ISO 13579-11:2017

(Main)Industrial furnaces and associated processing equipment - Method of measuring energy balance and calculating energy efficiency - Part 11: Evaluation of various kinds of efficiency

Industrial furnaces and associated processing equipment - Method of measuring energy balance and calculating energy efficiency - Part 11: Evaluation of various kinds of efficiency

ISO 13579-11:2017 specifies classifications and designations in the methodology of energy efficiency evaluation of industrial furnaces and associated processing equipment (TPE), including energy efficiency in terms of exergy as well as enthalpy. ISO 13579-11:2017does not apply to the following types of TPE: - blast furnaces, basic oxygen furnaces, coke ovens; - furnaces that generate gases to be used as fuel (including by-product gases); - special atmosphere gas generators; - industrial furnaces that are designed for chemical plants or petroleum plants; - installations where heating or combustion is performed in an open space; - installations that combust solid fuel; - waste incinerators.

Fours industriels et équipements associés — Méthode de mesure du bilan énergétique et de calcul de l'efficacité — Partie 11: Évaluation de différents types d'efficacité

General Information

- Status

- Published

- Publication Date

- 09-Aug-2017

- Technical Committee

- ISO/TC 244 - Industrial furnaces and associated processing equipment

- Drafting Committee

- ISO/TC 244 - Industrial furnaces and associated processing equipment

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 14-Dec-2022

- Completion Date

- 13-Dec-2025

Overview - What ISO 13579-11:2017 covers

ISO 13579-11:2017 provides a standardized methodology for evaluating the energy performance of industrial furnaces and associated processing equipment (TPE). The standard defines classifications and designations used when measuring energy balance and calculating energy efficiency both in terms of enthalpy (heat) and exergy (available energy). It clarifies boundaries for evaluation, describes components of energy and exergy flows, and sets out measurement and reporting practices to support consistent, comparable assessments.

Scope exclusions (not covered): blast furnaces, basic oxygen furnaces, coke ovens; furnaces producing fuel gases; special atmosphere gas generators; furnaces in chemical or petroleum plants; open-space combustion installations; solid-fuel combustion units; and waste incinerators.

Key technical topics and requirements

- Energy balance and boundary definition - classification of evaluation areas and how to treat energy (enthalpy) flows into and out of the system.

- Components of energy accounting - energy input to the heating chamber, process energy, exhaust sensible heat, recovered heat, thermal losses, electrical/electroheating losses, auxiliary equipment, utilities generation and recycled energy.

- Enthalpy-based efficiencies - general formulas and typical efficiency definitions (overall efficiency, heat efficiency, combustion efficiency, recovery ratios).

- Exergy-based efficiencies - classification and calculation of exergy flows (fuel exergy, electrical exergy, exergy of reactions, exhaust exergy, recovery exergy and exergy losses) and exergy-efficiency metrics for fair comparison across processes.

- Designation system and reporting - structured naming/labeling for items and operations, measurement procedures, and format for the evaluation report.

- Practical guidance and tools - informative annexes with worked examples (energy efficiency evaluation, enthalpy vs. exergy comparisons, and procedures for estimating energy savings).

Practical applications - who uses this standard

ISO 13579-11:2017 is used by:

- Plant and furnace designers to benchmark thermal system performance.

- Energy managers and sustainability teams to quantify savings and prioritize upgrades.

- Process engineers and maintenance teams to identify recovery opportunities (heat recovery, reduced losses).

- Energy auditors, certification bodies, and consultants assessing compliance, CDM projects or energy-efficiency investments.

- Equipment manufacturers and system integrators seeking consistent efficiency metrics for product claims.

Benefits include consistent energy accounting, improved decision-making for retrofits, fair comparisons between furnace types and operating modes, and better alignment with energy-saving programs.

Related standards

- ISO 13579 series (Parts 1–4 and others) - broader methods for furnace energy evaluation.

- ISO 13574:2015 - vocabulary for industrial furnaces and associated processing equipment.

Keywords: ISO 13579-11:2017, industrial furnaces, energy efficiency, energy balance, enthalpy, exergy, heat recovery, TPE evaluation, measurement and reporting.

Frequently Asked Questions

ISO 13579-11:2017 is a standard published by the International Organization for Standardization (ISO). Its full title is "Industrial furnaces and associated processing equipment - Method of measuring energy balance and calculating energy efficiency - Part 11: Evaluation of various kinds of efficiency". This standard covers: ISO 13579-11:2017 specifies classifications and designations in the methodology of energy efficiency evaluation of industrial furnaces and associated processing equipment (TPE), including energy efficiency in terms of exergy as well as enthalpy. ISO 13579-11:2017does not apply to the following types of TPE: - blast furnaces, basic oxygen furnaces, coke ovens; - furnaces that generate gases to be used as fuel (including by-product gases); - special atmosphere gas generators; - industrial furnaces that are designed for chemical plants or petroleum plants; - installations where heating or combustion is performed in an open space; - installations that combust solid fuel; - waste incinerators.

