ISO 22400-2:2014

(Main)Automation systems and integration - Key performance indicators (KPIs) for manufacturing operations management - Part 2: Definitions and descriptions

Automation systems and integration - Key performance indicators (KPIs) for manufacturing operations management - Part 2: Definitions and descriptions

ISO 22400 defines key performance indicators (KPIs) used in manufacturing operations management. ISO 22400-2:2014 specifies a selected number of KPIs in current practice. The KPIs are presented by means of their formula and corresponding elements, their time behaviour, their unit/dimension and other characteristics. ISO 22400-2:2014 also indicates the user group where the KPIs are used, and the production methodology to which they correspond. With reference to equipment, the KPIs in ISO 22400-2:2014 relate to work units, as specified in IEC 62264.

Systèmes d'automatisation et intégration — Indicateurs de la performance clé pour le management des opérations de fabrication — Partie 2: Définitions et descriptions

General Information

- Status

- Published

- Publication Date

- 05-Jan-2014

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 07-Aug-2023

- Completion Date

- 13-Dec-2025

Relations

- Effective Date

- 14-Aug-2021

Overview

ISO 22400-2:2014 is part of the ISO 22400 series and defines a selected set of key performance indicators (KPIs) for manufacturing operations management. The standard provides definitions and structured descriptions of KPIs in current industrial practice. Each KPI record in ISO 22400-2 includes its formula, time behaviour, unit/dimension and other attributes, plus the intended user group and applicable production methodology. For equipment-related measures the standard aligns KPI elements with work units as specified in IEC 62264 (ISA‑95).

Key topics and technical requirements

- KPI structure and attributes: standardized fields such as name/title, application, timing, formula, unit/dimension, rating, drill-down/analysis, user group, effect model and manufacturing type.

- Comprehensive element glossary: time elements (planned vs actual), maintenance terms (TTF, TBF, TTR, corrective/preventive maintenance), and logistical/quality/organizational terms (PQ, WIP, FGI, scrap, GP, IP).

- KPI catalogue: explicit KPI definitions and descriptions including - but not limited to - Worker efficiency, Allocation ratio, Throughput rate, Utilization efficiency, Overall Equipment Effectiveness (OEE), Availability, Quality ratio, First pass yield, Machine/process capability indices, Inventory turns, Production loss ratios, Mean time to failure/restore.

- Measurement rigor: each KPI is presented with its formula and supporting elements so organizations can consistently calculate, compare and integrate KPIs into manufacturing execution systems (MES) and dashboards.

- Effect models and analysis: annexes provide parameter‑indicator matrices and effect model diagrams to support root-cause analysis and performance improvement.

Practical applications

ISO 22400-2 is designed to be practical and actionable for:

- Implementing consistent production KPIs across plants and supply chains

- Standardizing KPI calculations for MES, SCADA and industrial automation systems

- Benchmarking and performance dashboards (OEE, throughput, availability)

- Supporting continuous improvement programs (Lean, Six Sigma), maintenance strategy (predictive vs corrective) and energy/efficiency monitoring

- Enabling interoperable KPI reporting and data exchange aligned with IEC 62264/ISA‑95 models

Who should use this standard

- Plant managers, operations managers and production engineers

- Industrial automation and MES integrators

- Maintenance and reliability engineers

- Quality and process improvement teams

- IT architects building manufacturing analytics and KPI dashboards

Related standards

- IEC 62264 (ISA‑95) - manufacturing / MES integration models and work unit definitions

- Other parts of the ISO 22400 series (overview and concepts) for broader KPI framework and implementation guidance

Keywords: ISO 22400-2, KPIs for manufacturing, manufacturing operations management KPIs, OEE, throughput, availability, inventory turns, IEC 62264, MES, production KPIs.

ISO 22400-2:2014 - Automation systems and integration -- Key performance indicators (KPIs) for manufacturing operations management

ISO 22400-2:2014 - Automation systems and integration -- Key performance indicators (KPIs) for manufacturing operations management

Frequently Asked Questions

ISO 22400-2:2014 is a standard published by the International Organization for Standardization (ISO). Its full title is "Automation systems and integration - Key performance indicators (KPIs) for manufacturing operations management - Part 2: Definitions and descriptions". This standard covers: ISO 22400 defines key performance indicators (KPIs) used in manufacturing operations management. ISO 22400-2:2014 specifies a selected number of KPIs in current practice. The KPIs are presented by means of their formula and corresponding elements, their time behaviour, their unit/dimension and other characteristics. ISO 22400-2:2014 also indicates the user group where the KPIs are used, and the production methodology to which they correspond. With reference to equipment, the KPIs in ISO 22400-2:2014 relate to work units, as specified in IEC 62264.

ISO 22400 defines key performance indicators (KPIs) used in manufacturing operations management. ISO 22400-2:2014 specifies a selected number of KPIs in current practice. The KPIs are presented by means of their formula and corresponding elements, their time behaviour, their unit/dimension and other characteristics. ISO 22400-2:2014 also indicates the user group where the KPIs are used, and the production methodology to which they correspond. With reference to equipment, the KPIs in ISO 22400-2:2014 relate to work units, as specified in IEC 62264.

ISO 22400-2:2014 is classified under the following ICS (International Classification for Standards) categories: 25.040.01 - Industrial automation systems in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 22400-2:2014 has the following relationships with other standards: It is inter standard links to ISO 22400-2:2014/Amd 1:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 22400-2:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 22400-2

ISO/TC 184/SC 5 Secretariat: ANSI

Voting begins on Voting terminates on

2011-10-04 2012-03-04

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ ORGANISATION INTERNATIONALE DE NORMALISATION

Automation systems and integration — Key performance

indicators for manufacturing operations management —

Part 2:

Definitions and descriptions

Systèmes d'automatisation industrielle et intégration — Indicateurs de la performance clé pour le

management des opérations de fabrication —

Partie 2: Définitions et descriptions

ICS 25.040.01

In accordance with the provisions of Council Resolution 15/1993 this document is circulated in

the English language only.

Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est distribué

en version anglaise seulement.

To expedite distribution, this document is circulated as received from the committee

secretariat. ISO Central Secretariat work of editing and text composition will be undertaken at

publication stage.

Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.

THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME

STANDARDS TO WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.

RECIPIENTS OF THIS DRAFT ARE INVITED TO SUBMIT, WITH THEIR COMMENTS, NOTIFICATION OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPORTING DOCUMENTATION.

© International Organization for Standardization, 2011

ISO/DIS 22400-2

Copyright notice

This ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user’s country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic,

photocopying, recording or otherwise, without prior written permission being secured.

