working element and processed element respectively.

Many of the vocabulary words are also derived from metal working terminology.

The CLDATA reference language (RL) is stream oriented, containing special

characters to delimit the elements of the RL. Annex A describes the rules for

representing the RL on record oriented media, and it is this representation that is

used for the purpose of describing the RL in this International Standard.

vi © ISO 2000 – All rights reserved

INTERNATIONAL STANDARD

Industrial automation systems — Numerical control of

machines — NC processor output — File structure and

language format

1 Scope 3 Co-ordinate system

ISO 841 is the basis for defining the co-ordinate system of

This International Standard defines a file structure format

CLDATA.

and a language format for the representation of CLDATA

on physical media.

The co-ordinate system is a right-handed rectangular

Cartesian system, related to a part mounted on a machine

The CLDATA reference language (RL) is used for the and aligned with the principal linear slideways of that

machining of parts. It provides for the control of technologi- machine. The positive direction of movement of a compo-

cal functions and movement at the numerical control ma- nent of a machine is that which causes an increasing

chine. positive dimension on the part.

In the CLDATA, the reference axes of the co-ordinate

Each processor using one of the numerical control pro-

system are x, y and z. Co-ordinates refer to a reference

gramming languages shall be capable of producing

point on a tool (usually the center of the tip) relative to the

CLDATA as defined in this International Standard.

part co-ordinate system. CLDATA can define the following

location and orientation components:

Each post processor shall be capable of using the

CLDATA defined in this International Standard as input. x Dimension parallel to X

y Dimension parallel to Y

z Dimension parallel to Z

The RL has been developed primarily for numerically

i X axis component of the tool axis vector

controlled machine tools.

j Y axis component of the tool axis vector

k Z axis component of the tool axis vector

l X axis component of a secondary orientation vector

2 Normative references

m Y axis component of a secondary orientation vector

n Z axis component of a secondary orientation vector

The following normative documents contain provisions

which, through reference in this text, constitute provisions

When specifying angles of planes, the positive direction is

of this International Standard. For dated references,

counterclockwise and the reference axis is as shown in

subsequent amendments to, or revisions of, any of these

table 1. The positive direction of angle is counterclockwise

publications do not apply. However, parties to

from the reference axis.

agreements based on this International Standard are

encouraged to investigate the possibility of applying the

Table 1 – Reference axes

most recent editions of the normative documents

indicated below. For undated references, the latest edition

of the normative documents referred to applies. Members

Plane Reference axis

of ISO and IEC maintain registers of currently valid

International Standards.

XY X

YZ Y

ISO/IEC 646:1991, Information technology – ISO 7-bit

ZX Z

coded character set for information interchange.

1)

ISO 841:— , Numerical control of machines – Axis and

Angles are expressed in degrees and decimal fractions of

motion nomenclature.

a degree.

ISO 4342:1985, Numerical control of machines – NC pro-

cessor input – Basic part program reference language.

4 General structure of CLDATA

ISO 4343:2000, Industrial automation systems – Numeri-

cal control of machines – NC processor output – Post CLDATA consists of a sequence of one or more records,

processor commands. which together comprise a CLDATA file.

1) To be published. (Revision of ISO 841:1974)

Each record consists of a sequence of elements, to a The first two elements of a record are always integers.

maximum of 245, where an element is capable of repre-

senting: The remaining elements can be any combination of integer

numbers, real numbers, literal character strings or key-

a) an integer number; words, respecting the syntax of the particular record.

b) a real number;

The first element of each record contains a sequence

number, commencing with 1, and incremented by 1.

c) a literal character string;

d) a keyword.

The second element contains a record type code as shown

in table 2.

Each element is composed of characters from the set of

characters defined by ISO/IEC 646.

Table 2 – CLDATA record types

Type Name Explanation

1 000 Original program sequence This record carries the sequence and identification of the statements

identification of the original numerical control programming language.

2 000 Integer code type post processor This record carries specific instructions for the post processor.

command

3 000 Surface data This record carries the canonical form of the input geometry.

