IEC TR 62271-310:2008

(Main)High-voltage switchgear and controlgear - Part 310: Electrical endurance testing for circuit-breakers above a rated voltage of 52 kV

High-voltage switchgear and controlgear - Part 310: Electrical endurance testing for circuit-breakers above a rated voltage of 52 kV

This technical report IEC/TR 62271-310:2008 is applicable to class E2 circuit-breakers above a rated voltage of 52 kV and above intended for use on overhead lines. The test programmes are based on accumulated electrical stresses due to current interruption during a period of 25 years, which was chosen as representative for a maintenance-free interval. This second edition of IEC/TR 62271-310 cancels and replaces the first edition published in 2004. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

- reduction of number tests in the wear stage;

- new definition of acceptance test for demonstration of end-of-life thermal interruption capability.

Appareillage à haute tension - Partie 310: Essais d'endurance électrique pour disjoncteurs de tension assignée supérieure à 52 kV

Ce rapport technique CEI/TR 62271 310:2008 s'applique à la classe E2 de disjoncteurs de tension assignée supérieure à 52 kV, prévus pour la manoeuvre de lignes aériennes. Les programmes d'essais sont basés sur des contraintes électriques cumulées dues à des interruptions de courant, durant une période de 25 ans, qui a été choisie comme représentative d'un intervalle de temps sans maintenance. Cette deuxième édition du CEI/TR 62271-310 annule et remplace la première édition parue en 2004. Elle constitue une révision technique. La présente édition inclut les modifications techniques significatives par rapport à l'édition précédente:

- réduction du nombre d'essais durant la période d'essais d'usure;

- nouvelle définition de l'essai d'acceptation pour démonstration de la capacité de coupure thermique de fin de vie.

General Information

- Status

- Published

- Publication Date

- 26-Mar-2008

- Technical Committee

- SC 17A - Switching devices

- Drafting Committee

- MT 40 - TC 17/SC 17A/MT 40

- Current Stage

- PPUB - Publication issued

- Start Date

- 30-Jun-2008

- Completion Date

- 27-Mar-2008

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC TR 62271-310:2008 is a technical report published by the International Electrotechnical Commission (IEC) that defines the electrical endurance testing procedures for high-voltage circuit-breakers rated above 52 kV. Specifically targeting class E2 circuit-breakers used on overhead lines, this standard outlines test programs designed to simulate 25 years of accumulated electrical stress without maintenance. As a revision of the 2004 edition, the 2008 update introduces a reduction in wear stage tests and a new acceptance test definition to demonstrate end-of-life thermal interruption capability.

This standard plays a crucial role in ensuring reliability, maintenance-free operation, and safe performance of high-voltage switchgear in power transmission networks, aligning with evolving industry demands for extended service life and evolving electrical grid challenges.

Key Topics

Scope & Applicability

IEC TR 62271-310 applies to class E2 circuit-breakers rated above 52 kV intended for overhead line applications. It focuses on extended electrical endurance, representing typical stresses accumulated over 25 years with no maintenance on interrupting parts.Extended Electrical Endurance (Class E2)

Circuit-breakers designed to meet class E2 criteria offer maintenance-free operation of the main interrupting components through their expected service life, supporting cost reduction and reliability improvements in high-voltage systems.Test Program Structure

The endurance testing is divided into two main stages:- Wear Stage: Simulates the cumulative electrical stress via equivalent breaking operations under controlled conditions. This stage minimizes intermediate maintenance interventions.

- Acceptance Tests: Conducted post-wear stage to verify that circuit-breakers maintain their interrupting capability and thermal interruption performance after extended electrical stress.

Testing Procedures

Tests are conducted typically as single-phase operations, with three-phase testing allowed when combined with type tests. The test includes interruption of specified currents and verification against time-resolved voltages (TRVs).Updates in 2008 Edition

- Reduction in the number of wear stage tests to optimize testing efficiency without compromising reliability assessments.

- Introduction of an acceptance test to demonstrate end-of-life thermal interruption capability, ensuring thermal stresses can be safely managed throughout circuit-breaker life.

Applications

IEC TR 62271-310 is indispensable for manufacturers, testing laboratories, and utilities that develop, validate, or procure high-voltage circuit-breakers designed for long-term reliability and maintenance-free operation in overhead transmission lines. Applications include:

- Power transmission companies requiring adherence to international endurance standards for circuit-breakers operating above 52 kV.

- Equipment manufacturers designing class E2 circuit-breakers aiming to demonstrate extended electrical endurance and thermal performance.

- Testing facilities conducting type tests and extended endurance qualification tests per IEC requirements.

- Utility asset managers aiming to optimize maintenance intervals and total cost of ownership through validated maintenance-free switchgear.

This standard supports critical infrastructure protection against electrical faults while adapting to shifts in electricity markets, deregulation, and increasing short-circuit stresses in modern power systems.

Related Standards

IEC 62271-100: High-voltage switchgear and controlgear – Part 100: Alternating-current circuit-breakers

Defines general requirements and classifications (including class E2) for high-voltage circuit-breakers and serves as a normative reference for IEC TR 62271-310.IEC 62271 Series: High-voltage switchgear and controlgear

A comprehensive suite of standards covering a wide range of testing, design, and safety requirements for high-voltage switchgear and controlgear equipment.CIGRE Reports on Circuit-Breaker Performance

Technical reports and data collections on electrical endurance and reliability of circuit-breakers, which informed the foundation and updates of IEC TR 62271-310.

By adhering to IEC TR 62271-310, stakeholders in the electrical power industry ensure that high-voltage circuit-breakers exhibit proven long-term performance and safety, supporting secure and efficient energy transmission worldwide.

IEC TR 62271-310:2008 - High-voltage switchgear and controlgear - Part 310: Electrical endurance testing for circuit-breakers above a rated voltage of 52 kV

IEC TR 62271-310:2008 - High-voltage switchgear and controlgear - Part 310: Electrical endurance testing for circuit-breakers above a rated voltage of 52 kV Released:3/27/2008 Isbn:2831896681

Frequently Asked Questions

IEC TR 62271-310:2008 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "High-voltage switchgear and controlgear - Part 310: Electrical endurance testing for circuit-breakers above a rated voltage of 52 kV". This standard covers: This technical report IEC/TR 62271-310:2008 is applicable to class E2 circuit-breakers above a rated voltage of 52 kV and above intended for use on overhead lines. The test programmes are based on accumulated electrical stresses due to current interruption during a period of 25 years, which was chosen as representative for a maintenance-free interval. This second edition of IEC/TR 62271-310 cancels and replaces the first edition published in 2004. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - reduction of number tests in the wear stage; - new definition of acceptance test for demonstration of end-of-life thermal interruption capability.