Requests for permission to reproduce should be addressed to either ISO at the address below or ISO’s

member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii © ISO 2011 – All rights reserved

ISO/DIS 22400-2

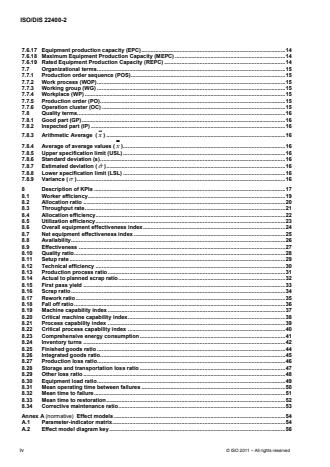

Contents Page

1 Scope . 1

2 Conformance . 1

3 Normative references . 1

4 Terms and definitions . 2

5 Symbols (and abbreviated terms) . 3

6 Structure of a KPI record . 5

6.1 Attributes of KPIs . 5

6.2 Name / Title of indicator . 5

6.3 Application . 5

6.4 Timing . 5

6.5 Formula . 5

6.6 Unit / Dimension . 6

6.7 Rating. 6

6.8 Analysis / Drill down . 6

6.9 User group: . 6

6.10 Effect model . 6

6.11 Manufacturing type . 6

7 Elements used in KPI description . 7

7.1 Time elements . 7

7.1.1 Notations . 7

7.1.2 Planned periods . 7

7.1.3 Actual times . 8

7.2 Maintenance terms . 10

7.2.1 Time to failure (TTF) . 10

7.2.2 Operating time between failures (TBF) . 10

7.2.3 Time to restoration (TTR). 10

7.2.4 Failure event (FE) . 10

7.2.5 Corrective maintenance time (CMT) . 10

7.2.6 Preventive maintenance time (PMT) . 10

7.3 Time model for production units . 11

7.4 Time model for manufacturing order . 12

7.5 Time model for employment . 12

7.6 Logistical tems . 13

7.6.1 Order quantity (POQ) . 13

7.6.2 Scrap quantity (SQ) . 13

7.6.3 Planned scrap quantity (PSQ) . 13

7.6.4 Good quantity (GQ) . 13

7.6.5 Rework quantity (RQ) . 13

7.6.6 Produced quantity (PQ) . 13

7.6.7 Raw materials inventory (RMI) . 13

7.6.8 Consumables inventory (CI) . 13

7.6.9 Finished goods inventory (FGI) . 13

7.6.10 Work in process inventory (WIP) . 13

7.6.11 Consumed material (CM) . 14

7.6.12 Integrated good quantity (IGQ) . 14

7.6.13 Loss . 14

7.6.14 Production loss (PL) . 14

7.6.15 Storage and transportation loss (STL) . 14

7.6.16 Other loss (OL) . 14

ISO/DIS 22400-2

7.6.17 Equipment production capacity (EPC) . 14

7.6.18 Maximum Equipment Production Capacity (MEPC) . 14

7.6.19 Rated Equipment Production Capacity (REPC) . 14

7.7 Organizational terms . 15

7.7.1 Production order sequence (POS) . 15

7.7.2 Work process (WOP) . 15

7.7.3 Working group (WG) . 15

7.7.4 Workplace (WP) . 15

7.7.5 Production order (PO) . 15

7.7.6 Operation cluster (OC) . 15

7.8 Quality terms . 16

7.8.1 Good part (GP) . 16

7.8.2 Inspected part (IP) . 16

7.8.3 Arithmetic Average (x ) . 16

7.8.4 Average of average values (x ) . 16

7.8.5 Upper specification limit (USL) . 16

7.8.6 Standard deviation (s) . 16

7.8.7 Estimated deviation (ˆ ) . 16

7.8.8 Lower specification limit (LSL) . 16

7.8.9 Variance ( ) . 16

8 Description of KPIs . 17

8.1 Worker efficiency . 19

8.2 Allocation ratio . 20

8.3 Throughput rate . 21

8.4 Allocation efficiency . 22

8.5 Utilization efficiency . 23

8.6 Overall equipment effectiveness index . 24

8.7 Net equipment effectiveness index . 25

8.8 Availability . 26

8.9 Effectiveness . 27

8.10 Quality ratio . 28

8.11 Setup rate . 29

8.12 Technical efficiency . 30

8.13 Production process ratio . 31

8.14 Actual to planned scrap ratio . 32

8.15 First pass yield . 33

8.16 Scrap ratio . 34

8.17 Rework ratio . 35

8.18 Fall off ratio . 36

8.19 Machine capability index . 37

8.20 Critical machine capability index . 38

8.21 Process capability index . 39

8.22 Critical process capability index . 40

8.23 Comprehensive energy consumption . 41

8.24 Inventory turns . 42

8.25 Finished goods ratio . 44

8.26 Integrated goods ratio. 45

8.27 Production loss ratio. 46

8.28 Storage and transportation loss ratio . 47

8.29 Other loss ratio . 48

8.30 Equipment load ratio . 49

8.31 Mean operating time between failures . 50

8.32 Mean time to failure . 51

8.33 Mean time to restoration . 52

8.34 Corrective maintenance ratio . 53

Annex A (normative) Effect models . 54

A.1 Parameter-indicator matrix . 54

A.2 Effect model diagram key . 56

iv © ISO 2011 – All rights reserved

ISO/DIS 22400-2

A.3 Worker efficiency . 57

A.4 Allocation ratio . 58

A.5 Throughput rate . 59

A.6 Allocation efficiency . 60

A.7 Utilization efficiency . 61

A.8 Overall equipment effectiveness index . 62

A.9 Net equipment effectiveness index . 63

A.10 Availability . 64

A.11 Effectiveness . 65

A.12 Quality ratio . 66

A.13 Set up rate . 67

A.14 Technical efficiency . 68

A.15 Production process ratio . 69

A.16 Actual to planned scrap ratio . 70

A.17 First pass yield . 71

A.18 Scrap ratio . 72

A.19 Rework ratio . 73

A.20 Fall-off rate . 74

A.21 Machine capability index and critical machine capability index . 75

A.22 Process capability index and critical process capability index . 76

A.23 Comprehensive energy consumption . 77

A.24 Inventory turns . 78

A.25 Finished goods ratio . 79

A.26 Integrated goods ratio. 80

A.27 Production loss ratio. 81

A.28 Storage and transportation loss ratio . 82

A.29 Other loss ratio . 83

A.30 Equipment load rate . 84

A.31 Mean operation time between failures . 85

A.32 Mean time to failures . 86

A.33 Mean time to restoration . 88

A.34 Corrective maintenance ratio . 89

B.3.1 Overall equipment effectiveness index . 91

B 3.2 Availability . 92

B 3.3 Performance Rate. 93

ISO/DIS 22400-2

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work. ISO

collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives,

Part 2.

The main task of technical committees is to prepare International Standards. Draft International

Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies

casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 22400-2 was prepared by Technical Committee ISO/TC 184, Automation systems and integration,

Subcommittee SC 5, Interoperability, integration and architectures of automation systems and

applications.

ISO 22400 consists of the following planned parts, under the general title Automation systems and

integration — Key performance indicators (KPIs) for manufacturing operations management

Part 1: Overview, concepts and terminology

Part 2: Definitions and descriptions

Part 3: Workflow and activity model

Part 4: Exchange and use

vi © ISO 2011 – All rights reserved

ISO/DIS 22400-2

Introduction

This standard focuses on Key Performance Indicators (KPIs) for manufacturing operations

management.

KPIs are defined as quantifiable and strategic measurements that reflects an organization‟s critical

success factors. Key Performance Indicators are very important for understanding and improving

manufacturing performance; both from the lean manufacturing perspective of eliminating waste and

from the corporate perspective of achieving strategic goals.

Manufacturing Operations Management is defined in IEC 62264. It defines a functional hierarchy

model of a manufacturing enterprise as shown in Figure 1. Figure 1 depicts the different levels of the

functional hierarchy model: business planning and logistics (level 4), manufacturing operations and

control (level 3), and batch, continuous, or discrete control (level 1-2). The levels provide different

functions and work in different timeframes.

Figure 1 — Functional hierarchy (from Figure 2 in IEC 62264-3)

The IEC 62264 standard also defines an hierarchical structure for the physical equipment, see Figure

2 Enterprise, Site and areas are generic terms, whereas there are specific terms for work centers and

work units that apply to batch production, continuous production, discrete or repetitive production, and

for storage and movement of materials and equipment.