4 000 Relative tool position This record carries the tool position with respect to the drive and

part surfaces.

5 000 Tool position This record carries tool position and motion vector information

relating to the tool.

6 000 Post processor information This record carries one type of information of tolerance, cutter or cut

flag information.

7 000 Starting information This record carries the tool position with respect to the startup

surfaces.

8 000 Relative tool direction This record carries information indicating tool direction with respect

to the last move.

9 000 Post processor parameters This record carries one type of multi-axis or base unit parameters.

14 000 Part program termination This record carries the termination record.

15 000 Unsegmented tool path This record carries unsegmented information concerning non linear

tool paths.

16 000 Workpiece contour description This record carries the workpiece contour description.

20 000 Literal type post processor This record carries specific instructions for the post processor.

command

21 000 Deferred processing command This record is under consideration to permit user-selected input

language statements to be passed to the CLDATA file in a literal

form for subsequent processing.

28 000

to Proprietary records These records will not be standardized.

32 000

2 © ISO 2000 – All rights reserved

5 CLDATA file structure

5.1 General comments

5.1.1 General semantics

A CLDATA file consists of records, each in turn consisting of elements. The basic entity of CLDATA therefore is the element,

which can represent either an integer number, a real number, a literal character string or a keyword.

5.1.2 Sub-contents

For

1) letters, see 5.2;

2) digits, see 5.3;

3) special characters, see 5.4;

4) characters, see 5.5;

5) symbol for a literal delimiter, see 5.6;

6) literal character strings, see 5.7;

7) unary operators, see 5.8;

8) integer numbers, see 5.9;

9) real numbers, see 5.10;

10) keywords, see 5.11;

11) symbol for an element separator, see 5.12;

12) elements, see 5.13;

13) symbol for a record separator, see 5.14;

14) records, see 5.15;

15) symbol for a file separator, see 5.16;

16) file, see 5.17.

5.1.3 Limitations

None.

5.2 Letters

5.2.1 Semantics

In general, letters have no individual meaning, being used for forming literal character strings or keywords.

5.2.2 Limitations

None.

5.2.3 Syntax

::= A | B | C|D | E | F|G | H|I|J|K |L|M|N|O |P |Q |R|S |T|U|V |W|X |Y |Z

4 © ISO 2000 – All rights reserved

5.3 Digits

5.3.1 Semantics

Digits have no individual meaning, being used for forming integer numbers, real numbers or literal character strings.

5.3.2 Limitations

None.

5.3.3 Syntax

::= 0|1|2|3|4|5|6|7|8|9

5.4 Special characters

5.4.1 Semantics

Special characters are used as punctuation marks (or separators) in the CLDATA file. When special characters are used

in literal character strings they are treated as characters with no syntactical significance. The special characters are

+ – unary operators, used to specify the sign of integers, reals and their exponents;

. decimal point, used to separate the whole portion of a real number from the fractional portion;

E e exponent identifier, used to adjust the value of a real number up or down by an integral power of 10;

’ apostrophe, used for delimitation of a literal character string;

, comma, used as a separator between the elements of a record ();

; semicolon, used as a separator between the records of a file ();

: colon, used for delimitation of a CLDATA file ().

The format control characters; horizontal tabulator (ISO/IEC 646 character code 9), line feed (code 10), form feed

(code 12), carriage return (code 13) and space (code 32), have no significance except in literal character strings.

5.4.2 Limitations

None.

5.4.3 Syntax

::= + | – | . | E | e | ’ | , | ; | :

6 © ISO 2000 – All rights reserved

5.5 Characters

5.5.1 Semantics

A character is a letter, digit, special character or other valid character.

5.5.2 Limitations

None.

5.5.3 Syntax

::= | | |

Other valid characters have no significance within this International Standard but are nevertheless considered as valid

input. These characters are not otherwise defined in this International Standard. They shall be manageable by the

specific implementation and be selected from the character set defined by ISO/IEC 646.