This technical report IEC/TR 62271-310:2008 is applicable to class E2 circuit-breakers above a rated voltage of 52 kV and above intended for use on overhead lines. The test programmes are based on accumulated electrical stresses due to current interruption during a period of 25 years, which was chosen as representative for a maintenance-free interval. This second edition of IEC/TR 62271-310 cancels and replaces the first edition published in 2004. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - reduction of number tests in the wear stage; - new definition of acceptance test for demonstration of end-of-life thermal interruption capability.

IEC TR 62271-310:2008 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 29.130.10 - High voltage switchgear and controlgear. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 62271-310:2008 has the following relationships with other standards: It is inter standard links to IEC TR 62271-310:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TR 62271-310:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/TR 62271-310

Edition 2.0 2008-03

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

High-voltage switchgear and controlgear –

Part 310: Electrical endurance testing for circuit-breakers above a rated voltage

of 52 kV

Appareillage à haute tension –

Partie 310: Essais d’endurance électrique pour disjoncteurs de tension assignée

supérieure à 52 kV

IEC/TR 62271-310:2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC/TR 62271-310

Edition 2.0 2008-03

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

High-voltage switchgear and controlgear –

Part 310: Electrical endurance testing for circuit-breakers above a rated voltage

of 52 kV

Appareillage à haute tension –

Partie 310: Essais d’endurance électrique pour disjoncteurs de tension

assignée supérieure à 52 kV

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

S

CODE PRIX

ICS 29.130.10 ISBN 2-8318-9668-1

– 2 – TR 62271-310 © IEC:2008

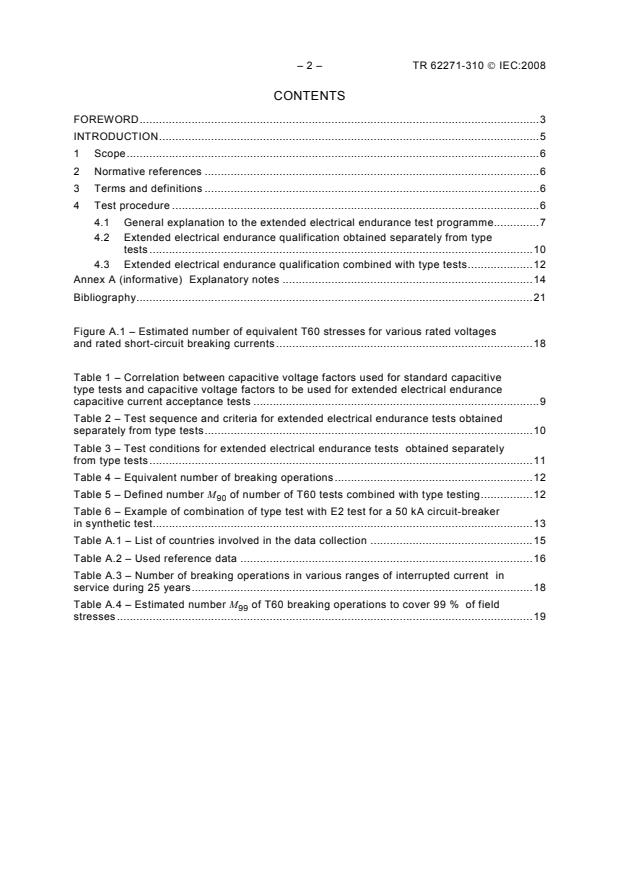

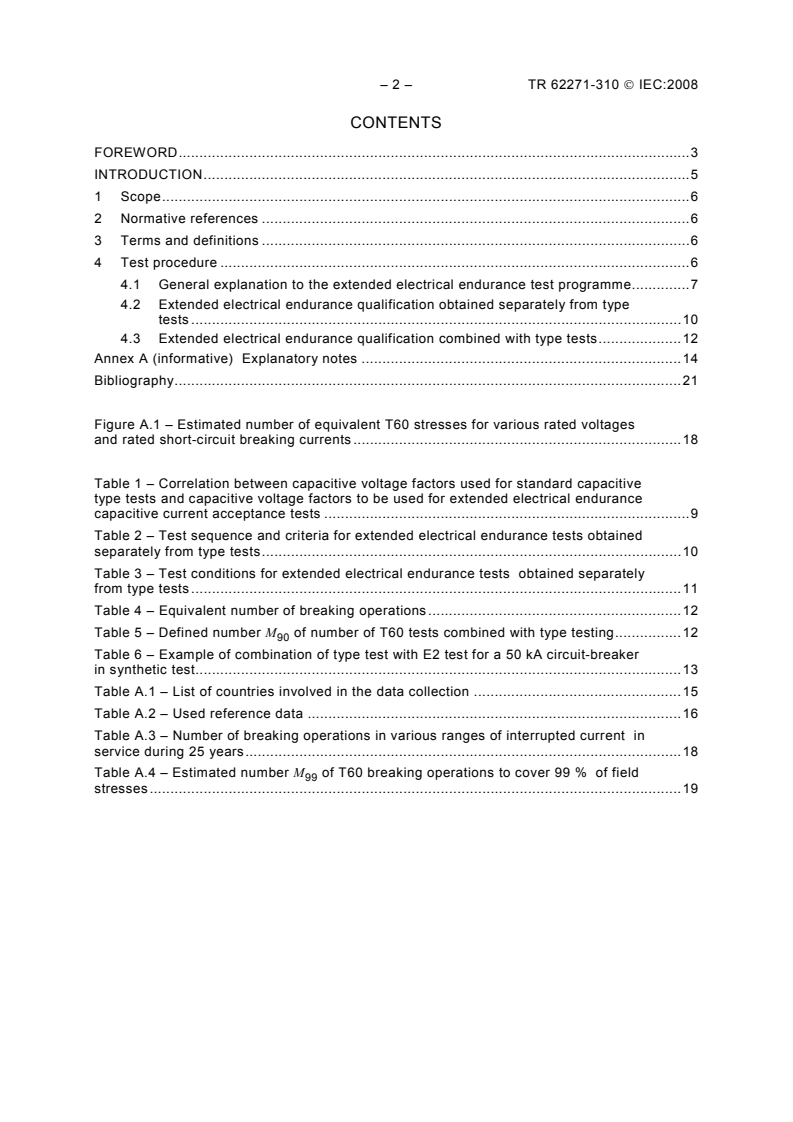

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.6

2 Normative references .6

3 Terms and definitions .6

4 Test procedure .6

4.1 General explanation to the extended electrical endurance test programme.7

4.2 Extended electrical endurance qualification obtained separately from type

tests .10

4.3 Extended electrical endurance qualification combined with type tests.12

Annex A (informative) Explanatory notes .14

Bibliography.21

Figure A.1 – Estimated number of equivalent T60 stresses for various rated voltages

