ISO/IEC 15896:1999

(Main)Information technology — Data interchange on 12,7 mm 208-track magnetic tape cartridges — DLT 5 format

Information technology — Data interchange on 12,7 mm 208-track magnetic tape cartridges — DLT 5 format

This International Standard specifies the physical and magnetic characteristics of a 12,7 mm wide, 208-track magnetic tape cartridge, to enable physical interchangeability of such cartridges between drives. It also specifies the quality of the recorded signals, a format - called Digital Linear Tape 5 (DLT 5) - and a recording method, thereby allowing data interchange between drives. Together with a labelling standard, for instance International Standard ISO 1001 for Magnetic Tape Labelling, it allows full data interchange by means of such magnetic tape cartridges.

Technologies de l'information — Échange de données sur cartouches de bande magnétique de 12,7 mm, 208 pistes — Format DLT 5

General Information

Standards Content (Sample)

INTERNATIONAL ISO/IEC

STANDARD 15896

First edition

1999-12-15

Information technology — Data

interchange on 12,7 mm 208-track

magnetic tape cartridges — DLT 5 format

Technologies de l'information — Échange de données sur cartouches

de bande magnétique de 12,7 mm, 208 pistes — Format DLT 5

Reference number

©

ISO/IEC 1999

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO/IEC 1999

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 � CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 734 10 79

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO/IEC 1999 – All rights reserved

ISO/IEC ISO/IEC 15896:1999 (E)