ISO/DIS 22400-2

ENTERPRISE

SITE

AREA

PROCESS PRODUCTION PRODUCTION STORAGE

WORK

CELL UNIT LINE ZONE

CENTERS

Contains Contains Contains Contains

WORK

WORK STORAGE

UNIT WORK STORAGE

UNIT

UNITS

UNIT

UNIT CELL UNIT

CELL UNIT

Equipment used Equipment used Equipment used Equipment used

in batch in continuous in repetitive or for storage or

production production discrete production movement

Figure 2 — Operation cluster hierarchy

This standard defines the KPIs “residing” at Level 3, i.e., related to manufacturing operations

management. These KPIs are generated/calculated within Level 3. Some of these KPIs are forwarded

to Level 4 for further usage. In order to generate these KPIs, parameters from level 2 and 1 might be

needed.

Manufacturing Operations Management, sometimes referred to as Manufacturing Execution Systems

(MES), is modeled using four information categories: production operations management,

maintenance operations management, quality operations management, and inventory operations

management. The KPIs in this standard are presented according to these information categories.

The KPIs in this standard use the most generic terms possible, i.e. work centers and work units,

instead of industry specific terms.

KPIs also reside at Level 4. i.e., KPIs related to business planning and logistics. Level 4 KPIs are often

related to economic, business, logistic and financial factors. These KPIs are used to assess the

progress or extent of compliance with regard to important objectives or critical success factors within a

company. Economic KPIs serve as a basis for decisions (problem identification, presentation,

information extraction), for economic control (target / actual comparison), for financial documentation

and for coordination (behaviour management) of important facts and relationships within the company

Manufacturing Operations Management, sometimes referred to as Manufacturing Execution Systems

(MES), is modelled using four categories: production operations management, maintenance

operations management, quality operations management, and inventory operations management.

Each category is further detailed by an Activity Model. Each Activity Model includes eight activities:

detailed scheduling, dispatching, execution management, resource management, definition

management, tracking, data collection, and analysis. These activities apply to production operations,

quality operations, inventory operations and maintenance operations. Analysis is the performance of

calculating KPIs using information from other activities. Workflows can be used to illustrate the

important events and steps needed in the calculation process for KPIs.

KPIs alone are not sufficient factors to perform the necessary management and execution operations

for an enterprise. For many of the indicators, a company specific threshold is defined. When the value

viii © ISO 2011 – All rights reserved

ISO/DIS 22400-2

of the indicator exceeds of falls below the threshold, actions are initiated to improve efficiency or

quality. Often it is necessary to define warning and action limits. Warning limits help to detect the

trends in process and equipment changes before company-specific thresholds are violated.

The KPIs gathered in this part of the International Standard have been used in various production

situations for many years. Although these KPIs were collected in a simple and readily understandable

form, different interpretations of these terms can exist.

To improve the productivity of the manufacturing resources, information provided by industrial

automation systems and control devices about process, equipment, operator, and material can be

more effectively used in providing critical feedback through KPIs.

A standardized schema for the expression of these KPIs is intended to:

a) facilitate the specification and procurement of integrated systems, in particular, the interoperability

requirements among MES applications;

b) provide a means to categorize productivity tools that can be used across applications.

ISO 22400 provides an overview of the concepts, the terminology, and the methods to describe and to

exchange key performance indicators (KPIs) for the purpose of managing manufacturing operations.

The audience are factory managers responsible for production performance, software suppliers

developing KPIs for factory management, engineers engaged in process planning of products,

planners and designers of manufacturing systems, and equipment and device suppliers.

ISO/DIS 22400-2

Automation systems and integration — Key performance

indicators for manufacturing operations management —

Part 2:

Definitions and descriptions

1 Scope

The scope of ISO 22400 is to give a clear and unique definition of Key Performance Indicators (KPIs)

used in Manufacturing Operations Management (MOM).

This part presents a selected number of KPIs in current practice. The KPIs are presented by means of

their formula and corresponding elements, their time behavior, unit/dimension and rating. It also

indicates the User group where the KPIs are used and to what production type they fit.

2 Conformance

To be compliant with the requirements of ISO 22400-2, KPIs shall conform to the relevant descriptions

in clause 8 and clause 9.

3 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

IEC 60050-191 ed1.0 International Electrotechnical Vocabulary. Chapter 191: Dependability and

quality of service

IEC 62264-3, Industrial-process measurement and control – Enterprise-control system integration –

Part 3: Activity models of manufacturing operations

IEC 62264-1, Industrial-process measurement and control – Enterprise-control system integration –

Part 1: Models and terminology

ISO/DIS 22400-2

4 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

4.1

Drill down

Examine the source of the data used to calculate a performance indicator

EXAMPLE

Within the OEE index the quality rate is to be analyzed. The drill down presents a direct indicator with reference to

workplace, product and time period as well as possible errors. This is a quick analysis which supports a most

rapid efficiency improvement by corrective actions, and thus reduces errors.

4.2

Enterprise Resource Planning

Business process of a company involving the enterprise-wide planning and business support functions,

such as, procurement, human resource management, customer support, finance and accounting,

master data management, etc.

4.3

Timing

Property of a KPI that shows how often an application can examine the value of the KPI

EXAMPLE

Categories include: Demand-oriented – determined by an operator; Periodic – calculated by system per specified

time intervals; Event-driven – updated whenever data changes and displayed immediately

2 © ISO 2011 – All rights reserved

ISO/DIS 22400-2

5 Symbols (and abbreviated terms)

x Arithmetic Average

x Average of average values

Estimated deviation

ADET Actual unit delay time

ADOT Actual unit downtime

AOET Actual order execution time

APAT Actual personnel attendance time

APT Actual production time

APWT Actual personnel work time

AQT Actual queueing time

ASUT Actual set up time

ATT Actual transport time

AUBT Actual unit busy time

AUPT Actual unit processing time

CI Consumables inventory

C Machine capability index

m

CM Consumed material

C Critical machine capability index

mk

CMT Corrective maintanance time

C Process capability index

p

C Critical process capability index

pk

DAY Day

EPC Equipment production capacity

FE Failure event

FGI Finished goods inventory

GP Good part

GQ Good quantity

IGQ Integrated good quantity

IP Inspected part

LSL Lower specification limit

LT Loading time

MEPC Maximum equipment production capacity

MOM Manufacturing operation management

NEE Net overall equipment effectiviness index

NOT Net operating time

OC operation cluster

OEE Overall equipment effectiviness index

OL Other loss

OPT Operating time

PBT Planned busy time

PL Production loss

PMT Preventive maintanance time

PO Production order

POET Planned order time

POQ Order quantity

POS Production order sequence

POT Planned operation time

PQ Produced quantity

PRTU Planned run time per unit

PSQ Planned scrap quantity

ISO/DIS 22400-2

PSUT Planned setup time

REPC Rated equipment production capacity

RMI Raw material inventory

RQ Rework quantity

s Standard deviation

SQ Scrap quantity

STL Storage and transportation loss

TBF Operating time between failure

ˆ

TTF time to failure

TTR time to restoration

USL Upper specification limit

VOT Valued operating time

WG Working group

WIP Work in process inventory

WOP Work process

WP Work place

WU work unit

σ Variance

4 © ISO 2011 – All rights reserved

ISO/DIS 22400-2

6 Structure of a KPI record

6.1 Attributes of KPIs

In accordance with ISO 22400-1, the KPI descriptions in this part of ISO 22400 are expressed using

the structure in Figure 2.