ISO 13579-11:2017 specifies classifications and designations in the methodology of energy efficiency evaluation of industrial furnaces and associated processing equipment (TPE), including energy efficiency in terms of exergy as well as enthalpy. ISO 13579-11:2017does not apply to the following types of TPE: - blast furnaces, basic oxygen furnaces, coke ovens; - furnaces that generate gases to be used as fuel (including by-product gases); - special atmosphere gas generators; - industrial furnaces that are designed for chemical plants or petroleum plants; - installations where heating or combustion is performed in an open space; - installations that combust solid fuel; - waste incinerators.

ISO 13579-11:2017 is classified under the following ICS (International Classification for Standards) categories: 25.180.01 - Industrial furnaces in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 13579-11:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13579-11

First edition

2017-08

Industrial furnaces and associated

processing equipment — Method

of measuring energy balance and

calculating energy efficiency —

Part 11:

Evaluation of various kinds of

efficiency

Fours industriels et équipements associés — Méthode de mesure du

bilan énergétique et de calcul de l’efficacité —

Partie 11: Évaluation de différents types d’efficacité

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

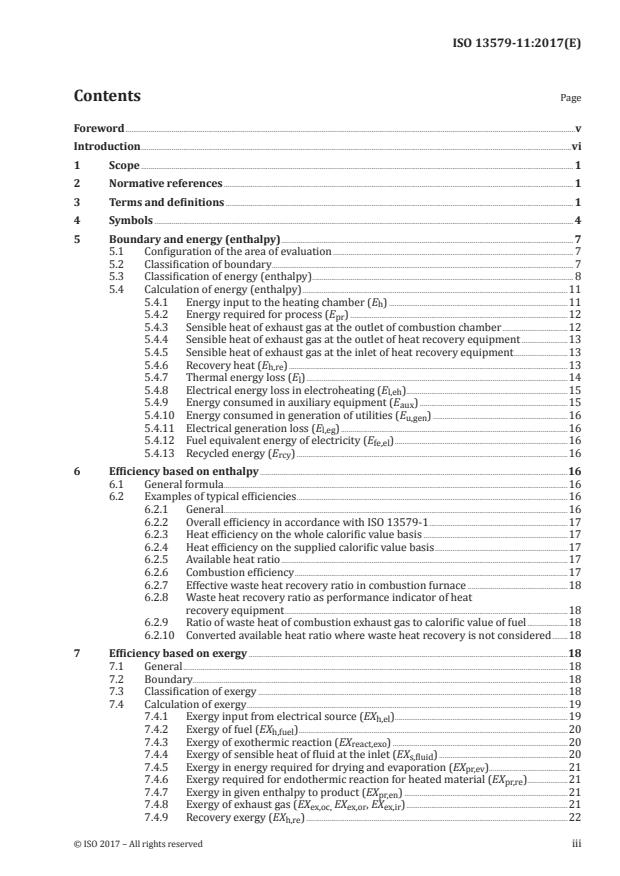

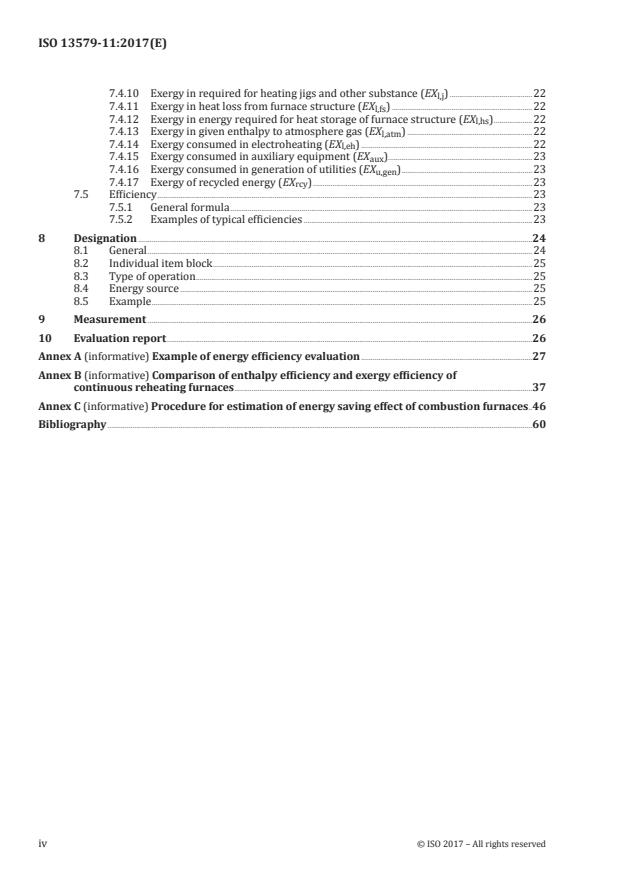

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols . 4

5 Boundary and energy (enthalpy) . 7

5.1 Configuration of the area of evaluation . 7

5.2 Classification of boundary . . 7

5.3 Classification of energy (enthalpy) . 8

5.4 Calculation of energy (enthalpy) .11

5.4.1 Energy input to the heating chamber (E ) .11

h

5.4.2 Energy required for process (E ) .12

pr

5.4.3 Sensible heat of exhaust gas at the outlet of combustion chamber .12

5.4.4 Sensible heat of exhaust gas at the outlet of heat recovery equipment .13

5.4.5 Sensible heat of exhaust gas at the inlet of heat recovery equipment .13

5.4.6 Recovery heat (E ) .13

h,re

5.4.7 Thermal energy loss (E ) .14

l

5.4.8 Electrical energy loss in electroheating (E ).15

l,eh

5.4.9 Energy consumed in auxiliary equipment (E ) .15

aux

5.4.10 Energy consumed in generation of utilities (E ) .16

u,gen

5.4.11 Electrical generation loss (E ) .16

l,eg

5.4.12 Fuel equivalent energy of electricity (E ) .16

fe,el

5.4.13 Recycled energy (E ) .16

rcy

6 Efficiency based on enthalpy .16

6.1 General formula .16

6.2 Examples of typical efficiencies .16

6.2.1 General.16

6.2.2 Overall efficiency in accordance with ISO 13579‑1 .17

6.2.3 Heat efficiency on the whole calorific value basis .17

6.2.4 Heat efficiency on the supplied calorific value basis .17

6.2.5 Available heat ratio .17

6.2.6 Combustion efficiency .17

6.2.7 Effective waste heat recovery ratio in combustion furnace .18

6.2.8 Waste heat recovery ratio as performance indicator of heat

recovery equipment .18

6.2.9 Ratio of waste heat of combustion exhaust gas to calorific value of fuel .18

6.2.10 Converted available heat ratio where waste heat recovery is not considered .18

7 Efficiency based on exergy .18

7.1 General .18

7.2 Boundary .18

7.3 Classification of exergy .18

7.4 Calculation of exergy .19