and rated short-circuit breaking currents .18

Table 1 – Correlation between capacitive voltage factors used for standard capacitive

type tests and capacitive voltage factors to be used for extended electrical endurance

capacitive current acceptance tests .9

Table 2 – Test sequence and criteria for extended electrical endurance tests obtained

separately from type tests.10

Table 3 – Test conditions for extended electrical endurance tests obtained separately

from type tests.11

Table 4 – Equivalent number of breaking operations.12

Table 5 – Defined number M of number of T60 tests combined with type testing.12

Table 6 – Example of combination of type test with E2 test for a 50 kA circuit-breaker

in synthetic test.13

Table A.1 – List of countries involved in the data collection .15

Table A.2 – Used reference data .16

Table A.3 – Number of breaking operations in various ranges of interrupted current in

service during 25 years.18

Table A.4 – Estimated number M of T60 breaking operations to cover 99 % of field

stresses.19

TR 62271-310 © IEC:2008 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HIGH-VOLTAGE SWITCHGEAR AND CONTROLGEAR –

Part 310: Electrical endurance testing for circuit-breakers

above a rated voltage of 52 kV

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC/TR 62271-310, which is a technical report, has been prepared by subcommittee 17A:

High-voltage switchgear and controlgear, of IEC technical committee 17: Switchgear and

controlgear.

This second edition of IEC/TR 62271-310 cancels and replaces the first edition published in

2004. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– reduction of number tests in the wear stage;

– 4 – TR 62271-310 © IEC:2008

– new definition of acceptance test for demonstration of end-of-life thermal interruption

capability.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

17A/803/DTR 17A/814/RVC

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 62271 series, under the general title High-voltage switchgear and

controlgear can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

TR 62271-310 © IEC:2008 – 5 –

INTRODUCTION

Based on experience with existing high-voltage circuit-breakers in service and with system

protection and maintenance policies, the majority of circuit-breaker applications are covered

by class E1 as defined in 3.4.112 of IEC 62271-100. No additional tests for extended

electrical endurance are required.

However, extended electrical endurance (class E2) as defined in 3.4.113 of IEC 62271-100

should be considered for the following reasons:

• Field experience collected so far by CIGRE is limited only for circuit-breaker designs

available before 1994 (see for example reference [1], [2], [3] and Annex A.3). For this

reason, the data collected by CIGRE so far can hardly be extrapolated to new designs.

Therefore, for new types of circuit-breakers, extended electrical endurance can only be

fully proven by laboratory tests.

• New maintenance practices tend towards “maintenance-free” circuit-breakers. The

reduction of maintenance costs is a major issue for most users today.

• Deregulation of the electricity market may increase the electrical stresses applied to the

circuit-breakers, within their proven capability. Installation of generation capacity by

independent power producers will increase short-circuit levels in certain areas and

consequently change stresses on breakers. This may result in higher stresses applied to

circuit-breakers compared to past practice when the short-circuit rating of the circuit-

breaker was in large excess of the actual fault currents.

• There is a need to standardize a single extended electrical endurance programme to avoid

the specification of different programmes from different users.

• Many manufacturers provide information about electrical endurance capabilities of circuit-

breakers during the purchasing process. There is a need to standardize the way this

information is given to the users.

It must be noted that circuit-breakers having extended electrical endurance capability, are not

intended for use in situations in which electrical arcing stress (which is a combination of high

probability of fault occurrence and high fault current level) is beyond the 90-percentile of the

electrical arcing stress, as summarized by the CIGRE survey [1] and calculations based on

this material [3]. In other words, for networks that are prone to a very high electrical arcing

stress, a custom made test programme, not covered by this technical report, is needed (see

Clause A.7). Similarly, if users consider an interval between major maintenance of the

electrical wearing parts of the interrupters of more than 25 years, a custom made test

programme has to be considered.

When extended electrical endurance capability is required, this capability is demonstrated by

the standardized test programmes outlined below as applicable to overhead line circuit-

breakers above a rated voltage of 52 kV.

———————

Figures in square brackets refer to the bibliography.

– 6 – TR 62271-310 © IEC:2008

HIGH-VOLTAGE SWITCHGEAR AND CONTROLGEAR –

Part 310: Electrical endurance testing for circuit-breakers

above a rated voltage of 52 kV

1 Scope

This technical report is applicable to class E2 circuit-breakers above a rated voltage of 52 kV

for use on overhead lines.

The test programmes are based on accumulated electrical stresses due to current interruption

during a period of 25 years, which was chosen as representative for a maintenance-free

interval.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 62271-100, High-voltage switchgear and controlgear – Part 100: Alternating-current

circuit-breakers

3 Terms and definitions

For the purposes of this document, the following terms and definition applies.

3.1

circuit-breaker class E2 (circuit-breaker with extended electrical endurance)

circuit-breaker designed so as not to require maintenance of the interrupting parts of the main

circuit during its expected operating life

NOTE “Expected operating life” in this definition means a minimum period of use without maintenance of the

interrupting parts. Normally the life expectancy of the design is higher.

4 Test procedure

The tests should be carried out on a specimen identical as per 6.1.2 and 6.101.1.1 of

IEC 62271-100, to one of those already submitted or to be submitted to type tests.

All tests should be performed as single-phase tests. In combination with type tests, three-

phase tests are acceptable.

No intermediate maintenance should be carried out during the extended electrical endurance

test programme.

The test programmes as described in 4.2 and 4.3 are divided into a wear stage followed by

acceptance tests.

During the wear stage, the circuit-breaker will be stressed with the equivalent number of

accumulated breaking operations, but, for convenience of testing, without specified TRV,

except when basic short-circuit test duties are used as described in 4.3.