Name / Title of indicator:

a

ID

Description

Application:

Timing

Definition and calculation

Formula:

Unit / Dimension:

Rating:

Analysis / Drill down:

Remarks

Notes / Explanation:

User group:

Effect model

Manufacturing type:

a

ID is not used in this part of ISO 22400, whose scope does not include KPI implementation and

exchange of KPIs.

Figure 3 – KPI structure

Explanations of the attributes (except ID) are provided in the remaining subclauses of clause 6.

6.2 Name / Title of indicator

Expression or designation of the KPI.

6.3 Application

A brief description of the benefits provided by the KPI, including its use and consequences in control

applications.

6.4 Timing

A KPI can be calculated either in real-time (i.e., after each new data acquisition event), on demand

(i.e., after a specific data selection request), or periodically (i.e., done at a certain interval, e.g., one

time per day).

6.5 Formula

The mathematical formula of the KPI based on its elements.

ISO/DIS 22400-2

6.6 Unit / Dimension

The basic unit or dimension in which the KPI is expressed.

6.7 Rating

The upper and lower logical limits of the KPI and the trend indicating improvement.

6.8 Analysis / Drill down

Description of related KPI elements to drill down and analyze the root cause of KPI results.

6.9 User group:

Description of the user groups that utilize the KPI.

6.10 Effect model

An assessment method used to find root causes of KPI value change and how it relates to other

elements and KPIs

6.11 Manufacturing type

The type of manufacturing (continuous, batch, discrete) for which the KPI can be used.

6 © ISO 2011 – All rights reserved

ISO/DIS 22400-2

7 Elements used in KPI description

7.1 Time elements

7.1.1 Notations

Many time models for performance indicator data are complete and conclusive for manually performed

production, but cannot always be used for automated production processes. To avoid potential

misunderstanding, the time elements used in KPI descriptions are explicitly defined below.

In this model, a production order is processed and completed when one or more tasks are performed

by a set of production resources, such as, production personnel, equipment and materials.

The identifying name for a time element is extended with a simple abbreviation in round brackets,

which is used below in KPI calculations.

7.1.2 Planned periods

7.1.2.1 Day

The day is the planned maximum time available for production and maintenance tasks. This depends

on the number of shifts being run. For example, a single shift corresponds to 8 hours that are

scheduled when a production resource is planned to be used to perform the tasks.

7.1.2.2 Planned order time (POET)

The planned order time is the scheduled time for executing an order based on the work plan.

NOTE: It is often calculated from the planned run time per unit multiplied by the order quantity plus the

planned setup time.

7.1.2.3 Planned operation time (POT)

The planned operation time is that time in which a work unit can be used. The operation time is a

scheduled time.

7.1.2.4 Planned setup time (PSUT)

The planned setup time is the scheduled time for the setup of a work unit for an order.

7.1.2.5 Planned busy time (PBT)

The planned busy time is the operating time minus the planned downtime. The planned down time

may be used for planned maintenance work. The planned busy period is available for the detailed

planning of the work unit for expected production orders.

7.1.2.6 Planned run time per unit (PRU)

The run time per unit is the scheduled time for producing one unit.

ISO/DIS 22400-2

7.1.3 Actual times

7.1.3.1 Actual personnel work time (APWT)

The actual personnel work time is the time that a personnel needs for the execution of a production

order.

7.1.3.2 Actual unit processing time (AUPT)

The actual unit processing time is the time needed for setup and for the production

7.1.3.3 Actual unit busy time (AUBT)

The actual unit busy time is the time that a work unit is used for the execution of a production order.

7.1.3.4 Actual order execution time (AOET)

The actual order execution time is the time difference between start time and end time of a production

order. It includes the busy time, the transport and queuing time.

7.1.3.5 Actual personnel attendance time (APAT)

The actual personnel attendance time is the total time that a worker is actually available to work on

production orders. It does not include time for company authorized break periods (i.e. lunch). It is the

difference between login and logout excluding breaks.

7.1.3.6 Actual production time (APT)

The actual production time is the time during a work unit is producing. It includes only the value-

adding functions.

7.1.3.7 Actual queuing time (AQT)

The actual queuing time is the time in which the material is not in progress of the manufacturing

process and also is not on transport.

7.1.3.8 Actual unit down time (ADOT)

The actual unit down time is the time when the work unit is not running with orders, although it is

available.

7.1.3.9 Actual unit delay time (ADET)

The actual unit delay times are actual times associated with malfunction-caused interrupts, minor

stoppages, and other unplanned time intervals that occur while tasks are being completed that lead to

unwanted extension of the order processing time

7.1.3.10 Actual setup time (ASUT)

The actual setup time is the time actually consumed for the preparation of an order at a work unit.

8 © ISO 2011 – All rights reserved

ISO/DIS 22400-2

7.1.3.11 Actual transport time (ATT)

The actual transport time is the time required for transport between work units, or to and from

inventory storage areas.

ISO/DIS 22400-2

7.2 Maintenance terms

Definitions of maintenance elements have been extracted from the standard IEC 60050-191 ed1.0

International Electro-technical Vocabulary. Chapter 191: Dependability and quality of service.

NOTE The term „item‟ used in the definitions below applies to the „work unit‟ in this standard.

7.2.1 Time to failure (TTF)

Total time duration of operating time of an item, from the instant it is first put in an up state, until failure

or, from the instant of restoration until next failure (IEC 60050-191)

7.2.2 Operating time between failures (TBF)

Total time duration of operat

...

INTERNATIONAL ISO

STANDARD 22400-2

First edition

2014-01-15

Automation systems and

integration — Key performance

indicators (KPIs) for manufacturing

operations management —

Part 2:

Definitions and descriptions

Systèmes d’automatisation et intégration — Indicateurs de

la performance clé pour le management des opérations de

fabrication —

Partie 2: Définitions et descriptions

Reference number

©

ISO 2014

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

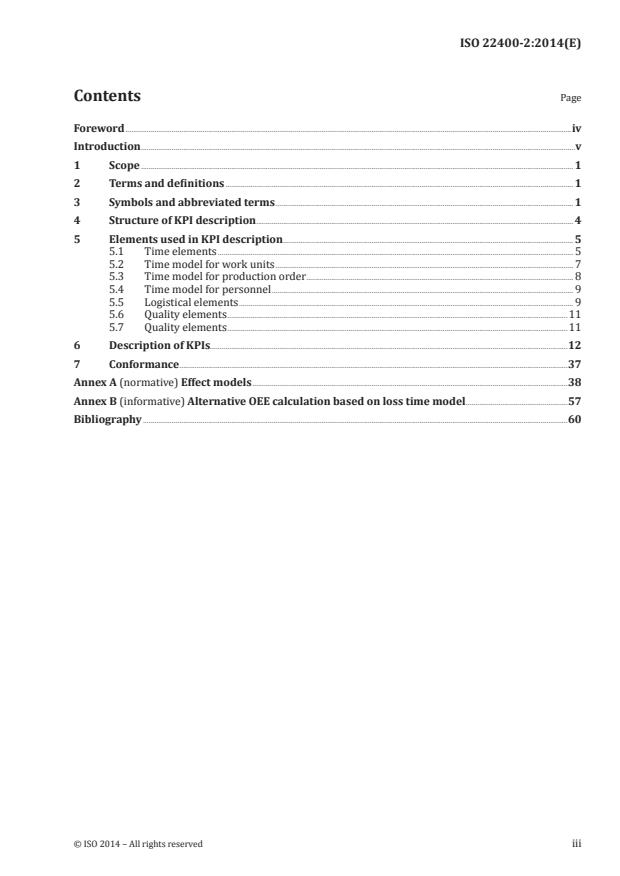

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Terms and definitions . 1

3 Symbols and abbreviated terms . 1

4 Structure of KPI description . 4

5 Elements used in KPI description . 5

5.1 Time elements . 5

5.2 Time model for work units . 7

5.3 Time model for production order . 8

5.4 Time model for personnel . 9

5.5 Logistical elements . 9

5.6 Quality elements .11

5.7 Quality elements .11

6 Description of KPIs.12

7 Conformance .37

Annex A (normative) Effect models .38

Annex B (informative) Alternative OEE calculation based on loss time model .57

Bibliography .60

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is Technical Committee ISO/TC 184, Automation systems

and integration, Subcommittee SC 5, Interoperability, integration and architectures of automation systems

and applications.