5.6 Symbol for literal delimiter

5.6.1 Semantics

The apostrophe is used at the beginning and at the end of a literal character string to indicate the extent of the literal string.

5.6.2 Example

cln,5000,5,’L1’,0,4.,2.5,6.;

where cln represents an integer value identifying the CLDATA record sequence number.

5.6.3 Limitations

None.

5.6.4 Syntax

::= ’

8 © ISO 2000 – All rights reserved

5.7 Literal character strings

5.7.1 Semantics

A literal character string may be used in records, for listing text, or in the post processor statements for passing special

information through to the post processor. The set of characters permissible is not limited to the set of letters, digits and

special characters defined in this International Standard. Within a literal character string, any special characters are treated

simply as characters without syntactical significance.

5.7.2 Example

cln,20000,0,PPRINT,’Set machine origin above front left corner of part’;

5.7.3 Limitations

None.

5.7.4 Syntax

0:n

::= [ ]

NOTES

1) The syntax of a literal character string implies that the empty string is allowed.

2) The format control characters; horizontal tabulator (ISO/IEC 646 character code 9), line feed (code 10), form feed (code 12),

carriage return (code 13) and space (code 32), are significant in literal character strings.

3) A literal character string not terminated by an apostrophe prior to an arbitrary physical record size limit (for example, column 72 in

annex A) is continued from the first column on the next physical record.

4) An apostrophe is represented by two apostrophes in a non-empty literal character string.

5.8 Symbol for unary operator

5.8.1 Semantics

The special characters + and – shall be used as unary operators, in which case the operator denotes the sign of the following

term.

+ denotes that the following term is to be positive;

– denotes that the following term is to be negative.

In the absence of a unary operator the following term shall be considered positive.

5.8.2 Examples

+ 45

– .82844E–3

72.6

5.8.3 Limitations

None.

5.8.4 Syntax

::= + | –

10 © ISO 2000 – All rights reserved

5.9 Integer numbers

5.9.1 Semantics

Integer numbers have their usual meaning, being built up of decimal digits, and optionally being preceded by a sign. The

integer number is considered positive if a sign is omitted.

Leading zeros have no significance.

5.9.2 Examples

– 14

+ 4527

5.9.3 Limitations

There is no defined limit to the number of digits within a number, the limit being implementation dependent, although at least

one digit must be specified.

5.9.4 Syntax

0:1 1:n

::= [ ] [ ]

5.10 Real numbers

5.10.1 Semantics

Real numbers have their usual meaning, being built up of decimal digits and a decimal character (required). Real numbers

can optionally be preceded by a sign. The number is considered positive if a sign is omitted. Real numbers can also be

optionally followed by an exponent raising (or lowering) the value, as indicated by the unary operator, by a integral power

of 10.

Leading and trailing zeros have no significance.

5.10.2 Examples

123.

– .14

+ 45.27

.6428E–2

5.10.3 Limitations

There is no defined limit to the number of digits within a number or within the exponent, the limit being implementation

dependent. No distinctions are made between whole real numbers and those containing a fractional part.

Number representation of real numbers within a computer is not necessarily exact. Therefore, approximations are used

where necessary to achieve the effect of exact operations. These approximations are computer dependent.

5.10.4 Syntax

::=

0:1 0:n 0:n

::= [ ] [ ] . [ ]

0:1

::= [ ]

::= E|e

NOTE – The syntax of a real number implies that a solitary decimal point is allowed and denotes a real value of 0,0.

12 © ISO 2000 – All rights reserved

5.11 Keywords

5.11.1 Semantics

Keywords have a fixed meaning within the language. They may be regarded as entries in a vocabulary list.

5.11.2 Example

cln,20000,0,SPINDL,OFF;

5.11.3 Limitations

Keywords shall start with a letter, consist only of letters, and have a length of at least two letters.

5.11.4 Syntax

2:n

::= [ ]

Keywords shall be selected from the set of Major and Minor words defined by ISO 4343.

5.12 Symbol for element separator

5.12.1 Semantics

The comma is used as a separator between elements in a record.