TR 62271-310 © IEC:2008 – 7 –

The acceptance tests should follow the wear stage of the test programmes. The purpose of

these acceptance tests is to demonstrate the interrupting capability of the circuit-breaker. It is

noted that the worn state of the circuit-breaker is taken into account by not requiring the full

interrupting capabilities as specified in IEC 62271-100, but normal service capabilities, in

accordance with "near end-of-maintenance-free period conditions" of the circuit-breaker.

The test arrangement should be such that no interference with the circuit-breaker between the

tests is necessary. However, if this is not possible and local safety rules require

depressurization to enter the test cell, it is allowed to decrease the pressure in the circuit-

breaker provided that at least 95 % of the gas is re-used when refilling the circuit-breaker.

There are various possible scenarios for performing a test programme for extended electrical

endurance qualification. To limit costs, two alternative possibilities are considered:

• extended electrical endurance qualification obtained separately from type tests;

• extended electrical endurance qualification combined with type tests.

4.1 General explanation to the extended electrical endurance test programme

As a general statement, in defining the extended electrical endurance test programme,

consideration has been given to the following:

– The maintenance-free period of 25 years.

NOTE Should any different period be considered, the number of breaking operations in the wear stage per current

ratings given above (Table 2 and Table 5) should be multiplied by the ratio of the new period and the assumed 25

year period.

– The basic need is that the test programme should maintain its technical soundness while

being simple and affordable.

– Merging of standard type tests and extended electrical endurance type tests into a single

test programme. Even if this does not represent the most likely situation to occur in

practice, the intent is to define designs with margins high enough to withstand basic

expected making and breaking stresses in worn conditions.

– The extended electrical endurance test programme has been defined using modified

standard type tests as acceptance tests. The only aim of combining type test with

electrical endurance test is cost reduction. It has been agreed that the extended electrical

endurance test programme should consist of a no load test, a wear stage (medium arcing

times, no TRV) and acceptance tests.

The characteristics and rationale behind each part of the test programme are as follows:

a) No-load test

Before starting any extended electrical endurance qualification on any design, a no-load

test as per 6.102.6 of IEC 62271-100 should be performed and results compared with

those derived from the reference no-load test to assure design consistency. This test

should be performed at the same pressure for interruption and operating mechanism as

used in type tests (as required in 6.102.6 of IEC 62271-100) to assure result

comparability.

b) Wear stage

This stage will consist of a number of breaking operations with medium arcing time

(determined from the arcing times used during standard type tests) and no TRV (except

when type tests are part of the wear stage; then IEC 62271-100 conditions will apply).

Pressure for operation and interruption and operating voltages are set at their rated values

(except when type tests are part of the wear stage; then IEC 62271-100 conditions will

apply). The number of breaking operations at 60 % of the rated short-circuit breaking

current is given in Table 2.

Operations at 60 % of the rated short-circuit breaking current are a simplification of the

wear expected over the maintenance-free period due to a spread in breaking currents from

– 8 – TR 62271-310 © IEC:2008

load currents to about 60 % of the rated short-circuit breaking current. Breaking operations

at lower short-circuit currents are most likely to occur (see Table A.3).

Operations at 10 % of the rated short-circuit breaking current are considered to be

important in order to represent the wear due to low currents. Nine breaking operations at

10 % of the rated short-circuit breaking current, with no TRV, are required together with

the breaking operations up to 60 % of the rated short-circuit breaking current in order to

complete the wear stage.

No-load tests at rated conditions should be made before the wear stage (to determine the

arcing times) and after the wear stage (to determine the arcing times for the acceptance

tests).

c) Acceptance tests

These tests consist of the following test duties (the preferred order of testing is as listed

below):

1) T10

As per IEC 62271-100, with the following variation: single O operations are performed.

Operating voltages and pressures at rated value are chosen to obtain a consistent

behaviour of the circuit-breaker during the duty. The minimum arcing time may change

due to the worn condition of the circuit-breaker. However, the aim of the test is to show

the full arc extinguishing window including the demonstration of the minimum arcing

time.

The rationale behind these T10 tests is based on the fact that openings at low currents

are the most likely duty in service. For this reason, it is important to check that the

circuit-breaker will, after a reasonable portion of its expected life, represented by the

wear stage, be able to successfully clear this duty over the entire arcing window.

2) L with 60 % of rated short-circuit breaking current

This test consists of L tests with a test-current of 60 % of the rated short-circuit

current as per 4.102.1 of IEC 62271-100 (regarding TRV parameters of the supply

side) and 4.105, with the following variation:

– The supply side current in case of a terminal fault is equal to 75 % of the rated

short-circuit breaking current (addition of a L line side circuit will then yield 60 %

current). Only due to test laboratory limitations reduction of supply circuit voltage is

allowed as an alternative to obtain 60 % of the rated short circuit current.

– Single O operations should be performed.

– Operating voltages and pressures at rated value are chosen.

– The line side time delay of TRV is 0,2 μs or 0,5 μs depending on rated voltage as

stated in 4.105 of IEC 62271-100.

The minimum arcing time may change due to the worn condition of the circuit-breaker.

However, the aim of the test is to show the full arc extinguishing window including the

demonstration of the minimum arcing time.

The rationale behind the selection of this duty is demonstration of short-line fault

interruption capability in practical cases where less (75 %) than 100 % rated short-

circuit breaking current is available at the breaker terminal.

, L short-line fault tests because the

This test is chosen instead of the standard L

90 75

probability to deal with short-line faults with current as high as 90 % or 75 % of the

rated short-circuit breaking current is considered very low.

3) Capacitive current switching

Depending on the restrike performance class assigned to the circuit-breaker (C1 or C2

in accordance with IEC 62271-100) a different test duty is performed. The duty

consists of either 24 O operations for class C1or 48 O operations for class C2.

Opening operations are performed “round the clock” by moving the setting of the

opening signal by 15°.

The capacitive voltage factors (k in 6.111.7 of IEC 62271-100) will be reduced, with

c

respect to those used for standard type tests, to 80 % with the exception of circuit-

TR 62271-310 © IEC:2008 – 9 –

breakers rated for voltage factors equal to 1,2 where relaxation to 80 % would lead to

a test voltage lower than system voltage. Table 1 correlates the capacitive voltage

factors to be used for capacitive current switching tests for electrical endurance with

capacitive voltage factors used for standard type tests.