ISO 22400 consists of the following parts, under the general title Automation systems and integration —

Key performance indicators (KPIs) for manufacturing operations management

— Part 1: Overview, concepts and terminology

— Part 2: Definitions and descriptions

The following parts are under preparation:

— Part 3: Exchange and use

— Part 4: Relationships and dependencies

iv © ISO 2014 – All rights reserved

Introduction

This part of ISO 22400 focuses on key performance indicators (KPIs) for manufacturing operations

management.

KPIs are defined as quantifiable and strategic measurements that reflect an enterprise’s critical success

factors. KPIs are very important for understanding and improving manufacturing performance, both

from the lean manufacturing perspective of eliminating waste and from the corporate perspective of

achieving strategic goals.

Manufacturing operations management (MOM) is a term used in IEC 62264 to specify a portion of the

functional hierarchy model of a manufacturing enterprise. Figure 1 depicts the different levels of the

functional hierarchy model: business planning and logistics (Level 4), manufacturing operations and

control (Level 3), and batch, continuous, or discrete control (Level 1-2). The levels provide different

functions and work in different timeframes.

NOTE Adapted from IEC 62264-3.

Figure 1 — Functional hierarchy

IEC 62264 also specifies a hierarchical structure for the physical equipment (see Figure 2). Enterprise,

site and areas are generic terms, whereas there are specific terms for work centres and work units that

apply to batch production, continuous production, discrete or repetitive production, and for storage and

movement of materials and equipment.

NOTE Adapted from IEC 62264-3.

Figure 2 — Role based equipment hierarchy

This part of ISO 22400 specifies the KPIs “residing” at Level 3, i.e. related to MOM. These KPIs are

generated/calculated within Level 3. Some of these KPIs are forwarded to Level 4 for further usage. In

order to generate these KPIs, parameters from Levels 2 and 1 might be needed.

The KPIs in this part of ISO 22400 use the most generic terms possible (e.g. work centres and work

units), instead of industry specific terms.

MOM, sometimes referred to as manufacturing execution systems (MES), models four major categories

of operations management:

— production operations management;

— maintenance operations management;

— quality operations management;

— inventory operations management.

An activity model further details each category. Each activity model includes eight activities:

— detailed scheduling;

— dispatching;

— execution management;

— resource management;

— definition management;

— tracking;

vi © ISO 2014 – All rights reserved

— data collection;

— analysis.

These activities apply to production operations, quality operations, inventory operations and

maintenance operations.

Analysis is the performance of calculating KPIs using information from other activities. Workflows can

be used to illustrate the important events and steps needed in the calculation process for KPIs.

KPIs alone are not sufficient factors to perform the necessary management and execution operations for

an enterprise. For many of the indicators, a company specific threshold is defined. When the value of the

indicator exceeds or falls below the threshold, actions are initiated (e.g. to improve efficiency or quality).

Often it is necessary to define warning and action limits. Warning limits help to detect the trends in

process and equipment changes before company-specific thresholds are violated.

To improve the productivity of the manufacturing resources, information provided by industrial

automation systems and control devices about process, equipment, operator, and material can be useful

for providing critical feedback through KPIs.

A standardized schema for the expression of these KPIs is intended to:

a) facilitate the specification and procurement of integrated systems, in particular, the interoperability

requirements among MES applications;

b) provide a means to categorize productivity tools that can be used across applications.

ISO 22400 provides an overview of the concepts, the terminology and the methods to describe and to

exchange KPIs for the purpose of managing manufacturing operations. The audience is factory managers

responsible for production performance, software suppliers developing KPIs for factory management,

engineers engaged in process planning of products, planners and designers of manufacturing systems,

and equipment and device suppliers.

KPIs also reside at Level 4, i.e. KPIs related to business planning and logistics, which are outside the

scope of this part of ISO 22400. Level 4 KPIs are often related to economic, business, logistic and financial

factors. These KPIs are used to assess the progress or extent of compliance with regard to important

objectives or critical success factors within a company. Economic KPIs serve as a basis for decisions

(problem identification, presentation, information extraction), for economic control (target/actual

comparison), for financial documentation and for coordination (behaviour management) of important

facts and relationships within the company.

INTERNATIONAL STANDARD ISO 22400-2:2014(E)

Automation systems and integration — Key performance

indicators (KPIs) for manufacturing operations

management —

Part 2:

Definitions and descriptions

1 Scope

ISO 22400 specifies key performance indicators (KPIs) used in manufacturing operations management

(MOM).

This part of ISO 22400 specifies a selected number of KPIs in current practice. The KPIs are presented

by means of their formula and corresponding elements, their time behaviour, their unit/dimension and

other characteristics. This part of ISO 22400 also indicates the user group where the KPIs are used, and

the production methodology to which they correspond.

With reference to equipment, the KPIs in this part of ISO 22400 relate to work units, as specified in

IEC 62264.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

reference time

base timeline used for time models, corresponding to the planned maximum time interval available for

production and maintenance tasks

EXAMPLE A calendar day with 24 hours; a week.

2.2

planned time

planned duration of a specific time period

EXAMPLE The intended duration of an operation or a resource state according to the planning.

2.3

actual time

realized duration of a specific time period

EXAMPLE The actual duration of an operation or a resource state.

Note 1 to entry: Actual time may be less than, equal to, or greater than corresponding planned time.

2.4

time model

partition of the reference time

3 Symbols and abbreviated terms

ADET actual unit delay time

ADOT actual unit downtime

AOET actual order execution time

APAT actual personnel attendance time

APT actual production time

APWT actual personnel work time

AQT actual queuing time

AUST actual unit setup time

ATT actual transport time

AUBT actual unit busy time

AUPT actual unit processing time

CI consumables inventory

C machine capability index

m

CM consumed material

C critical machine capability index

mk

CMT corrective maintenance time

C process capability index

p

C critical process capability index

pk

EPC equipment production capacity

FE failure event

FGI finished goods inventory

GP good part

GQ good quantity

IGQ integrated good quantity

IP inspected part

LSL lower specification limit

LT loading time

MOM manufacturing operations management

NEE net overall equipment effectiveness index

NOT net operating time

OC operation cluster

OEE overall equipment effectiveness

OL other loss

2 © ISO 2014 – All rights reserved

OPT operating time

PBT planned busy time

PL production loss

PMT preventive maintenance time

PO production order

POET planned order execution time

POQ planned order quantity

POS production order sequence

POT planned operation time

PQ produced quantity

PRI planned run time per item

PSQ planned scrap quantity

PUST planned unit setup time

RMI raw material inventory

RQ rework quantity

σ standard deviation

SQ scrap quantity

STL storage and transportation loss

TBF operating time between failure

TTF time to failure

TTR time to repair

USL upper specification limit

WG working group

WIP work in process inventory

WOP work process

WP work place

x

arithmetic average

x

average of average values

σ

estimated deviation

σ variance

4 Structure of KPI description

KPI specifications are expressed using the structure in Table 1 and are in accordance with ISO 22400-1.