5.12.2 Example

cln,1000,45,’ ’;

5.12.3 Limitations

None.

5.12.4 Syntax

::= ,

14 © ISO 2000 – All rights reserved

5.13 Elements

5.13.1 Semantics

An element is the basic entity of information in the CLDATA. It can represent either an integer number, a real number, a

literal character string or a keyword.

5.13.2 Limitations

None.

5.13.3 Syntax

::= | | |

5.14 Symbol for record separator

5.14.1 Semantics

The semicolon is used as a separator between records in a file.

5.14.2 Example

cln,1000,1,’ ’;

cln,2000,1045,’Sample Program’;

cln,1000,17,’ ’;

cln,6000,6,1.;

5.14.3 Limitations

None.

5.14.4 Syntax

::= ;

NOTE – The character is the sole method of delimiting the end of record. Examples in this International Standard list records one

per line to aid understanding. This does not imply that format control characters are required between records of a CLDATA file.

16 © ISO 2000 – All rights reserved

5.15 Records

5.15.1 Semantics

A record is a complete instruction or unit of information comparable with a sentence in a natural language.

A record consists of two or more elements, each separated from the other by an element separator character, terminated

by a record termination character.

The first two elements of a record shall be type integer.

The remaining elements of a record can be any combination of integer numbers, real numbers, strings of characters or

keywords, respecting the syntax of the particular record.

5.15.2 Limitations

None.

5.15.3 Syntax

0:n

::= [ ]

5.16 Symbol for file separator

5.16.1 Semantics

The colon is used as a separator between files.

5.16.2 Example

cln,14000;

:

5.16.3 Limitations

None.

5.16.4 Syntax

::= :

18 © ISO 2000 – All rights reserved

5.17 File

5.17.1 Semantics

A CLDATA file is a logically complete and ordered sequence of records, which after post processing will produce a

correspondingly complete and ordered machine program.

A CLDATA file consists of one or more records, followed by a trailing file separator.

5.17.2 Example

1,20000,0,PARTNO,’EXAMPLE’;

2,6000,6,1.5,.,.75,.,.,.,3.;

3,20000,0,RAPID;

4,5000,5,’’,0,.,.,1.;

...

...

342,20000,0,END;

343,14000;

:

5.17.3 Limitations

None.

5.17.4 Syntax

1:n

::= [ ]

6 Record structure

6.1 General comments

6.1.1 General semantics

Various record structures are defined in this International Standard. Each structure (or class) provides a capability to pass

a specific type of information. The order and content of records within CLDATA define the type and sequence of actions

desired at the numerical control machine.

6.1.2 Sub-contents

For

1) original program sequence identification record, see 6.2;

2) integer code type post processor command record, see 6.3;

3) surface data record, see 6.4;

4) relative tool position record, see 6.5;

5) tool position record, see 6.6;

6) post processor information record, see 6.7;

7) starting information record, see 6.8;

8) relative tool direction record, see 6.9;

9) post processor parameters record, see 6.10;

10) part program termination record, see 6.11;

11) unsegmented tool path record, see 6.12;

12) part contour description record, see 6.13;

13) literal type post processor command record, see 6.14;

14) deferred processing command record, see 6.15;

15) proprietary records, see 6.16.

6.1.3 Limitations

The part program termination record shall only occur as the last record of a CLDATA file.

6.1.4 Syntax

< record > ::= | |

| | | |

| | |

| | |

20 © ISO 2000 – All rights reserved

6.2 Original program sequence identification

cln

1 000

original_program_sequence_number

original_program_identification

opt_original_program_statement

6.2.1 Semantics

This record carries the sequence and identification of the statements of the original numerical control programming language.

This record identifies one or more subsequent CLDATA records as being produced by a particular source statement in the

original part program.

cln (integer) is the CLDATA record sequence number.

1 000 (integer) identifies the record as an original program sequence identification.

original_program_sequence_number (integer) is the statement number of the original program.

original_program_identification (text) is the identification of the statement in the original program.

opt_original_program_statement (text) is an optional text element containing the original program statement.