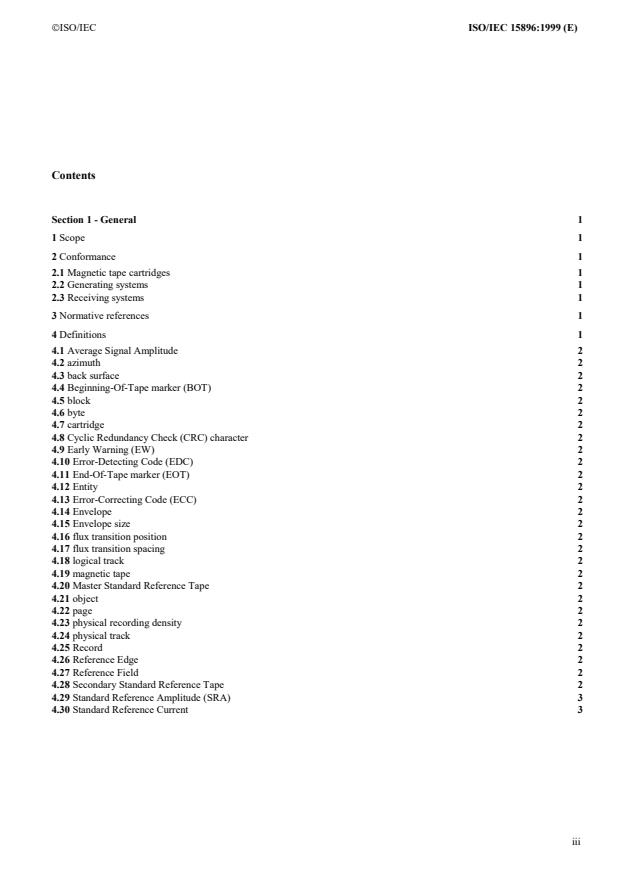

Contents

Section 1 - General 1

1 Scope 1

2 Conformance 1

2.1 Magnetic tape cartridges 1

2.2 Generating systems 1

2.3 Receiving systems 1

3 Normative references 1

4 Definitions 1

4.1 Average Signal Amplitude 2

4.2 azimuth 2

4.3 back surface 2

4.4 Beginning-Of-Tape marker (BOT) 2

4.5 block 2

4.6 byte 2

4.7 cartridge 2

4.8 Cyclic Redundancy Check (CRC) character 2

4.9 Early Warning (EW) 2

4.10 Error-Detecting Code (EDC) 2

4.11 End-Of-Tape marker (EOT) 2

4.12 Entity 2

4.13 Error-Correcting Code (ECC) 2

4.14 Envelope 2

4.15 Envelope size 2

4.16 flux transition position 2

4.17 flux transition spacing 2

4.18 logical track 2

4.19 magnetic tape 2

4.20 Master Standard Reference Tape 2

4.21 object 2

4.22 page 2

4.23 physical recording density 2

4.24 physical track 2

4.25 Record 2

4.26 Reference Edge 2

4.27 Reference Field 2

4.28 Secondary Standard Reference Tape 2

4.29 Standard Reference Amplitude (SRA) 3

4.30 Standard Reference Current 3

iii

4.31 Test Recording Current 3

4.32 Typical Field 3

5 Conventions and notations 3

5.1 Representation of numbers 3

5.2 Dimensions 3

5.3 Names 3

5.4 Acronyms 3

6 Environment and safety 3

6.1 Cartridge and tape testing environment 3

6.2 Cartridge operating environment 4

6.3 Cartridge storage environment 4

6.4 Safety 4

6.4.1 Safeness 4

6.4.2 Flammability 4

6.5 Transportation 4

Section 2 - Requirements for the unrecorded tape 5

7 Mechanical and electrical requirements 5

7.1 Material 5

7.2 Tape length 5

7.3 Width 5

7.4 Total thickness 5

7.5 Discontinuity 5

7.6 Longitudinal curvature 5

7.6.1 Requirement 5

7.6.2 Procedure 5

7.7 Out-of-Plane distortions 5

7.8 Cupping 5

7.9 Roughness of the coating surfaces 5

7.9.1 Roughness of the back coating surface 5

7.9.2 Roughness of the magnetic coating surface 5

7.10 Coating adhesion 6

7.11 Layer-to-layer adhesion 6

7.11.1 Requirements 6

7.11.2 Procedure 6

7.12 Modulus of elasticity 7

7.12.1 Requirement 7

7.12.2 Procedure 7

7.13 Flexural rigidity 7

7.13.1 Requirement 7

7.13.2 Procedure 7

7.14 Tensile yield force 8

7.14.1 Procedure 8

7.15 Electrical resistance 8

7.15.1 Requirement 8

7.15.2 Procedure 8

7.16 Inhibitor tape 9

7.17 Abrasivity 9

7.17.1 Requirement 9

7.17.2 Procedure 9

7.18 Light transmittance of the tape and the leader 9

7.19 Coefficient of dynamic friction 9

7.19.1 Requirements 9

7.19.2 Procedure for the measurement of the friction between the magnetic surface and the back surface 10

iv

ISO/IEC ISO/IEC 15896:1999 (E)