The structure in Table 1 identifies KPI descriptive elements in the left column and gives a description of

each element in the right column.

Table 1 — Structure of KPI description

KPI description

Content:

Name Name of the KPI

ID A user defined unique identification of the KPI in the user environment

Description A brief description of the KPI

Scope Identification of the element that the KPI is relevant for, which can be a work unit, work centre

or production order, product or personnel

Formula The mathematical formula of the KPI specified in terms of elements

Unit of measure The basic unit or dimension in which the KPI is expressed

Range Specifies the upper and lower logical limits of the KPI

Trend Is the information about the improvement direction, higher is better or lower is better

Context:

Timing A KPI can be calculated either in

• real-time - after each new data acquisition event

• on demand - after a specific data selection request

• periodically - done at a certain interval, e.g. once per day

Audience Audience is the user group typically using this KPI. The user groups used in this part of

ISO 22400 are

• Operators – personnel responsible for the direct operation of the equipment

• Supervisors – personnel responsible for directing the activities of the operators

• Management – personnel responsible for the overall execution of production

Production methodology Specifies the production methodology that the KPI is generally applicable for

• Discrete

• Batch

• Continuous

Effect model diagram The effect model diagram is a graphical representation of the dependencies of the KPI elements

that can be used to drill down and understand the source of the element values.

NOTE This is a quick analysis which supports rapid efficiency improvement by corrective

actions, and thus reduces errors

Notes Can contain additional information related to the KPI. Typical examples are

• Constraints

• Usage

• Other information

4 © ISO 2014 – All rights reserved

5 Elements used in KPI description

5.1 Time elements

5.1.1 Notations

In the time model of this part of ISO 22400, in order to process and complete a production order, one or

more tasks are performed using a set of production resources, e.g. production personnel, equipment and

materials.

NOTE 1 Since many continuous operations (e.g. refineries and other petrochemical facilities) define

“throughput” using an arbitrary time period (e.g. a day or a shift), rather than a production order based time

interval, KPIs derived using this production order time model need to be adjusted for those industries.

NOTE 2 The identifying element name abbreviations indicated in round brackets in this clause are used in KPI

calculations in Clause 6.

NOTE 3 Definitions of maintenance elements have been taken from IEC 60050-191.

NOTE 4 The term “time” in the element specifications refers to a duration of time.

5.1.2 Planned times

5.1.2.1 Planned order execution time (POET)

The planned order execution time shall be the planned time for executing an order.

NOTE It is often calculated from the planned run time per item multiplied by the order quantity plus the

planned setup time.

5.1.2.2 Planned operation time (POT)

The planned operation time shall be the planned time in which a work unit can be used. The operation

time is a scheduled time.

5.1.2.3 Planned unit setup time (PUST)

The planned unit setup time shall be the planned time for the setup of a work unit for an order.

5.1.2.4 Planned busy time (PBT)

The planned busy time shall be the planned operation time minus the planned downtime.

NOTE The planned down time can be used for planned maintenance work. The planned busy period is

available for the detailed planning of the work unit for expected production orders.

5.1.2.5 Planned run time per item (PRI)

The planned run time per item shall be the planned time for producing one quantity unit.

5.1.3 Actual times

5.1.3.1 Actual personnel work time (APWT)

The actual personnel work time shall be the time that a worker needs for the execution of a production

order.

5.1.3.2 Actual unit processing time (AUPT)

The actual unit processing time shall be the time needed for setup and for the production.

5.1.3.3 Actual unit busy time (AUBT)

The actual unit busy time shall be the actual time that a work unit is used for the execution of a production

order.

5.1.3.4 Actual order execution time (AOET)

The actual order execution time shall be the time difference between start time and end time of a

production order. It includes the actual busy time, the actual transport and the actual queuing time.

5.1.3.5 Actual personnel attendance time (APAT)

The actual personnel attendance time shall be the actual time that a worker is available to work on

production orders. It does not include actual time for company authorized break periods (e.g. lunch). It

shall be the difference between login and logout excluding breaks.

5.1.3.6 Actual production time (APT)

The actual production time shall be the actual time during which a work unit is producing. It includes

only the value-adding functions.

5.1.3.7 Actual queuing time (AQT)

The actual queuing time shall be the actual time in which the material is either in transport or progressing

through a manufacturing process, i.e. the material is waiting for the process to begin.

5.1.3.8 Actual unit down time (ADOT)

The actual unit down time shall be the actual time when the work unit is not executing order production

although it is available.

5.1.3.9 Actual unit delay time (ADET)

The actual unit delay time shall be the actual time associated with malfunction-caused interruptions,

minor stoppages, and other unplanned time intervals that occur while tasks are being completed that

lead to unwanted extension of the order processing time.

5.1.3.10 Actual unit setup time (AUST)

The actual unit setup time shall be the time consumed for the preparation of an order at a work unit.

5.1.3.11 Actual transport time (ATT)

The actual transport time shall be the actual time required for transport between work units.

5.1.3.12 Actual unit processing time (AUPT)

The actual unit processing time shall be the actual production time plus the actual unit setup time.

5.1.3.13 Actual unit busy time (AUBT)

The actual unit busy time shall be the actual unit processing time plus the actual unit delay time.

6 © ISO 2014 – All rights reserved

5.1.3.14 Actual order execution time (AOET)

The actual order execution time shall be the time from the start of the order until the time of the

completion of the order.

5.1.4 Maintenance times

5.1.4.1 Time between failures (TBF)

The time between failures shall be the actual unit busy time (AUBT) between two consecutive failures of

a work unit including setup time, production time and repair time related to the orders being processed

and without delay times.

5.1.4.2 Time to repair (TTR)

The time to repair shall be the actual time during which a work unit is unavailable due to a failure.

5.1.4.3 Time to failure (TTF)

The time to failure shall be the time between failures minus the time to repair.

5.1.4.4 Failure event count (FE)

The failure event count shall be the count over a specified time interval of the terminations of the ability

for a work unit to perform a required operation.

5.1.4.5 Corrective maintenance time (CMT)

The corrective maintenance time shall be the part of the maintenance time during which corrective

maintenance is performed on a work unit, including technical delays and logistic delays inherent in

corrective maintenance (see IEC 60050-191).

5.1.4.6 Preventive maintenance time (PMT)

The preventive maintenance time shall be that part of the maintenance time during which preventive

maintenance is performed on a work unit, including technical delays and logistic delays inherent in

preventive maintenance (see IEC 60050-191).

5.2 Time model for work units

This time model applies to time considerations for the use of work units. Figure 3 shows the relationship

between specific periods. In Figure 3, the difference between time elements constitutes a loss of

operation time.

Figure 3 — Time lines for work units

NOTE Annex B provides a time model for work units with different time element partitions for which KPIs

(e.g. OEE) generated using that model are different from those specified in Clause 6.

5.3 Time model for production order

This time model is valid for executing the production order. Figure 4 shows the production order

processing time line consisting of multiple occurrences of operations equipment time lines (see Figure

3). The work unit time lines for a production order may be carried out in separate operations at several

work units.

Figure 4 — Time lines for production order processing

8 © ISO 2014 – All rights reserved

5.4 Time model for personnel

This time model applies to time considerations for personnel.

