ISO 22156:2021

(Main)Bamboo structures — Bamboo culms — Structural design

Bamboo structures — Bamboo culms — Structural design

This document applies to the design of bamboo structures whose primary load bearing structure is made of round bamboo or shear panel systems in which the framing members are made from round bamboo. Except as indicated in Clause 12, this document applies to one- and two-storey residential, small commercial or institutional and light industrial buildings not exceeding 7 m in height. This document is concerned only with requirements for mechanical resistance, serviceability and durability of bamboo structures. This document permits an allowable load-bearing capacity design (ACD) and/or allowable stress design (ASD) approach for the design of bamboo structures. Allowable load-bearing capacity and allowable stress approaches may be used in combination in the same structure. This document additionally recognises design approaches based on partial safety factor design (PSFD) and/or load and resistance factor design (LRFD) methods (5.11.1), previous established experience (5.11.2), or documented ‘design by testing’ approaches (5.11.3). Other requirements, such as those concerning thermal or sound insulation, are not considered. Bamboo structures may require consideration of additional requirements beyond the scope of this document. Execution is covered to the extent that it impacts the quality of construction materials and products required to comply with the design requirements contained herein. This document provides a number of modification factors, designated Ci. These are empirically derived factors, based on best available engineering judgement, that are believed to be universally applicable to bamboo materials that are appropriate for building construction. Parameters affecting bamboo material performance are many and are addressed explicitly through the use of experimentally determined characteristic values of strength and stiffness. Annex A provides a summary of the bases upon which the provisions of this document were developed. This document does not apply to — structures made of engineered bamboo products such as glue-laminated bamboo, cross-laminated bamboo, oriented strand, or densified bamboo materials, — bamboo-reinforced materials where bamboo is not the primary load-bearing constituent. This includes bamboo-reinforced concrete, masonry and soil, or, — scaffold structures constructed with bamboo.

Structures en bambou — Tiges de bambou — Conception des structures

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 22156

Second edition

2021-06

Bamboo structures — Bamboo culms

— Structural design

Structures en bambou — Tiges de bambou — Conception des

structures

Reference number

©

ISO 2021

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

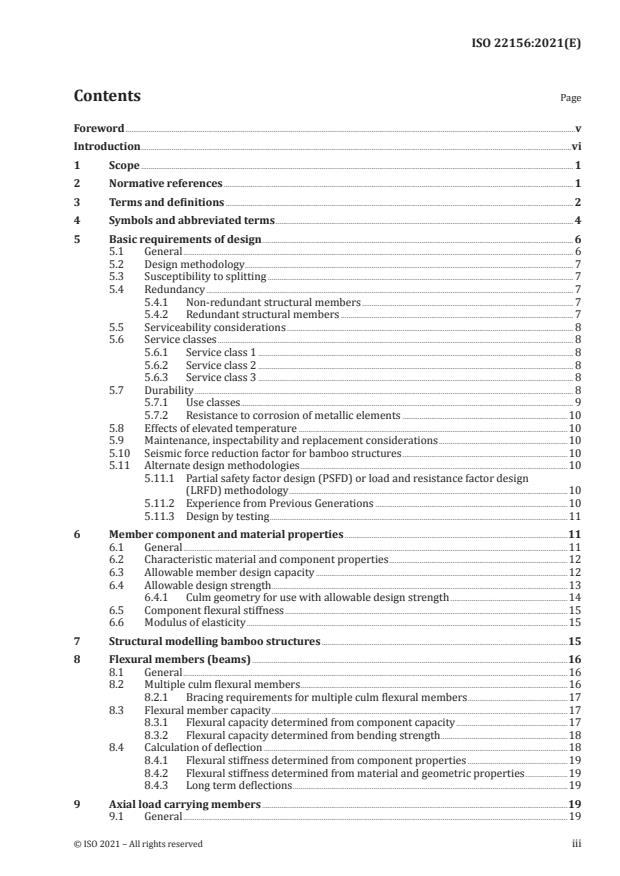

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Symbols and abbreviated terms . 4

5 Basic requirements of design . 6

5.1 General . 6

5.2 Design methodology. 7

5.3 Susceptibility to splitting . 7

5.4 Redundancy . 7

5.4.1 Non-redundant structural members . 7

5.4.2 Redundant structural members . 7

5.5 Serviceability considerations . 8

5.6 Service classes . 8

5.6.1 Service class 1 . 8

5.6.2 Service class 2 . 8

5.6.3 Service class 3 . 8

5.7 Durability . 8

5.7.1 Use classes . 9

5.7.2 Resistance to corrosion of metallic elements .10

5.8 Effects of elevated temperature .10

5.9 Maintenance, inspectability and replacement considerations .10

5.10 Seismic force reduction factor for bamboo structures .10

5.11 Alternate design methodologies .10

5.11.1 Partial safety factor design (PSFD) or load and resistance factor design

(LRFD) methodology .10

5.11.2 Experience from Previous Generations .10

5.11.3 Design by testing .11

6 Member component and material properties .11

6.1 General .11

6.2 Characteristic material and component properties .12

6.3 Allowable member design capacity .12

6.4 Allowable design strength .13

6.4.1 Culm geometry for use with allowable design strength .14

6.5 Component flexural stiffness .15

6.6 Modulus of elasticity .15

7 Structural modelling bamboo structures .15

8 Flexural members (beams) .16

8.1 General .16

8.2 Multiple culm flexural members .16

8.2.1 Bracing requirements for multiple culm flexural members .17

8.3 Flexural member capacity .17

8.3.1 Flexural capacity determined from component capacity .17

8.3.2 Flexural capacity determined from bending strength .18

8.4 Calculation of deflection .18

8.4.1 Flexural stiffness determined from component properties .19

8.4.2 Flexural stiffness determined from material and geometric properties .19

8.4.3 Long term deflections .19

9 Axial load carrying members .19

9.1 General .19

9.2 Compression member effective length.20

9.2.1 Lateral restraint of compression members .20

9.3 Compression capacity .21

9.3.1 Compression capacity from geometric and material properties .21

9.3.2 Crushing capacity .21

9.3.3 Buckling capacity . .22

9.4 Tension capacity .22

9.4.1 Tension capacity from component capacity .22

9.4.2 Tension capacity from geometric and material properties .23

9.5 Combined axial and flexural loads .23

10 Joints and splices .23

10.1 General .23

10.2 Design properties by complete joint testing .24

10.3 Design properties by component capacities .24

10.4 Allowable joint design capacity .24

10.5 Joint stiffness .25

10.6 Ductility of joints .25

10.7 Robustness against culm splitting .25

10.7.1 Radial clamping to resist splitting .26

10.8 Splices joints .26

10.9 Requirements for non-bamboo components of joints .26

10.9.1 Metallic components of joints .26

10.9.2 Joints utilising flowable infill material (grouted joints) .26

10.9.3 Lashing .27

10.9.4 Mechanical and proprietary joint systems .27

10.10 End bearing capacity of bamboo culms .27

10.11 Circumferential bearing capacity of bamboo culms .27

10.12 Joints having through culm wall dowels .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.