7.19.3 Procedure for the measurement of the friction between the magnetic surface or the back surface and calcium

titanate ceramic 10

8 Magnetic recording characteristics 10

8.1 Typical Field 11

8.2 Signal amplitude 11

8.3 Resolution 11

8.4 Overwrite 11

8.4.1 Requirement 11

8.5 Peak shift 11

8.5.1 Requirement 11

8.5.2 Procedure 11

9 Tape quality 12

9.1 Missing pulses 12

9.1.1 Requirement 12

9.2 Missing pulse zone 12

9.2.1 Requirement 12

9.3 Tape durability 12

Section 3 - Mechanical specifications of the tape cartridge 12

10 General 12

10.1 Bottom side and right side 13

10.2 Back side and left side 14

10.3 Tape reel 14

10.4 Tape leader 15

10.5 Front side 16

10.6 Operation of the cartridge 16

10.7 Tape winding 17

10.8 Moment of inertia 17

10.9 Material 18

Section 4 - Requirements for an interchanged tape 27

11 Method of recording 27

11.1 Physical recording density 27

11.2 Channel bit cell length 27

11.2.1 Average Channel bit cell length 27

11.2.2 Long-term average Channel bit cell length 27

11.2.3 Short-term average Channel bit cell length 27

11.3 Flux transition spacing 27

11.4 Read signal amplitude 27

11.5 Azimuth 28

11.6 Channel skew 28

12 Tape format 28

12.1 Reference Edge 28

12.2 Direction of recording 28

12.3 Tape layout 28

12.4 Calibration and Directory Area 28

12.4.1 Scratch Area 29

12.4.2 Guard Area G1 29

12.4.3 Calibration Tracks Area 29

12.4.4 Guard Area G2 30

12.4.5 Directory Area 30

12.4.6 Guard Area G3 30

12.5 Data Area 30

12.5.1 Physical tracks 31

v

12.5.2 Logical tracks 33

13 Data format 34

13.1 Data Bytes 34

13.2 Data Blocks 34

13.3 Types of Blocks 34

13.4 Entities 34

13.5 Envelopes 34

13.6 Block format 34

13.6.1 Preamble 35

13.6.2 Sync 35

13.6.3 Data Field 35

13.6.4 EDC 36

13.6.5 Control Field 1 (CF1) 37

13.6.6 Control Field 2 (CF2) 38

13.6.7 CRC 39

13.6.8 Postamble 39

14 Use of blocks 39

14.1 Data Blocks 39

14.2 Filler Blocks 39

14.3 End of Track Blocks (EOTR) 40

14.4 End of Data Blocks (EOD) 40

14.5 ECC Blocks 40

15 Format of Entities 40

16 Format of Envelopes 40

17 Error handling 40

Annexes

A - Measurement of light transmittance 41

B - Generation of the Data Block CRCs 44

C - ECC generation 45

D - Generation of page CRCs 48

E - Format of MAP entries 49

F - Format of Control Field 1 50

G - Format of Control Field 2 51

H - Recommendations for transportation 52

J - Inhibitor tape 53

K - Recommendations on tape durability 54

L - Handling guidelines 55

vi

ISO/IEC ISO/IEC 15896:1999 (E)

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical Commission)

form the specialized system for worldwide standardization. National bodies that are members of ISO or IEC

participate in the development of International Standards through technical committees established by the

respective organization to deal with particular fields of technical activity. ISO and IEC technical committees

collaborate in fields of mutual interest. Other international organizations, governmental and non-governmental, in

liaison with ISO and IEC, also take part in the work.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

In the field of information technology, ISO and IEC have established a joint technical committee, ISO/IEC JTC 1.

Draft International Standards adopted by the joint technical committee are circulated to national bodies for voting.

Publication as an International Standard requires approval by at least 75% of the national bodies castinga vote.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject of

patent rights. ISO and IEC shall not be held responsible for identifying any or all such patent rights.

International Standard ISO/IEC 15896 was prepared by ECMA — European association for standardizing

information and communication systems (as ECMA-259) and was adopted, under a special “fast-track procedure”,

by Joint Technical Committee ISO/IEC JTC 1, Information technology, in parallel with its approval by national

bodies of ISO and IEC.

Annexes A toG form a normative part of this International Standard. Annexes H toL are for information only.

vii

Introduction

This International Standard constitutes a further development of the magnetic tape cartridge specified in International Standard

ISO/IEC 15307. The number of tracks is raised to 208. As a result a native capacity of 35 Gbytes or, with compressed data, of

typically at least 70 Gbytes is achieved.

viii

4.1 Average Signal Amplitude: The average peak-to-peak value of the output signal from the read head at the physical

recording density of 2 254 ftpmm measured over a minimum length of track of 25,4 mm, exclusive of missing pulses.

4.2 azimuth: The angular deviation, in degrees of arc, of the mean flux transition line of the recording made on a track

from the line normal to the Reference Edge.

4.3 back surface:

The surface of the tape opposite the magnetic coating which is used to record data.

4.4 Beginning-Of-Tape marker (BOT): A hole punched on the centreline of the tape towards the end nearest to the

leader.

4.5 block: A set of contiguous bytes recorded on a physical track and considered as a unit.

4.6 byte: An ordered set of bits acted upon as a unit.

Note - In this International Standard, all bytes are 8-bit bytes.

4.7 cartridge: A case containing a single supply reel of 12,7 mm wide magnetic tape with a leader attached at the outer

end.