6.2.2 Example

th

The following ISO 4342 statement, occurring as the 400 statement in the input program, and having the text “JOB00135”

in card columns 73 through 80,

FEDRAT/10,PERMIN

would be represented by the following CLDATA statements,

cln,1000,400,’JOB00135’;

cln,20000,0,FEDRAT,10.,PERMIN;

6.2.3 Limitations

None.

6.2.4 Syntax

::= 1 000

::=

::=

0:1

::= [ ]

6.3 Integer code type post processor command

cln

2 000

pp_command_integer_code

opt_pp_command_integer_code_par_list

The opt_pp_command_integer_code_par_list is a structure containing any combination of the following elements.

integer_number

real_number

literal_character_string

integer_code_canonical_form

The integer_code_canonical_form is an ordered structure of the following elements.

form_type_designator

form_size

form_name

form_subscript

form_data_list

6.3.1 Semantics

This record carries specific instructions for the post processor.

cln (integer) is the CLDATA record sequence number.

2 000 (integer) identifies the record as an integer code type post processor command.

pp_command_integer_code (integer) is the integer code of the Major word identifying the post processor command.

opt_pp_command_integer_code_par_list (various) is an optional list of post processor command parameters.

integer_number (integer) represent the integer code of the Minor words used in the post processor command.

real_number (real) represent scalar constants and scalar identifiers used in the post processor command. No distinction

is made in post processor commands between integer values and real values, both are represented as real numbers in

the CLDATA.

801 (integer) identifies the start of a canonical form structure.

integer_form_type_designator (integer) is a code identifying the type of the canonical form.

1 symbol for point;

2 symbol for line;

3 symbol for plane;

4 symbol for circle;

5 symbol for cylinder;

6 symbol for ellipse;

7 symbol for hyperbola;

8 symbol for cone;

9 symbol for general conic;

10 symbol for loft conic;

11 symbol for vector;

12 symbol for matrix;

13 symbol for sphere;

14 symbol for quadratic;

17 symbol for tool definition;

18 symbol for pattern;

19 symbol for space line;

20 symbol for pntvec;

21 symbol for torus.

form_size (integer) specifies the total number of elements contained within the following three entities.

22 © ISO 2000 – All rights reserved

form_name (text) identifies the name of the canonical form. A blank or empty string indicates an unnamed canonical

form.

form_subscript (integer) identifies the subscript number of the canonical form. A value of 0 (zero) indicates an

unsubscripted canonical form.

form_data_list (real) specifies the numeric values of the canonical form. See ISO 4342 for a description of the canonical

forms for each form type listed in form_type_designator.

6.3.2 Example

The following ISO 4342 statement,

SPINDL/RPM,500,RANGE,2

would be represented as follows in the CLDATA,

cln,2000,1031,78,500.,145,2.;

where the integer code for SPINDL is 1031, the integer code for RPM is 78 and the integer code for RANGE is 145.

6.3.3 Limitations

The pp_command_integer_code shall be a positive, non-zero, value.

The opt_pp_command_integer_code_par_list shall contain at least one parameter if the pp_command_integer_code value

exceeds or equals 1 000.

The opt_pp_command_integer_code_par_list shall be empty if the pp_command_integer_code value is in the range 1

through 999.

6.3.4 Syntax

::= 2 000

::=

0:n

::= [ [ | |

| ] ]

::= 801

::=

::=

::=

::=

(form_size-2):(form_size-2)

::= [ ]

The pp_command_integer_code and any integer_number within the opt_pp_command_integer_code_par_list shall be

selected from the set of Major and Minor word codes defined by ISO 4343.

NOTE – See 6.14 for an alternative method of carrying post processor instructions.