7.4.1 Exergy input from electrical source (EX ) .19

h,el

7.4.2 Exergy of fuel (EX ) .20

h,fuel

7.4.3 Exergy of exothermic reaction (EX ) .20

react,exo

7.4.4 Exergy of sensible heat of fluid at the inlet (EX ) .20

s,fluid

7.4.5 Exergy in energy required for drying and evaporation (EX ).21

pr,ev

7.4.6 Exergy required for endothermic reaction for heated material (EX ) .21

pr,re

7.4.7 Exergy in given enthalpy to product (EX ) .21

pr,en

7.4.8 Exergy of exhaust gas (EX EX , EX ) .21

ex,oc, ex,or ex,ir

7.4.9 Recovery exergy (EX ) .22

h,re

7.4.10 Exergy in required for heating jigs and other substance (EX ) .22

l,j

7.4.11 Exergy in heat loss from furnace structure (EX ) .22

l,fs

7.4.12 Exergy in energy required for heat storage of furnace structure (EX ) .22

l,hs

7.4.13 Exergy in given enthalpy to atmosphere gas (EX ) .22

l,atm

7.4.14 Exergy consumed in electroheating (EX ) .22

l,eh

7.4.15 Exergy consumed in auxiliary equipment (EX ) .23

aux

7.4.16 Exergy consumed in generation of utilities (EX ) .23

u,gen

7.4.17 Exergy of recycled energy (EX ) .23

rcy

7.5 Efficiency .23

7.5.1 General formula .23

7.5.2 Examples of typical efficiencies .23

8 Designation .24

8.1 General .24

8.2 Individual item block .25

8.3 Type of operation .25

8.4 Energy source .25

8.5 Example .25

9 Measurement .26

10 Evaluation report .26

Annex A (informative) Example of energy efficiency evaluation .27

Annex B (informative) Comparison of enthalpy efficiency and exergy efficiency of

continuous reheating furnaces .37

Annex C (informative) Procedure for estimation of energy saving effect of combustion furnaces .46

Bibliography .60

iv © ISO 2017 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO’s adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see the following

URL: w w w . i s o .org/ iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 244, Industrial furnaces and associated

processing equipment.

A list of all parts in the ISO 13579 series can be found on the ISO website.

Introduction

The Kyoto Protocol of the UN Framework Convention on Climate Change defines a system for emission

reduction called the Clean Development Mechanism (CDM). In order for the industrial furnace

manufacturers industry to address global warming based on the Kyoto Protocol, it is necessary to have

fair guidelines to make use of CDM.

ISO 13579‑1 to ISO 13579‑4 focus on evaluating the overall efficiency of industrial furnaces and

associated processing equipment (TPE) system, including electrical energy consumption as fuel

equivalent energy, to help the industry facilitate implementation of CDM.

However, these documents do not define and specify efficiencies of each specific component of TPE

(e.g. heat recovery equipment, heating chambers, etc.), which are directly related to and available for

energy‑saving measures. With this in mind, this document has been developed to specify and provide

the following information:

— definitions of the various kinds of efficiency of TPE using designation systems and by defining

energy balance boundaries within the TPE based on its elements;

NOTE The definition for TPE efficiency varies according to region.

— evaluation formulae of energy reduction factors, which are available for actual energy conservation

based on the energy balance measurements.