Table 1 – Correlation between capacitive voltage factors used for standard capacitive

type tests and capacitive voltage factors to be used for extended electrical endurance

capacitive current acceptance tests

Capacitive voltage factor k used

c

for standard capacitive current 1,2 1,4 1,7

type tests

Capacitive voltage factor k used

c

during extended electrical

1,12 1,12 1,36

endurance capacitive current

acceptance tests

Acceptance criteria will be in agreement with 6.111.11.1 b) of IEC 62271-100, i.e. no

restrike over 24 O operations, or, in case of 1 restrike, completion of the duty and

repetition with no further restrikes (class C1) and either no restrike over 48 O

operations or, in case of 1 restrike, completion of the duty and repetition with no

further restrikes (class C2).

The rationale behind this requirement is that the capacitive current switching duty is

the most common duty for the circuit-breaker, and therefore a check as to its ability to

successfully switch capacitive currents near the end of its expected maintenance-free

period is needed.

Users need and require that a circuit-breaker, even after a certain period of service,

and after having accumulated a certain amount of short-circuits, should be capable of

providing reasonable behaviour in terms of statistical restrike performance.

The capacitive current-switching testing protocol, as a stand-alone type test, requires a

high number of breaking operations, and included in the test procedure is a number of

tests performed at minimum arcing time. This results in an acceleration factor so that a

statistical assessment of restrike performance in service based on laboratory tests can

be obtained.

The capacitive current-switching duty required by the acceptance tests in the extended

electrical endurance test programme is chosen to verify that a reasonable restrike

probability performance remains in circuit-breakers approaching their end-of-

maintenance-free period based on short-circuit wear.

Statistical evaluation has shown that the reduced capacitive voltage factor, in

combination with the absence of tests at minimum arcing time, has made this

acceptance test procedure approximately 25 % as severe as the standard capacitive

current switching type test with relation to the restrike probability.

Considering the relatively short length of overhead lines based on the collected data,

the test current will correspond to test duty 1 (10 % to 40 % of the rated capacitive

switching current of the concerned circuit-breaker).

Capacitive current switching tests are performed with rated pressure for operation,

insulation and interruption.

No-load tests at rated conditions should be made after the acceptance tests (for

information only).

4) Condition check

A voltage test as condition check, in agreement with 6.2.11 of IEC 62271-100 but with

rated pressure for operation, insulation and interruption, should be performed as the

final acceptance test. This test is intended to provide confidence that the circuit-

breaker, at the completion of the extended electrical endurance test programme, is still

able to provide sufficient voltage withstand between contacts without requiring

– 10 – TR 62271-310 © IEC:2008

inspections that might be of a subjective nature. No visual inspection is required after

the condition check.

4.2 Extended electrical endurance qualification obtained separately from type tests

Tables 2 and 3 summarize the kind of tests, acceptance criteria and test conditions to be used

for the extended electrical endurance qualification obtained separately from type tests.

For convenience of testing, the order shown in Table 2 and Table 3 of the T10, T60 breaking

operations in the wear and acceptance stage can be changed.

Table 2 – Test sequence and criteria for extended electrical

endurance tests obtained separately from type tests

Rated short circuit

25 kA 31,5 kA 40 kA 50 kA 63 kA 80 kA

≤ 20 kA

breaking current

Type of test

No-load test As per IEC 62271-100, 6.102.6 (see 4.1.a)

Wear tests

As per IEC 62271-100, 6.102.6, except with operating voltages and pressure for

No-load test

interruption at rated conditions (see 4.1.b)

T60 breaking

operations 18 15 12 10 8 7 5

(number of O)

T10 breaking

operations 9

(number of O)

As per IEC 62271-100, 6.102.6, except with operating voltages and pressure for

No-load test

interruption at rated conditions (see 4.1.b)

Acceptance tests

As per IEC 62271-100, with the following variation:

T10

single O operations are performed

As per IEC 62271-100, with the following variations:

L75 with 60 % of

- single O operations are performed

rated short-circuit

- reduction of test current to 60% of rated short-circuit breaking current by

current

increased impedance of the supply circuit.

- For circuit-breakers rated class C1:

0 restrikes over 24 O or 1 restrike over 48 O

LC1

- For circuit-breakers rated class C2:

0 restrikes over 48 O or 1 restrike over 96 O

As per IEC 62271-100, 6.102.6, except with operating voltages and pressure for

No-load test

interruption at rated conditions (see 4.1.c)

According to 6.2.11 of IEC 62271-100 except with operating voltages and pressure

Condition check

for interruption at rated conditions (see 4.1.c)

NOTE The number of T60 breaking operations in the wear stage is based on the assumption that 3

breaking operations with 60 % of the rated short-circuit current are performed in the acceptance stage. When

the number of interruptions performed in the acceptance stage is anticipated to be higher than 3 (i.e. when

synthetic tests are performed), This means that when more than 3 tests are expected in the acceptance stage

(for example 4 in synthetic tests), the number of tests in the wear stage should be reduced accordingly. All

the extra tests during the acceptance stage should be made with TRV.

TR 62271-310 © IEC:2008 – 11 –

The test conditions are given in Table 3. The tests should be performed using rated values of

pressure for operating and interrupting and auxiliary voltages.

Table 3 – Test conditions for extended electrical endurance tests

obtained separately from type tests

Operating

voltage and

Type of test Operations Test voltage/test current pressure for Arcing time

interruption and

operation

Wear tests

No load test As per IEC 62271-100, 6.102.6 Minimum

No load test

As per IEC 62271-100, 6.102.6, but with rated Rated

pressure for operation, insulation and interruption

T60 Only opening According to T60 type test as per Rated Medium arcing

operations 6.106.3 of IEC 62271-100 without time according

TRV to T60 type

test

T10 Only opening According to T10 type test as per Rated Medium arcing

operations 6.106.1 of IEC 62271-100 without time according

TRV to T10 type

test

No load test As per IEC 62271-100, 6.102.6, but with rated Rated

pressure for operation, insulation and interruption

Acceptance tests

T10 Only opening According to T10 type test as per Rated See NOTE 1

operations 6.106.1 of IEC 62271-100

L75 with 60 % of Only opening As per 6.109.4 of IEC 62271-100. Rated See NOTE 1

rated short-circuit operations Reduction of test current to 60 %

current of rated short-circuit breaking

current by increased impedance

of the supply circuit (see

NOTE 4)

LC1 According to 6.111 of IEC 62271- Rated Around the

100. The test voltage is the clock every 15°

highest value between 80 % of (electrical

test voltage specified for type degrees)

tests and the value

corresponding to a voltage factor

of 1,12 (see Table 1)

No load test As per IEC 62271-100, 6.102.6, but with rated Rated

pressure for operation, insulation and interruption

Condition check As per 6.2.11 of IEC 62271-100, but with rated Rated

pressure for operation, insulation and interruption

NOTE 1 For acceptance tests T10 and L with 60 % current the arcing times may vary from those shown

during type tests due to different pressures for operation and interruption, or due to the worn condition of the

circuit-breaker. However the full extinguishing window should be shown including the demonstration of the

minimum arcing time.