Figure 5 — Time lines for personnel

5.5 Logistical elements

5.5.1 Planned order quantity (POQ)

The planned order quantity shall be the planned quantity of products for a production order (lot size,

production order quantity).

5.5.2 Scrap quantity (SQ)

The scrap quantity shall be the produced quantity that did not meet quality requirements and either has

to be scrapped or recycled.

5.5.3 Planned scrap quantity (PSQ)

The planned scrap quantity shall be the amount of process-related scrap that is expected when

manufacturing the product (e.g. at the start or ramp-up phases of the manufacturing systems).

5.5.4 Good quantity (GQ)

The good quantity shall be the produced quantity that meets quality requirements.

5.5.5 Rework quantity (RQ)

The rework quantity shall be the quantity that fails to meet the quality requirements, but where these

requirements can be met by subsequent work.

5.5.6 Produced quantity (PQ)

The produced quantity shall be the quantity that a work unit has produced in relation to a production

order.

5.5.7 Raw materials (RM)

The raw materials shall be the materials that are changed into finished goods through the production.

5.5.8 Raw materials inventory (RMI)

The raw materials inventory shall be the inventory of materials that are changed into intermediates or

finished goods through production.

5.5.9 Finished goods inventory (FGI)

The finished goods inventory shall be the amount of acceptable quantity which can be delivered.

5.5.10 Consumable inventory (CI)

The consumable inventory shall be material which is transformed in quantity or quality during the

production process and which is no longer available for use in production operations.

EXAMPLE Fuel.

NOTE Consumables are specified in detail in IEC 62264-1.

5.5.11 Consumed material (CM)

The consumed material shall be the summed quantity of materials consumed by a process.

NOTE In the process industry (e.g. oil refining and chemicals), consumed material is usually used in the

denominator to calculate the related KPIs. In some industrial processes, input can be less than the output. Many

chemical and physical changes occur during production, and product yield has fluctuation and uncertainty. It is

therefore difficult to calculate and measure the output.

5.5.12 Integrated good quantity (IGQ)

The integrated good quantity shall be the summed product count or quantity resulting from a multi-

product production process used in KPI calculations instead of GQ.

EXAMPLE If the quality of a product has not reached a higher level “A”, it can be sold as a product with a

lower quality level “B”. Then the ratio of products of level “B” raises as the ratio of products of level “A” declines.

Therefore, KPIs are calculated from the view of all related products, e.g. the level “A” plus level “B” products.

NOTE Since IGQ represents the quantity of all products during production, all products need to be measured

in the same unit of measure, or be converted to the same unit of measure. A list of conversion coefficients can be

used to unify the measurement modes of different products.

5.5.13 Production loss (PL)

The production loss shall be the quantity lost during production, calculated as output minus input.

NOTE Used in batch and continuous manufacturing.

5.5.14 Storage and transportation loss (STL)

The storage and transportation loss shall be the quantity lost during storage and transportation, e.g.

inventory lost during an inventory calculation or material lost during movement from one place to

another.

NOTE Used in batch and continuous manufacturing.

5.5.15 Other loss (OL)

Other loss shall be the quantity lost due to extraordinary incidents, e.g. natural disasters.

NOTE Used in batch and continuous manufacturing.

5.5.16 Equipment production capacity (EPC)

Equipment production capacity is the maximum production quantity of production equipment.

NOTE Used in batch and continuous manufacturing.

10 © ISO 2014 – All rights reserved

5.6 Quality elements

5.6.1 Good part (GP)

A good part shall be the count of individual identifiable parts, e.g. by serialization, which meets the

quality requirements.

NOTE In discrete manufacturing, a part is typically a single produced item. In batch manufacturing, a party

refers to a specified material lot.

5.6.2 Inspected part (IP)

An inspected part shall be the count of individual identifiable parts, e.g. by serialization, which was

tested against the quality requirements.

NOTE In discrete manufacturing, a part is typically a single produced item. In batch manufacturing, a party

refers to a specified material lot.

5.6.3 Upper specification limit (USL)

An upper specification limit is a value below which performance of a product or process is acceptable. It

represents the maximum acceptable value of a variable.

5.6.4 Lower specification limit (LSL)

A lower specification limit is a value above which performance of a product or process is acceptable. It

represents the minimum acceptable value of a variable.

5.7 Quality elements

5.7.1 Arithmetic average ( x )

If, in a series of n measurements, each measured value x ,…,x ,…,x was measured independently based

1 i n

on repetition conditions, then x (“x-bar”) represents the arithmetic average value from these n

individual values.

5.7.2 Average of average values ( x )

x is calculated from the average of single sample average values ( x ).

5.7.3 Estimated deviation (σ )

The estimated deviation is calculated by the average value of the standard deviation from a sequence

of samples with constant random inspection size, multiplied by a confidence factor depending on the

random inspection size of the standard deviations.

5.7.4 Standard deviation (σ)

The standard deviation is a measure for the dispersion of measured values around its average value, and

is determined from the square root of the variance.

5.7.5 Variance (σ )

The variance is a measure which describes how strongly a measured variable (characteristic) strews. It

is calculated as the distances of the measured values from the average value are squared, summed up

and divided by the number of measured values.

6 Description of KPIs

Tables 2 to 35 describe the KPIs for MOM. Annex A specifies the logical relation among the KPI elements.

Annex A is mandatory for any implementation of this part of ISO 22400, although not all elements of

Annex A are required in all implementations.

Table 2 — Worker efficiency

KPI description

Content

Name Worker efficiency

ID

Description The worker efficiency considers the relationship between the actual personnel work

time (APWT) related to production orders and the actual personnel attendance time

(APAT) of the employee.

Scope Worker, workgroup, work unit

Formula Worker efficiency = APWT / APAT

Unit of measure %

Range Min: 0%

Max: 100%

Trend The higher the better

Context

Timing Periodically

Audience Supervisor, management

Production methodology Discrete, batch, continuous

Effect model diagram see Figure A.1

Notes When calculating worker efficiency be careful of possible double counts if the worker is

working on several work units or production orders simultaneously

12 © ISO 2014 – All rights reserved

Table 3 — Allocation ratio

KPI description

Content

Name Allocation ratio

ID

Description The allocation ratio is the relationship of the complete actual busy time over all work

units (AUBT) involved in a production order to the actual order execution time of a

production order (AOET).

Scope Product, production order, and plant

Formula Allocation ratio = ∑AUBT / AOET

∑AUBT = sum of the AUBT of all work units involved in a production order.

Unit of measure %

Range Min: 0%

Max: 100%

>100% is possible in case of overlapping of production operations

Trend The higher the better

Context

Timing Periodically

Audience Supervisor, management

Production methodology Discrete, batch, continuous

Effect model diagram see Figure A.2

Notes The allocation ratio is an index for the wait times and delay times. It shows how much of

the throughput time of a production order is caused by actual processing. Too much wait

and down time extend the throughput time.

Table 4 — Throughput rate

KPI description

Content

Name Throughput rate

ID

Description Process performance in terms of produced quantity of an order (PQ) and the actual

execution time of an order (AOET).

Scope Product, production order, and plant

Formula Throughput rate = PQ/AOET

Unit of measure Quantity unit / Time unit

Range Min: 0 quantity units / time unit

Max: product-specific

Trend The higher the better

Context

Timing On demand, periodically

Audience Supervisor, management

Production methodology Discrete, batch

Effect model diagram see Figure A.3

Notes The Throughput rate is an index for the performance of a process. This performance

indicator is an important index for the efficiency in production

The performance indicator is calculated per order after order closing. Hours or days are

typical time-units to rate throughput specific for a product.