In addition to these evaluations in terms of enthalpy, this document also deals with energy efficiency

based on exergy, i.e. efficiency based on availability of fuel energy, for the following reasons.

— The whole amount of “energy” in the “closed” terrestrial system is preserved due to the conservation

law of energy while “exergy” inherently decreases. The term “energy” related to energy crisis or

energy issue is “exergy”. Therefore, it may be said that controlling the degrees of a decrease in

exergy (or dissipation of available energy) is the essence of the energy crisis. As such, exergy is one

of the indexes to evaluate the energy efficiency of TPE.

— It enables a fair comparison among heating furnaces with different heating conditions or heated

materials as a result of a common thermodynamic viewpoint.

— Improvement in exergy efficiency leads to essential efficiency‑enhancing measures in energy usage.

vi © ISO 2017 – All rights reserved

INTERNATIONAL STANDARD ISO 13579-11:2017(E)

Industrial furnaces and associated processing

equipment — Method of measuring energy balance and

calculating energy efficiency —

Part 11:

Evaluation of various kinds of efficiency

1 Scope

This document specifies classifications and designations in the methodology of energy efficiency

evaluation of industrial furnaces and associated processing equipment (TPE), including energy

efficiency in terms of exergy as well as enthalpy.

This document does not apply to the following types of TPE:

— blast furnaces, basic oxygen furnaces, coke ovens;

— furnaces that generate gases to be used as fuel (including by‑product gases);

— special atmosphere gas generators;

— industrial furnaces that are designed for chemical plants or petroleum plants;

— installations where heating or combustion is performed in an open space;

— installations that combust solid fuel;

— waste incinerators.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 13574:2015, Industrial furnaces and associated processing equipment — Vocabulary

ISO 13579-1:2013, Industrial furnaces and associated processing equipment — Method of measuring

energy balance and calculating efficiency — Part 1: General methodology

ISO 13579-2:2013, Industrial furnaces and associated processing equipment — Method of measuring

energy balance and calculating efficiency — Part 2: Reheating furnaces for steel

ISO 13579-3:2013, Industrial furnaces and associated processing equipment — Method of measuring

energy balance and calculating efficiency — Part 3: Batch-type aluminium melting furnaces

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 13574, ISO 13579‑1 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at www .iso .org/ obp

— IEC Electropedia: available at www .electropedia .org

3.1 General terms

3.1.1

boundary

enclosed section that is defined for an energy balance evaluation of object(s)

Note 1 to entry: The energy efficiency evaluations are possible once a boundary is set.

3.1.2

product

item processed in a TPE, including auxiliary material

EXAMPLE Auxiliary material loaded in scrap melting process in addition to the main material (i.e. scraps).

Note 1 to entry: Product does not include by‑products formed in the thermo‑processing, e.g. formation of oxidized

substance such as iron-scale and aluminium oxide.

Note 2 to entry: Product does not include the accessories, e.g. jigs or fixtures that are heated simultaneously with

product.

[SOURCE: ISO 13574:2015, 2.134, modified]

3.1.3

energy balance analysis

grouping of energy values into either input energy or output energy, by measuring and calculating

provided energy, including by exothermic reaction and outflowing energy, which also includes by

endothermic reaction to/from the boundary

Note 1 to entry: The total energy input and the total energy output inherently balance.

3.1.4

energy efficiency

efficiency defined as specific energy output (3.1.5) divided by specific energy input (3.1.6)

Note 1 to entry: Energy efficiencies are expressed in percentages. Specific energy output and specific energy

input are defined in this document.

3.1.5

specific energy output

specific energy defined in this document as effective energy output from the boundary for calculation

of an index of efficiency of TPE

EXAMPLE Enthalpy accumulated in product through a TPE process.

3.1.6

specific energy input

amount of supplied energy defined in this document as energy brought to the boundary for calculation

of an index of efficiency

3.1.7

available heat

calorific value which is required in a heating chamber of a furnace under specified operating or

equipment conditions

Note 1 to entry: Available heat is a form of specific energy output defined in 6.2.5.

Note 2 to entry: “Available energy” in exergy terms has a different concept.

Note 3 to entry: See A.2.5.

2 © ISO 2017 – All rights reserved

3.1.8

available heat ratio

index of efficiency defined as available heat (3.1.7) divided by the calorific value of fuel

Note 1 to entry: This term is one of the significant indexes of a combustion furnace.

3.1.9

fuel equivalent energy of electricity

amount of primary energy which is equivalent to the calorific value of fuel input consumed in electrical

generation

3.1.10

fuel equivalent energy conversion

conversion of electrical energy consumption to fuel equivalent energy of electricity (3.1.9)

Note 1 to entry: The factor for calculation, which is generally available, is not considered loss between the power

receiving station to the TPE’s power receiving terminal.

Note 2 to entry: The unit kJ/kWh is generally used.

Note 3 to entry: The value for fuel equivalent energy conversion varies depending on governments or regions.

Note 4 to entry: It should be indicated when the conversion is conducted.