NOTE 2 For the wear tests T10 and T60, 50 Hz tests cover 60 Hz requirements, provided that the tests have

been performed with a medium arcing time belonging to 50 Hz. For acceptance test LC1, 60 Hz tests cover

50 Hz requirements.

NOTE 3 Unit testing according to 6.102.4.2 of IEC 62271-100 is permissible.

NOTE 4 In synthetic testing, this condition is most easily met by designing the circuit for the L test duty, and

then inserting an additional reactance equal to the artificial line reactance into the synthetic supply circuit.

– 12 – TR 62271-310 © IEC:2008

4.3 Extended electrical endurance qualification combined with type tests

When extended electrical endurance qualification combined with type tests is desired, it is

recognized that dictating too stringent constraints may impair the economic viability of such a

combination.

In order to allow maximum freedom within this combined programme during the wear tests,

the number of breaking operations at T60 with medium arcing time can be replaced by other

test duties. Limited to the purpose of this qualification, Equation (1) provides the equivalence

between breaking operations carried out at medium arcing time, with current values as used

during type tests, and breaking operations at T60 at medium arcing time.

Table 4 – Equivalent number of breaking operations

One single breaking operation at medium arcing time Equivalent number of breaking operation at 60 % of

and current value as in rated short-circuit breaking current (T60)

T10 0,01

OP2 0,15

T30 0,25

T60 1

NOTE During the performance of type tests, some additional breaking operations may occur for no particular

reason. In such a case, an evaluation of the equivalence in terms of wear should be made, taking into

consideration the actual arcing time (it is assumed that the wear is proportional to the arcing time for the same

current).

0,01N + 0,15N + 0,25N +N =M (1)

10 OP2 30 60 90

with

N the number of breaking operations with 10 % rated short-circuit breaking current;

N the number of breaking operations at test-duty OP2;

OP2

N the number of breaking operations with 30 % rated short-circuit breaking current;

N the number of breaking operations with 60 % rated short-circuit breaking current;

M the number (of T60 tests in the combined test programme) as defined in Table 5 aimed

to cover 90 % of cumulative electrical stresses in 25 years.

Table 5 – Defined number M of number of T60 tests combined with type testing

Rated short-circuit

≤ 20 kA 25 kA 31,5 kA 40 kA 50 kA 63 kA 80 kA

breaking current

M 18 15 12 10 8 7 5

Apart from the equivalence criterion expressed in Equation (1), the following requirements

should be fulfilled:

– The combined test program should include at least 3 breaking operations at 60 % current,

even when in the type-test part of the combined programme a sufficient wear is obtained.

– The combined test program should include at least 9 breaking operations at 10 % current,

even when in the type-test part of the combined programme a sufficient wear is obtained.

– Current values of the breaking operations considered in Equation (1) should be at

maximum 60 % of the rated short-circuit breaking current.

The acceptance stage should be in accordance with Tables 2 and 3.

TR 62271-310 © IEC:2008 – 13 –

The order of testing in the wear stage of the combined program is arbitrary.

A more general equation considering the equivalency of any current (other than the well

defined test-duty values) can be found as Equation (A.1) in A.6.2.

In Table 6, an example is given of a combination of type test with an extended electrical

endurance test.

Table 6 – Example of combination of type test with E2 test

for a 50 kA circuit-breaker in synthetic test

Expected

equivalent Applicable to

number of Applicable to wear

Duty number of T 60 acceptance

breaking stage

arcing stress stage

operations

Type tests only

T100s 5 No: current > 60 % No

T100a 4 No: current > 60 % No

L 5 No: current > 60 % No

L 5 No: current > 60 % No

Not applicable

DEF (Double Earth Fault) 1 No: current > 60 % No

SEF (Single Earth Fault) 1 No: current > 60 % No

LC1 Variable No No

LC2 Variable No No

Combined section of test programme (type tests + wear test for E2 qualification)

0,6 Yes No

OP2 4

1,25 Yes No

T30 5

0,05 Yes No

T10 5

0,04 Yes No

T10 additional to type test 4 to reach 9 T10

T60 5 5 Yes No

T60 additional to type test 1 1 Yes No

Intermediate sum 7,9 (< 8 from Table 5, additional test necessary)

Acceptance tests for E2 qualification

L with 60 % current 4 1 (see NOTE) Yes, 1 test counts Yes

T10 4 Not applicable No Yes

LC1 See Table 2 Not applicable No Yes

Sum 8,9 (> 8 from Table 5)

NOTE Because of synthetic testing, 1 of the 4 60 % tests in the acceptance stage may be added to the 7,9 in the

wear stage, adding up to 8,9 > 8 from Table 5 (see also NOTE in Table 2).

For convenience of testing the order of T10, T60 testing can be changed.

– 14 – TR 62271-310 © IEC:2008

Annex A

(informative)

Explanatory notes

A.1 Introduction

Extended electrical endurance test programmes for rated voltages up to and including 52 kV

have already been introduced in IEC 62271-100. New low-maintenance circuit-breaker

designs are now available, with properties not yet proven over their defined maintenance-free

period. There is also an increasing trend followed by various utilities to install equipment with

specification closer to the needs than before and an increasing demand for “quality of supply”.

These are all issues that require the circuit-breaker to prove its ability to perform successfully

over its expected maintenance-free period, and on this basis, introduction of extended

electrical endurance test programmes to rated voltages above 52 kV may be considered.

At the same time it is recognized that any new extended electrical endurance tests should be

based on actual short-circuit fault statistics and on a sound and traceable process for

determination of the test programme. Over-specification should be avoided, since it leads to

increased cost of the circuit-breakers.

A.2 Determination of extended electrical endurance test programmes

This annex is aimed at providing the information, assumptions and methodology adopted for

selecting extended electrical endurance test programmes for high-voltage circuit-breakers.

The following subclauses describe the collected data, their statistical nature, the choice and

assumptions made and the methodological approach used to derive the extended electrical

endurance test programmes provided in this technical report. The purpose of this report is to

make available all the information backing up the test procedures so that future amendments

may start by positive criticism and feedback of what was made available and collected for

issuing the present technical report.