6.4 Surface data

cln

3 000

surface_use_designator

surface_condition_designator

surface_type_designator

surface_size

surface_name

surface_subscript

surface_canonical_list

6.4.1 Semantics

This record carries the canonical form of input geometry. This record is an indication to the post processor that the following

tool position record (see 6.6 and 6.12) contains one or more co-ordinates interpolated along the specified surface type. The

interpolation spacing is a function of the tolerance (see 6.7). In general practice, only circular type drive surface information

(i.e. surface_type_designator 4 or 5) is output to the post processor.

cln (integer) is the CLDATA record sequence number.

3 000 (integer) identifies the record as surface data.

surface_use_designator (integer) is a code identifying the use of the surface within the NC processor.

1 symbol for part surface in a startup command;

2 symbol for drive surface;

3 symbol for check surface;

4 symbol for part surface in a continuous path command.

surface_condition_designator (integer) is a code identifying the relationship of the tool to the surface.

1 symbol for tool to the surface (TO);

2 symbol for tool past the surface (PAST);

3 symbol for tool on the surface (ON);

4 symbol for tool tangent to the surface (TANTO).

surface_type_designator (integer) is a code identifying the type of the surface.

4 symbol for circle;

5 symbol for cylinder.

surface_size (integer) specifies the total number of elements contained within the following three entities.

surface_name (text) identifies the name of the surface. A blank or empty string indicates an unnamed surface.

surface_subscript (integer) identifies the subscript number of the surface. A value of 0 (zero) indicates an unsubscripted

surface.

surface_data_list (real) specifies the canonical form of the surface. See ISO 4342 for a description of the canonical forms

for each the surface types listed for the surface_type_designator.

6.4.2 Example

The following ISO 4342 input statements,

GOFWD/(C1=CIRCLE/CENTER,4,2,0,RADIUS,6),PAST,L1

would have its surface data represented as follows in the CLDATA.

cln,3000,2,4,4,9,’C1’,0,4.,2.,.,.,.,1.,6.;

6.4.3 Limitations

Surface_size shall be a positive integer number greater than or equal to 2.

The combined number of elements in surface_name, surface_subscript and surface_data_list shall match the value of

surface_size.

24 © ISO 2000 – All rights reserved

6.4.4 Syntax

::= 3 000

::=

::=

::=

::=

::=

::=

(surface_size-2):(surface_size-2)

::= [ ]

6.5 Relative tool position

cln

4 000

tool_position_designator

6.5.1 Semantics

This record carries the tool position with respect to the drive and part surfaces.

cln (integer) is the CLDATA record sequence number.

4 000 (integer) identifies the record as relative tool position data.

tool_position_designator (integer) is a code identifying the position of the tool with respect to the drive and part surfaces.

1 symbol for tool to the left of the drive surface (TLLFT);

2 symbol for tool to the right of the drive surface (TLRGT);

3 symbol for tool on the drive surface (TLON);

5 symbol for tool on the part surface (TLONPS);

6 symbol for tool offset to the part surface (TLOFPS).

The path of a tool can be controlled by two surfaces, the part surface and drive surface. In general, the part surface is the

one on which the bottom of the tool is resting, and the drive surface is the one that contacts the side of the tool or that

intersects the tool centre.

6.5.2 Example

The following records indicate that the tool end point is offset to the part surface and on the left side of the drive surface

when viewed from behind the tool in the forward direction of motion.

cln,4000,6;

cln,4000,1;

6.5.3 Limitations

None.

6.5.4 Syntax

::= 4 000

::=

26 © ISO 2000 – All rights reserved

6.6 Tool position

cln

5 000

tool_position_type_designator

surface_name

surface_subscript

tool_position_list

6.6.1 Semantics

This record carries tool position and tool vector information relating to the tool. This information can represent the

co-ordinates, orientation and surface normal of a single point or a succession of points.

cln (integer) is the CLDATA record sequence number.

5 000 (integer) identifies the record as motion data.

tool_position_type_designator (integer) is a code identifying the type of motion.