3.1.11

energy performance indicator

amount of energy that is consumed per specific production unit of utilities or per specific output of

auxiliary equipment

3.1.12

exergy

maximum work which can be extracted under the ambient temperature of a place, which is generally

defined as

EX = ΔH – T ΔS

where

EX is the exergy (maximum work);

ΔH is the change in enthalpy;

T is the ambient temperature, in Kelvin;

ΔS is the change in entropy.

Note 1 to entry: There are chemical exergy, pressure exergy, mixing exergy and thermal exergy in a combustion

system. But pressure exergy and mixing exergy are negligibly small.

3.1.13

exergy loss

difference between exergy that flows in to and flows out from the targeted boundary (3.1.1)

3.1.14

furnace structure

sum of furnace walls, cooling water equipment, furnace opening, etc.

3.2 Balance table

NOTE See Table A.3 and Table A.7 as examples.

3.2.1

energy balance table

table on which breakdowns of energy input and energy output are listed

3.2.2

efficiency evaluation table

reorganized table from an energy balance table (3.2.1) to categorize energy groups such as specific

energy input (3.1.6) or specific energy output (3.1.5) to calculate an efficiency index while maintaining

the energy balance

4 Symbols

4.1 Symbols for energy/exergy

Symbol Definition

E energy consumed in auxiliary equipment per tonne of product

aux

E available heat per tonne of product

available

E available heat of the baseline, in MJ/t

available I

E available heat after energy saving measure, in MJ/t

available II

E sensible heat of exhaust gas per tonne of product

ex

E sensible heat of exhaust gas from fuel at the inlet of heat recovery equipment per tonne of product

ex,ir

E sensible heat of exhaust gas from fuel at the outlet of combustion chamber per tonne of product

ex,oc

E sensible heat of exhaust gas from fuel at the outlet of heat recovery equipment per tonne of product

ex,or

E sensible heat of exhaust gas from raw materials at the inlet of heat recovery equipment per tonne

exrm,ir

of product

E sensible heat of exhaust gas from raw materials at the outlet of combustion chamber per tonne

exrm,oc

of product

E sensible heat of exhaust gas from raw materials at the outlet of heat recovery equipment per tonne

exrm,or

of product

E fuel equivalent energy of electricity per tonne of product

fe,el

E energy input to the heating chamber per tonne of product

h

E heat energy by electroheating per tonne of product

h,el

E calorific value of fuel per tonne of product

h,fuel

E energy consumption (calorific value of fuel) of the baseline, in MJ/t

h,fuel I

E estimated energy consumption after energy saving measure, in MJ/t

h,fuel II

E recovery heat per tonne of product

h,re

E recovery heat from sensible heat of exhaust gas per tonne of product

h,reex

E recovery heat from sensible heat of product per tonne of product

h,repr

E thermal energy loss per tonne of product

l

E energy loss by atmosphere gas per tonne of product

l,atm

E electrical generation loss per tonne of product

l,eg

E electrical energy loss in electroheating per tonne of product

l,eh

E energy loss by exhaust gas from raw material

l,exrm

E energy loss from furnace structure per tonne of product

l,fs

E energy required for heating jigs and other substance per tonne of product

l,j

E energy required for heat storage of furnace structure per tonne of product

l,hs

E other energy loss per tonne of product

l,other

E energy loss by uncombusted content per tonne of product

l,uc

E enthalpy of product at the time of loading into the boundary per tonne

p1

4 © ISO 2017 – All rights reserved

Symbol Definition

E enthalpy of product at the time of extraction from the boundary per tonne

p2

E energy required for process per tonne of product

pr

E enthalpy change in product per tonne

pr,en

E energy required for drying and evaporation per tonne of product

pr,ev

E energy required for endothermic reaction for heated material (product)

pr,re

E recycled energy per tonne of product

rcy

E sensible heat of combustion air or other oxidant which is not preheated per tonne of product

s,air

E sensible heat of atomization agent per tonne of product

s,atomize

E sensible heat of fuel per tonne of product

s,fuel

E sensible heat of fluid at the inlet per tonne of product

s,fluid

E sensible heat of infiltration air per tonne of product

s,infilt

E specific energy input per tonne of product

sp-in

E specific energy output per tonne of product

sp-out

E heat of exothermic reaction per tonne of product

react,exo

E energy consumed in generation of utilities per tonne of product

u,gen

EX exergy consumed in auxiliary equipment per tonne of product

aux

EX available exergy per tonne of product

available

EX exergy of exhaust gas at the inlet of heat recovery equipment per tonne of product

ex,ir

EX exergy of exhaust gas at the outlet of combustion chamber per tonne of product

ex,oc

EX exergy of exhaust gas at the outlet of heat recovery equipment per tonne of product

ex,or

EX exergy input from electrical source per tonne of product

h,el

EX exergy of fuel per tonne of product

h,fuel

EX recovery exergy per tonne of product

h,re

EX exergy in given enthalpy to atmosphere gas per tonne of product

l,atm

EX exergy loss in electroheating per tonne of product

l,eh

EX exergy in heat loss from furnace structure per tonne of product

l,fs

EX exergy in energy required for heat storage of furnace structure per tonne of product