A.3 Collected data

Since the objective is an extended electrical endurance test programme, it has to represent,

at best, the actual fault statistics in the field. The larger the amount of collected data, the

more representative they are .

A.3.1 Countries involved in the data collection

Several countries participated in the data collection. Depending on the local situation, one or

more utilities may operate in a country. In some cases, data were collected from more than a

single utility per country, again with the aim of collecting as much data as possible,

representative of the country’s fault statistics. The list of participating countries is given in

Table A.1 .

———————

Data were collected through a co-operation between CIGRE WG 13.08 and IEC SC 17A/WG 29 around 1996. In

2005, new detailed fault data from Japan was added [3], used to verify the statistical calculation model leading

to the number of necessary T60 tests in the electrical endurance test programme.

3 To avoid misunderstandings with countries which are not represented in the table, it should be stressed that the

data collection took place through direct contact between CIGRE WG 13.08 and IEC SC 17A/WG 29 members

with utilities’ representatives. This direct contact was needed to obtain data within the specified time schedule.

TR 62271-310 © IEC:2008 – 15 –

Table A.1 – List of countries involved in the data collection

BELGIUM FRANCE

NETHERLANDS SWITZERLAND

BRAZIL USA

ITALY SWEDEN

SPAIN GERMANY

JAPAN CANADA

INDIA

Several types of data per voltage class were the subject of the inquiry, for example:

– number of short-circuits per 100 km of overhead line/year;

– average overhead li

...

IEC/TR 62271-310

Edition 2.0 2008-03

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

High-voltage switchgear and controlgear –

Part 310: Electrical endurance testing for circuit-breakers above a rated voltage

of 52 kV

Appareillage à haute tension –

Partie 310: Essais d’endurance électrique pour disjoncteurs de tension assignée

supérieure à 52 kV

IEC/TR 62271-310:2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC/TR 62271-310

Edition 2.0 2008-03

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

High-voltage switchgear and controlgear –

Part 310: Electrical endurance testing for circuit-breakers above a rated voltage

of 52 kV

Appareillage à haute tension –

Partie 310: Essais d’endurance électrique pour disjoncteurs de tension

assignée supérieure à 52 kV

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

S

CODE PRIX

ICS 29.130.10 ISBN 2-8318-9668-1

– 2 – TR 62271-310 © IEC:2008

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.6

2 Normative references .6

3 Terms and definitions .6

4 Test procedure .6

4.1 General explanation to the extended electrical endurance test programme.7

4.2 Extended electrical endurance qualification obtained separately from type

tests .10

4.3 Extended electrical endurance qualification combined with type tests.12

Annex A (informative) Explanatory notes .14

Bibliography.21

Figure A.1 – Estimated number of equivalent T60 stresses for various rated voltages

and rated short-circuit breaking currents .18

Table 1 – Correlation between capacitive voltage factors used for standard capacitive

type tests and capacitive voltage factors to be used for extended electrical endurance

capacitive current acceptance tests .9

Table 2 – Test sequence and criteria for extended electrical endurance tests obtained

separately from type tests.10

Table 3 – Test conditions for extended electrical endurance tests obtained separately

from type tests.11

Table 4 – Equivalent number of breaking operations.12

Table 5 – Defined number M of number of T60 tests combined with type testing.12

Table 6 – Example of combination of type test with E2 test for a 50 kA circuit-breaker

in synthetic test.13

Table A.1 – List of countries involved in the data collection .15

Table A.2 – Used reference data .16

Table A.3 – Number of breaking operations in various ranges of interrupted current in

service during 25 years.18

Table A.4 – Estimated number M of T60 breaking operations to cover 99 % of field

stresses.19

TR 62271-310 © IEC:2008 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HIGH-VOLTAGE SWITCHGEAR AND CONTROLGEAR –

Part 310: Electrical endurance testing for circuit-breakers

above a rated voltage of 52 kV

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC/TR 62271-310, which is a technical report, has been prepared by subcommittee 17A:

High-voltage switchgear and controlgear, of IEC technical committee 17: Switchgear and

controlgear.

This second edition of IEC/TR 62271-310 cancels and replaces the first edition published in

2004. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– reduction of number tests in the wear stage;

– 4 – TR 62271-310 © IEC:2008

– new definition of acceptance test for demonstration of end-of-life thermal interruption

capability.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

17A/803/DTR 17A/814/RVC

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 62271 series, under the general title High-voltage switchgear and

controlgear can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

TR 62271-310 © IEC:2008 – 5 –

INTRODUCTION

Based on experience with existing high-voltage circuit-breakers in service and with system

protection and maintenance policies, the majority of circuit-breaker applications are covered

by class E1 as defined in 3.4.112 of IEC 62271-100. No additional tests for extended

electrical endurance are required.

However, extended electrical endurance (class E2) as defined in 3.4.113 of IEC 62271-100

should be considered for the following reasons:

• Field experience collected so far by CIGRE is limited only for circuit-breaker designs

available before 1994 (see for example reference [1], [2], [3] and Annex A.3). For this

reason, the data collected by CIGRE so far can hardly be extrapolated to new designs.

Therefore, for new types of circuit-breakers, extended electrical endurance can only be

fully proven by laboratory tests.

• New maintenance practices tend towards “maintenance-free” circuit-breakers. The

reduction of maintenance costs is a major issue for most users today.

• Deregulation of the electricity market may increase the electrical stresses applied to the

circuit-breakers, within their proven capability. Installation of generation capacity by

independent power producers will increase short-circuit levels in certain areas and

consequently change stresses on breakers. This may result in higher stresses applied to

circuit-breakers compared to past practice when the short-circuit rating of the circuit-

breaker was in large excess of the actual fault currents.

• There is a need to standardize a single extended electrical endurance programme to avoid

the specification of different programmes from different users.

• Many manufacturers provide information about electrical endurance capabilities of circuit-

breakers during the purchasing process. There is a need to standardize the way this

information is given to the users.

It must be noted that circuit-breakers having extended electrical endurance capability, are not

intended for use in situations in which electrical arcing stress (which is a combination of high

probability of fault occurrence and high fault current level) is beyond the 90-percentile of the

electrical arcing stress, as summarized by the CIGRE survey [1] and calculations based on

this material [3]. In other words, for networks that are prone to a very high electrical arcing

stress, a custom made test programme, not covered by this technical report, is needed (see

Clause A.7). Similarly, if users consider an interval between major maintenance of the

electrical wearing parts of the interrupters of more than 25 years, a custom made test

programme has to be considered.