3 symbol for a startup motion (FROM);

4 symbol for a relative motion (GODLTA);

5 symbol for an absolute motion (GOTO);

6 symbol for the continuation of the previous motion data record.

surface_name (text) identifies the name of the surface being formed by the motion of the tool, or the name of the surface

to which the tool is being positioned. A blank or empty string indicates an unnamed surface.

surface_subscript (integer) identifies the subscript number of the surface. A value of 0 (zero) indicates an unsubscripted

surface.

tool_position_list (real) specifies one or more sets of tool position data (X,Y,Z), tool position and tool axis vector data

(X,Y,Z,I,J,K), or tool position, tool axis vector and surface normal vector data (X,Y,Z,I,J,K,L,M,N).

The tool position data are the x, y, and z co-ordinates of the end point of the tool and are always expressed as an absolute

dimension in cartesian co-ordinates. Therefore, a tool_position_type_designator value of 4 indicates that the absolute tool

position data contained in the record was generated as a result of a relative tool position directive.

6.6.2 Example

The following ISO 4342 input statement,

GOTO/(PTA(6)=POINT/2,7,4)

would be represented by the following tool position record.

cln,5000,5,’PTA’,6,2.,7.,4.;

6.6.3 Limitations

The interpretation of the tool_position_list is dependent on the most recent state of the pp_parameter_record, tool_posi-

tion_format_specification subtype, tool_position_format_designator. The designator state can be one of:

0 tool position data (X,Y,Z);

1 tool position and tool axis vector data (X,Y,Z,I,J,K);

2 tool position, tool axis vector and surface normal vector data (X,Y,Z,I,J,K,L,M,N).

In the absence of this record subtype the tool_position_list is assumed to contain only X, Y and Z triplets of tool position

data.

The magnitude of the I, J, K components of the tool axis vector shall equal 1,0 (one).

The magnitude of the L, M, N components of the surface normal vector shall equal 1,0 (one).

6.6.4 Syntax

::= 5 000

::=

::=

::=

1:80 1:40 1:26

::= [ ] | [ ] | [

]

3:3

::= [ ]

3:3

::= [ ]

3:3

::= [ ]

28 © ISO 2000 – All rights reserved

6.7 Post processor information

6.7.1 General semantics

This record carries one type of information of tolerance, tool or cut flag information.

6.7.2 Sub-contents

For

1) cut flag information, see 6.7.5;

2) tolerance information, see 6.7.6;

3) tool information, see 6.7.7.

6.7.3 Limitations

None.

6.7.4 Syntax

::= | |

6.7.5 Cut flag information

cln

6 000

cut_flag_designator

6.7.5.1 Semantics

This record subtype carries cut flag information. All tool positions encountered while cutting is disabled shall be ignored by

the post processor. Normally this function is carried out by the NC processor and the cut flag status is for post processor

information only.

cln (integer) is the CLDATA record sequence number.

6 000 (integer) identifies the record as post processor information.

1 (integer) identifies the record subtype as cut flag information.

cut_flag_designator (integer) is a code identifying the state of the cut flag.

0 Symbol for cutting enabled (CUT);

1 Symbol for cutting disabled (DNTCUT).

6.7.5.2 Example

The following ISO 4342 program segment,

GOTO/1,2,3

DNTCUT

GOTO/4,5,6

GOTO/7,8,9

CUT

GOTO/11,12,13

would result in the following CLDATA program segment, ignoring identification records for the sake of clarity.

cln,5000,5,’’,0,1.,2.,3.;

cln,6000,1,1;

cln,6000,1,0;

cln,5000,5,’’,0,7.,8.,9.;

cln,5000,5,’’,0,11.,12.,13.;

6.7.5.3 Limitations

The post processor and NC processor shall signal an error if the cut flag is in a disabled state at program termination.

6.7.5.4 Syntax

::= 6 000 1

::=

30 © ISO 2000 – All rights reserved

6.7.6 Tolerance information

cln

6 000

tolerance_designator

tolerance_specification_list

6.7.6.1 Semantics

This record subtype carries tolerance information. This information is an indication to the post processor that subsequent

tool positions might deviate from the nominal co-ordinates by an amount up to and including the specified tole

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...