l,hs

EX exergy in required for heating jigs and other substance per tonne of product

l,j

EX exergy in other energy loss per tonne of product

l,other

EX exergy in given enthalpy to product per tonne

pr,en

EX exergy in energy required for drying and evaporation per tonne of product

pr,ev

EX exergy required for endothermic reaction for heated material

pr,re

EX exergy of exothermic reaction per tonne of product

react,exo

EX specific exergy input per tonne of product

sp-in

EX specific exergy output per tonne of product

sp-out

EX exergy of sensible heat of fluid at the inlet

s,fluid

EX exergy of recycled energy per tonne of product

rcy

EX exergy consumed in generation of utilities per tonne of product

u,gen

EX recovery of exergy as steam

v

4.2 Other symbols

Symbol Definition

A theoretical volume of combustion air per unit fuel consumption, in m (n)

c weight fraction of carbon contained in liquid fuel

C mean specific heat of air, in kJ/(kg·K)

a

Symbol Definition

C mean specific heat of exhaust gas, in kJ/(kg·K)

g

c mean specific heat of exhaust gas, in kJ/(kg·K)

pm,ex

c mean specific heat of fluid (fuel or combustion air), in kJ/(kg·K)

pm,fl

c mean specific heat of combustion gas, in kJ/(kg·K)

pm,c

c mean specific heat of liquid water, in kJ/(kg·K)

pm,w

c mean specific heat of preheated item (e.g. product, fluid), in kJ/(kg·K)

pm,ph

c mean specific heat of water vapour, in kJ/(kg·K)

pm,v

0 3

e chemical exergy per unit quantity of fuel, in kJ/m (n)

c

G theoretical volume of exhaust gas per unit fuel consumption, in m (n)

h weight fraction of hydrogen contained in liquid fuel

H sensible heat of exhaust gas at the outlet of combustion chamber per unit fuel consumption, in MJ/

ex

m (n) or MJ/kg

H gross calorific value of fuel per unit quantity of fuel, in kJ/kg or kJ/m (n)

h

H net calorific value of fuel per unit quantity of fuel, in J/kg or kJ/m (n)

l

H sensible heat of preheated combustion air per unit fuel consumption, in MJ/ m (n) or MJ/kg

r

H recovered enthalpy by generation of steam per tonne of product, in kJ/t

v

ΔH change in enthalpy per tonne of product, in kJ/t

L latent heat of vaporization of water, in kJ/kg

m air ratio

m air ratio of baseline

I

m air ratio after energy saving measure

II

m mass of exhaust gas per tonne of product, in kg/t

ex

m mass of fluid (fuel or combustion air) per tonne of product, in kg/t

fl

m summation of mass of fluid provided per tonne of product and mass of theoretical combustion air

fl,c

corresponding to the amount of fuel, in kg/t

m mass of preheated item (e.g. product, fluid) per tonne of product, in kg/t

ph

m mass of steam as atomization agent required per tonne of product, in kg/t

v1

m mass of steam recycled from exhausted energy required per tonne of product, in kg/t

v2

O weight fraction of oxygen contained in liquid fuel

R gas constant

s weight fraction of sulfur contained in liquid fuel

ΔS change in entropy per tonne of product, in kJ/K/t

t temperature of preheated combustion air, in K

a

t temperature of exhaust gas at the outlet of combustion chamber, in K

gout

T adiabatic flame temperature, in K

ad

T ambient temperature, in K

T temperature of exhaust gas at defined location in K

ex

T temperature inside furnace, in K

fc

T temperature of fluid (fuel or combustion air), in K

fl

T temperature of preheated item (e.g. product, fluid), in K

ph

T temperature of water vapour as atomization agent, in K

v1

T temperature of water vapour recycled from exhausted energy, in K

v2

V fuel consumption per tonne of product, in m (n)/t or kg/t

f

x volume fraction of fuel component i

i

α energy saving ratio (%)

es

6 © ISO 2017 – All rights reserved

Symbol Definition

η specific energy efficiency of enthalpy

η overall efficiency in accordance with ISO 13579‑1

η heat efficiency on the whole calorific value basis

η heat efficiency on the supplied calorific value basis

η combusted fuel ratio

η ratio of waste heat recovery in combustion furnace

η* available heat ratio

η* available heat ratio of the baseline

Ι

η* estimated available heat ratio after energy saving measure

ΙΙ

η* converted available heat ratio where waste heat recovery is not considered

η electrical generation efficiency

e

η ratio of waste heat of combustion exhaust gas to calorific value of fuel

exh

η specific exergy efficiency

ex

η * ratio of exergy in available heat to the input exergy

ex

η overall exergy efficiency in accordance with ISO 13579‑1 using Gibbs free energy of fuel

ex1

η heat exergy efficiency on the whole calorific value basis using Gibbs free energy of fuel

ex2

η ratio of waste heat of combustion exhaust gas to calorific value of fuel

exh

η effective ratio of waste heat recovery in combustion furnace

R

η effective ratio of waste heat recovery in combustion furnace of the baseline

R I

η effective waste heat recovery ratio in combustion furnace after energy saving measure

R II

η ratio of enthalpy which is recovered in the generated steam to the whole enthalpy provided to the

rcy,steam

steam generator

5 Boundary and energy (enthalpy)

5.1 Configuration of the area of evaluation

The general configuration of the area of evaluation under the scope of this document consists of the

following:

— heating chamber (key 1);

— burner (key 2);

— heat recovery equipment (preheating equipment using exhaust gas) (key 3);

— electrical generation (key 4);

— electrical auxiliary equipment (e.g. fan motor, compressor) (key 5);

— generation of utilities (e.g. endothermic gas generator) (key 6);

— electrical heating (key 7).