When extended electrical endurance capability is required, this capability is demonstrated by

the standardized test programmes outlined below as applicable to overhead line circuit-

breakers above a rated voltage of 52 kV.

———————

Figures in square brackets refer to the bibliography.

– 6 – TR 62271-310 © IEC:2008

HIGH-VOLTAGE SWITCHGEAR AND CONTROLGEAR –

Part 310: Electrical endurance testing for circuit-breakers

above a rated voltage of 52 kV

1 Scope

This technical report is applicable to class E2 circuit-breakers above a rated voltage of 52 kV

for use on overhead lines.

The test programmes are based on accumulated electrical stresses due to current interruption

during a period of 25 years, which was chosen as representative for a maintenance-free

interval.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 62271-100, High-voltage switchgear and controlgear – Part 100: Alternating-current

circuit-breakers

3 Terms and definitions

For the purposes of this document, the following terms and definition applies.

3.1

circuit-breaker class E2 (circuit-breaker with extended electrical endurance)

circuit-breaker designed so as not to require maintenance of the interrupting parts of the main

circuit during its expected operating life

NOTE “Expected operating life” in this definition means a minimum period of use without maintenance of the

interrupting parts. Normally the life expectancy of the design is higher.

4 Test procedure

The tests should be carried out on a specimen identical as per 6.1.2 and 6.101.1.1 of

IEC 62271-100, to one of those already submitted or to be submitted to type tests.

All tests should be performed as single-phase tests. In combination with type tests, three-

phase tests are acceptable.

No intermediate maintenance should be carried out during the extended electrical endurance

test programme.

The test programmes as described in 4.2 and 4.3 are divided into a wear stage followed by

acceptance tests.

During the wear stage, the circuit-breaker will be stressed with the equivalent number of

accumulated breaking operations, but, for convenience of testing, without specified TRV,

except when basic short-circuit test duties are used as described in 4.3.

TR 62271-310 © IEC:2008 – 7 –

The acceptance tests should follow the wear stage of the test programmes. The purpose of

these acceptance tests is to demonstrate the interrupting capability of the circuit-breaker. It is

noted that the worn state of the circuit-breaker is taken into account by not requiring the full

interrupting capabilities as specified in IEC 62271-100, but normal service capabilities, in

accordance with "near end-of-maintenance-free period conditions" of the circuit-breaker.

The test arrangement should be such that no interference with the circuit-breaker between the

tests is necessary. However, if this is not possible and local safety rules require

depressurization to enter the test cell, it is allowed to decrease the pressure in the circuit-

breaker provided that at least 95 % of the gas is re-used when refilling the circuit-breaker.

There are various possible scenarios for performing a test programme for extended electrical

endurance qualification. To limit costs, two alternative possibilities are considered:

• extended electrical endurance qualification obtained separately from type tests;

• extended electrical endurance qualification combined with type tests.

4.1 General explanation to the extended electrical endurance test programme

As a general statement, in defining the extended electrical endurance test programme,

consideration has been given to the following:

– The maintenance-free period of 25 years.

NOTE Should any different period be considered, the number of breaking operations in the wear stage per current

ratings given above (Table 2 and Table 5) should be multiplied by the ratio of the new period and the assumed 25

year period.

– The basic need is that the test programme should maintain its technical soundness while

being simple and affordable.

– Merging of standard type tests and extended electrical endurance type tests into a single

test programme. Even if this does not represent the most likely situation to occur in

practice, the intent is to define designs with margins high enough to withstand basic

expected making and breaking stresses in worn conditions.

– The extended electrical endurance test programme has been defined using modified

standard type tests as acceptance tests. The only aim of combining type test with

electrical endurance test is cost reduction. It has been agreed that the extended electrical

endurance test programme should consist of a no load test, a wear stage (medium arcing

times, no TRV) and acceptance tests.

The characteristics and rationale behind each part of the test programme are as follows:

a) No-load test

Before starting any extended electrical endurance qualification on any design, a no-load

test as per 6.102.6 of IEC 62271-100 should be performed and results compared with

those derived from the reference no-load test to assure design consistency. This test

should be performed at the same pressure for interruption and operating mechanism as

used in type tests (as required in 6.102.6 of IEC 62271-100) to assure result

comparability.

b) Wear stage

This stage will consist of a number of breaking operations with medium arcing time

(determined from the arcing times used during standard type tests) and no TRV (except

when type tests are part of the wear stage; then IEC 62271-100 conditions will apply).

Pressure for operation and interruption and operating voltages are set at their rated values

(except when type tests are part of the wear stage; then IEC 62271-100 conditions will

apply). The number of breaking operations at 60 % of the rated short-circuit breaking

current is given in Table 2.

Operations at 60 % of the rated short-circuit breaking current are a simplification of the

wear expected over the maintenance-free period due to a spread in breaking currents from

– 8 – TR 62271-310 © IEC:2008

load currents to about 60 % of the rated short-circuit breaking current. Breaking operations

at lower short-circuit currents are most likely to occur (see Table A.3).

Operations at 10 % of the rated short-circuit breaking current are considered to be

important in order to represent the wear due to low currents. Nine breaking operations at

10 % of the rated short-circuit breaking current, with no TRV, are required together with

the breaking operations up to 60 % of the rated short-circuit breaking current in order to

complete the wear stage.

No-load tests at rated conditions should be made before the wear stage (to determine the

arcing times) and after the wear stage (to determine the arcing times for the acceptance

tests).

c) Acceptance tests

These tests consist of the following test duties (the preferred order of testing is as listed

below):

1) T10

As per IEC 62271-100, with the following variation: single O operations are performed.

Operating voltages and pressures at rated value are chosen to obtain a consistent

behaviour of the circuit-breaker during the duty. The minimum arcing time may change

due to the worn condition of the circuit-breaker. However, the aim of the test is to show

the full arc extinguishing window including the demonstration of the minimum arcing

time.

The rationale behind these T10 tests is based on the fact that openings at low currents

are the most likely duty in service. For this reason, it is important to check that the

circuit-breaker will, after a reasonable portion of its expected life, represented by the

wear stage, be able to successfully clear this duty over the entire arcing window.

2) L with 60 % of rated short-circuit breaking current

This test consists of L tests with a test-current of 60 % of the rated short-circuit