Table 5 — Allocation efficiency

KPI description

Content

Name Allocation efficiency

ID

Description The allocation efficiency is the ratio between the actual allocation time of a work unit

expressed as the actual unit busy time (AUBT) and the planned time for allocating the

work unit expressed as the planned unit busy time (PBT).

Scope Product, production order, and work unit

Formula Allocation efficiency = AUBT / PBT

Unit of measure %

Range Min: 0%

Max: 100%

Trend The higher the better

Context

Timing On-demand

Audience Operator, supervisor, management

Production methodology Discrete, batch, continuous

Effect model diagram see Figure A.4

Notes The allocation efficiency indicates how strongly the planned capacity of the work unit is

already used and how much planned capacity is still available

The allocation efficiency is only affected by the actual unit idle time while the availabil-

ity KPI takes the actual unit delay time into account.

Table 6 — Utilization efficiency

KPI description

Content

Name Utilization efficiency

ID

Description The utilization efficiency is the ratio between the actual production time (APT) and the

actual unit busy time (AUBT)

Scope Work unit

Formula Utilization efficiency = APT / AUBT

Unit of measure %

Range Min: 0%

Max: 100%

Trend The higher the better

Context

Timing On-demand, periodically, real-time

Audience Operator, supervisor, management

Production methodology Discrete, batch, continuous

Effect model diagram See Figure A.5

Notes This indicator identifies the productivity of work units. Because only the production

time affects an added value which will be paid by the market, the goal should be to get a

high indicator value.

14 © ISO 2014 – All rights reserved

Table 7 — Overall equipment effectiveness index

KPI description

Content

Name Overall equipment effectiveness index

ID

Description The OEE index represents the availability of a work unit (see Table 9), the effectiveness

of the work unit (see Table 10), and the quality ratio (see Table 11) KPIs integrated in a

single indicator.

Scope Work unit, product, time period, product, defect types

Formula OEE index = Availability * Effectiveness * Quality ratio

Unit of measure %

Range Min: 0%

Max: 100%

Trend The higher, the better

Context

Timing On-demand, periodically, real-time

Audience Operator. supervisor, management

Production methodology Discrete, batch, continuous

Effect model diagram See Figure A.6

Notes Overall equipment effectiveness (OEE) is an indicator for the efficiency of work units,

work centres and areas with several work units or an entire work centre. The OEE index

forms the basis for improvements by better production information, identification of

production losses, and improvement of the product quality by optimized processes.

The calculation of OEE based on the hierarchy structure (see Figure 2) is only useful if

the characteristic of the work unit processes would be comparable. Before starting a

benchmark based on the OEE index the criteria for comparability should be checked.

Table 8 — Net equipment effectiveness index

KPI description

Content

Name Net equipment effectiveness index

ID

Description The net equipment effectiveness (NEE) index combines the ratio between actual unit

processing time (AUPT) and planned busy time (PBT), the effectiveness KPI (see

Table 10) and the quality ratio KPI (see Table 11) into a single indicator

Scope Work unit, product, time period, product, defect types

Formula NEE index = AUPT / PBT * Effectiveness * Quality ratio

Unit of measure %

Range Min: 0%

Max: 100%

Trend The higher, the better

Context

Timing On-demand, periodically

Audience Supervisor, management

Production methodology Discrete, batch, continuous

Effect model diagram See Figure A.7

Notes The net equipment effectiveness (NEE) index is comparable with the OEE index but it

includes the setup time within a modified availability KPI that is calculated as the ratio

between the actual unit processing time and the planned busy time.

The NEE index indicates losses by work unit delays, cycle time losses and losses by

rework.

Table 9 — Availability

KPI description

Content

Name Availability

ID

Description Availability is a ratio that shows the relation between the actual production time (APT)

and the planned busy time (PBT) for a work unit.

Scope Work unit, product, time period, product

Formula Availability = APT / PBT

Unit of measure %

Range Min: 0%

Max: 100%

Trend The higher, the better

Context

Timing On-demand, periodically

Audience Supervisor, management

Production methodology Discrete, batch, continuous

Effect model diagram See Figure A.8

Notes Availability indicates how strongly the capacity of a work unit for the production is used

in relation to the available capacity.

The term availability is also called degree of utilization or capacity factor.

Table 10 — Effectiveness

KPI description

Content

Name Effectiveness

ID

Description Effectiveness represents the relationship between the planned target cycle and the

actual cycle expressed as the planned runtime per item (PRI) multiplied by the produced

quantity (PQ) divided by the actual production time (APT).

Scope Work unit, work centre, area, product, time period, product

Formula Effectiveness = PRI * PQ / APT

Unit of measure %

Range Min: 0%

Max: 100%

Trend The higher, the better

Context

Timing On-demand, periodically, real-time

Audience Operator, supervisor, management

Production methodology Discrete, batch, continuous

Effect model diagram See Figure A.9

Notes The effectiveness can be calculated in short periods and indicates how effective a work

unit will be during the production time.

The specification uses the element planned runtime per item (PRI) also known as cycle

time. This specifies how long it takes to produce a fixed quantity of produced material.

Batch and continuous production methodologies typically express the expected output

per time as the quantity that can be produced in a specified period of time (e.g. HL per

hour). This value is reciprocal to the PRI element and can be converted into a PRI by

specifying a fixed quantity of the produced material.

16 © ISO 2014 – All rights reserved

Table 11 — Quality ratio

KPI description

Content

Name Quality ratio

ID

Description The quality ratio is the relationship between the good quantity (GQ) and the produced

quantity (PQ).

Scope Work unit, work centre, area, product, time period, product, defect types

Formula Quality ratio = GQ / PQ

Unit of measure %

Range Min: 0%

Max: 100%

Trend The higher, the better

Context

Timing On-demand, periodically, real-time

Audience Operator, supervisor, management

Production methodology Discrete, batch, continuous

Effect model diagram See Figure A.10

Notes This indicator is usable as real-time indicator for the operator level.

Table 12 — Setup ratio

KPI description

Content

Name Setup ratio

ID

Description The setup ratio is the ratio of actual unit setup time (AUST) to actual unit processing

time (AUPT). It specifies the percentage time used for setup compared to the actual time

used for processing.

Scope Work unit, product, production order

Formula Setup ratio = AUST / AUPT

Unit of measure %

Range Min: 0%

Max: 100%

Trend The lower, the better

Context

Timing On-demand, periodically

Audience Supervisor, management

Production methodology Discrete, batch, continuous

Effect model diagram See Figure A.11

Notes The setup ratio indicates the relative loss of value adding opportunity for the work unit.

The higher the value of the indicator is the higher is the setup time in relation to the

processing time of a production order which adds value to the product. For an enterprise

a high setup ratio means a consumption of (potential) value added time.

The setup ratio has to be considered especially when the order lot size is decreasing

which may happen in a response to the demand for a flexible supply chain.

Table 13 — Technical efficiency

KPI description

Content

Name Technical efficiency

ID

Description The technical efficiency of a work unit is the relationship between the actual production

time (APT) and the sum of the actual production time (APT) and the actual unit delay

time (ADET) which includes the delays and malfunction-caused interruptions.

Scope Work unit, product, and production order

Formula Technical efficiency = APT / (APT + ADET)

Unit of measure %

Range Min: 0%

Max: 100%

Trend The higher, the better

Context

Timing On-demand, periodically, real-time

Audience Operator, supervisor, management

Production methodology Discrete, batch, continuous

Effect model diagram See Figure A.12