NOTE For keys, see Figure 1.

5.2 Classification of boundary

The codes for each classification of boundaries drawn for the evaluation of energy efficiency of TPE

specified in Table 1 apply.

Table 1 — Classification of boundary

Symbol Classification of boundary Description

EB1 Overall process of TPE As specified in ISO 13579‑1.

a

Electric generator can be excluded when fuel equivalent

energy conversion is not considered.

See 6.2.2 for typical efficiency applicable to this boundary.

EB2a Heating chamber with heat Recovery heat shall be considered as internal circulating heat.

recovery equipment

b c

Auxiliary equipment and utility generator shall be excluded.

EB2b Heating chamber and cooling

See 6.2.4, 6.2.5 and 6.2.7 for typical efficiency applicable to

zone with heat recovery

this boundary.

equipment

EB3a Heating chamber Heat recovery equipment shall be outside the boundary.

EB3b Heating chamber and cooling b c

Auxiliary equipment and utility generator shall be excluded.

zone

See 6.2.3, 6.2.5 and 6.2.7 for typical efficiency applicable to

this boundary.

EB4 Heat recovery equipment

Boundary shall be set adjacent to the heat recovery equip-

EB4a Combustion air preheating

d

ment .

equipment

EB4f Fuel preheating equipment

See 6.2.6 for typical efficiency applicable to this boundary.

EB4p Product preheating equipment

b e

EB5 Auxiliary equipment Auxiliary equipment shall explicitly be specified .

c f

EB6 Utility generator Utility generator shall explicitly be specified .

NOTE Keys mentioned are found in Figure 1.

a

See key 4.

b

See key 5.

c

See key 6.

d

See key 3.

e

For example, blower.

f

For example, O generator.

5.3 Classification of energy (enthalpy)

The classification of energy types and symbols specified in Table 2 apply.

The basic unit of energy specified in Table 2 is 1 kJ per tonne (i.e. 1 000 kg) of product, unless otherwise

specified.

For calculation of each classification of energy, see 5.4.

Table 2 — Classification of energy

Classification Symbol Description

Energy input to the heating chamber E 5.4.1

h

Energy input from electrical source

E 5.4.1.2

h,el

Calorific value of fuel E 5.4.1.3

h,fuel

Heat of exothermic reaction E 5.4.1.4

react,exo

Sensible heat of fluid at the inlet E 5.4.1.5

s,fluid

NOTE See Figure 1.

8 © ISO 2017 – All rights reserved

Table 2 (continued)

Classification Symbol Description

Energy required for process E 5.4.2

pr

Energy required for drying and

evaporation

E 5.4.2.2

pr,ev

Energy required for endothermic E 5.4.2.3

pr,re

reaction for heated material

(product)

Enthalpy change in product E 5.4.2.4

pr,en

Sensible heat of exhaust gas at the Sensible heat of exhaust gas from E 5.4.3.1

ex,oc

outlet of combustion chamber fuel

Sensible heat of exhaust gas from E 5.4.3.2

exrm,oc

raw materials

Sensible heat of exhaust gas at the Sensible heat of exhaust gas from E 5.4.4.1

ex,or

outlet of heat recovery equipment fuel

Sensible heat of exhaust gas from E 5.4.4.2

exrm,or

raw materials

Sensible heat of exhaust gas at the Sensible heat of exhaust gas from E 5.4.5.1

ex,ir

inlet of heat recovery equipment fuel

Sensible heat of exhaust gas from E 5.4.5.2

exrm,ir

raw materials

Recovery heat Recovery heat E 5.4.6

h,re

Recovery heat from sensible heat of E 5.4.6.2

h,reex

exhaust gas

Recovery heat from sensible heat E 5.4.6.3

h,repr

of product

Thermal energy loss E 5.4.7

l

Energy loss by uncombusted content

E 5.4.7.2

l,uc

Energy required for heating jigs and

E 5.4.7.3

l,j

other substance

Energy loss from furnace structure E 5.4.7.4

l,fs

Energy required for heat storage of

E 5.4.7.5

l,hs

furnace structure

Energy loss by atmosphere gas E 5.4.7.6

l,atm

Energy loss by exhaust gas from

E 5.4.7.7

l,exrm

raw material

Other energy loss E 5.4.7.8

l,other

Electrical energy loss in electroheat- Electrical energy loss in E 5.4.8

l,eh

ing electroheating

Additional energy consumption Energy consumed in auxiliary E 5.4.9

aux

equipment

Energy consumed in generation E 5.4.10

u,gen

of utilities

Electrical generation loss Electrical generation loss E 5.4.11

l,eg

Fuel equivalent energy of electricity Fuel equivalent energy of electricity E 5.4.12

fe,el

Energy to be used outside TPE Recycled energy E 5.4.13

rcy

NOTE See Figure 1.