4.8 Cyclic Redundancy Check (CRC) character: A 64-bit character, generated by a mathematical computation,

used for error detection.

4.9 Early Warning (EW): A signal generated by the drive indicating the approaching end of the recording area.

4.10 Error-Detecting Code (EDC): A mathematical computation yielding check bytes used for error detection.

4.11 End-Of-Tape marker (EOT): A hole punched on the centreline of the tape towards the end farthest from the

leader.

4.12 Entity: A group of twenty blocks treated as a logical unit and recorded on a logical track, except Filler Blocks ,if any.

4.13 Error-Correcting Code (ECC): A mathematical computation yielding check bytes used for the correction of

errors detected by the CRC and the EDC.

4.14 Envelope: A group of Entities.

4.15 Envelope size:

The number of Entities in an Envelope.

4.16 flux transition position: The point which exhibits the maximum free-space flux density normal to the tape surface.

4.17 flux transition spacing: The distance on the magnetic tape between successive flux transitions.

4.18 logical track: A group of four physical tracks that are written or read simultaneously.

4.19 magnetic tape: A tape that accepts and retains magnetic signals intended for input, output, and storage purposes on

computers and associated equipment.

4.20 Master Standard Reference Tape: A tape selected as the standard for Reference Field, signal amplitude,

resolution, peak shift, and overwrite characteristics.

Note - The Master Standard Reference Tape has been established by the Quantum Corporation.

4.21 object: A Record or a page of type Tape Mark.

4.22 page:

A logical division of a block.

4.23 physical recording density: The number of recorded flux transitions per unit length of track, expressed in flux

transitions per millimetre (ftpmm).

4.24 physical track: A longitudinal area on the tape along which a series of magnetic signals can be recorded.

4.25 Record: A collection of User Bytes, the number of which is determined by the host.

4.26 Reference Edge:

The bottom edge of the tape when viewing the magnetic coating of the tape with the BOT to the

left and the EOT to the right of the observer.

4.27 Reference Field: The Typical Field of the Master Standard Reference Tape.

4.28 Secondary Standard Reference Tape: A tape the characteristics of which are known and stated in relation to

those of the Master Standard Reference Tape.

Note - Secondary Standard Reference Tapes can be ordered under Reference "SSRT/DLT4"from Quantum Corporation, 333 South Street, Shrewsbury, Mass.

01545-4195, USA. It is intended that these be used for calibrating tertiary reference tapes for routine calibration.

In principle, these Secondary Standard Reference Tapes will be available for a period of 10 years from the publication of the first version of this International

Standard. However, this period may be changed to take into account the demand for such Secondary Standard Reference Tapes.

ISO/IEC ISO/IEC 15896:1999 (E)

4.29 Standard Reference Amplitude (SRA): The Average Signal Amplitude from the Master Standard Reference

Tape when it is recorded with the Test Recording Current at 2 254 ftpmm.

4.30 Standard Reference Current: The current that produces the Reference Field.

4.31 Test Recording Current: The current that is 1,1 times the Standard Reference Current.

4.32 Typical Field: In the plot of the Average Signal Amplitude against the recording field at the physical recording

density of 2 254 ftpmm, the minimum field that causes an Average Signal Amplitude equal to 95 % of the maximum

Average Signal Amplitude.

5 Conventions and notations

5.1 Representation of numbers

The following conventions and notations apply in this International Standard, unless otherwise stated.

− A measured value is rounded off to the least significant digit of the corresponding specified value. It implies that a specified

value of 1,26 with a positive tolerance +0,01, and a negative tolerance -0,02 allows a range of measured values from 1,235

to 1,275.

− In each block and in each field the bytes shall be arranged with Byte 1, the least significant, first. Within each byte the bits

shall be arranged with Bit 1, the least significant, first and Bit 8, the most significant bit, last. This order applies to the data,

and to the input and output of the error-detecting and error-correcting codes, and to the cyclic redundancy characters.

− Letters and digits in parentheses represent numbers in hexadecimal notation.

− The setting of bits is denoted by ZERO or ONE.

− Numbers in binary notation and bit patterns are re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.