Key

a

1 heating chamber/combustion chamber Energy required for process (E ) and thermal energy losses (E ).

pr l

b

2 burner E (air) + E .

s,fluid h,re

c

3 heat recovery equipment E + E (fuel).

h,fuel s,fluid

d

4 electrical generation E + E (fuel) + E .

h,fuel s,fluid h,re

e

5 electrical auxiliary equipment E or E .

ex,or ex,ir

6 generation of utilities

7 electrical heating

8 boundary of efficiency evaluation

9 energy flow

Figure 1 — Example configuration of TPE and boundaries of efficiency evaluation

10 © ISO 2017 – All rights reserved

5.4 Calculation of energy (enthalpy)

5.4.1 Energy input to the heating chamber (E )

h

5.4.1.1 General

Calculate energy input to the heating chamber per tonne of product using Formula (1):

EE= (1)

hh∑ i

where E is the individual applicable energy input to the heating chamber per tonne of product.

h i

Calculate each applicable energy, as appropriate, in accordance with the following:

— energy input from electrical source (E ), as defined in 5.4.1.2;

h,el

— calorific value of fuel (E ), as defined in 5.4.1.3;

h,fuel

— heat of exothermic reaction (E ), as defined in 5.4.1.4;

react,exo

— sensible heat of fluid at the inlet (E ), as defined in 5.4.1.5.

s,fluid

5.4.1.2 Energy input from electrical source (E )

h,el

This classification is for energy supplied for electroheating as energy source. This includes resistance

heating, induction heating, arc heating, dielectric heating and microwave heating. Fuel equivalent

energy conversion is necessary depending on the condition of energy evaluation (e.g. in the case of EB1).

5.4.1.3 Calorific value of fuel (E )

h,fuel

This classification is for energy that is generated by combustion reaction of gaseous and/or liquid fuel.

Sensible heat of fuel or air is not included.

Calculate calorific value of fuel according to ISO 13579‑1:2013, 9.2.1, if applicable.

5.4.1.4 Heat of exothermic reaction (E )

react,exo

This classification is for energy that is generated by exothermic reactions such as oxidation reaction of

product and calorific value by reactions such as exothermic reaction of auxiliary material or oxidation

reaction of the electrode. Heat of exothermic reaction may be excluded from calculation of energy

required for product depending on the condition of energy evaluation.

Calculate heat generated by the formation of scale of steel product according to ISO 13579‑2:2013, 9.2.5,

if applicable.

Calculate heat generated by the formation of aluminium oxide according to ISO 13579‑3:2013, 9.2.7, if

applicable.

5.4.1.5 Sensible heat of fluid at the inlet (E )

s, fluid

This classification is for summation of sensible heat of fluid and/or air at the inlet of heating chamber

excluding recovery heat. This classification of energy includes sensible heat of infiltration air and

atomization agent. When water/moisture is provided, its sensible heat and latent heat of vaporizing (as

negative value) shall be taken into account. This item may be omitted when the value is small enough to

neglect comparing to the entire energy input.

Calculate sensible heat input from fluid per tonne of product using Formula (2):

EE= (2)

∑

s, fluid s, fluid i

where E is the individual applicable sensible heat of fluid per tonne of product, e.g. sensible heat

s, fluid i

of fuel, sensible heat of combustion air, sensible heat of atomization agent, sensible heat of infiltration

air, etc.

Calculate sensible heat of each fluid in accordance with the following references, where applicable:

— ISO 13579-1:2013, 9.2.4.1 for fuel (E );

s,fuel

— ISO 13579-1:2013, 9.2.5 for combustion air (E );

s,air

— ISO 13579-1:2013, 9.2.6 for atomization agent (E );

s,atomize

— ISO 13579‑1:2013, 9.2.8 for infiltration air (E ).

s,infilt

5.4.2 Energy required for process (E )

pr

5.4.2.1 General

This classification is for the net energy required for the intended process itself. Energy required for the

process is the summation of any combination of the following three classifications of energy:

— energy required for drying and evaporation (E ), as defined in 5.4.2.2;

pr,ev

— energy required for endothermic reaction for heated material (E ), as defined in 5.4.2.3;

pr,re

— enthalpy change in product (E ), as defined in 5.4.2.4.

pr,en

5.4.2.2 Energy required for drying and evaporation (E )

pr,ev

This classification is for energy required for drying and evaporation in the thermo processing.

5.4.2.3 Energy required for endothermic reaction for heated material (product) (E )

pr,re

This classification is for energy required for chemical reaction for heated material in the thermo

processing. The energy is absorbed energy by chemical reactions, e.g. CaCO + E → CaO + CO .

3 pr,re 2

5.4.2.4 Enthalpy change in product (E )

pr,en

This classification is for the amount of change in the enthalpy of a product in the boundary.

Calculat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...